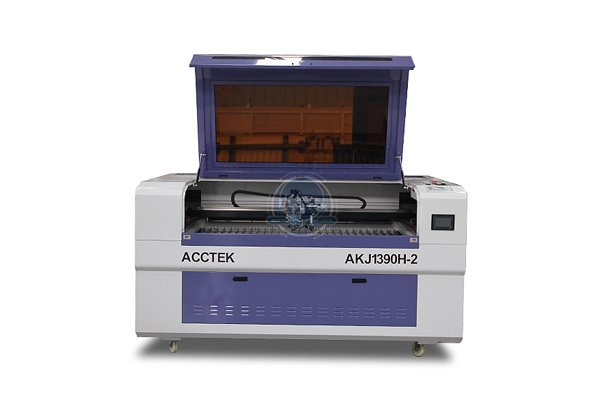

ACCTEK CO2 laser cutting machine is mainly composed

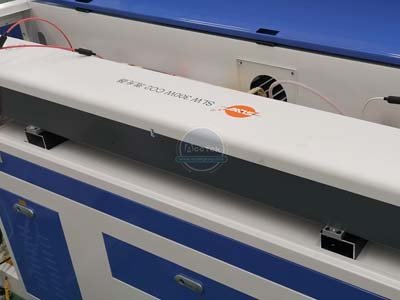

1.Laser tube

Laser tube, full - name glass - sealed CO2 laser.Because the structure is glass tube packaging and become, therefore is commonly known as laser tube.Working principle: high voltage discharge excites high concentration CO2 gas to produce laser with wavelength of 10.6um.It is mainly composed of hard glass, resonator and electrode.

2. Control panel

Ruida control system, USB off-line, has good anti-high voltage and anti-static ability, can control the device to realize the X, Y, Z axis movement, but also control the laser output power.Thus used to control the whole cutting process.

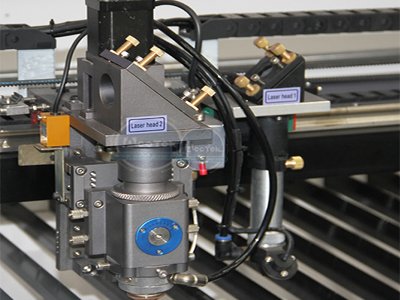

3. Optical circuit system

A refracting reflector used to direct the laser in the desired direction.To prevent the beam path from malfunction, all mirrors should be protected by a protective cover and pass through a clean positive pressure protective gas to protect the lens from contamination.

4. Cooling system

Used for cooling laser generator.Laser is the use of electric energy into light energy device, such as CO2 gas laser conversion rate is generally 20%, the remaining energy will be converted into heat.Cooling water carries the excess heat away to keep the laser generator working properly.The chiller also cools the external optical path mirror and focusing mirror of the machine tool to ensure the stable beam transmission quality and effectively prevent the lens from deformation or cracking due to excessive temperature.

5. Smoke extraction system

During the processing, it is used to extract the smoke and dust produced by cutting and carry out filtration treatment to make the cutting clean and tidy

Following are the specific installation steps:

1) First take the machine out of the packing box and then gently lay it flat

2) Take out the water pump, air pump and exhaust fan in turn from the package

3) First step is the installation of the laser tube: take out the laser tube and fix it on the tail of the fuselage through a fixed ring. The front and rear ends are respectively connected to the high and low voltage line of the laser power supply.The pipe body is connected to the cold water pipe Reci laser pipe inlet at the high pressure end (mouth down) and the water outlet at the low pressure end (mouth up).The import and export of Chengdu laser tube 80W is opposite to that of Spurs.It's low in and low out, and the other one is the same thing.There are two positive (red) and negative (black) lines at both ends of the laser tube. The red line is the high-tension line

4) Installation of water pump: take the water pump out of the box, plug the water nozzle into the water outlet of the water pump, take one of the two water pipes after the engraving machine, and insert the pipe into the mouth of the water pump

5) Install the exhaust device to plug one end of the smoke pipe into the fan outlet, and insert the fan into the exhaust slot on the right side of the fuselage

6) Connect ventilating fan, cooling water pump, carving electromechanical source, and connect ground wire, connect reliable ground wire.

7) Start the water pump after the normal circulation of cooling water, start the exhaust fan and turn on the switch of laser engraving machine. At this time, the laser engraving machine should be self-checked and reset automatically.

8) After the above accessories are installed, proceed with the following steps:

1, pump water

2. Reset the machine with power on

3. Connect the air pump and open the exhaust fan

4. Processing test of connection software

● High quality AKJ1530 CO2 laser cutting machine

● ATC CNC Router with a horizontal spindle

● High quality AK30F fiber laser marking machine

● High quality AK20F laser fiber marking machine

● Big news: we're building a new factory

● Polish customer purchased AKM1530 high quality CNC engraving machine

● Heavy duty ATC CNC router with horizontal spindle AKM2030C

● Acctek exhibition footprint

● Cost-effective fiber laser cutting machine AKJ1530F1

● ACCTEK cnc router wishes everyone a Merry Christmas

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd