Product Introduction

1kW Laser Cutting Capacity

| Material | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| Carbon Steel | 0.8 | 18 | 0 | 1 | N2/Air | 1.5 | 10 |

| 1 | 10 | 0 | 1 | N2/Air | 1.5 | 10 | |

| 2 | 4 | 3 | 0.8 | O2 | 1.2 | 2 | |

| 3 | 3 | 3 | 0.8 | O2 | 1.2 | 0.6 | |

| 4 | 2.3 | 3 | 0.8 | O2 | 1.2 | 0.6 | |

| 5 | 1.8 | 3 | 0.8 | O2 | 1.2 | 0.6 | |

| 6 | 1.5 | 3 | 0.8 | O2 | 1.5 | 0.6 | |

| 8 | 1.1 | 3 | 0.8 | O2 | 1.5 | 0.6 | |

| 10 | 0.8 | 3 | 0.8 | O2 | 2.5 | 0.6 | |

| Stainless Steel | 1 | 15-18 | 0 | 0.8 | N2 | 2 | 10 |

| 2 | 4-4.5 | 0 | 0.5 | N2 | 2 | 12 | |

| 3 | 1.5-2 | -1 | 0.5 | N2 | 2 | 12 | |

| 4 | 1-1.3 | -1.5 | 0.5 | N2 | 2.5 | 15 | |

| 5 | 0.6-0.8 | -2 | 0.5 | N2 | 3 | 15 | |

| 1 | 18-20 | 0 | 0.8 | Air | 2 | 10 | |

| 2 | 5-6 | 0 | 0.5 | Air | 2 | 10 | |

| 3 | 2-2.5 | -1 | 0.5 | Air | 2 | 10 | |

| 4 | 1.5-1.7 | -1.5 | 0.5 | Air | 2.5 | 10 | |

| 5 | 0.8-1 | -2 | 0.5 | Air | 3 | 10 | |

| Aluminum | 0.8 | 18 | 0 | 0.8 | N2 | 1.5 | 12 |

| 1 | 10 | 0 | 0.5 | N2 | 1.5 | 12 | |

| 2 | 5 | -1 | 0.5 | N2 | 2 | 14 | |

| 3 | 1.5 | -1.5 | 0.5 | N2 | 3 | 16 | |

| Brass | 1 | 9 | 0 | 0.5 | N2 | 2 | 12 |

| 2 | 2 | -1 | 0.5 | N2 | 2 | 14 | |

| 3 | 0.8 | -1.5 | 0.5 | N2 | 3 | 16 | |

| Titanium | 1 | 1.3-2.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 0.1-1.4 | -1 | 0.5 | N2 | 2 | 12 | |

| Galvanized Steel | 1 | 4.8-7.2 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 2.4-3.6 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 1.2-1.8 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 0.8-1.2 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 0.6-0.9 | -2 | 0.6 | N2 | 2 | 14 | |

| Nickel-Alloy | 1 | 2.4-3.6 | 0 | 0.8 | N2 | 1.4 | 14 |

| 2 | 1.0-1.4 | -0.8 | 0.8 | N2 | 1.4 | 14 | |

| 3 | 0.5-0.7 | -1.2 | 0.6 | N2 | 1.8 | 16 |

Compatible Materials

- Carbon Steel

- Stainless Steel

- Mild Steel

- Alloy Steel

- Tool Steel

- Bronze

- Zinc

- Inconel

- Hastelloy

- Waspaloy

- Rene alloys

- Stellite

- Galvanized Steel

- Chrome-Plated Steel

- Aluminized Steel

Application of 1kW Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Feature | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Cutting Precision | Very high (±0.05 mm) | Medium (±0.5 mm) | Very high (±0.1 mm) | Low (±1–2 mm) |

| Edge Quality | Smooth, minimal post-processing | Rougher, may need grinding | Excellent, no heat effect | Rough edges, heavy finishing |

| Material Range | Metals, reflective materials | Conductive metals only | Almost all materials (metal, stone, glass, composites) | Ferrous metals only |

| Max Cutting Thickness | Up to 50 mm (with high-power lasers) | Up to 150 mm | Up to 200+ mm | Up to 300 mm (steel) |

| Cutting Speed (Thin Sheets) | Fastest for <20 mm | Fast for medium-thick plates | Slower | Slow |

