Fiber laser has the advantages of large heat dissipation area, good beam quality and small size. Compared with bulky gas lasers and solid-state lasers, it has obvious advantages. The

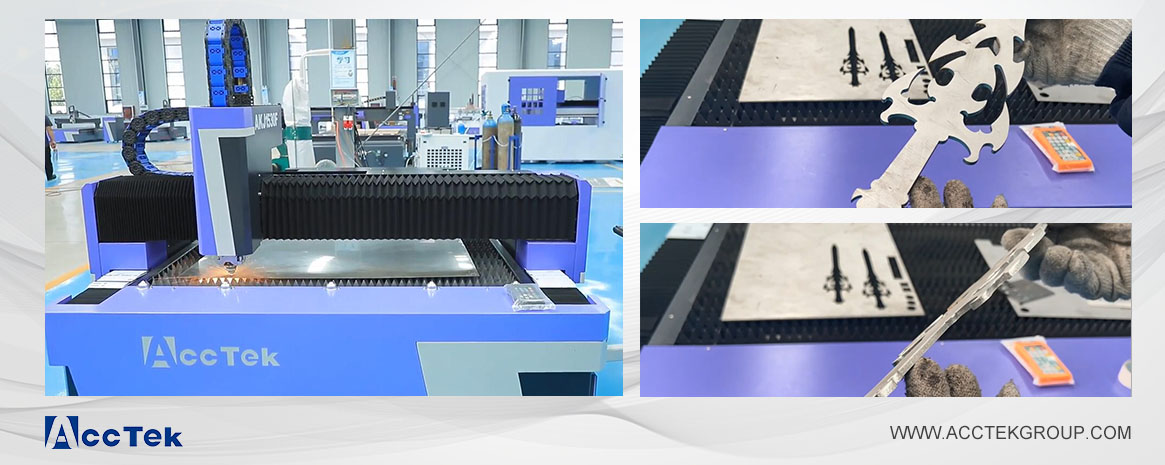

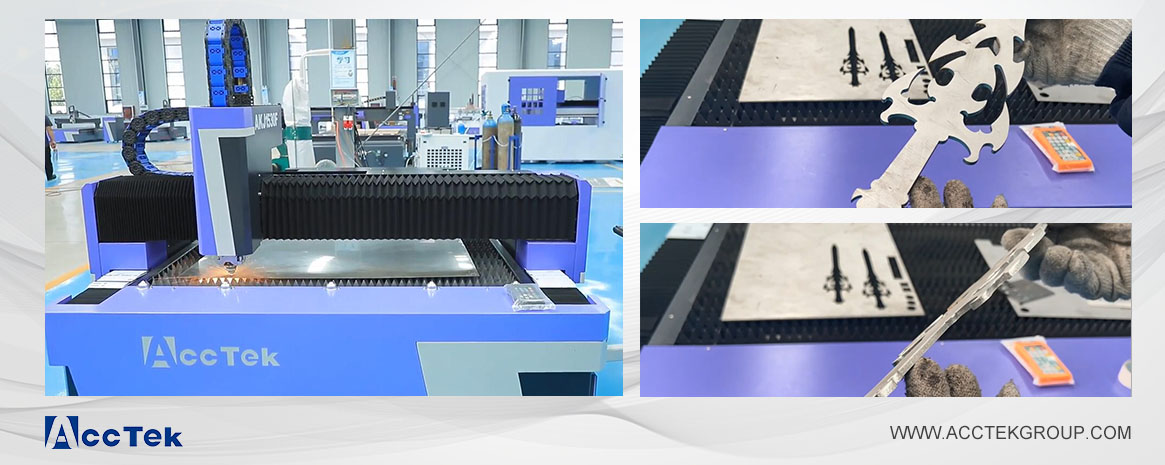

fiber laser cutting machine can be used for both plane cutting and bevel cutting, and the edges are neat and smooth. It is suitable for high-precision cutting of metal plates. Compared with ordinary carbon dioxide laser cutting machines, it saves space and gas consumption, and has high photoelectric conversion rate. It is a new energy-saving and environmentally friendly product and one of the world's leading technology products.

