Laser marking is often misunderstood as a single, uniform process. In reality, laser marking is an umbrella term that encompasses several distinct techniques—most commonly laser marking (in the narrow sense), laser engraving, and laser etching. These processes differ not by the machine’s appearance, but by energy density and thermal interaction between the laser beam and the material surface. Energy density refers to how much laser energy is concentrated into a given area, while thermal interaction describes how that energy changes the material through heating, melting, oxidation, or vaporization.

In laser marking (such as annealing or color marking), the laser uses relatively low energy density. Instead of removing material, the laser modifies the surface chemistry or structure, often producing a color change or contrast shift. This approach is ideal when surface integrity must be preserved, such as in medical devices or electronic components. Laser etching increases the energy density, causing localized melting and slight material removal. The result is a shallow, tactile mark that remains highly legible but does not significantly weaken the part. Laser engraving applies the highest energy density, vaporizing material to create deep, permanent marks that can withstand extreme wear, heat, and abrasion.

These differences matter because every material reacts differently to heat. Metals absorb and dissipate energy differently from plastics or coated surfaces. Even within the same material category, variations in alloy composition or additives can change how the laser behaves. This is why laser wavelength, pulse duration, power output, and beam quality must be carefully matched to the intended marking type.

Ultimately, the distinction between laser marking, engraving, and etching lies in how much energy is delivered and how the material thermally responds. Recognizing laser marking as an umbrella term helps explain why multiple laser marking machine types exist. Selecting the correct process—and the right machine—ensures clear markings, protects material integrity, and optimizes performance for specific industrial applications.

When examining what types of laser marking machines are available, classifying them by laser source offers the most technically accurate and practically useful framework. The laser source defines the wavelength, pulse structure (continuous, nanosecond, picosecond, femtosecond), peak power, repetition rate, beam quality, and overall system efficiency. These characteristics directly control energy density and thermal interaction, which determine whether the laser causes surface oxidation, foaming, melting, ablation, or deep material removal.

Because materials absorb different wavelengths and respond differently to thermal input, no single laser source can address all marking needs. This diversity explains why multiple laser marking machine types exist and why selecting the correct source is critical for achieving consistent quality, high productivity, and long-term reliability.

Green laser marking machines operate at 532 nm and are particularly effective on highly reflective metals such as copper, gold, and silver. These materials often reflect infrared laser energy, reducing marking efficiency with fiber lasers.

Green lasers are commonly used in electronics, battery manufacturing, solar components, and precision metal applications. They also perform well on certain plastics and specialty materials that do not respond well to infrared wavelengths.

Nd:YAG laser marking machines were once the standard for metal marking. Although they share the same wavelength as fiber lasers, they use lamp-pumped or diode-pumped solid-state technology, which typically requires more maintenance and energy.

While increasingly replaced by fiber lasers, Nd:YAG laser marking systems are still found in legacy installations and some specialized applications.

Diode laser marking machines use semiconductor diodes at various wavelengths. They are compact, energy-efficient, and cost-effective, making them suitable for light-duty marking, desktop systems, and simple plastic or coated material applications.

However, limited power output and beam quality restrict their use in demanding industrial environments.

The most meaningful way to classify laser marking machines is by laser source, as it determines wavelength, pulse behavior, thermal interaction, and application scope. Fiber lasers dominate metal marking, CO2 lasers excel with organic materials, UV and green lasers address precision and reflective challenges, while Nd:YAG and diode lasers serve legacy and niche roles. Selecting the correct laser source is essential for achieving optimal marking quality, efficiency, and long-term performance.

When evaluating what types of laser marking machines are available, it is not enough to consider only the laser source. Equally important is how the laser beam is delivered to the workpiece and how motion is achieved during marking. The beam delivery and motion system determines marking speed, positional accuracy, field size, depth consistency, and the machine’s ability to handle flat, curved, or uneven surfaces. Two machines using the same laser source can perform very differently if one relies on high-speed optical scanning while the other depends on mechanical movement.

This classification becomes especially critical in industrial environments where throughput, repeatability, and geometric flexibility directly affect productivity and cost. Understanding these machine types helps ensure the marking system matches the part size, shape, and production volume.

Galvo laser marking machines use high-speed galvanometer-driven mirrors to deflect the laser beam across the marking field. Because only lightweight mirrors move, galvo systems achieve extremely fast acceleration and deceleration, making them the fastest solution for most marking tasks.

