In the process of using the engraving machine, the spindle of the

CNC woodcarving machine has a large workload and high frequency, and it is also one of the parts that are very easily damaged. When the damage is more serious, the CNC woodcarving machine will make noise. The machine makes noise, how should we solve it? We will introduce how to deal with the noise of the engraving machine from the following aspects?

You should first check whether the moving parts are loose or damaged, so the customer needs to check the machine transmission parts, such as wire rods, light rods, bearings, etc. These parts move relatively large. Generally speaking, the screw of the

cutting machine is worn or the beads in the bearing are loose, which may cause abnormal noise during the engraving process, or the side rail sliders may be loose. This requires replacement of these levers, bearings or slider components.

Secondly, check whether the lubrication system of the

engraving machine is good. If the engraving machine cannot maintain the lubricating oil for a long time, the machine will have friction problems with the transmission parts during the movement, and of course it will produce noise. Therefore, whether it is a frame-driven

wood engraving machine, Customers need regular maintenance and refueling of stone engraving machines, wire rod-driven advertising engraving machines, and jade mold engraving machines.

Check whether the configuration of the

engraving machine is correct. Sometimes the machine has problems with identification and guidance in the absence of company technicians. Private repackaging will cause abnormal noise. Generally, if you encounter such problems, please consult professional technology immediately. Personnel or contact professionals to come to guide.

There is a flapping sound

When the actuator and roller vibrate and trigger, they are easily affected by torque, load or radial clearance. The accuracy of the bonder should be improved, bearings with small clearances should be selected or preloaded on the bearings, torque load should be reduced, device errors should be reduced, and good oil should be selected.

There is a buzzing noise

The motor works without load by declaring the same sound as the buzzer, and the motor has abnormal axial vibration and buzzing when switching or switching. At present, most bearings are in a poor state, as well as in winter and double-ended ball bearing motors, mainly when the shaft function is not good, the axial vibration is affected by unstable vibration.

The sound that appears when there is impurities

The irregular sound of the high-speed motor, and some unclean impurities around the main shaft. Good grease should be selected to improve the cleanliness of the pre-spray, strengthen the bearing sealing function, and improve the environmental cleanliness of the equipment

Dada's voice appears

The sound frequency changes with the bearing speed, and the surface ripple is the main cause of noise. Improve the surface processing quality of the bearing roller, reduce the ripple amplitude, reduce the impact, intermittent gap pre-tightening force and coordination, see the work of the self-end bearing, improve the bearing and the precision installation method of the bearing seat.

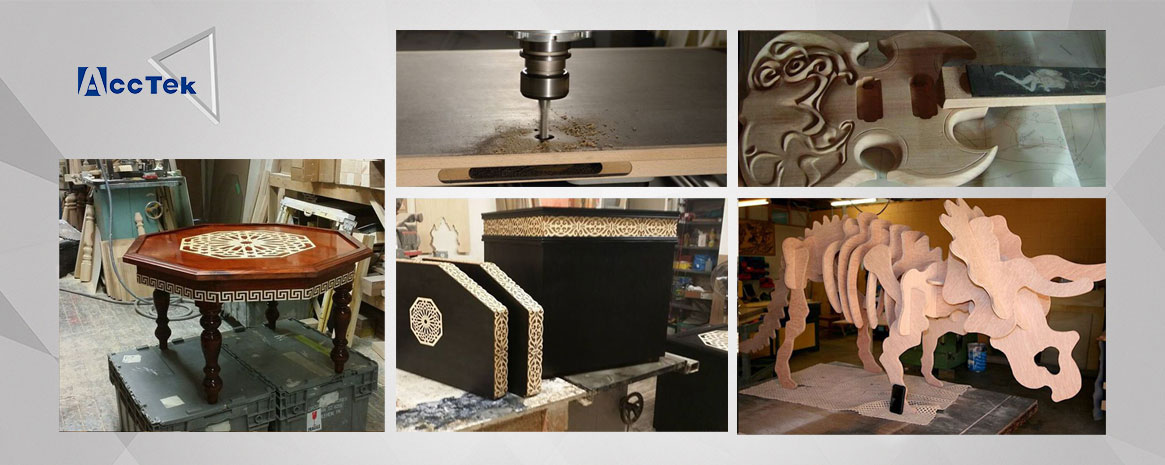

The above are several phenomena and solutions for the unknown sound of the

engraving machine. If you want to learn more about the engraving machine or laser machine or want to consult some questions, you can contact our staff online at any time.