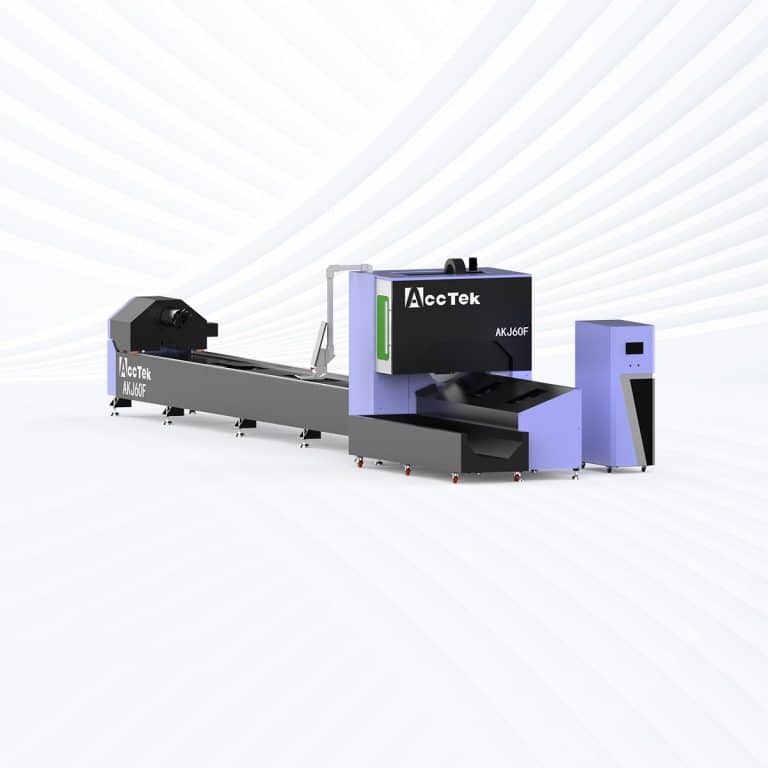

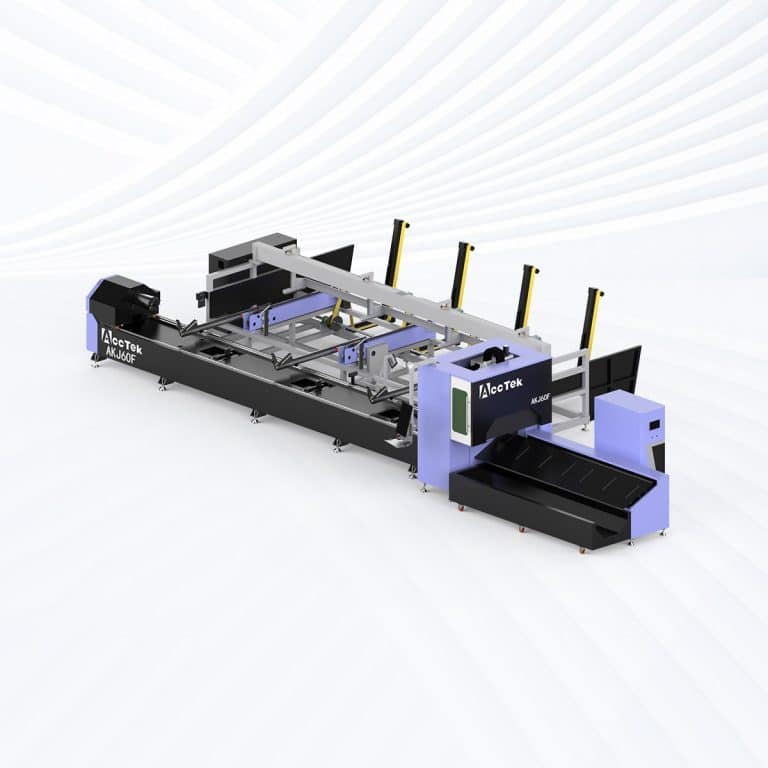

Product Introduction

2kW Laser Cutting Capacity

| Material | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| Carbon Steel | 1 | 25 | 0 | 1 | N2/Air | 1.5 | 10 |