These machines excel at high-throughput applications such as serial numbers, QR codes, barcodes, logos, and text. They offer excellent repeatability and are commonly integrated into automated production lines. However, galvo systems have a fixed working field defined by the lens, and as the field size increases, spot size and focus uniformity can degrade near the edges. This makes them best suited for small to medium-sized marking areas.

Gantry laser marking machines rely on mechanical motion systems, such as linear motors or ball-screw-driven XY stages, to move either the laser head or the workpiece. The laser beam itself remains relatively stationary while the motion system positions the marking location.

This approach allows gantry systems to maintain a consistent spot size and focus across very large marking areas, making them ideal for oversized parts, flat panels, long components, and large-format marking. They are commonly used in aerospace, heavy equipment, signage, and sheet-metal marking. The tradeoff is speed, as mechanical movement is inherently slower than optical scanning.

Hybrid laser marking systems combine a galvo scanner with a mechanical XY stage. In this configuration, the stage moves the workpiece or marking head to different zones, while the galvo performs rapid marking within each zone.

This design offers a balance between speed and coverage, allowing large parts to be marked efficiently without sacrificing precision. Hybrid systems are particularly valuable in high-mix or variable-size production environments where flexibility is essential. They also enable consistent mark quality across large surfaces by minimizing galvo field limitations.

Rotary axis laser marking machines incorporate one or more rotational axes synchronized with the laser beam. This enables precise marking on cylindrical, conical, or ring-shaped parts.

By rotating the workpiece during marking, these machines maintain consistent focus, spacing, and alignment around the entire circumference. Rotary systems are widely used for marking pipes, tubes, shafts, bearings, medical implants, and jewelry. They are often combined with galvo scanners to achieve both speed and precision.

3D dynamic focusing laser marking machines, commonly called 3D galvo systems, add a dynamic Z-axis to control the focal position in real time. This allows the laser to remain in focus while marking surfaces with varying heights or complex contours.

These systems are ideal for deep engraving, mold cavities, stepped surfaces, and curved or sloped parts. By continuously adjusting focus, 3D galvo machines ensure uniform mark width, depth, and clarity even on challenging geometries. They are widely used in mold making, automotive tooling, and advanced manufacturing applications.

Classifying laser marking machines by beam delivery and motion system is essential for understanding their real-world capabilities. Galvo systems provide unmatched speed, gantry systems excel at large-area consistency, hybrid systems combine speed and flexibility, rotary systems handle cylindrical parts, and 3D dynamic focusing machines enable precise marking on uneven or deep surfaces. Choosing the correct motion system is critical for achieving optimal performance, accuracy, and efficiency in laser marking applications.

Another highly practical way to understand what types of laser marking machines are available is by classifying them according to the intended marking result. In real manufacturing scenarios, the desired outcome of the mark—how it looks, how deep it is, how readable it remains over time, and how it interacts with the material—often matters more than the laser’s technical specifications alone. A marking system selected purely on laser source may fail if it cannot achieve the required contrast, durability, or precision.

The intended marking result is controlled by a combination of factors, including energy density, pulse duration, repetition rate, focal strategy, and thermal interaction with the material. Machines optimized for one result, such as fast traceability marking, may be entirely unsuitable for another, such as micro-marking or glass engraving. Understanding these categories ensures the marking solution aligns with functional, regulatory, and aesthetic requirements.

High-contrast surface marking machines are designed to produce clear, easily readable marks with minimal material removal. Their primary role is traceability, enabling permanent identification through serial numbers, batch codes, barcodes, and QR codes.

These machines typically rely on surface oxidation, foaming, or slight texturing to create contrast against the base material. Speed and consistency are critical, as traceability marking is often integrated directly into high-volume production lines. The marks are shallow but permanent, ensuring they do not compromise part strength or dimensional accuracy. These systems are widely used in automotive manufacturing, electronics, appliances, and industrial components.

Deep engraving marking machines focus on creating physically recessed marks by removing material through repeated laser passes. Unlike surface marking, the goal here is depth and durability rather than speed.

