Product Introduction

1.5kW Laser Welding Capacity

| Material Type | Welding Form | Thickness (mm) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|

| Carbon Steel (Q235B) | Butt Welding | 0.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 15~20 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Stainless Steel (SUS304) | Butt Welding | 0.5 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Brass | Butt Welding | 0.5 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

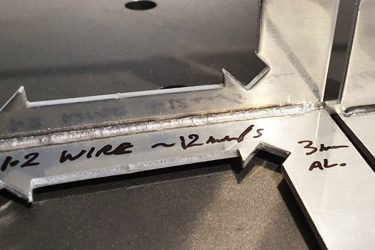

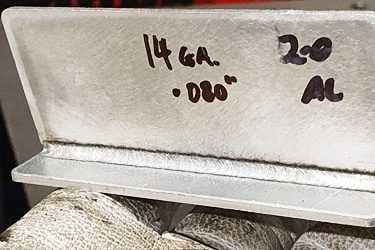

| 1-3 Series Aluminum Alloys | Butt Welding | 0.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 10~20 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 4-7 Series Aluminum Alloys | Butt Welding | 0.5 | 60~65 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 20~30 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Copper | Butt Welding | 0.5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

Compatible Materials

- Carbon Steel

- Stainless Steel

- Mild Steel

- Galvanized Steel

- High-Strength Steel

- Tool Steel

- Spring Steel

- Alloy Steel

- Cast Iron

- Aluminum

- Aluminum Alloys

- Copper

- Brass

- Bronze

- Titanium

- Titanium Alloys

- Nickel

- Nickel Alloys

- Inconel

- Monel

- Hastelloy

- Cobalt

- Cobalt Alloys

- Magnesium

- Magnesium Alloys

- Molybdenum

- Tantalum

- Zirconium

- Tungsten

- Gold

- Gold

- Platinum

- Palladium

- Electrical Steels

- Duplex Stainless Steel

- Super Duplex Stainless Steel

- Nitinol

- Low-Alloy Steels

- Clad Metals

- Bimetallic Joints

Application of 1.5kW Laser Welding Machines

Customer Testimonials

Comparison VS Other WeldingTechnologies

| Features | Laser Welding | TIG Welding (GTAW) | MIG Welding (GMAW) | Plasma Arc Welding |

|---|---|---|---|---|

| Weld Quality | Superior precision, smooth, minimal defects | Excellent, very clean | Good, but prone to spatter | High, may need post-finishing |

| Heat Input | Very low, minimal distortion | Moderate, localized | Higher, risk of warping | Higher than laser, less than MIG |

| Welding Speed | Very fast | Slow | Faster than TIG | Moderate |

| Penetration Depth | High, effective on thin and medium materials | Shallow to moderate | Moderate, strong on thicker parts | Deep penetration possible |

| Automation Compatibility | Excellent, robotics integration | Limited automation | Compatible, less precise | Good automation potential |

| Material Versatility | Wide: stainless, aluminum, copper, titanium, alloys | Wide, but struggles on thin sheets | Wide, best on medium/thick metals | Wide, effective on conductive metals |

| Setup Time | Short with presets, quick changeover | Long, requires skill | Moderate | Longer than MIG |

| Skill Requirement | Low–moderate, user-friendly | High, operator expertise needed | Moderate | High, requires trained operators |

| Maintenance | Low, few consumables | High (electrode wear, gas usage) | Medium (wire + shielding gas) | Higher (gas + electrodes) |

| Consumables Cost | Very low | High (tungsten electrodes, gas) | Medium (wire, gas) | Medium (gas, electrodes) |

| Operational Cost | Low, energy-efficient, less rework | Medium | Medium | High, more energy-intensive |

| Welding Thickness Range | Best for thin to medium sections | Thin to medium | Medium to thick | Medium to very thick |

| Spatter & Cleanup | None or negligible | Minimal | Significant spatter, cleanup needed | Some spatter |

| Safety Considerations | Enclosed systems reduce exposure | High UV/IR exposure | High arc light + fumes | High UV, PPE required |

| Suitability for Mass Production | Excellent, scalable for automation | Poor | Good, common in production | Moderate |

Why Choose Us

High Precision

Our machines deliver accurate, clean welds with minimal heat input, reducing distortion and ensuring strong, consistent joints across a wide range of materials and thicknesses.

Easy Operation

Designed with intuitive controls and user-friendly interfaces, our systems allow both experienced operators and new users to achieve professional results with minimal training.

Durable & Reliable

Built with high-quality components and strict quality standards, our welding machines provide stable performance, long service life, and low maintenance requirements.