In recent years, technological competition in the field of fiber laser cutting machines has been particularly fierce. From the rise of laser cutting machine companies, to the replacement of YAG, CO2 and other machines by fiber laser cutting machines, to the launch of high-power laser cutting machines, there is a trend of competition. Laser cutting machines can be divided into small power, medium power and high power according to the power. Low power laser cutting machines are mainly used in light industry manufacturing such as electronics, ceramics, glass, hardware, textiles, and auto parts. High-power laser cutting machines are generally used in heavy equipment manufacturing industries such as sheet metal processing, large-scale machinery manufacturing, petrochemical industry, and aerospace.

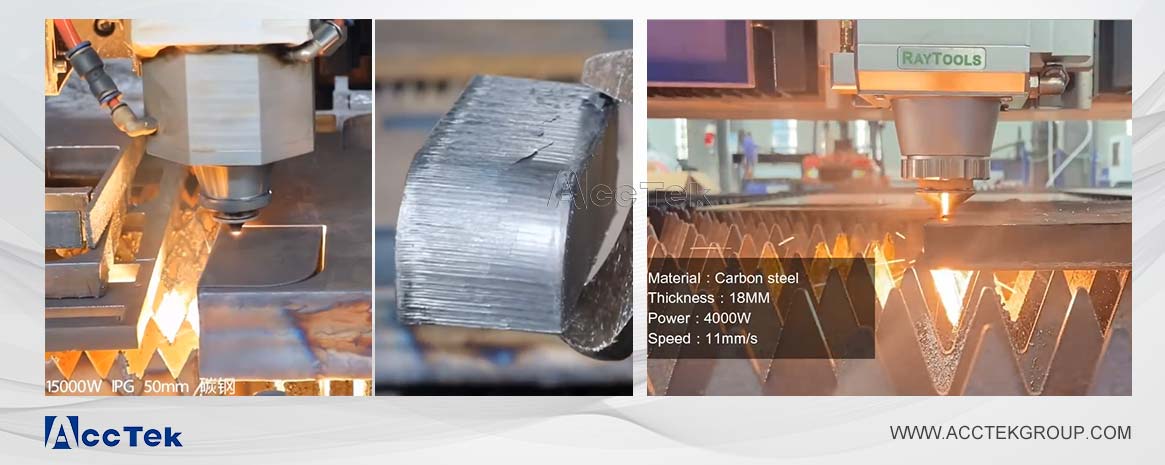

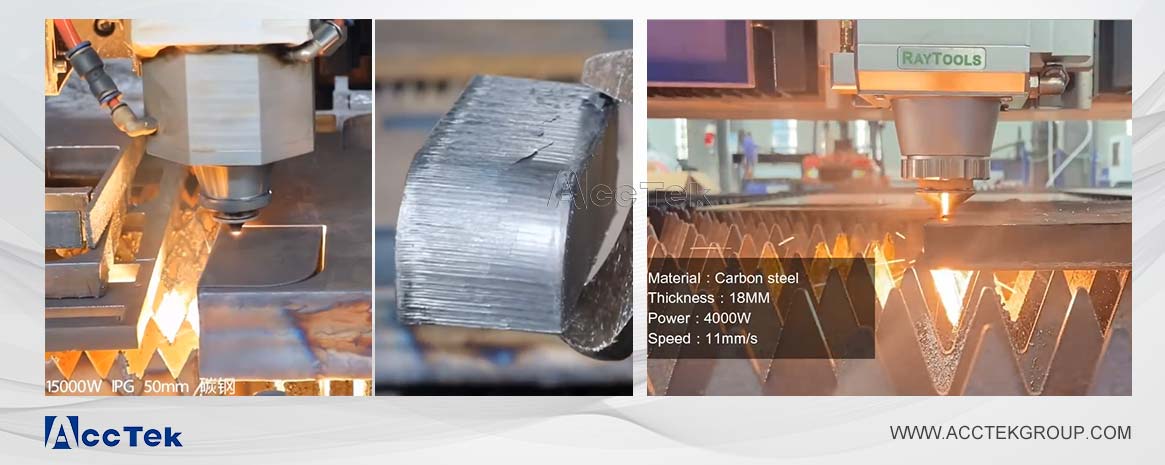

For stainless steel plates and carbon steel plates with small thickness, a low-power laser cutting machine can perform good cutting. For cutting thick plates and cutting efficiency, high-power equipment can be well realized. In recent years, high-power machines have become a hot topic in the field of laser cutting. Many companies have launched 10,000-watt fiber laser cutting machines. This high-power machine seems to have a trend of occupying domestic and foreign markets.

For the sheet metal processing industry, the birth of high-power laser cutting equipment has greatly improved the thickness and efficiency of sheet metal cutting. In between, the small and medium power metal laser cutting machine can only cut carbon steel within 20mm and stainless steel within 12mm. And high-power equipment, such as 15000W fiber laser cutting machine, can cut 40mm aluminum alloy plate and 50mm carbon steel plate. The emergence of this high-power laser machine constantly breaks the limit of material cutting thickness. As a result, the price of processing thick plates is reduced, forming a virtuous circle and promoting the further expansion of the application field of laser cutting.

The

high-power fiber laser cutting machine is easy to operate, has a large cutting width, fast cutting speed, can cut thicker metal sheets, and has stable performance, providing more efficient technical support for the production efficiency of all walks of life. High efficiency, high quality, and high reliability can also bring users high value returns, and at the same time better help the development of all walks of life.