These machines are essential in applications where parts are exposed to abrasion, heat, chemicals, repainting, or surface finishing. Tooling, molds, aerospace components, and heavy machinery parts commonly require deep engraving to ensure markings remain legible throughout the product’s lifespan. While deep engraving is slower and more energy-intensive, it provides unmatched longevity and resistance to wear.

Color marking machines are designed to produce controlled color effects on specific materials, most notably stainless steel and titanium. Instead of removing material, the laser precisely controls thermal input to form ultra-thin oxide layers that create visible colors through light interference.

Achieving consistent color marking requires precise control of pulse width, frequency, and energy density. These machines are commonly used for branding, decorative elements, medical instruments, and premium consumer products. While visually appealing, color marks are generally shallow and best suited for applications where aesthetics are prioritized over extreme durability.

Black marking machines specialize in producing deep black, high-contrast marks on metal surfaces, particularly stainless steel. Unlike standard surface marking, black marking relies on microstructuring or controlled oxidation to create a matte, light-absorbing surface.

These marks offer excellent readability for both human operators and machine vision systems. Black marking is especially valuable in regulated industries such as medical devices, food processing, and pharmaceuticals, where clarity, corrosion resistance, and cleanliness are critical. The resulting marks are durable, non-reflective, and resistant to fading.

Micro-marking machines are optimized for extremely small features, including tiny alphanumeric characters, micro-QR codes, fine lines, and delicate components. These systems prioritize precision over speed or depth.

They use small spot sizes, high beam stability, and minimal thermal input to avoid damaging sensitive parts. Micro-marking is commonly required in electronics, semiconductors, medical implants, and precision instruments, where space is limited and tolerances are extremely tight. Even minor thermal distortion can render a part unusable, making these machines highly specialized.

Glass and crystal marking machines are designed to handle brittle, transparent materials that are highly sensitive to thermal stress. These systems create marks through controlled surface frosting, micro-fracturing, or internal engraving, depending on the application.

They are widely used for bottles, laboratory glassware, architectural glass, optical components, and decorative crystal products. The main challenge is achieving clear, consistent marks without cracking or weakening the material. This requires careful control of laser energy, focus depth, and marking speed to balance visibility with material integrity.

Classifying laser marking machines by intended marking result focuses on the functional and visual outcome rather than the technology alone. High-contrast traceability marking, deep recessed engraving, color and black marking, micro-marking, and glass marking each require different machine designs and laser control strategies. Understanding these categories ensures that the selected laser marking machine delivers the required appearance, durability, readability, and compliance for its specific application.

When discussing what types of laser marking machines are available, classification by physical form factor and production workflow is essential for understanding how laser marking systems are actually deployed in real manufacturing environments. Even with the correct laser source and motion system, a machine can fail to deliver value if its physical design does not align with space constraints, safety regulations, production volume, or automation requirements.

This classification focuses on how operators interact with the machine, how parts flow through the marking process, and how easily the system integrates into existing production lines. From compact standalone units to fully automated robotic cells, each form factor is designed to support specific operational goals, cost structures, and scalability needs.

Desktop or benchtop laser marking machines are compact, self-contained systems designed for small parts and low- to medium-volume production. They are typically manually loaded and unloaded, making them ideal for workshops, laboratories, R&D centers, and customization environments.

These machines prioritize ease of use, affordability, and minimal footprint. While their working area and laser power are usually limited compared to industrial systems, desktop markers excel at prototyping, short runs, personalization, and precision marking of small components. They are often used where flexibility is more important than throughput.

