Q&A

1. The problem of carbon steel plate hole punched in the thick plate processing time accounts for a large proportion, most factories use the fast perforation technology, a more representative is high-energy perforated holes (Fried), the advantage of this approach is faster for t16mm (1 second, for example, the same below), but the defect is not only affect the shape of a small processing, punch the injection of huge energy make plate temperature will affect the whole cutting process.With a low power pulse, the perforation time is long (12 seconds), resulting in a decrease in cutting efficiency and an increase in unit cost.

2. Quality problem of cutting surface, cutting section often encountered in the processing of medium thick plate, such cutting is not only the quality of the finished product is questioned, but also accompanied by over-burning and serious sticky slag, so that it does not reflect the value of high-priced laser processing machine different from other cutting means.

3. The stability of the whole plate processing. In the whole plate processing of steel, the phenomenon of poor local processing often occurs.This phenomenon is sometimes very random, even when the processing machine is in good condition.

1. Peak perforation (HPP) scheme

The peak value pulse laser with small duty ratio and non-fuel injection on the material surface were used to clear the attachment at the edge of the hole, and the reasonable frequency of pulse was controlled while cooling and perforating.It is characterized by relatively long hole blast time (3 seconds), but the diameter of the hole is small (about 4mm) and the edge of the hole without attachment and low heat input, which is convenient for the following normal cutting and processing. Compared with ordinary hole blast, the efficiency is increased by 4 times.

2.For carbon steel, the important factor to improve the cutting section is to control the heat input to the plate and ensure the full combustion of the laser irradiation part.

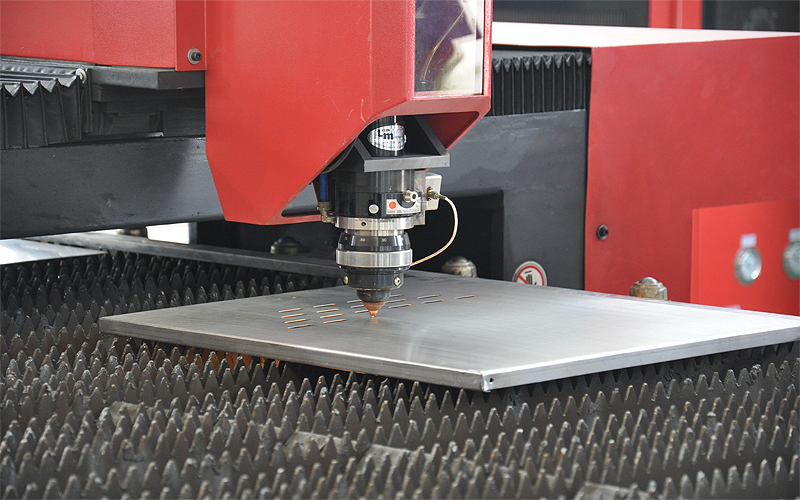

3.At present, in order to improve the running speed of the processing machine, the laser machine mostly adopts the structure known as flight light path, that is, the material tray is not moved and the processing head moves in the whole machined area.In order to compensate the change of the relative position of the machining head and the light source, the curvature variable refractor is a popular choice.This method, although simple in structure, will change the depth of focus, making it difficult to cut in a very sensitive to the depth of focus plate (both to keep the same spot and the same depth of focus).Make the spot and focal depth consistent.In addition, the attention to heat intake can control the heat accumulated in the plate and solve the stability problem well.

● High quality AKJ1530 CO2 laser cutting machine

● ATC CNC Router with a horizontal spindle

● High quality AK30F fiber laser marking machine

● High quality AK20F laser fiber marking machine

● Big news: we're building a new factory

● Polish customer purchased AKM1530 high quality CNC engraving machine

● Heavy duty ATC CNC router with horizontal spindle AKM2030C

● Acctek exhibition footprint

● Cost-effective fiber laser cutting machine AKJ1530F1

● ACCTEK cnc router wishes everyone a Merry Christmas

Get a Free Quote Now!

Useful Link

Recommend Machine

Big discount

Headquarters: 3-1007, Minghu Plaza, No. 777 Minghu West Street,Jinan City / Branch: A2-1-1802, Hanyu Jingu, High-tech Zone, Jinan City

Factory: No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province

Copyright © Jinan AccTek Machinery Co.,Ltd