| 2 | 9 | -1 | 0.5 | N2/Air | 2 | 10 | |

| 2 | 5.2 | 3 | 0.8 | O2 | 1 | 0.6 | |

| 3 | 4.2 | 3 | 0.8 | O2 | 1 | 0.6 | |

| 4 | 3 | 3 | 0.8 | O2 | 1 | 0.6 | |

| 5 | 2.2 | 3 | 0.8 | O2 | 1.2 | 0.6 | |

| 6 | 1.8 | 3 | 0.8 | O2 | 1.2 | 0.6 | |

| 8 | 1.3 | 2.5 | 0.8 | O2 | 2 | 0.6 | |

| 10 | 1.1 | 2.5 | 0.8 | O2 | 2 | 0.5 | |

| 12 | 0.9 | 2.5 | 0.8 | O2 | 2.5 | 0.5 | |

| 14 | 0.8 | 2.5 | 0.8 | O2 | 3 | 0.5 | |

| 16 | 0.7 | 2.5 | 0.8 | O2 | 3.5 | 0.6 | |

| 18 | 0.5 | 3 | 0.8 | O2 | 4 | 0.6 | |

| 20 | 0.4 | 3 | 0.8 | O2 | 4 | 0.6 | |

| Stainless Steel | 1 | 28 | 0 | 0.8 | N2 | 1.5 | 10 |

| 2 | 10 | -1 | 0.5 | N2 | 2 | 12 | |

| 3 | 5 | -1.5 | 0.5 | N2 | 2 | 12 | |

| 4 | 3 | -2 | 0.5 | N2 | 2.5 | 14 | |

| 5 | 2 | -2.5 | 0.5 | N2 | 3 | 14 | |

| 6 | 1.5 | -3 | 0.5 | N2 | 3 | 14 | |

| 8 | 0.6 | -4 | 0.5 | N2 | 3 | 16 | |

| Aluminum | 1 | 20 | 0 | 0.8 | N2 | 1.5 | 12 |

| 2 | 10 | -1 | 0.5 | N2 | 2 | 12 | |

| 3 | 4 | -1.5 | 0.5 | N2 | 2 | 14 | |

| 4 | 1.5 | -2 | 0.5 | N2 | 2.5 | 14 | |

| 5 | 0.9 | -2.5 | 0.5 | N2 | 3 | 16 | |

| 6 | 0.6 | -3 | 0.5 | N2 | 3 | 16 | |

| Brass | 1 | 18 | 0 | 0.8 | N2 | 1.5 | 12 |

| 2 | 8 | -1 | 0.5 | N2 | 2 | 12 | |

| 3 | 3 | -1.5 | 0.5 | N2 | 2.5 | 14 | |

| 4 | 1.3 | -2 | 0.5 | N2 | 3 | 16 | |

| 5 | 0.8 | -2.5 | 0.5 | N2 | 3 | 16 | |

| Titanium | 1 | 2.3-3.5 | 0 | 0.8 | N2 | 1.5 | 12 |

| 2 | 1.7-2.6 | -1 | 0.5 | N2 | 2 | 12 | |

| 3 | 1.3-2.0 | -1.5 | 0.5 | N2 | 2 | 14 | |

| 4 | 1.0-1.5 | -1.5 | 0.5 | N2 | 2 | 14 | |

| 5 | 0.65-1.0 | -2 | 0.5 | N2 | 2 | 14 | |

| Galvanized Steel | 1 | 8.2-12.2 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 4.1-6.1 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 2.0-3.1 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 1.4-2.0 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 1.0-1.5 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 0.8-1.2 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 0.5-0.8 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 0.4-0.6 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 0.3-0.4 | -3 | 0.5 | N2 | 2.5 | 14 | |