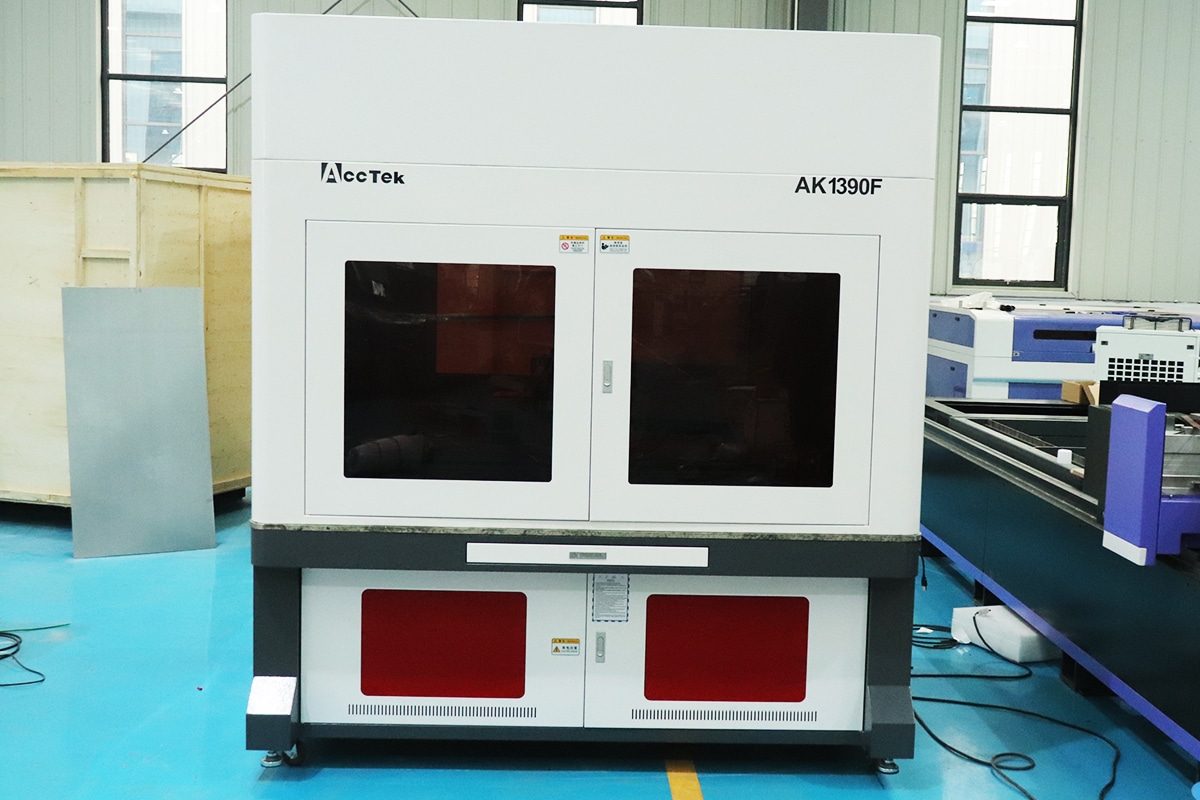

Cabinet or fully enclosed laser marking machines are designed to meet Class 1 laser safety standards, meaning no hazardous laser radiation is accessible during normal operation. All laser activity occurs within a sealed enclosure equipped with safety interlocks.

These machines are the standard choice for industrial environments where operator safety, regulatory compliance, and repeatability are critical. Enclosed systems often include integrated fume extraction, automated doors, and standardized workholding. They are well-suited for continuous operation and can be easily integrated into semi-automated or automated workflows without additional safety infrastructure.

Open workstation laser marking machines provide greater physical access to the marking area than enclosed cabinets. Instead of full enclosures, they rely on external safety measures such as light curtains, safety scanners, shields, or laser-safe barriers.

These machines are commonly used for large, heavy, or awkwardly shaped parts that cannot fit inside standard enclosures. Open workstations offer flexibility in part size and handling but require strict safety protocols, trained operators, and careful risk assessment. They are frequently found in heavy industry, tooling, and custom fabrication environments.

Handheld laser marking machines are portable systems designed for marking parts that are too large, fixed, or difficult to move. The laser head is brought to the workpiece rather than the other way around.

These systems are widely used in construction, shipbuilding, steel fabrication, pipeline marking, mold maintenance, and field service operations. Handheld markers offer unmatched mobility and convenience, but they typically sacrifice speed, repeatability, and precision compared to fixed systems. Operator skill and safety management are especially important in this category.

Online flying laser marking machines are integrated directly into production lines and synchronized with conveyor motion. They mark products on the fly, without stopping or slowing down the production process.

These systems are essential in high-speed industries such as food and beverage, pharmaceuticals, cosmetics, and consumer goods. They are commonly used for date codes, batch numbers, expiration dates, and regulatory information. Flying marking systems maximize throughput and reduce bottlenecks, but they require precise synchronization and stable production conditions.

Multi-station turntable laser marking machines use a rotating platform with multiple workstations. While one part is being marked, other stations are simultaneously loading, unloading, or positioning parts.

