Product Introduction

6kW Laser Welding Capacity

| Material Type | Welding Form | Thickness (mm) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel (Q2358) | Butt Welding | 0.5 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 6 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 7 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Stainless Steel (SUS304) | Butt Welding | 0.5 | 110~120 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 6 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 7 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Brass | Butt Welding | 0.5 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 6 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

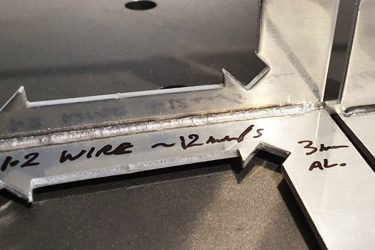

| 1-3 Series Aluminum Alloys | Butt Welding | 1 | 110~120 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1.5 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 6 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

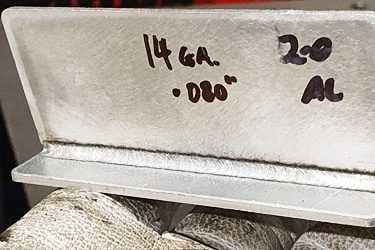

| 4-7 Series Aluminum Alloys | Butt Welding | 1 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Copper | Butt Welding | 0.5 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

Compatible Materials

- Carbon Steel

- Stainless Steel

- Mild Steel

- Galvanized Steel

- High-Strength Steel

- Tool Steel

- Spring Steel

- Alloy Steel

- Cast Iron

- Aluminum

- Aluminum Alloys

- Copper

- Brass

- Bronze

- Titanium

- Titanium Alloys

- Nickel

- Nickel Alloys

- Inconel

- Monel

- Hastelloy

- Cobalt

- Cobalt Alloys

- Magnesium

- Magnesium Alloys

- Molybdenum

- Tantalum

- Zirconium

- Tungsten

- Gold

- Gold

- Platinum

- Palladium

- Electrical Steels

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Nitinol

- Low-Alloy Steels

- Clad Metals

- Bimetallic Joints

Application of 6kW Laser Welding Machines

Customer Testimonials

Comparison VS Other WeldingTechnologies

| Features | Laser Welding | TIG Welding (GTAW) | MIG Welding (GMAW) | Plasma Arc Welding |

|---|---|---|---|---|

| Weld Quality | Superior precision, smooth, minimal defects | Excellent, very clean | Good, but prone to spatter | High, may need post-finishing |

| Heat Input | Very low, minimal distortion | Moderate, localized | Higher, risk of warping | Higher than laser, less than MIG |

| Welding Speed | Very fast | Slow | Faster than TIG | Moderate |

| Penetration Depth | High, effective on thin and medium materials | Shallow to moderate | Moderate, strong on thicker parts | Deep penetration possible |

| Automation Compatibility | Excellent, robotics integration | Limited automation | Compatible, less precise | Good automation potential |

| Material Versatility | Wide: stainless, aluminum, copper, titanium, alloys | Wide, but struggles on thin sheets | Wide, best on medium/thick metals | Wide, effective on conductive metals |

| Setup Time | Short with presets, quick changeover | Long, requires skill | Moderate | Longer than MIG |

| Skill Requirement | Low–moderate, user-friendly | High, operator expertise needed | Moderate | High, requires trained operators |

| Maintenance | Low, few consumables | High (electrode wear, gas usage) | Medium (wire + shielding gas) | Higher (gas + electrodes) |

| Consumables Cost | Very low | High (tungsten electrodes, gas) | Medium (wire, gas) | Medium (gas, electrodes) |

| Operational Cost | Low, energy-efficient, less rework | Medium | Medium | High, more energy-intensive |

| Welding Thickness Range | Best for thin to medium sections | Thin to medium | Medium to thick | Medium to very thick |

| Spatter & Cleanup | None or negligible | Minimal | Significant spatter, cleanup needed | Some spatter |

| Safety Considerations | Enclosed systems reduce exposure | High UV/IR exposure | High arc light + fumes | High UV, PPE required |

| Suitability for Mass Production | Excellent, scalable for automation | Poor | Good, common in production | Moderate |

Why Choose Us

High Precision

Our machines deliver accurate, clean welds with minimal heat input, reducing distortion and ensuring strong, consistent joints across a wide range of materials and thicknesses.

Easy Operation

Designed with intuitive controls and user-friendly interfaces, our systems allow both experienced operators and new users to achieve professional results with minimal training.

Durable & Reliable

Built with high-quality components and strict quality standards, our welding machines provide stable performance, long service life, and low maintenance requirements.

Custom Options

We offer a variety of models and customizable features to match specific production needs, helping businesses improve workflow and adapt to changing manufacturing demands.

Related Resources

Laser Welding Brass Guide

This article is a comprehensive guide to brass laser welding, covering welding techniques, parameters, challenges, equipment selection, and best practices for achieving precise, high-quality welds.