| Heat-Affected Zone (HAZ) | Very small | Medium | None | Large |

| Operating Cost | Low (energy-efficient, minimal consumables) | Medium (electrodes, gas) | High (abrasive, water, pump) | Low (fuel and oxygen) |

| Initial Investment | Medium to high | Low to medium | Very high | Low |

| Maintenance | Low (fiber lasers are reliable) | Medium (torch wear, consumables) | High (pump, nozzle, abrasive lines) | Low |

| Automation Compatibility | Excellent (CNC, software-driven) | Good | Good | Limited |

| Surface Finish | Clean, ready-to-use | Requires secondary finishing | Excellent | Poor |

| Environmental Impact | Low (no chemicals, low waste) | Moderate (fumes, slag) | High (abrasive waste disposal) | High (fumes, CO₂) |

| Energy Efficiency | High (especially fiber lasers) | Moderate | Low (energy-intensive pumps) | Moderate |

| Noise Levels | Low | High | High | High |

| Best Use Case | Precision sheet/plate cutting, prototyping, high-quality parts | Structural steel, medium-to-thick plates | Ultra-thick, exotic, or non-metal materials | Heavy plate cutting, construction |

| Industry Adoption | Automotive, aerospace, fabrication, electronics, signage | Shipbuilding, repair, construction | Aerospace, defense, custom fabrication | Heavy industry, construction |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Frequently Asked Questions

How Much Do 1kW Laser Cutting Machines Cost?

- Open Laser Cutting Machine ($13,000–$29,000): These are entry-level systems with a simple frame and open cutting area. They are cost-effective and suitable for small to medium-sized businesses that cut sheet metals, such as stainless steel, carbon steel, and aluminum. The trade-off is lower safety and more exposure to dust, sparks, and laser radiation, making protective gear and ventilation essential.

- Enclosed Laser Cutting Machine ($22,000–$37,000): With a fully enclosed design, these machines offer enhanced safety, improved dust control, and increased operator protection. They comply better with workplace safety standards, which is critical in professional or industrial environments. The higher price reflects the additional enclosure system, automatic doors, and stronger extraction units.

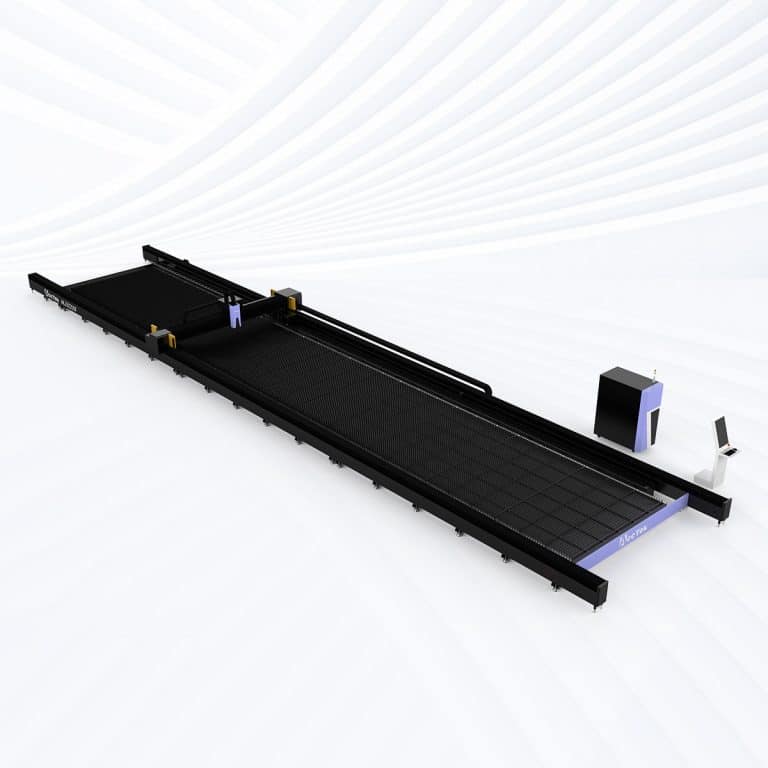

- Open Laser Cutting Machine with Exchange Worktable ($22,000–$33,000): Adding an exchange worktable boosts productivity by allowing one sheet to be prepared while the machine cuts another. This feature reduces downtime and is valuable for businesses with higher throughput needs. Costs rise slightly compared to the basic open version, but it’s still more affordable than enclosed systems.