Custom Options

We offer a variety of models and customizable features to match specific production needs, helping businesses improve workflow and adapt to changing manufacturing demands.

Related Resources

Laser Welding Brass Guide

This article is a comprehensive guide to brass laser welding, covering welding techniques, parameters, challenges, equipment selection, and best practices for achieving precise, high-quality welds.

Autogenous VS Filler Laser Welding

This article explains the differences between autogenous and filler laser welding, detailing their principles, processes, parameters, and applications in industrial manufacturing.

Laser Welding Copper Guide

A detailed guide to laser welding copper, outlining process modes, parameters, challenges, joint designs, and industrial applications for efficient and high-quality copper welding.

Laser Welding Aluminum Guide

This article explores the process of laser welding aluminum, including key techniques, material properties, safety measures, and productivity considerations for efficient and high-quality welding.

Frequently Asked Questions

How Much Do 1.5kW Laser Welding Machines Cost?

- Entry-Level Models: Machines priced at the lower end, around $3,800, are generally basic models designed for lighter welding tasks. They include standard functions and manual parameter adjustments, making them ideal for startups or workshops handling thin to medium metal sheets.

- Mid-Range Options: At the higher end of the range, around $5,000, machines often come equipped with advanced features such as intelligent control systems, touch-screen interfaces, and integrated wire feeders. These provide greater precision, improved weld consistency, and higher efficiency for professional production lines.

- Additional Costs to Consider: Besides the base price, buyers should budget for essential accessories such as protective laser safety goggles, assist gas systems, and maintenance tools. Other potential expenses include operator training, installation services, and extended warranty plans.

What Is The Power Consumption Of 1.5kW Laser Welding Machines?

- Laser Generator Power: The laser generator is the core of the machine, responsible for producing the high-intensity beam needed for welding. For 1.5kW laser welding machines, the laser generator power is approximately 4500W (4.5kW). This ensures strong penetration for a variety of metal thicknesses while maintaining stable performance during continuous production.

- Chiller Power: To prevent overheating, the machine uses a dedicated cooling system. The chiller power is about 1640W (1.64kW), which circulates coolant through the laser source and other components to maintain optimal operating temperatures and extend the equipment’s lifespan.

- Total Power Requirement: When combining both systems, the total power consumption reaches around 6140W (6.14kW). Businesses should ensure they have a stable power source with proper voltage and circuit protection to handle this load safely.

How Can I Purchase 1.5kW Laser Welding Machines?

- Identify Your Needs: Before making a purchase, determine your specific requirements, including the types of materials you will weld, production volume, and desired features such as automatic wire feeding or intelligent control systems. This helps narrow down suitable models and avoid overspending on unnecessary features.

- Find Trusted Suppliers: Look for reputable manufacturers or authorized distributors who specialize in industrial laser equipment. Reliable suppliers often provide machine demonstrations, technical consultations, and comprehensive after-sales services. Checking online platforms, trade shows, or industry networks is a good way to find reliable sellers.

- Compare Prices and Features: The typical price range for 1.5kW laser welding machines is $3,800 to $5,000. Compare multiple options to evaluate performance, including accessories, warranty coverage, and maintenance support. Avoid purchasing solely based on the lowest price, as quality and service are equally important.

- Finalize the Purchase: Once you have chosen a supplier, confirm the payment terms, shipping details, and warranty policies. Some suppliers offer installation and training services, which are valuable for smooth machine setup and operator safety.

What Are The Disadvantages Of 1.5kW Laser Welding Machines?

- Limited Thickness Capability: While suitable for thin to medium metal sheets, 1.5kW laser welding machines may struggle with thicker materials, leading to poor penetration or incomplete welds. For heavy-duty industrial applications, a higher-powered machine may be required, which increases overall investment.

- Higher Initial and Operating Costs: Although relatively affordable compared to higher-powered models, the initial purchase price of 1.5kW laser welding machines still represents a significant investment for small businesses. Additionally, operational costs, including electricity, assist gases, and regular maintenance, can add up over time.

- Training and Skill Requirements: Laser welding involves precise settings and safety precautions. Operators must undergo specialized training to achieve consistent results and prevent accidents. Without proper knowledge, there is a risk of equipment misuse or weld defects.

- Maintenance and Component Wear: Components such as protective lenses, nozzles, and cooling systems require frequent inspection and replacement. If neglected, performance may decline, leading to downtime and costly repairs.

- Safety Risks: The concentrated laser beam poses hazards like eye and skin injuries, while fumes generated during welding can be harmful if proper ventilation or fume extraction systems are not in place. Strict safety measures and protective gear are essential.

What PPE Is Required When Operating 1.5kW Laser Welding Machines?