| Nickel-Alloy | 1 | 3.6-5.4 | 0 | 0.8 | N2 | 1.4 | 14 |

| 2 | 1.4-2.2 | -0.8 | 0.8 | N2 | 1.4 | 14 | |

| 3 | 0.7-1.1 | -1.2 | 0.6 | N2 | 1.8 | 16 | |

| 4 | 0.5-0.7 | -1.2 | 0.6 | N2 | 1.8 | 16 | |

| 5 | 0.4-0.5 | -1.8 | 0.6 | N2 | 1.8 | 16 |

Compatible Materials

- Carbon Steel

- Stainless Steel

- Mild Steel

- Alloy Steel

- Tool Steel

- Bronze

- Zinc

- Inconel

- Hastelloy

- Waspaloy

- Rene alloys

- Stellite

- Galvanized Steel

- Chrome-Plated Steel

- Aluminized Steel

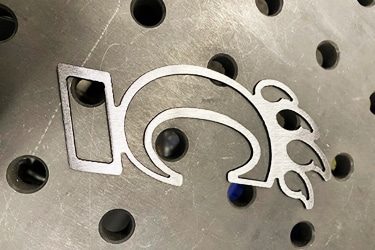

Application of 2kW Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Feature | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Cutting Precision | Very high (±0.05 mm) | Medium (±0.5 mm) | Very high (±0.1 mm) | Low (±1–2 mm) |

| Edge Quality | Smooth, minimal post-processing | Rougher, may need grinding | Excellent, no heat effect | Rough edges, heavy finishing |

| Material Range | Metals, reflective materials | Conductive metals only | Almost all materials (metal, stone, glass, composites) | Ferrous metals only |

| Max Cutting Thickness | Up to 50 mm (with high-power lasers) | Up to 150 mm | Up to 200+ mm | Up to 300 mm (steel) |

| Cutting Speed (Thin Sheets) | Fastest for <20 mm | Fast for medium-thick plates | Slower | Slow |

| Heat-Affected Zone (HAZ) | Very small | Medium | None | Large |

| Operating Cost | Low (energy-efficient, minimal consumables) | Medium (electrodes, gas) | High (abrasive, water, pump) | Low (fuel and oxygen) |

| Initial Investment | Medium to high | Low to medium | Very high | Low |

| Maintenance | Low (fiber lasers are reliable) | Medium (torch wear, consumables) | High (pump, nozzle, abrasive lines) | Low |

| Automation Compatibility | Excellent (CNC, software-driven) | Good | Good | Limited |

| Surface Finish | Clean, ready-to-use | Requires secondary finishing | Excellent | Poor |

| Environmental Impact | Low (no chemicals, low waste) | Moderate (fumes, slag) | High (abrasive waste disposal) | High (fumes, CO₂) |

| Energy Efficiency | High (especially fiber lasers) | Moderate | Low (energy-intensive pumps) | Moderate |

| Noise Levels | Low | High | High | High |

| Best Use Case | Precision sheet/plate cutting, prototyping, high-quality parts | Structural steel, medium-to-thick plates | Ultra-thick, exotic, or non-metal materials | Heavy plate cutting, construction |

| Industry Adoption | Automotive, aerospace, fabrication, electronics, signage | Shipbuilding, repair, construction | Aerospace, defense, custom fabrication | Heavy industry, construction |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Frequently Asked Questions