- Enclosed Laser Cutting Machine with Exchange Worktable ($27,000–$38,000): This setup combines the safety of an enclosure with the efficiency of an exchange worktable. It’s a balanced choice for workshops aiming for both compliance and speed. The additional automation justifies the higher cost compared to standard enclosed models.

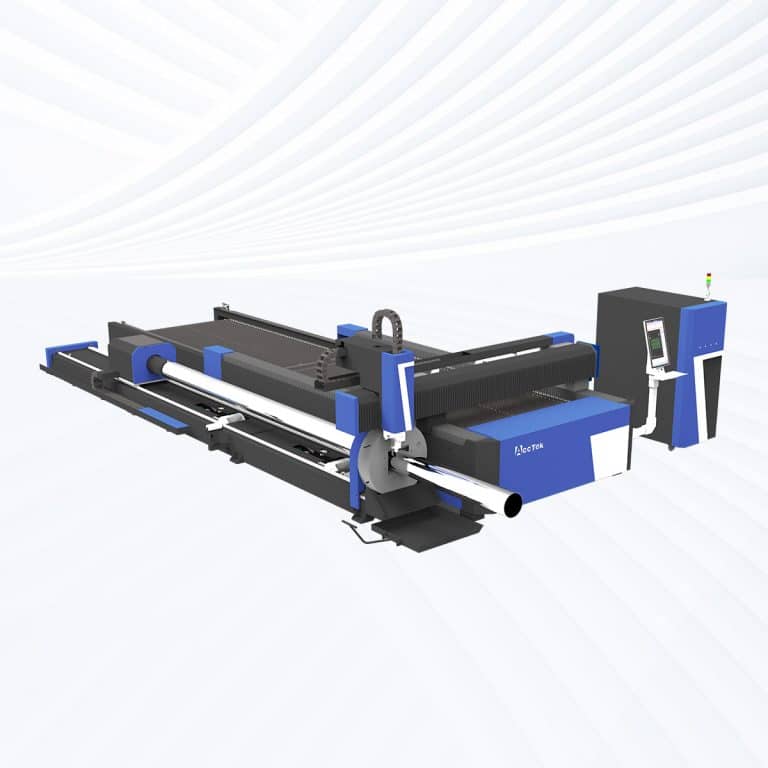

- Open Tube-Sheet Laser Cutting Machine ($29,000–$40,000): Designed for both flat sheets and round or square tubes, these machines add flexibility for industries like furniture, automotive, and construction. The added mechanics for rotary cutting and dual-purpose functionality raise the price compared to sheet-only machines.

- Open Tube-Sheet Laser Cutting Machine with Exchange Worktable ($36,000–$47,000): This upgrade merges multitasking capability (tubes and sheets) with high-efficiency exchange tables. It’s ideal for mid- to large-scale production shops needing faster turnaround. The cost reflects both the tube cutting system and automated sheet handling.

- Enclosed Tube-Sheet Laser Cutting Machine with Exchange Worktable ($40,000–$51,000): At the top end of the 1kW market, these machines offer maximum safety, productivity, and versatility. They are suited for professional environments handling diverse jobs at high volumes. The enclosure reduces risks from sparks and fumes, while exchange worktables and tube-sheet compatibility provide peak efficiency.

What Is The Power Consumption Of 1kW Laser Cutting Machines?

- Laser Generator Power (≈3000W): The laser generator is the heart of the machine, producing the high-energy beam used for cutting. Even though it outputs 1kW of cutting power, it typically consumes around 3kW of electrical power to do so. This is due to conversion losses in the diode modules and power supply. The efficiency of fiber laser cutting machines is higher than that of CO2 laser cutting systems, but they still require more input power than their optical output.

- Chiller Power (≈1310W): Laser generators produce a significant amount of heat, and overheating can cause damage or reduce precision. An industrial-grade chiller circulates cooling fluid around the laser source and optics to maintain stable temperatures. Chillers run continuously while the laser is in use, and their power draw (around 1.3kW) is a constant background load to factor into operating costs.