Laser cutting technology has begun to develop in the direction of thick plates and large sizes, which has promoted the design of laser cutting equipment in this direction, thereby further improving industrial processing technology. After China joined the World Trade Organization, frequent international exchanges prompted various industries to gradually join the international Competitive ranks. In this process, industries such as automobiles and aviation need to continuously apply laser cutting technology in the development process.

In recent years, the popularity of 10,000-watt laser cutting machines has continued to rise, and they are used in aerospace, high-speed rail, petrochemical and other fields. Cutting, bright surface cutting, ultra-thick plate cutting and other directions. Although the 10,000-watt laser cutting machine industry has a good development prospect, due to the high price and mainly used in high-end fields, the current market demand is relatively small.

The mainstream market trends always give users some guidance. The emergence of the 10,000-watt laser cutting machine makes users feel that the higher the power, the better the laser cutting machine. However, in the actual production process, the laser cutting equipment used by various enterprises, such as the use of 10,000-watt laser cutting machines to cut metal sheet metal, is relatively few at present. To a large extent, the pursuit of greater cutting power is only a manifestation of the technical capabilities of the enterprise. And from the perspective of enterprise cost, the higher the power, the more expensive the equipment, and there is also a surplus of functional requirements.

For stainless steel plates and carbon steel plates with a small thickness, a low-power laser cutting machine can be used to cut, which not only ensures efficiency, but also saves costs. If the plate you need to cut is thick or thin, and the production demand is large and can afford a large cost, then you can consider a high-power cutting machine. Properly adjust the cutting speed and replace the auxiliary gas, this high-power equipment can control the cutting quality well.

Therefore, when purchasing a

laser cutting machine, it is necessary to make a reasonable choice according to its own material material, material thickness, etc., and do not blindly pursue high power. The purchase of high-power laser cutting equipment, of course, needs to be purchased according to customer needs. Judging from the current development trend, in the metal processing market, large and medium-sized enterprises have gradually upgraded from 500W, 1000W, 2000W laser cutting machines to 6000W, 8000W, 10000W, and even 20000W. It seems that they are all showing their strengths and grabbing the market. Here, Acctek warmly reminds you not to blindly pursue power, but to decide according to the actual cutting needs. Buying valuable laser equipment is right for you.