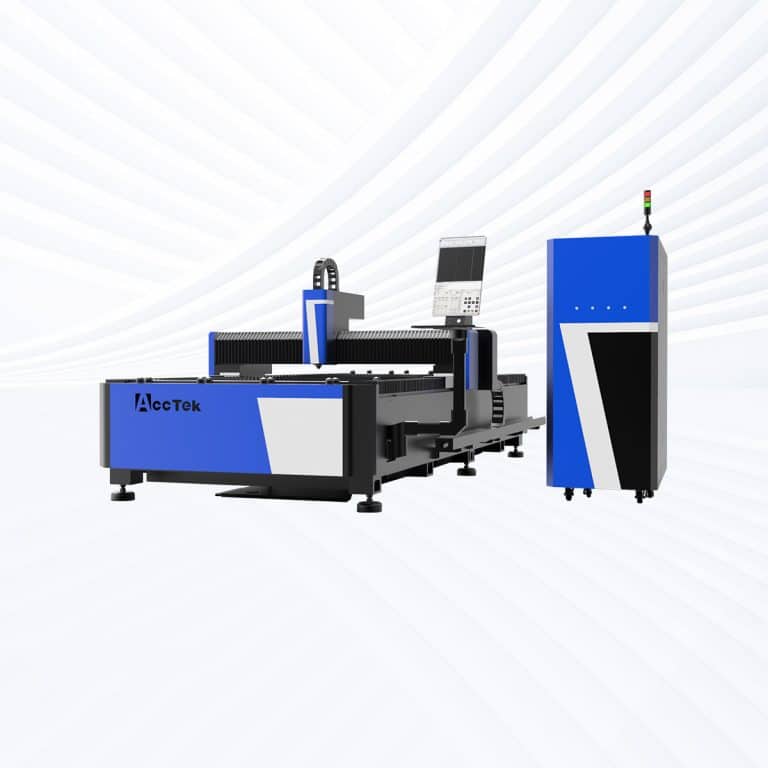

How Much Do 2kW Laser Cutting Machines Cost?

- Open Laser Cutting Machine ($15,000-$36,000): The most economical option, open-frame machines are simple in structure and easy to operate. They are suitable for workshops focused on cutting thin-to-medium metal sheets. However, because they lack enclosures, they require strict PPE use and good ventilation to manage sparks and fumes.

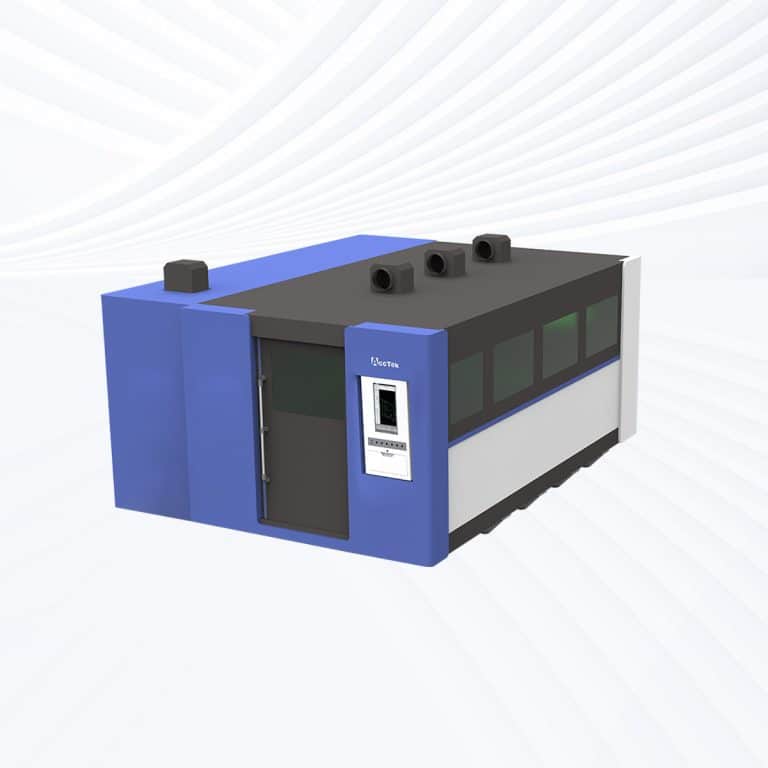

- Enclosed Laser Cutting Machine ($24,000-$39,000): These machines provide enhanced safety with full enclosures that shield operators from laser radiation and sparks. Enclosures also help control fumes and dust, making them more suitable for professional environments. The higher price reflects these added protections and compliance with workplace safety standards.

- Open Laser Cutting Machine with Exchange Worktable ($24,500-$39,000): This type adds productivity by allowing one sheet to be loaded or unloaded while another is cut. Exchange worktables reduce downtime and are valuable for businesses that need higher throughput. Being open-frame, they still have lower safety levels than enclosed designs.

