At present, the

fiber laser cutting machine is the most widely used in the metal cutting industry. Today, the development of fiber laser is just 10 years. Prior to this, plasma cutting machine and CO2 laser cutting machines accounted for the vast majority of metal plate cutting in the market. But now fiber laser cutting machine has attracted extensive attention in various fields with its advantages of high speed and high precision. It has 10 years of practical experience, cutting efficiency and low consumption, environmental protection and energy conservation! Save enterprise production costs, solve production and processing problems, cost-effective! But how do we find a suitable high-precision fiber laser cutting machine?

At present, our optical fiber cutter models include AKJ1390F AKJ1325F AKJ1530F AKJ1530FB AKJ1530FR AKJ1530FC AKJ2030F AKJ2060F ETC. Before selecting the fiber laser cutting machine, first of all, you must determine how much power is required, because the power of the fiber laser cutting machine determines its ability to cut metal plates! How to choose the power of industrial fiber laser cutting machine?

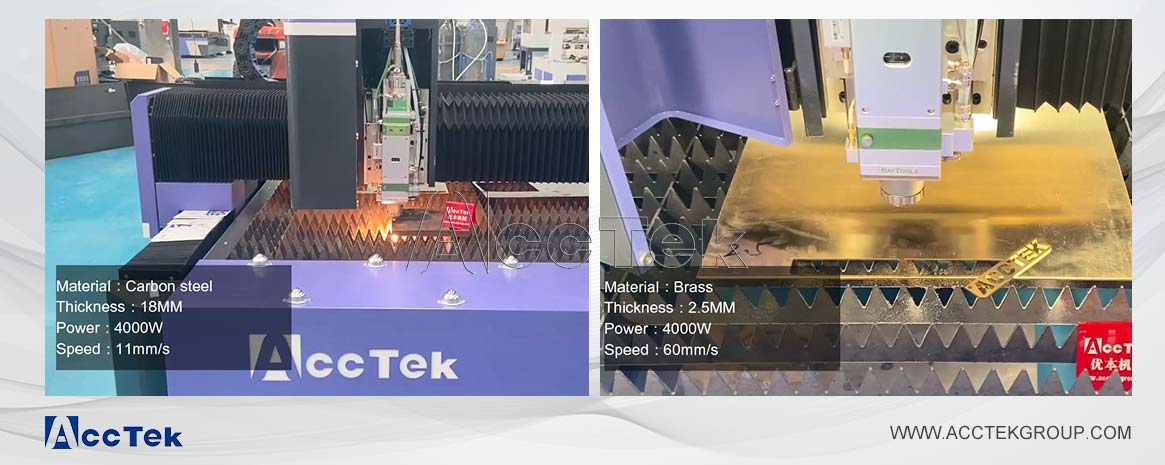

Generally, the laser power of the machine used to cut and process metal materials should also reach about 1000W. Especially the continuous laser has a very good cutting effect. If you want to cut 10mm carbon steel, 1500W laser cutting machine is the best choice; if you want to cut 18mm carbon steel, 4KW laser cutting machine is the best choice. Among all the accessories, fiber laser is very important. The core of a metal laser cutting machine is also in the laser The relatively stable fiber laser brands are Raycus, IPG, Max, JPT. For example, when cutting high anti reflective metal materials, we'd better choose JPT or IPG.

At the same time, in order to ensure stable operation, the metal laser cutting machine's own control system and bed structure are also very important. For the metal cutting system, we use Aultech and Cyput. Generally, Au3tech system is selected for 1000W-2000W, and Cyput control system is selected for high power.

If the plate cut by the fiber laser cutting machine is very thick, the whole plate will be very heavy, so the stable bed structure has a great impact on the precision of the machine cutting. We choose high temperature quenching for the bed, which is not easy to deform. The heavy plate welding workbench has no deformation in 20 years, and is suitable for ultra-high power 10000W fiber laser cutting machine. The increase of weight is very beneficial to the cutting speed of laser cutting machine.

After knowing the performance of the

metal laser cutting machine, let's talk about how to choose a suitable machine. Cutting is divided into cutting plane or pipe cutting. If cutting plane, single platform machine can meet the requirements, but if cutting round or square pipes, a rotation axis is required. The rotating shaft is a fixture design, with electric fixtures on both sides, which can automatically adjust the center. The diagonal line can be adjusted within 20-220mm. Of course, if you just need to cut pipes, you need a professional laser tube cutting machine. For example, we have a professional metal tube cutting machine that can automatically load and unload materials, which greatly improves the efficiency.

For precision cutting, we choose fiber laser cutting machine AKJ1390F, which is small in size and high in precision. It is suitable for relatively precise material cutting. For example, the cutting of gold, silver and copper. Double rail and double driver design. In order to prevent the cutting line deformation caused by the bending of Y-axis screw, the Y-axis on both sides is equipped with two guide rails and double ball drive screw design to ensure the straightness and radian during high-speed cutting operation.

For thinner materials, we suggest to choose a single platform, and for thicker materials, we suggest to choose a single platform plus a switching platform, using up and down switching platforms. The inverter is responsible for controlling the switching motor. The machine can complete the platform exchange within 15 seconds. Because the exchange platform can save manual material handling, convenient, time-saving and labor saving. For example, after the machine finishes cutting a board, it needs to lift the current board and lift up the new board. But with the exchange platform, it is automatically completed by the machine.

In addition, if you are worried about the harm of smoke and dust to your environment, you need to choose a full closed structure, which can effectively prevent the damage caused by laser. Fully enclosed design is adopted, and the observation window is made of European CE standard laser protective glass. The smoke generated by cutting can be filtered internally, which is pollution-free and environmentally friendly AKJ1530FB belongs to Full closed heavy bed structure.

For another example, if the customer wants to cut not only metal, but also nonmetal, we suggest to choose the fiber laser cutting machine with CO2 laser cutting head. It can not only cut metal, but also nonmetal. There are two options: Double Dragon Gate and Double Head.

In a word, the selection of a

high-precision laser cutting machine depends on the specific needs of the customer, such as the cutting thickness, cutting materials, and environmental requirements.