Product Introduction

Benefits of Laser Cleaning Composite

Non-Destructive Surface Treatment

Laser cleaning is a contactless process that gently removes contaminants without damaging the composite substrate. This is crucial for preserving the mechanical strength, layered structure, and surface integrity of sensitive composite materials like carbon fiber or fiberglass.

No Chemicals or Abrasives Needed

Laser cleaning eliminates the need for solvents, acids, or abrasive materials, reducing health and environmental risks. This eco-friendly method also minimizes the generation of secondary waste, simplifying cleanup and ensuring a safer workplace for operators.

Precise Layer-Selective Cleaning

Advanced laser settings allow for the selective removal of coatings, paint, or surface residues without affecting the base layer. This makes it ideal for preparing composite surfaces for bonding, painting, or further processing with exact depth control.

Avoids Microcracks and Delamination

Traditional cleaning methods like sanding or blasting may cause surface damage, delamination, or fiber exposure. Laser cleaning minimizes these risks, ensuring the composite structure remains intact and reliable for high-performance applications like aerospace or automotive.

Improves Surface Adhesion

By removing contaminants and activating the surface, laser cleaning enhances adhesion properties for subsequent coatings or adhesives. This results in stronger, more durable bonds in manufacturing and repair processes involving composite parts.

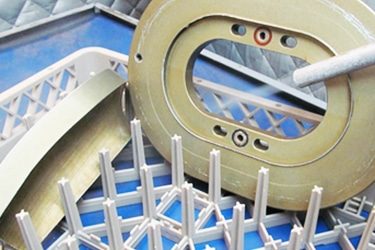

Suitable for Automation and Complex Shapes

Laser cleaning systems can be integrated with robotic arms or CNC systems, allowing efficient and uniform cleaning of complex geometries. This ensures consistency and scalability for industries requiring high-precision composite processing.

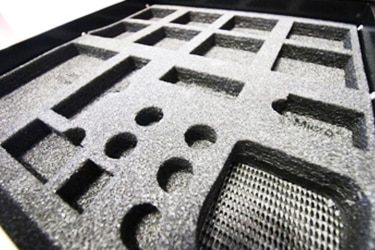

Compatible Composite Materials

- Carbon Fiber Reinforced Polymer

- Glass Fiber Reinforced Polymer

- Kevlar Reinforced Polymer

- Aramid Fiber Composites

- Boron Fiber Composites

- Basalt Fiber Composites

- Natural Fiber Composites

- Epoxy Composites

- Phenolic Resin Composites

- Polyester Resin Composites

- Vinyl Ester Composites

- Thermoplastic Composites

- Thermoset Composites

- Carbon Fiber/Epoxy Laminates

- Glass Fiber/Epoxy Laminates

- Metal Matrix Composites

- Ceramic Matrix Composites

- Carbon/Carbon Composites

- Hybrid Composites

- Fiber Metal Laminates

- Aluminum Composite Panels

- Titanium Composite Panels

- Bismaleimide Composites

- Polyimide Matrix Composites

- Polyurethane Foam Composites

- Structural Insulated Panels

- Honeycomb Core Composites

- Sandwich Panel Composites

- Particle Reinforced Composites

- Whisker Reinforced Composites

- Recycled Composite Materials

- Biodegradable Composites

- Polymer-Clay Nanocomposites

- Graphene-Reinforced Composites

- Carbon Nanotube Composites

- Conductive Polymer Composites

- FR4

- PEEK Composites

- PEKK Composites

- PPS Composites

Application of Composite Laser Cleaning Machines

Customer Testimonials

Comparison VS Other Cleaning Technologies

| Comparison Item | Laser Cleaning | Sandblasting | Chemical Cleaning | Ultrasonic Cleaning |

|---|---|---|---|---|

| Cleaning Method | Laser ablation, non-contact | Abrasive blasting | Chemical dissolution | Cavitation from high-frequency sound waves |

