Leather is a material widely used in daily necessities, shoes, wallets, belts, accessories, packaging bags and many other products are made of leather. Leather products are very durable, and are more beautiful after engraving various patterns, and are loved by the public. If your shop has leather materials that need to be engraved, cut or hollowed out, then choosing a suitable laser cutting machine can bring you higher processing efficiency.

1. New-style high-efficiency Reci CO2 laser tube is adopted. Compared with the laser tube of the same level, slim and stable beam, high quality spot. Usage age is more than 10000 hours. Each CO2 laser cutting machine of ACCTEK is equipped installation of reinforcement stings, the laser tube is not easy to collide and cause damage when moving the machine.

2. Red dot position system is added in standard configuration, contributing to simple and precise working position. Cutting head always follows the material to keep the cutting point location unchanged.

3. Advanced Ruida control system, with professional motion control chip, has the function of consecutively high-speed curve cutting and the shortest path selection, which largely improves your working efficiency. Ruida control system supports USB cable controlled by computer and and also offline control system by just a U disk. The operation is more convenient and faster.

4. The

laser cutter machine is equipped with square tube framework, with more than 40% higher fuselage strength than iron sheet structure. This design prevents the laser machine from quivering, resonance and distortion during long term work.

5. Taiwan HIWIN square linear guide rail installed on X Y axis, with good bearing capacity. It makes sure the works stably and precisely.

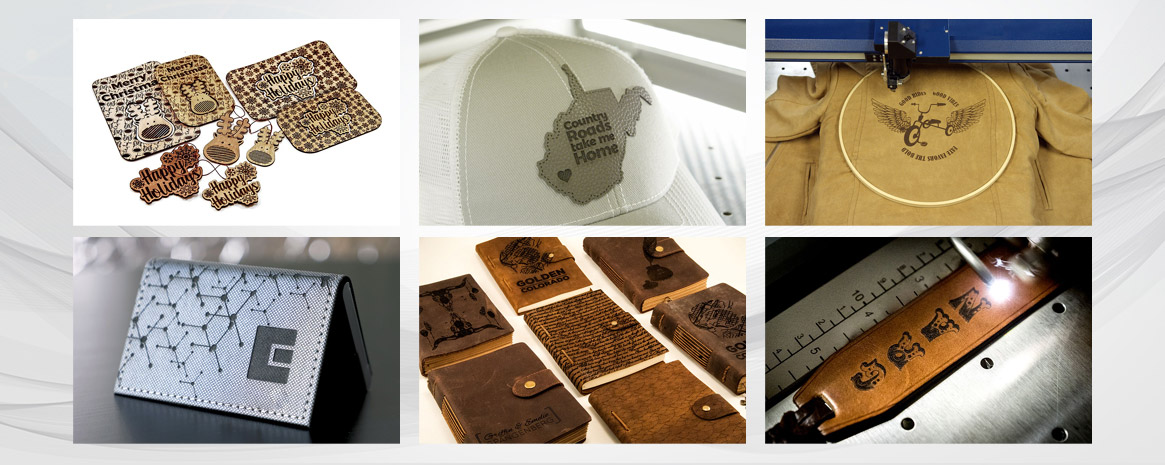

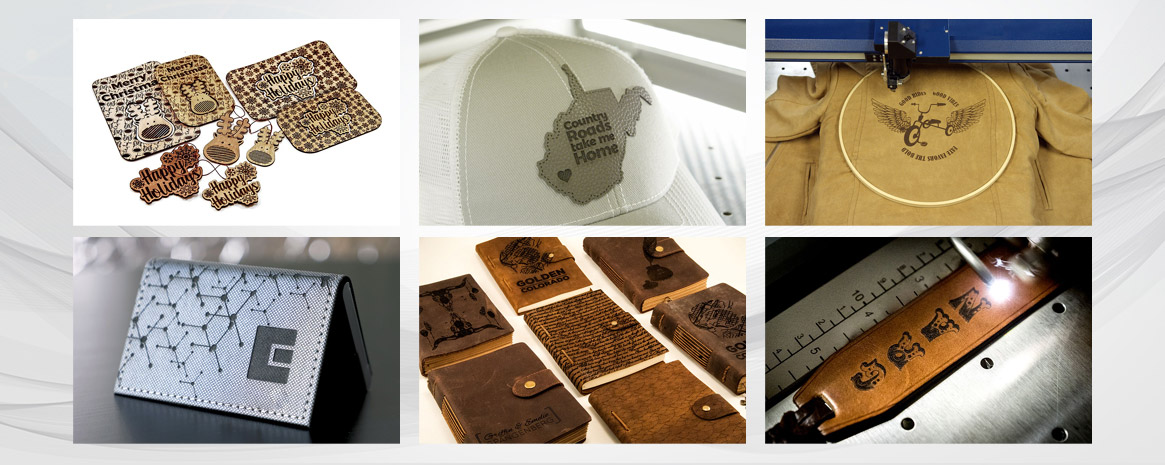

Features of laser engraved leather

The process of engraving or etching leather results in a debossed effect and, depending on the surface of the leather, produces a noticeable and clean contrast. Light-colored leathers produce significant color contrast, whereas engraving darker leathers results in a more subtle contrast. If you need a dynamic color contrast, go with a tan, beige, or light brown leather.

Your engraving results are mostly dependent on the type of leather used as well as your laser speed, power, and frequency settings. As with any material, we always recommend testing different parameters until you achieve your desired results.

There are several benefits to using your laser to cut leather. First, the laser provides sealed cuts that won’t fray or otherwise deteriorate. Secondly, unlike manual leather cutting tools such as utility knives and rotary cutters, cutting leather with a laser is incredibly fast, precise, and perhaps most importantly, consistent. Additionally, cutting with the laser eliminates warping that can sometimes happen with hand tools.

When using the laser to cut leather, there is no part-to-part contact, which means there are no blades or costly parts to replace. Lastly, there’s no time wasted clamping down leather for processing. Simply insert the sheet into your laser bed and engrave or cut your desired pattern.

The application of

laser cutting machine is very extensive, in addition to leather, wood, acrylic, cloth and other materials can also be engraved or cut by laser machine. No matter what industry you are in, as long as you need engraving and cutting equipment, you can consult online to get your own suggestions and solutions.