This configuration significantly improves productivity by reducing idle time and balancing manual labor with automation. Turntable systems are well-suited for medium- to high-volume production where consistent cycle times are needed, but full automation is not yet justified. They are commonly used in electronics, medical devices, and precision components.

Robotic laser marking cells represent the most advanced and flexible form factor. An industrial robot manipulates either the laser head or the workpiece, allowing marking on complex geometries, multiple faces, and hard-to-reach areas.

These systems are ideal for large, three-dimensional parts such as automotive frames, aerospace structures, welded assemblies, and cast components. Robotic cells are often integrated with vision systems, automated loading, safety fencing, and production monitoring software. They support high levels of automation and are a key element of smart factories and Industry 4.0 strategies.

Classifying laser marking machines by physical form factor and production workflow highlights how marking technology fits into real-world manufacturing operations. Desktop and handheld machines emphasize flexibility and portability, enclosed and open workstations balance safety with accessibility, while online, turntable, and robotic systems enable high-throughput and automated production. Selecting the right form factor ensures efficient integration, operator safety, scalability, and long-term productivity.

In addition to broad classifications by laser source, motion system, or physical form factor, the laser marking industry also offers a wide range of highly specialized laser marking machines tailored to specific applications and industries. These systems are engineered to meet unique requirements such as regulatory compliance, extreme precision, surface integrity, aesthetic quality, and long-term durability. When manufacturers ask what types of laser marking machines are available, these specialized solutions often represent the final and most practical decision point.

Specialized laser marking machines are not generic tools. They combine carefully selected laser technologies, optics, software algorithms, and fixturing to deliver consistent, validated results for demanding use cases. Many include application-specific features such as vision systems, automated alignment, material databases, and process validation to ensure repeatability and compliance.

Nameplate and tag marking machines are designed to create permanent, legible, and durable markings on metal or plastic plates used for product identification, branding, and regulatory compliance. These machines commonly mark serial numbers, model information, certification logos, safety warnings, and traceability data.

Because nameplates and tags are often exposed to harsh environments—heat, chemicals, UV radiation, abrasion, and outdoor conditions—these systems prioritize high-contrast marking or deep engraving. They are widely used in industrial machinery, electrical equipment, infrastructure projects, and asset management. Consistency and long-term readability are the primary performance criteria.

PCB and electronics marking machines are engineered for extreme precision and minimal thermal impact. They are used to mark printed circuit boards, microchips, connectors, housings, and electronic components with traceability codes, part numbers, and manufacturer identifiers.

These systems typically feature ultra-fine spot sizes, high-resolution optics, and precise motion control to produce micro-QR codes and tiny alphanumeric characters. Clean marking without debris or thermal damage is essential, as even minor defects can affect functionality. Integration with automated production lines and vision inspection systems is common in electronics manufacturing.

Medical device marking machines are built to meet strict regulatory, cleanliness, and biocompatibility standards. They are widely used to apply Unique Device Identification (UDI) codes, serial numbers, and logos to surgical instruments, implants, and diagnostic equipment.

These systems focus on high-contrast, corrosion-resistant marking methods such as annealing or black marking. The marking process must not compromise material strength, surface finish, or sterilization compatibility. Validation, repeatability, and documentation are critical, making medical marking machines some of the most rigorously engineered laser marking systems on the market.

Jewelry laser marking machines are optimized for fine detail, aesthetic quality, and material preservation. They are used to engrave logos, hallmarks, serial numbers, and decorative patterns on precious metals such as gold, silver, platinum, and titanium.

These systems emphasize smooth edges, controlled depth, and minimal heat input to avoid distortion or discoloration. Jewelry marking machines often support intricate designs and micro-engraving, making them popular among luxury brands, custom jewelers, and watch manufacturers. Visual quality is just as important as permanence in this category.

Mold texturing and decorative surface structuring systems extend beyond simple marking to create functional or decorative surface textures. These machines are used to texture molds, dies, and tools used in injection molding, stamping, and casting processes.

By precisely controlling laser scanning patterns and energy delivery, these systems can create complex textures, matte finishes, leather-like surfaces, or micro-patterns that enhance grip, appearance, or performance. They are widely used in automotive interiors, consumer electronics, appliances, and industrial design, offering design flexibility that traditional mechanical methods cannot achieve.