| Surface Damage Risk | Extremely low, safe for composites | High—can erode or weaken fibers | Moderate—may degrade resin or bonding agents | Low, but limited to small parts |

| Thermal Impact | Low and controllable | Minimal heat, but mechanical damage possible | Can cause chemical heat reactions | Minimal thermal effect |

| Environmental Impact | No chemicals or media; eco-friendly | Generates dust and waste media | Hazardous chemical waste | Requires fluid disposal |

| Cleaning Precision | Very high; controllable depth and area | Low; affects surrounding areas | Moderate precision | High for small, submerged items |

| Suitability for Composites | Excellent—non-damaging to resin/fiber matrix | Poor—risk of delamination or abrasion | Limited—chemicals can degrade composite layers | Moderate—only applicable to certain parts |

| Selective Cleaning Ability | Highly selective; programmable | Non-selective; blasts entire surface | Limited control | Low selectivity |

| Waste Generation | Minimal (vaporized contaminants) | High (abrasive and surface particles) | High (chemical runoff and residues) | Medium (contaminated cleaning liquid) |

| Health and Safety | Requires laser safety protocols only | Risk of airborne particles; needs PPE | Risk of toxic fumes and handling hazards | Safer but needs fluid handling care |

| Cleaning Speed | Fast and adjustable | Fast on large, flat surfaces | Slow to moderate | Slow; best for precision cleaning |

| Automation Compatibility | Easy to integrate with robotics and CNC systems | Difficult to automate | Limited automation potential | Mostly batch/manual processes |

| Equipment Maintenance | Low; minimal consumables | High; media replacement and wear parts | High; chemical replenishment and disposal | Medium; fluid monitoring and tank care needed |

| Operating Cost | Low long-term; no abrasives or chemicals | High recurring media costs | High chemical and disposal costs | Moderate operation costs |

| Surface Preparation Quality | Excellent for bonding, painting, inspection | Rough finish; may require rework | May leave residues that need rinsing | Clean finish on internal cavities |

| Portability | Highly portable models available | Bulky and often fixed | Chemical tanks limit portability | Stationary or benchtop systems only |

Why Choose Us

Efficient Cleaning

Our machines offer fast, precise cleaning without chemicals or abrasion, making them ideal for delicate surfaces and complex materials across various industries.

Safe & Eco-Friendly

Laser cleaning eliminates the need for harsh chemicals and generates no secondary pollution, creating a safer and more environmentally friendly workspace.

Stable Performance

Built with high-quality components and advanced control systems, our machines ensure consistent cleaning results with minimal maintenance and long service life.

Custom Solutions

We provide flexible configurations and tailored options to match different cleaning requirements, helping customers achieve optimal performance for their specific applications.

Related Resources

Comprehensive Guides to Choosing the Right Laser Cleaning Parameters

This comprehensive guide explores the key factors in choosing the right laser cleaning parameters, including material types, contamination levels, and practical considerations for optimal results.

What Training Is Required to Operate Laser Cleaning Machines

This article is a comprehensive guide outlining the safety, operation, maintenance, and certification training required for operators of modern industrial laser cleaning machines.

What Are the Common Problems With Laser Cleaning Machines

This article addresses the most common problems with laser cleaning machines, including performance issues, maintenance challenges, and practical solutions for reliable operation.

What Precautions Should Be Taken During Laser Cleaning

This article explains key precautions for safe laser cleaning, covering equipment setup, operator protection, ventilation, maintenance, and compliance with safety standards.

Frequently Asked Questions

What Laser Power Options Are Available For Composite Laser Cleaning Machines?

- Continuous Laser Power Options: Composite systems with a continuous mode typically offer power levels such as 1000W, 1500W, 2000W, 3000W, and 6000W. These settings are used for aggressive, high-speed cleaning, particularly effective on robust materials or thick coatings. Higher wattages like 3000W and 6000W allow for deep-layer removal, suitable for industrial-scale jobs or heavily contaminated surfaces.