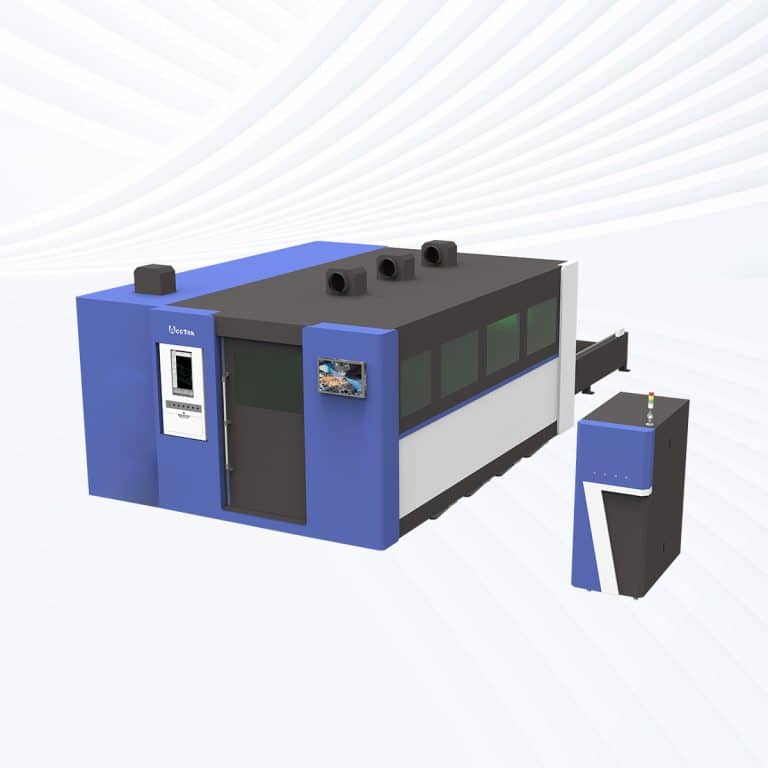

- Enclosed Laser Cutting Machine with Exchange Worktable ($28,500-$43,000): Combining enclosure safety with the efficiency of an exchange worktable, these machines are well-suited for mid- to large-scale operations. They balance operator protection with productivity, justifying their higher cost compared to non-exchange models.

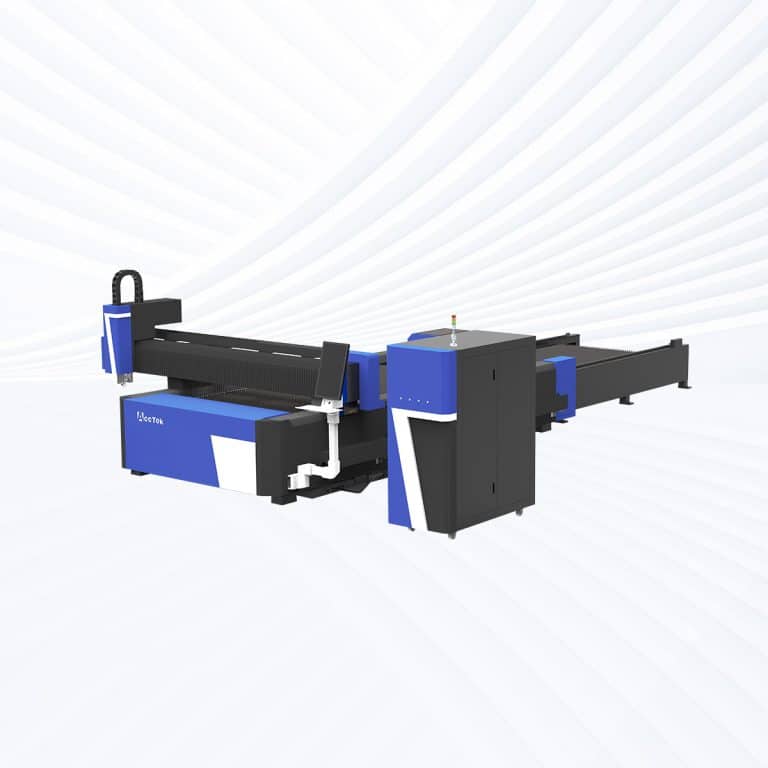

- Open Tube-Sheet Laser Cutting Machine ($26,000-$40,000): These versatile systems handle both flat sheets and round or square tubes, serving industries like furniture, automotive, and construction. While they add flexibility, the open-frame design means more exposure to sparks and dust, so safety measures are still important.