Specialized laser marking machines are purpose-built solutions designed to meet the precise demands of specific industries. From rugged nameplate marking and ultra-precise electronics coding to regulated medical device marking, luxury jewelry engraving, and advanced mold texturing, these systems demonstrate the adaptability of laser marking technology. Understanding these specialized machine types provides a complete picture of the diverse laser marking solutions available in today’s market and helps ensure the right system is chosen for each application.

When determining what types of laser marking machines are available, one of the most reliable and application-driven methods is to classify them by material compatibility. Materials differ greatly in how they absorb laser wavelengths, conduct heat, and react chemically or physically to energy input. A laser that produces perfect results on one material may cause burning, melting, cracking, or no visible mark at all on another.

Choosing the right laser marking machine by material involves more than identifying the substrate—it requires understanding surface finish, additives, thickness, heat sensitivity, and the required marking result (contrast, depth, permanence, or aesthetics). Proper material–laser matching ensures readable marks, protects material integrity, and reduces production waste and rework.

Organic materials absorb infrared energy efficiently, making CO2 laser marking machines (10.6 μm) the optimal choice. These materials typically mark through controlled carbonization or vaporization, producing natural contrast without inks or consumables.

CO2 lasers are widely used for branding, decorative marking, packaging, and labeling. Power and speed control are crucial, as excessive energy can burn or weaken thin materials. For textiles and leather, precise parameter control ensures clean edges without fraying or excessive darkening.

Coated, painted, and anodized materials require selective energy control to modify or remove the surface layer without damaging the substrate. Fiber lasers are widely used for anodized aluminum, producing high-contrast marks by selectively removing or altering the anodic layer.

Painted and coated metals may be marked using fiber, green, or UV lasers, depending on coating thickness, adhesion, and heat sensitivity. Green and UV lasers are especially useful for thin or delicate coatings where infrared energy may penetrate too deeply. Accurate focus control and parameter optimization are essential to achieve clean edges and consistent results.

Choosing the right laser marking machine type by material is fundamental to marking success. Metals typically favor fiber or green lasers, plastics often require UV systems, organic materials perform best with CO2 lasers, and glass, ceramics, and coated surfaces demand precise energy control. Understanding how each material interacts with laser energy ensures high-quality markings, protects product integrity, and maximizes long-term performance across diverse applications.

A practical way to decide what types of laser marking machines are available for your application is to start with the mark specification—the real-world performance requirements the mark must meet, not just the material you’re marking. Two companies could mark the same stainless-steel part and still need completely different laser marking machine types because their requirements for durability, readability, speed, or appearance are different.

A mark specification typically answers five core questions: How long must the mark last? How easy must it be to read or scan? How fast must it be produced? How small and precise must it be? And how “pretty” must it look? Each requirement pushes you toward certain laser sources (fiber, UV, CO2, green, ultrafast), motion systems (galvo, gantry, hybrid), and marking modes (surface marking, annealing, deep engraving, micro-marking, color/black marking). Getting this right upfront prevents common failures like faint codes, damaged surfaces, scan rejects, or premature wear.

The stronger the environment, the more you should favor marking methods that either remove material (engraving) or create a chemically stable surface change rather than a light cosmetic contrast.

If scanning is critical, you don’t just need a laser that “marks”—you need a process that produces repeatable contrast and clean edges every time.

A common mistake is choosing a system that produces beautiful marks—but slows the entire line. The right machine type matches the required mark to the available cycle time.

If your smallest features are near the limit of what a typical mark can produce, you must prioritize spot size control, beam stability, and thermal management.

Aesthetic specs are where “it works” is not enough—you need a machine type capable of producing the required look repeatably, not just once in a demo.

Choosing the right laser marking machine type by mark specification means matching the machine to real performance demands: permanence under abrasion/heat/chemicals, contrast and scan reliability, cycle time, precision at the smallest feature size, and aesthetic quality (color, finish, and smoothness). When these specifications are defined clearly, selecting between surface marking, black/color marking, micro-marking, and deep engraving systems becomes far easier—and the final marks are more consistent, compliant, and production-ready.

When evaluating what types of laser marking machines are available, it’s easy to focus almost entirely on the laser source—fiber, CO2, UV, green, or ultrafast. However, in real-world use, two machines with the same laser can produce very different results. The reason lies in the supporting subsystems that control how the laser beam is delivered, focused, managed, and operated. These subsystems directly influence marking speed, edge quality, repeatability, uptime, operator safety, and long-term stability.