- Driver Power (≈2650W): Servo motors and motion control systems consume a large share of power. These drivers control the X, Y, and Z axes of the cutting head with precision and speed. Rapid acceleration, high-speed positioning, and synchronized movement all require strong electrical input. Depending on job complexity and cutting speed, this subsystem can account for over 2.6kW of power draw.

- Draught Fan Power (≈1500W): Dust, smoke, and metal fumes are byproducts of laser cutting. A powerful draught (extraction) fan removes these particles from the cutting area, ensuring clean optics and a safe environment for operators. This adds another 1.5kW to the total system consumption, and while it doesn’t affect cutting performance directly, it is critical for long-term machine reliability and workplace safety.

What Is The Accuracy Of 1kW Laser Cutting Machines?

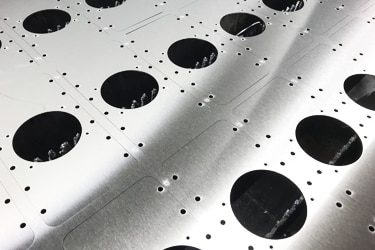

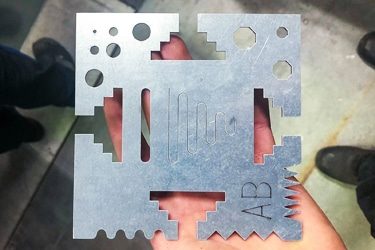

- Dimensional Accuracy (±0.05 mm): Most 1kW laser cutting machines achieve positioning accuracy within ±0.05 mm, which is more than sufficient for sheet metal fabrication, signage, and mechanical parts. This level of precision ensures tight-fitting components and minimal post-processing. However, results vary depending on material thickness, operator settings, and machine calibration.

- Repeatability (±0.02 mm): Repeatability is crucial for mass production, where hundreds of identical parts must be cut consistently. A typical 1kW system can repeat the same cut with a variance of just ±0.02 mm. This reliability makes fiber lasers ideal for industries requiring standardized parts, such as electronics, automotive, and aerospace components.

- Edge Quality: Fiber lasers produce smooth, burr-free edges, especially on thin to medium sheet metals. With proper parameters, cuts require little to no secondary finishing. On thicker materials, however, dross (residual molten metal) may form at the edges, slightly affecting precision unless removed. Gas choice (oxygen vs. nitrogen) and nozzle condition also play a role in maintaining edge quality.

- Influence of Material Thickness: Accuracy is best on thin to mid-range metals (1–6 mm). At thicker gauges, precision decreases slightly due to heat buildup and slower cutting speeds. For example, stainless steel at 8–10 mm may show wider kerf widths and less sharp detailing compared to thinner sheets.

- Machine Structure and Motion System: Rigid machine frames, high-quality linear guides, and servo motors significantly improve accuracy. Open-frame, entry-level models may have slightly lower stability compared to enclosed, industrial-grade systems. Precision drops if mechanical vibrations, poor calibration, or low-quality optics are present.

Are 1kW Laser Cutting Machines Easy To Operate?

- User Interface and Software: Most 1kW machines are equipped with touchscreen control panels and CAD/CAM software integration. Operators can import DXF or other design files, adjust cutting parameters, and monitor progress in real time. The software often includes libraries of preset cutting conditions for common materials, making the learning curve much shorter for beginners.

- Setup and Calibration: Initial machine setup, including aligning optics, calibrating the cutting head, and configuring gas flows, requires some technical knowledge. Fortunately, many systems now include automatic focus adjustment, collision detection, and nozzle calibration features that reduce manual effort. Still, routine checks are important for maintaining accuracy and consistent performance.

- Material Handling: Open-frame machines require manual loading and unloading of sheets, which can be labor-intensive for large metal plates. Exchange worktables or automatic feeders streamline this process, making the operation easier and faster. Tube-sheet models may demand more setup steps since they handle both flat and cylindrical materials.

- Training and Skill Level: Basic cutting tasks can be performed by operators with minimal training, thanks to intuitive controls and built-in automation. However, advanced tasks—such as optimizing cutting parameters for new materials, troubleshooting dross, or maximizing efficiency—benefit from skilled technicians. Most suppliers provide training to ensure operators quickly become comfortable with the system.

- Maintenance and Safety: Daily operation is straightforward, but maintenance (like cleaning optics, checking filters, and inspecting consumables) must not be neglected. Safety systems such as enclosures, interlocks, and fume extraction make enclosed machines safer and easier for beginners, while open-frame models require stricter adherence to safety protocols.