- Open Tube-Sheet Laser Cutting Machine with Exchange Worktable ($38,500-$53,500): This option combines multitasking (sheet + tube) with high productivity. The exchange worktable reduces downtime, making it ideal for workshops with diverse production needs. The added cost reflects the dual cutting system and automation features.

- Enclosed Tube-Sheet Laser Cutting Machine with Exchange Worktable ($43,000-$58,000): The most advanced and expensive option, this configuration offers maximum safety, productivity, and versatility. It is suited for industrial-scale production where clean environments, operator protection, and fast turnaround are essential. The enclosure minimizes laser hazards and fume exposure, while the exchange system speeds up operations.

What Is The Power Consumption Of 2kW Laser Cutting Machines?

- Laser Generator Power (≈6000W): The generator is the heart of the system, converting electrical energy into a high-powered cutting beam. To achieve 2kW of optical output, the source typically consumes about 6kW of input power due to conversion losses. While more efficient than CO2 lasers, the laser generator remains the largest single consumer of electricity.

- Chiller Power (≈3180W): Fiber lasers generate heat not only in the source but also in optics and electronics. A water chiller circulates coolant to maintain stable temperatures, preventing overheating and ensuring long-term reliability. At over 3kW, the chiller is the second-highest power draw, and it runs continuously while the machine is in use.

- Driver Power (≈2650W): Servo motors and motion drivers power the cutting head’s precise movements along the X, Y, and Z axes. These systems require around 2.6kW to support fast positioning, acceleration, and smooth operation. The efficiency of the motion system directly affects productivity and cut quality.

- Draught Fan Power (≈1500W): A draught fan removes fumes, dust, and metal particles from the cutting area. While not directly affecting cutting performance, it is essential for maintaining a safe environment and protecting machine optics. At 1.5kW, it contributes significantly to overall system power consumption.

How Should I Choose 2kW Laser Cutting Machines?

- Open vs. Enclosed Designs: Open-frame machines are more affordable and easier to maintain, but leave operators exposed to sparks, fumes, and laser radiation. They require strong ventilation and strict PPE usage. Enclosed models, by contrast, contain the beam and integrate exhaust systems, offering a safer, cleaner, and regulation-compliant workspace.

- Worktable Configurations: A standard fixed worktable is enough for light production and occasional cutting. For higher output, an exchange worktable is more efficient. It allows one sheet to be prepared while another is being cut, reducing downtime and increasing throughput in continuous operations.

- Sheet vs. Tube-Sheet Cutting: If your work is limited to flat sheets, a sheet-only machine is sufficient. But for industries such as construction, furniture, or automotive, a tube-sheet machine adds flexibility, letting you process round or square tubing alongside standard sheet metal. This dual capability broadens applications and increases long-term value.

- Assist Gas Selection: The choice of assist gas depends on the materials being cut. Oxygen is common for carbon steel, producing an oxidized edge. Nitrogen is used for stainless steel and aluminum, delivering clean, oxide-free edges ideal for high-quality applications. Compressed air can be used on thinner sheets as a cost-effective alternative, though with less precision.

- Production Volume and Power Needs: At 2kW, these machines are best suited for thin-to-medium sheet cutting and light industrial production. They provide a balance between capability and operating cost. Higher-powered machines (3kW and above) may be more suitable if you regularly cut very thick materials or require faster speeds.

- After-Sales Service and Support: Reliable technical support, training, and availability of spare parts are critical. Machines with advanced nesting software and automation features can also increase efficiency, making a big difference in overall productivity.