- Pulse Laser Power Options: On the pulse side, composite machines include adjustable settings like 100W, 200W, 300W, 500W, 1000W, and up to 2000W. These power levels are optimized for precision cleaning, where thermal damage needs to be minimized. Lower wattages are ideal for fine detail or sensitive surfaces, while higher pulse settings increase cleaning speed without sacrificing control.

What Is The Price of Composite Laser Cleaning Machines?

- Continuous Laser Cleaning Machines: When operating in continuous mode, composite machines typically match the price range of dedicated continuous systems, which is around $3,500 to $7,500. This mode is best for high-speed, large-area cleaning tasks where fine precision is not the priority. It’s suitable for removing rust, paint, or thick coatings from sturdy surfaces like metal and stone.

- Pulse Laser Cleaning Machines: The pulse mode in composite machines reflects the same advanced control and precision found in standalone pulse systems. Depending on power and configuration, pulse-capable composite systems fall within the $6,000 to $70,000 range. These are ideal for sensitive surfaces, including historical restoration or intricate components, where thermal damage must be avoided.

How Does Laser Power Affect The Speed of Cleaning Composites?

- Continuous Laser Cleaning Machines: Available in 1000W, 1500W, 2000W, 3000W, and 6000W, continuous lasers operate with a steady beam that rapidly removes contaminants like resin, coatings, or corrosion. Higher wattage increases cleaning speed, making a 3000W or 6000W system much faster than a 1000W unit. However, continuous lasers also generate more heat, which can be problematic for thermally sensitive composites. High power is ideal for robust or heavily layered materials, but precision must be managed carefully to avoid surface damage.

- Pulse Laser Cleaning Machines: Pulse options include 100W, 200W, 300W, 500W, 1000W, and 2000W, and deliver energy in short, high-intensity bursts. These bursts clean without overheating the material, making pulse lasers better for sensitive or layered composites. Lower power levels (100W–300W) are suited for delicate applications but result in slower cleaning. Higher wattages (1000W–2000W) increase the cleaning rate significantly while still preserving the surface.

How To Select Composite Laser Cleaning Machines?

- Material Sensitivity: For composite surfaces that are thermally sensitive—such as carbon fiber panels, aerospace-grade laminates, or reinforced polymers—pulse mode is essential. It allows controlled energy delivery that avoids damaging the material. If the composite is more durable or coated with thick contaminants, the continuous mode offers faster removal without compromising effectiveness.

- Contaminant Type and Layer Thickness: Pulse lasers are ideal for delicate cleaning tasks, such as removing adhesives, films, or oxidation from layered composites. Continuous lasers handle heavier build-up, such as industrial coatings, corrosion, or cured epoxies. If the job requires switching between both, composite machines with a wide power range (such as 1000W–2000W pulse and 1500W–6000W continuous) offer the most flexibility.

- Cleaning Speed Requirements: Higher power settings mean faster results. Choose a 3000W or 6000W continuous laser for speed on large surfaces, or a 1000W+ pulse laser for a balance of speed and safety on more fragile materials. Lower wattage machines clean more slowly but are gentler, suitable for lab environments or precision applications.

- Worksite Conditions: Handheld composite lasers with portability features are better suited for on-site maintenance or field operations. For workshop environments, fixed or semi-mobile units with integrated cooling and exhaust systems provide more control and stability.

- Budget and Use Frequency: Since composite machines include both laser types, their price reflects the added capability, usually between $6,000 and $70,000, depending on power and features. If the machine will be used regularly for different materials and tasks, the investment pays off in versatility. For more specialized or occasional use, a lower-powered unit may be sufficient.

Does Laser Cleaning Damage The Surface of Composites?

- Continuous Laser Cleaning Machines: These systems operate in power ranges like 1000W, 1500W, 2000W, 3000W, and 6000W, delivering constant energy for fast cleaning. On durable composites with thick surface build-up, they remove coatings efficiently. However, high-power continuous beams can overheat or scorch lightweight or layered composites if settings are not properly adjusted. This mode is better suited for robust applications where surface texture is less critical.