- Laser Safety Glasses: Specialized laser safety goggles are mandatory to protect the eyes from direct or reflected laser beams. The glasses must match the specific wavelength of the laser to prevent serious eye injuries or permanent vision damage.

- Protective Clothing: Operators should wear flame-resistant, non-reflective clothing to guard against sparks, spatter, and accidental contact with hot materials. Long sleeves and pants are recommended to minimize skin exposure.

- Gloves: Heat-resistant gloves protect hands from burns caused by hot workpieces and spatter during the welding process. They also provide protection when handling machine components after extended use.

- Respiratory Protection: Laser welding can produce harmful fumes and gases, especially when working with coated or treated metals. A proper respirator or fume extraction system should be used to ensure clean air and operator safety.

- Footwear: Operators should wear steel-toe safety boots to protect their feet from heavy materials and accidental drops, as well as to maintain a stable stance while working.

How Should I Choose 1.5kW Laser Welding Machines?

- Understand Your Welding Needs: First, determine the types of materials you will be welding, their thickness, and the required production speed. 1.5kW laser welding machines are ideal for thin to medium-thickness metals such as stainless steel, carbon steel, and aluminum. If you need to weld thicker materials, consider higher power models.

- Evaluate Key Features: Look for essential features like adjustable power settings, integrated wire feeding, and touch-screen controls for ease of operation. Advanced machines may also include intelligent welding modes and real-time monitoring to improve efficiency and weld quality.

- Check Build Quality and Safety: Choose a machine with durable construction and built-in safety systems, such as emergency shut-off switches and protective shields. Reliable cooling systems are also critical to prevent overheating and extend the machine’s lifespan.

- Consider After-Sales Support: A good supplier should offer training, installation assistance, and technical support. Access to spare parts and maintenance services will reduce downtime and ensure the machine stays in top condition.

- Compare Costs and Value: The typical price range for these machines is $3,800 to $5,000. While cost is important, focus on the overall value, including features, warranty, and support, rather than just the lowest price.

What Are The Environmental Requirements For 1.5kW Laser Welding Machines?

- Temperature and Humidity Control: The machine should operate in an environment with a temperature range between 10℃ and 40℃ (50℉–104℉). Excessive heat can cause the laser generator to overheat, while very low temperatures can affect the cooling system and optical components. Humidity should be kept below 70% to prevent condensation, which can damage electrical circuits and optical elements.

- Ventilation and Fume Extraction: Laser welding produces fumes, gases, and fine particles, especially when working with coated or treated metals. A well-ventilated workspace with a proper fume extraction system is essential to maintain clean air and protect operator health. Poor ventilation can also lead to reduced visibility and contamination of sensitive machine parts.

- Dust-Free and Clean Environment: The presence of dust, oil mist, or corrosive substances in the air can interfere with the laser beam and damage precision components. A clean, dust-free workshop is ideal for ensuring consistent weld quality and reducing maintenance needs.

- Stable Power Supply: The machine requires a stable electrical power source to handle its total power consumption of about 6.14kW. Voltage fluctuations or sudden power loss can cause errors or damage to sensitive electronics. Installing a voltage stabilizer or UPS (uninterruptible power supply) is recommended.

- Safety Space and Layout: Provide enough clearance around the machine for operation, maintenance, and emergency access. Laser-protected curtains or enclosures should be used to shield other workers from laser radiation.

What Training Is Required To Operate 1.5kW Laser Welding Machines?

- Laser Safety Training: Since laser welding involves high-powered laser beams, safety training is essential. Operators must understand laser classifications, radiation hazards, and the correct use of personal protective equipment (PPE) such as laser safety goggles and flame-resistant clothing. This training also covers the importance of proper fume extraction to prevent inhalation of harmful gases.

- Machine Operation Basics: Training includes step-by-step guidance on starting, operating, and shutting down the machine. Operators learn to set welding parameters such as power, speed, and focus adjustments for different materials. This ensures consistent weld quality and reduces the risk of errors or material damage.

- Material Knowledge and Welding Techniques: Operators need to understand the properties of metals like stainless steel, aluminum, and carbon steel. Training focuses on selecting the right assist gases (argon, nitrogen, helium) and mastering techniques like spot welding, seam welding, and penetration control.

- Maintenance and Troubleshooting: Basic maintenance skills are taught to help operators keep the machine in good condition. This includes cleaning optical components, checking coolant levels, replacing consumables, and identifying early signs of wear or malfunction.

- Certification and Compliance: In some industries, operators may be required to obtain certification to comply with local safety and production regulations. Manufacturers or training centers often provide certification programs after completing the course.