Autogenous VS Filler Laser Welding

This article explains the differences between autogenous and filler laser welding, detailing their principles, processes, parameters, and applications in industrial manufacturing.

Laser Welding Copper Guide

A detailed guide to laser welding copper, outlining process modes, parameters, challenges, joint designs, and industrial applications for efficient and high-quality copper welding.

Laser Welding Aluminum Guide

This article explores the process of laser welding aluminum, including key techniques, material properties, safety measures, and productivity considerations for efficient and high-quality welding.

Frequently Asked Questions

How Much Do 6kW Laser Welding Machines Cost?

- Entry-Level Models: At the lower end of the price range, around $15,000, machines typically come with essential functions and manual parameter adjustments. These are suitable for companies upgrading from traditional welding equipment and working with medium-to thick metals.

- Mid-to-High-End Models: Machines priced closer to $16,000 often include advanced automation features, such as intelligent control systems, touchscreen interfaces, automatic wire feeders, and real-time welding monitoring. These models are designed for continuous, large-scale production with maximum efficiency and precision.

- Additional Costs: When purchasing 6kW laser welding machines, businesses should consider extra expenses for assist gases (argon, helium, or nitrogen), fume extraction systems, and safety equipment such as laser goggles. There may also be costs for operator training, machine installation, and extended warranties.

What Is The Power Consumption Of 6kW Laser Welding Machines?

- Laser Generator Power: The laser generator is the heart of the machine, producing the high-energy laser beam for welding. 6kW laser welding machines typically require 18,000W (18kW) to operate. This high power enables it to weld thick materials, achieve deep penetration, and support high-speed production.

- Chiller Power: To prevent overheating, a robust cooling system is necessary. The chiller power is approximately 6,000W (6kW), ensuring stable temperature control for the laser source and other critical components, which is essential for consistent performance and long equipment life.

- Total Power Requirement: When combined, the total power consumption of the machine reaches around 24,000W (24kW). This means the facility must have a reliable, stable power supply, often with dedicated circuits and voltage regulators, to handle the demand and protect sensitive electronics from fluctuations.

Do 6kW Laser Welding Machines Require Welding Wire?

- Wire-Free Welding (Autogenous Welding): In many cases, especially when working with precisely fitted joints and clean base materials, 6kW laser welding machines can perform autogenous welding, which does not require filler wire. The laser’s high energy melts and fuses the base metals directly, resulting in a smooth, clean weld. This method is commonly used in industries like electronics, automotive components, and aerospace parts, where minimal heat input and high precision are critical.

- Welding with Filler Wire: For thicker materials, wider gaps, or dissimilar metal joints, filler wire is necessary. The wire provides extra material to bridge gaps, increase weld strength, and reduce the risk of defects such as cracks or porosity. In structural applications, such as shipbuilding, heavy machinery, and construction, using filler wire helps achieve stronger, more durable welds.

- Automatic Wire Feeding Systems: Most 6kW laser welding machines are compatible with automatic wire feeding systems, which ensure consistent wire delivery and improved production efficiency. These systems reduce operator error and maintain stable weld quality, especially in high-volume manufacturing.

What Assist Gases Can Be Used With 6kW Laser Welding Machines?

- Argon: Argon is the most commonly used inert shielding gas for laser welding. It provides excellent protection against oxidation by creating a stable, oxygen-free environment around the weld. Argon produces smooth, clean welds with minimal spatter and is ideal for welding stainless steel, titanium, and aluminum. It is especially suitable for high-precision applications where aesthetic appearance is important.

- Nitrogen: Nitrogen is another popular choice, especially for stainless steel welding. It helps prevent discoloration and increases weld strength by reducing oxidation. Nitrogen is also cost-effective compared to argon. However, it may react with certain metals, so compatibility testing is essential before use.

- Helium: Helium provides deeper penetration and higher welding speeds due to its superior heat transfer properties. It is often used for thicker materials or highly reflective metals, such as copper and brass. While helium is more expensive, it is sometimes mixed with argon to balance performance and cost.

- Mixed Gases: For specialized applications, combinations like argon-helium or argon-nitrogen are used to enhance weld quality. Mixed gases allow customization of shielding effects for specific metals and production needs.

What PPE Is Required When Operating 6kW Laser Welding Machines?

- Laser Safety Glasses: The most critical PPE is laser safety goggles specifically rated for the wavelength of the laser being used. These glasses protect the eyes from direct or reflected laser beams, which can cause severe and permanent vision damage.

- Protective Clothing: Operators should wear flame-resistant, non-reflective clothing to protect the body from sparks, hot metal spatter, and intense heat. Long sleeves and pants made from heavy-duty materials are recommended to minimize skin exposure.