Are 2kW Laser Cutting Machines Easy To Operate?

- Control and Programming: These machines typically come with CNC software and touch-screen controls that streamline setup and operation. Pre-loaded material libraries allow operators to choose cutting parameters quickly. Automatic nesting functions optimize material use, while built-in diagnostics guide the user through error detection and correction.

- Automation Support: Many 2kW models integrate automatic focusing, nozzle cleaning, and height control. These features reduce the manual effort required and help new operators achieve consistent results. Exchange worktables add efficiency by minimizing downtime during sheet changes, making high-volume production easier to manage.

- Operator Training: Although user-friendly, these machines still require training to operate safely and effectively. Key skills include loading and unloading materials, selecting appropriate assist gases, and carrying out routine maintenance. Most suppliers offer training packages, and once operators are familiar with the basics, the workflow becomes straightforward.

- Safety Management: Ease of operation does not mean reduced responsibility. Open designs require strict attention to PPE, ventilation, and fire prevention. Enclosed designs are safer, shielding operators from sparks and radiation, but still demand careful gas handling and maintenance.

- Learning Curve: Beginners may need time to understand how different materials respond to laser cutting and how to adjust settings for optimal quality. With practice, operators usually find fiber lasers simpler and faster than plasma or mechanical alternatives.

Is It Safe To Use 2kW Laser Cutting Machines?

- Laser Radiation Protection: The laser beam itself poses the most significant hazard. Open machines expose operators to radiation risks, requiring strict use of protective eyewear, barriers, and PPE. Enclosed machines are safer, as their protective housing and interlock systems prevent accidental exposure to the beam.

- Fume and Dust Extraction: Cutting metals generates smoke, dust, and fumes that may contain hazardous particles. Effective extraction systems and good workshop ventilation are critical to maintaining safe air quality. Enclosed models typically integrate dust collection units, making them safer for continuous use.

- Fire and Heat Hazards: At 2kW, the machine generates concentrated heat capable of igniting flammable materials. Operators should never cut unsafe materials and must supervise the cutting process to prevent fires. A dedicated fire extinguisher and automatic fire detection systems further enhance safety.

- Gas Handling: Assisting gases such as oxygen, nitrogen, or compressed air must be managed carefully. Oxygen, in particular, increases fire risks if mishandled. Safe storage, leak checks, and correct regulator settings are all essential parts of safe operation.

- Operator Training and Procedures: Safety also depends on the user. Operators should be trained in machine startup, shutdown, emergency stop functions, and routine maintenance. Following manufacturer guidelines helps minimize risks and ensures reliable operation.

- Electrical and Mechanical Safety: Since the total power demand is high, proper electrical grounding and a stable power supply are necessary. Motion systems and exchange worktables should also be handled carefully to avoid mechanical accidents.

What Problems Might I Encounter When Using 2kW Laser Cutting Machines?

- Cutting Quality Issues: Incorrect settings, worn nozzles, or dirty optics can result in rough edges, incomplete cuts, or excessive burrs. Thicker materials, especially stainless steel and aluminum, may require fine-tuned parameters to achieve clean results. Regular calibration and maintenance are key to consistent quality.

- Material Limitations: While 2kW laser cutting machines cut thin-to-medium sheets well, very thick metals may push the system’s limits. Attempting to cut beyond recommended thickness can slow productivity, increase gas consumption, and reduce edge quality. In such cases, higher-power machines may be more suitable.

- Assist Gas Problems: Improper gas type, flow rate, or pressure can cause poor cut quality, oxidation, or dross buildup. Oxygen leaks pose safety risks, while nitrogen usage may increase operating costs. Ensuring the gas system is properly set up and maintained prevents most of these issues.

- Optics and Lens Contamination: Dust, fumes, or spatter can accumulate on the protective lens and mirrors, reducing cutting efficiency and potentially damaging components. Without regular cleaning and replacement, this can lead to frequent downtime and higher operating costs.