In many production environments, limitations are not caused by the laser itself, but by scanner accuracy, optical distortion, poor focus control, inadequate fume extraction, or restrictive software. Understanding these differentiating subsystems is essential for selecting the right laser marking machine type for both current needs and future scalability.

The marking head—most commonly a galvanometer (galvo) scanner—controls how rapidly and precisely the laser beam moves across the marking field. High-quality galvo systems offer fast acceleration, high angular resolution, excellent repeatability, and minimal thermal drift. These characteristics are critical for producing sharp edges, consistent line widths, and accurate positioning, especially at high marking speeds.

Lower-quality scanners may exhibit distortion at field edges, inconsistent line spacing, or positional errors during rapid motion. Over time, heat buildup and mechanical wear can further degrade accuracy. For applications involving dense QR codes, small characters, or high-speed production, scanner quality is often the limiting factor that separates industrial-grade machines from entry-level systems.

The F-theta lens and overall optical path determine how the laser beam is focused and distributed across the marking area. A well-designed optical system ensures that the spot size remains consistent and that positional accuracy is maintained from the center of the field to the edges.

Optical quality directly affects mark sharpness, contrast, and uniformity. Poor optics can introduce field distortion, uneven energy density, or loss of focus at the edges, resulting in faded or distorted marks. High-end machines often use wavelength-optimized lenses, advanced coatings, and tighter manufacturing tolerances to support demanding applications such as micro-marking or large-field consistency.

The Z-axis and focusing mechanism control the working distance between the laser and the part. Basic systems rely on manual focus adjustment, which can be adequate for flat, uniform parts but introduces variability and setup time.

More advanced machines use motorized Z-axes, autofocus systems, or dynamic focusing to maintain optimal focus across parts with varying heights or complex geometries. Accurate focus control is critical because even small deviations can change spot size and energy density, affecting contrast, depth, and precision. For uneven surfaces or deep engraving, sophisticated focus control can be as important as laser power.

Safety and environmental control are major differentiators between laser marking machine types. Fully enclosed machines are designed to meet Class 1 laser safety standards, preventing hazardous radiation exposure and simplifying compliance with workplace regulations.

Equally important is fume extraction. Laser marking generates smoke, particulates, and potentially hazardous vapors depending on the material. Integrated extraction systems protect operators, keep optics clean, and reduce maintenance. Machines intended for continuous industrial use often feature sealed enclosures, interlocks, filtered extraction, and provisions for external exhaust or centralized filtration systems.

The software platform is the operational core of laser marking machines. Advanced software provides precise control over laser parameters, motion paths, and marking sequences, enabling consistent and repeatable results.

Modern systems support variable data marking, barcode and QR code generation, vision-assisted alignment, database connectivity, and integration with PLCs and MES systems. Intuitive user interfaces reduce training time and operator error, while robust control features enable automation and high-mix production. In many cases, software capability determines whether a machine is suitable for simple manual tasks or complex, automated workflows.

While the laser source defines the theoretical capability of a laser marking machine, the key subsystems beyond the laser determine how effectively that capability is realized. Galvo scanner quality, optical design, focus control, safety and fume management, and software sophistication all play critical roles in marking quality, speed, reliability, and usability. Understanding these subsystems helps explain why laser marking machines vary widely in performance and cost—and why choosing the right machine requires a holistic evaluation rather than a focus on the laser alone.

One of the most practical ways to understand what types of laser marking machines are available is to look at how different industries actually apply laser marking in day-to-day production. While many laser marking systems can technically mark the same material, industry-specific requirements—such as regulatory compliance, production speed, durability, cleanliness, and precision—strongly influence which machine types are preferred.

In real manufacturing environments, laser marking machines are chosen not only for their technical capability, but for how reliably they perform under production pressure. Factors such as uptime, ease of automation, long-term readability, and process validation often matter more than raw laser power. As a result, each industry tends to converge on certain machine types that best fit its operational needs.

The automotive industry places extreme importance on traceability, permanence, and production speed. Components such as engine blocks, transmission parts, braking systems, and safety-critical components must be permanently marked so they can be tracked throughout the vehicle’s life cycle.