- Heat-Resistant Gloves: Welding generates extreme temperatures, and heat-resistant gloves are essential for protecting the hands from burns when handling hot workpieces or machine components.

- Respiratory Protection: The welding process can release harmful fumes and gases, especially when working with coated or treated metals. Operators should use respiratory masks or work in areas with proper fume extraction systems to ensure clean, breathable air.

- Safety Footwear: Sturdy, steel-toe safety boots should be worn to protect feet from falling objects, heavy workpieces, or accidental contact with hot surfaces.

- Hearing Protection (If Necessary): In some industrial settings, additional hearing protection may be required if the welding area has high noise levels from machinery or ventilation systems.

What Are The Environmental Requirements For 6kW Laser Welding Machines?

- Temperature and Humidity Control: The machine should be operated in a temperature range of 10℃ to 40℃ (50℉ to 104℉). Excessively high temperatures can cause overheating, while very low temperatures may affect cooling efficiency. Humidity levels should stay below 70% to prevent condensation, which could damage sensitive electrical and optical components.

- Ventilation and Fume Extraction: Laser welding produces smoke, fumes, and gases, particularly when welding coated or treated metals. A well-ventilated workspace equipped with a fume extraction system is necessary to maintain clean air and protect operators from respiratory hazards. Good airflow also reduces contamination on optical components and improves weld quality.

- Dust-Free and Clean Environment: Dust, oil mist, and chemical vapors can interfere with the laser beam and damage the machine’s optical parts. The workspace should be clean and free of airborne contaminants, ensuring consistent precision and reducing maintenance needs.

- Stable Power Supply: 6kW laser welding machines have a total power consumption of about 24kW, including the laser generator and cooling system. It must be connected to a dedicated, stable electrical circuit with voltage protection to prevent fluctuations that could cause operational errors or damage sensitive electronics.

- Safety Layout and Space Requirements: The machine should be placed in an area with adequate clearance for operator access and maintenance. Laser safety curtains or enclosures should be installed to protect nearby personnel from accidental exposure to laser radiation.

What Training Is Required To Operate 6kW Laser Welding Machines?

- Laser Safety Training: Operators must first complete laser safety training, which covers understanding laser classifications, potential hazards, and safe work practices. This includes learning how to use personal protective equipment (PPE), such as laser safety goggles, flame-resistant clothing, and respiratory protection. Training also emphasizes the importance of fume extraction and proper handling of assist gases.

- Machine Operation Skills: Training should include detailed instruction on machine setup, calibration, and parameter adjustment. Operators learn how to set laser power, focus position, welding speed, and assist gas flow for different materials. This ensures optimal weld quality and prevents issues like burn-through or incomplete penetration.

- Material Knowledge: Since 6kW laser welding machines work with a variety of metals—including stainless steel, carbon steel, aluminum, and titanium—operators must understand material behavior during welding. This includes selecting the correct assist gases, preparing surfaces properly, and managing thermal effects such as warping or cracking.

- Maintenance and Troubleshooting: Operators are trained to perform routine maintenance tasks, such as cleaning optics, checking coolant levels, and inspecting wire feeding systems. Basic troubleshooting skills help identify common issues like misaligned beams or faulty components, reducing downtime and repair costs.

- Regulatory Compliance and Certification: In many industries, operators may need to complete certification programs to meet local or international safety and quality standards. This provides documentation that the operator is qualified to run high-power laser equipment.

How Should 6kW Laser Welding Machines Be Maintained?

- Daily Cleaning and Inspection: Operators should perform daily cleaning of optical components, such as protective lenses and nozzles, to prevent dust, spatter, and debris buildup. A visual check of the laser head, wire feeding system, and assist gas lines helps identify potential issues early.

- Cooling System Maintenance: The chiller unit must be inspected frequently to ensure proper coolant flow and temperature regulation. Coolant levels should be checked regularly, filters cleaned, and hoses inspected for leaks or blockages. Using clean, high-quality coolant prevents corrosion and overheating problems.

- Optics and Beam Alignment: Lenses and mirrors should be inspected for scratches, dirt, or misalignment. Any contamination can reduce beam quality, affect weld penetration, and damage optical components. Regular alignment checks ensure consistent laser power delivery.

- Electrical and Mechanical Checks: Inspect electrical connections, cables, and grounding systems to avoid operational faults or safety hazards. Moving components like wire feeders and motorized parts should be lubricated and checked for wear to maintain smooth operation.

- Scheduled Preventive Maintenance: Following the manufacturer’s maintenance schedule is critical for replacing consumables such as nozzles, protective windows, and filters. Periodic servicing by certified technicians ensures calibration accuracy, software updates, and overall system health.

- Environmental Control: Keeping the work area clean, well-ventilated, and temperature-controlled reduces contamination risks and extends machine lifespan. Preventing dust, moisture, and corrosive fumes from entering sensitive components protects both optics and electronics.