- Electrical and Cooling System Failures: The machine’s high power demand requires stable electricity and reliable cooling. Voltage fluctuations, inadequate grounding, or chiller malfunctions can lead to overheating, machine errors, or even component damage. Maintaining proper infrastructure reduces these risks.

- Software or Programming Errors: Incorrect cutting paths, improper nesting, or faulty programming can waste materials and reduce productivity. Operators should double-check programs before cutting and use simulation tools when available to avoid mistakes.

- Maintenance Neglect: Skipping routine checks—like nozzle replacement, filter cleaning, and lubrication—can shorten machine lifespan and lead to unexpected breakdowns. Preventive maintenance is essential for reliable performance.

What Training Is Required To Operate 2kW Laser Cutting Machines?

- Basic Machine Operation: Operators should first learn the control system, including the CNC interface, touchscreen controls, and software functions. Training covers loading and unloading sheets, selecting cutting parameters, and monitoring performance during operation. Simulation tools are often used to teach programming without wasting material.

- Material Knowledge and Parameter Setting: Each material behaves differently under the laser. Operators are trained to choose appropriate assist gases (oxygen, nitrogen, or air) and set cutting speeds, power levels, and focus positions for different metals and thicknesses. Mastering these adjustments is key to achieving consistent edge quality and minimizing waste.

- Safety Procedures: Laser safety is a major part of training. Operators learn how to handle PPE, manage ventilation and fume extraction, and follow fire prevention practices. For open machines, extra emphasis is placed on eye protection and safe work distances. Enclosed machines reduce direct exposure but still require training in gas handling and machine shutdown procedures.

- Maintenance and Troubleshooting: Operators are taught routine checks such as cleaning optics, replacing nozzles, inspecting gas lines, and maintaining filters. Training also includes diagnosing common problems like poor cut quality, gas leaks, or electrical alarms, along with knowing when to escalate issues to technicians.

- Software and Automation Skills: Modern 2kW laser cutting systems often include automation features like auto-focusing, nesting software, and exchange worktables. Training ensures operators can use these features efficiently to reduce downtime and maximize material utilization.

- Emergency Procedures: A critical part of training is learning how to respond to emergencies. Operators practice using emergency stop systems, shutting down safely during malfunctions, and handling fire risks quickly to protect both personnel and equipment.

How Do I Maintain 2kW Laser Cutting Machines?

- Optical Component Care: The protective lens and nozzle are directly exposed to spatter, smoke, and dust during cutting. Regular cleaning prevents contamination that can reduce beam quality and increase wear. Damaged or heavily soiled optics should be replaced promptly to maintain cutting accuracy and efficiency.

- Gas Supply System: Assisting gases like oxygen and nitrogen must be delivered at the correct flow and pressure. Operators should inspect regulators, pipes, and connections for leaks or blockages. Filters in the gas system should also be cleaned or replaced regularly to prevent impurities from affecting cut quality.

- Cooling System Maintenance: The chiller keeps the laser source and optics within safe operating temperatures. Coolant levels must be checked frequently, and the fluid should be replaced according to the manufacturer’s schedule. Filters, pumps, and hoses also require inspection to avoid overheating or coolant contamination.

- Dust and Fume Extraction: The extraction system removes smoke, dust, and fine particles generated during cutting. Filters should be cleaned or replaced regularly to keep airflow strong. Without proper extraction, both machine performance and operator safety are compromised.

- Mechanical Components: Rails, bearings, and drive systems must be cleaned and lubricated to prevent wear and ensure smooth motion. Misalignment or buildup of debris can lead to poor precision and uneven cuts. Periodic calibration of the motion system ensures accuracy over time.

- Software and System Checks: Machine control software should be kept updated, and operators should perform regular diagnostics to detect errors. Backing up parameter settings and cutting programs protects against data loss.

- Scheduled Maintenance and Inspections: Following the manufacturer’s recommended maintenance schedule is critical. This includes routine daily checks (like lens cleaning and coolant inspection), weekly tasks (lubrication and filter cleaning), and long-term service such as replacing worn parts and updating firmware.