Automotive manufacturers typically prefer fiber laser marking machines with galvo scanners due to their speed, reliability, and excellent performance on metals. Marks often need to withstand heat, vibration, oils, fuels, and cleaning chemicals, which is why deep engraving, annealing, or robust surface marking processes are commonly used. For high-volume lines, inline or hybrid marking systems are integrated directly into automated production cells, where cycle time consistency and minimal downtime are critical.

Electronics and semiconductor manufacturing demand ultra-high precision, minimal thermal impact, and extremely small feature sizes. Printed circuit boards, integrated circuits, connectors, and miniature housings often require micro-QR codes, fine alphanumeric characters, or logos placed within very limited space.

To meet these demands, manufacturers frequently choose UV laser marking machines or ultrafast laser marking systems. These machines enable cold marking with clean edges and virtually no heat-affected zone, protecting sensitive components and substrates. Vision alignment, high-resolution optics, and integration with automated handling systems are common. In this industry, consistency and cleanliness are paramount—any marking defect can lead to functional failure or scrap.

Medical device manufacturing is governed by strict regulatory standards that require permanent, biocompatible, and corrosion-resistant markings. Surgical instruments, implants, and diagnostic devices must carry UDI codes, serial numbers, and branding that remain legible after repeated sterilization and cleaning cycles.

For metal medical devices, manufacturers often rely on fiber laser marking machines configured for black marking or annealing, as these processes produce high contrast without compromising surface integrity. For medical plastics, UV laser marking machines are preferred due to their cold marking capability and clean cosmetic results. Process validation, repeatability, and documentation are critical, and aesthetic quality is closely monitored to avoid surface roughness or contamination risks.

The packaging and FMCG sectors prioritize speed, flexibility, and low operating costs. Products often require date codes, batch numbers, lot codes, and regulatory information applied at very high speeds across multiple packaging formats.

CO2 laser marking machines are widely used for marking paper, cardboard, films, labels, and some plastics due to their efficiency on organic materials. Fiber lasers are also used for metal packaging or coated surfaces. Online flying laser marking systems are strongly preferred, as they can mark products on moving conveyors without interrupting production. Ease of integration, minimal consumables, and low maintenance are key drivers in this industry.

Tooling, mold-making, and heavy industrial equipment manufacturers require deep, durable, and highly precise markings that survive extreme mechanical and environmental stress. Marks may include part numbers, cavity identifiers, logos, or even functional surface textures.

These applications typically favor high-power fiber laser marking or engraving machines, often combined with gantry systems or 3D dynamic focusing for complex geometries. Speed is less critical than depth control, accuracy, and long-term durability. In mold texturing and surface structuring, lasers are also used to create decorative or functional patterns that influence the final molded product’s appearance or performance.

Industry use cases strongly shape which laser marking machine types are preferred. Automotive manufacturing favors fast, durable fiber-based systems for traceability; electronics and semiconductors rely on UV and ultrafast lasers for precision and cleanliness; medical devices demand validated, biocompatible marking processes; packaging and FMCG depend on high-speed CO2 and inline systems; and tooling and industrial equipment require deep, robust engraving solutions. Understanding these industry-driven preferences provides valuable guidance when selecting the most appropriate laser marking machine for real-world production needs.

Laser marking machines come in many forms because no single system can meet every material, marking, and production requirement. Understanding what types of laser marking machines are available requires looking beyond the laser source alone and considering how machines differ by laser wavelength, beam delivery, and motion system, intended marking result, physical form factor, and industry application. Fiber, CO2, UV, green, and ultrafast lasers each serve distinct roles, while galvo, gantry, hybrid, rotary, and 3D systems determine speed, coverage, and geometric flexibility.

Equally important are the desired marking outcomes—whether high-contrast traceability marks, deep engraving, color or black marking, micro-marking, or glass and crystal marking. These results depend on precise control of energy density, thermal interaction, optics, and focus. Physical configuration also matters, from compact desktop units and enclosed workstations to online conveyor systems and robotic marking cells that support high-volume automation.

Material compatibility, mark specifications, and industry-specific requirements ultimately guide the final choice. Automotive, electronics, medical, packaging, and tooling industries each favor different laser marking machine types based on durability, precision, speed, compliance, and aesthetics. By understanding these classifications and the subsystems that differentiate machines, manufacturers can confidently select laser marking solutions that deliver consistent quality, efficiency, and long-term value.