What Are The Environmental Requirements For 1kW Laser Cutting Machines?

- Temperature Control (5–35℃/ 41–95℉): Fiber laser cutting systems are sensitive to overheating. The machine’s generator and optics must be kept within a stable temperature range, typically between 5–35℃. Excessive heat can reduce accuracy, while very low temperatures risk condensation on optical components. Climate-controlled workshops or supplemental air conditioning are recommended for consistent operation.

- Humidity (≤70% non-condensing): High humidity can cause condensation, corrosion of optics, and electrical faults in sensitive components. Operating the machine in environments above 70% relative humidity risks damage and unstable cutting quality. A dehumidifier may be necessary in regions with high seasonal moisture.

- Ventilation and Air Quality: Cutting metals produces fumes, dust, and microscopic particles. Proper fume extraction systems and air filtration are essential to protect both the operator and the machine’s optics. Enclosed models usually include integrated exhaust systems, while open-frame models rely heavily on external ventilation setups. Clean, dust-free workshop environments also extend machine lifespan.

- Electrical Stability: 1kW laser cutting machines draw 8–9 kW of power in total, making them dependent on stable electricity. Voltage fluctuations or surges can disrupt operation and damage components. Installing an industrial-grade voltage stabilizer or uninterruptible power supply (UPS) is strongly recommended, especially in areas with unstable grids.

- Gas Supply and Storage: Fiber lasers often use assist gases like nitrogen or oxygen. Proper storage of gas cylinders in well-ventilated, temperature-stable areas is critical. Lines must be clean, dry, and regulated to avoid pressure fluctuations that affect cut quality.

- Vibration Control: Excessive vibration from nearby heavy machinery can impact cutting precision. Placing the machine on a stable, level floor away from vibration sources ensures smoother motion control and prevents calibration drift.

- Space and Layout: Adequate clearance is needed around the machine for safe loading, unloading, and maintenance. Open machines require more operator-accessible space, while enclosed machines reduce exposure but still need room for ventilation ducts, gas storage, and access panels.

Is It Safe To Use 1kW Laser Cutting Machines?

- Laser Radiation (Class 4 Hazard): Lasers at 1kW fall under Class 4 laser systems, meaning direct exposure to the beam can cause severe eye and skin damage. Enclosed models provide built-in shielding to minimize risks, while open-frame machines require strict protective protocols such as laser safety glasses and restricted work areas.

- Fumes and Particulates: Cutting metals generates smoke, fine particulates, and potentially hazardous fumes. For example, cutting galvanized steel releases zinc oxide fumes, which can be harmful if inhaled. Proper fume extraction, filtration, and workshop ventilation are essential for protecting operator health and maintaining clear optics.

- Electrical and Power Safety: 1kW laser cutting machines consume 8–9 kW of electrical power across all components. Improper wiring or unstable voltage can create fire risks or damage sensitive electronics. Machines should be connected through grounded, industrial-grade circuits, with stabilizers or UPS systems in areas prone to power fluctuations.

- Fire and Heat Risks: The laser beam can ignite flammable materials, especially when misapplied to non-metallic substances. Even metals can produce sparks that pose a fire hazard in poorly managed environments. Operators must keep the cutting area clear of combustibles and monitor the process closely. Fire suppression equipment, such as CO2 extinguishers, should always be nearby.

- Gas Safety: Laser cutting often requires assist gases such as oxygen or nitrogen. Improper handling or storage of high-pressure cylinders can lead to leaks, explosions, or asphyxiation risks. Cylinders must be secured upright, stored in ventilated areas, and regularly inspected for leaks.

- Mechanical and Operational Hazards: Moving components like the gantry, cutting head, and exchange tables can pinch, crush, or collide if operators are careless. Modern machines include collision detection and emergency stop buttons, but training operators to avoid unsafe interaction with moving parts remains critical.

- Operator Training and PPE: Safety relies heavily on operator knowledge. Proper training in startup, shutdown, emergency procedures, and troubleshooting reduces risks significantly. In addition to safety glasses, operators may require gloves, hearing protection, and protective clothing depending on the work environment.

What Problems May Occur When Using 1kW Laser Cutting Machines?