- Pulse Laser Cleaning Machines: Pulse lasers, available in 100W, 200W, 300W, 500W, 1000W, and 2000W, operate using controlled bursts of energy that target contaminants without transferring excess heat. This method is ideal for protecting heat-sensitive composite substrates, preserving surface structure and finish. When used correctly, pulse lasers clean without causing delamination, melting, or fiber exposure.

- Material Considerations: Not all composites react the same way. Carbon fiber reinforced polymers (CFRP) and glass fiber composites may begin to degrade or discolor at lower thresholds than metals or ceramics. Surface damage can occur if the laser is misaligned, too powerful, or if the dwell time is excessive.

What Is The Power Consumption of Composites Laser Cleaning Machines?

- Continuous Laser Cleaning Machines: These systems require more energy to maintain a steady, high-power beam, especially at industrial output levels. Power consumption increases with wattage as follows:

- 1000W: approximately 5 kW

- 1500W: approximately 6.5 kW

- 2000W: approximately 8.5 kW

- 3000W: approximately 12 kW

- 6000W: approximately 20 kW

- Pulse Laser Cleaning Machines: Pulse lasers deliver power in short, controlled bursts, making them more energy-efficient overall. Power consumption across pulse models is typically:

- 100W: approximately 0.5 kW

- 200W: approximately 1 kW

- 300W: approximately 1.5 kW

- 500W: approximately 2.5 kW

- 1000W: approximately 5 kW

- 2000W: approximately 8.5 kW

Does Laser Cleaning Damage The Surface of Composites?

- Continuous Laser Cleaning Machines: Operating at 1000W to 6000W, continuous lasers emit a steady beam that is highly effective for stripping thick, stubborn layers. However, this method can overheat or degrade sensitive composite surfaces if used improperly. Excessive energy may lead to resin melting, discoloration, or surface pitting, especially in carbon fiber or thermoplastic-based composites. Continuous lasers are better suited for high-durability composites or large, coated areas where fine surface detail is not critical.

- Pulse Laser Cleaning Machines: Pulse lasers operate at 100W to 2000W, delivering energy in controlled bursts that are more surface-selective. This mode is ideal for preserving the integrity of composite materials, as it minimizes heat buildup and avoids damaging the fiber structure or matrix. When properly configured, pulse lasers clean without causing burn marks, delamination, or weakening of the composite layers.

- Material Sensitivity and Laser Settings: Not all composites respond the same way. Carbon fiber reinforced polymers (CFRP), fiberglass, and aramid-based laminates each have different thermal tolerances. Incorrect settings—such as high dwell time or beam overlap—can result in micro-cracking or fiber exposure. Proper calibration, spot size, and scanning speed are critical for safe cleaning.

Does Laser Cleaning Composites Produce Harmful Byproducts?

- Carbon Fiber and Glass Fiber Composites: When cleaning carbon fiber reinforced polymers (CFRP) or fiberglass, laser ablation can release microscopic fiber fragments and resin fumes. These airborne particles may be respiratory irritants or even toxic, depending on the resin matrix used. Inhalation of carbon or glass fiber dust should be strictly avoided, making fume extraction and filtration essential.

- Paints, Adhesives, and Coatings: Many composite surfaces are coated with paints, primers, or epoxy-based adhesives. Laser removal of these layers can generate toxic fumes, including VOCs (volatile organic compounds), particulates, and chemical byproducts such as phenols or formaldehyde, depending on the chemical composition of the coatings.

- Thermoplastic and Thermoset Polymers: Laser energy breaking down plastic binders or polymer matrices can produce noxious gases and smoke, especially from high-temperature thermosets like polyimides or epoxy resins. These emissions can include substances harmful to both health and the environment.

- Byproduct Control and Safety: A high-efficiency fume extractor with HEPA and activated carbon filters is required to safely manage laser cleaning emissions from composites. Additionally, operators should wear appropriate respiratory protection and work in well-ventilated areas to prevent exposure.