- Insufficient Cutting Power on Thick Materials: 1kW lasers are best suited for thin to medium sheet metals (typically up to 8–10 mm in carbon steel, less for stainless steel and aluminum). Attempting to cut thicker plates may result in incomplete penetration, rough edges, or excessive dross. For heavy-duty cutting, higher-power systems (2kW and above) are more suitable.

- Edge Quality Issues (Burrs and Dross): Incorrect cutting parameters, worn nozzles, or improper assist gas selection can lead to burrs or slag sticking to the underside of the cut. This reduces part quality and may require additional grinding or polishing. Consistent maintenance and parameter optimization are necessary to minimize edge defects.

- Inconsistent Piercing: During the initial piercing process, some materials—especially reflective ones like aluminum or copper—may cause unstable pierce holes or incomplete starts. This can affect precision in detailed cuts. Using the correct gas settings and protective coatings can help reduce piercing issues.

- Optical Component Contamination: Dust, fumes, or metal particles can contaminate the lens and protective window, reducing laser transmission efficiency. This leads to weaker cutting power and inconsistent results. Regular cleaning and replacement of consumables are required to maintain performance.

- Gas Flow Problems: Assisting gases like oxygen and nitrogen must be delivered at stable pressures and flow rates. Leaks, clogged nozzles, or fluctuating supply pressures can degrade cut quality and increase operating costs. Proper gas line maintenance is critical.

- Heat Distortion on Thin Sheets: While lasers excel at precision, very thin metals may warp or deform due to concentrated heat if parameters are not carefully adjusted. Using lower speeds or pulsed cutting can minimize thermal distortion.

- Electrical or Software Faults: Voltage fluctuations, unstable power supplies, or control system errors can interrupt cutting operations. These issues can cause downtime or even damage sensitive electronics. Installing voltage stabilizers and keeping software updated helps reduce these risks.

- Mechanical Wear and Misalignment: Over time, motion systems (such as guide rails, belts, and servo motors) may develop wear or misalignment. This reduces cutting precision and may cause irregular kerf widths. Routine calibration and preventive maintenance extend system accuracy.

How Should 1kW Laser Cutting Machines Be Maintained?

- Optical Components (Lens and Protective Windows): The laser head’s protective lens and focusing optics are exposed to fumes, spatter, and dust. Regular inspection and cleaning prevent contamination that reduces laser transmission and weakens cutting performance. Damaged or heavily soiled lenses should be replaced immediately to avoid beam distortion.

- Cooling System (Chiller): The laser generator and optics rely on stable cooling to prevent overheating. The chiller’s water level, quality, and temperature must be checked frequently. Using purified or distilled water with antifreeze additives (where recommended) prevents scaling and blockages. Filters and water lines should also be cleaned regularly to maintain efficiency.

- Assist Gas System: Oxygen and nitrogen lines, regulators, and nozzles must be kept clean and leak-free. Any clogging or pressure instability will directly affect cut quality and increase operating costs. Routine checks for leaks, replacing worn nozzles, and ensuring gas cylinders are stored safely are essential parts of maintenance.

- Machine Bed and Cutting Area: Slag buildup and metal debris accumulate on the cutting bed over time, obstructing sheets and reducing cut precision. Regular cleaning of the bed, support slats, and worktable ensures smooth material handling and prevents collisions between the nozzle and workpiece.

- Motion System (Rails, Motors, and Belts): The precision of the machine depends on linear rails, ball screws, and servo motors. Lubrication schedules should be followed closely, and rails must be kept free of dust and debris. Any signs of misalignment, vibration, or unusual noise should be addressed promptly through calibration or part replacement.

- Electrical Components and Software: Periodic inspection of electrical connections prevents loose wiring and overheating. Voltage stabilizers and surge protection extend the life of sensitive electronics. Software and firmware updates should be applied to ensure compatibility, improved performance, and access to new features.

- Air Filtration and Exhaust Systems: Extraction fans and filters must be maintained to prevent blockages and loss of suction power. A well-functioning exhaust system not only ensures operator safety by removing fumes but also keeps optics and electronics free from contamination.

- Preventive Inspections: Regular inspections (weekly, monthly, and annually) should be scheduled for critical components like the laser source, cooling unit, and motion controls. Keeping detailed maintenance logs helps identify recurring issues early and reduces downtime.