Introduction to Laser Marking

Principles of Laser Marking

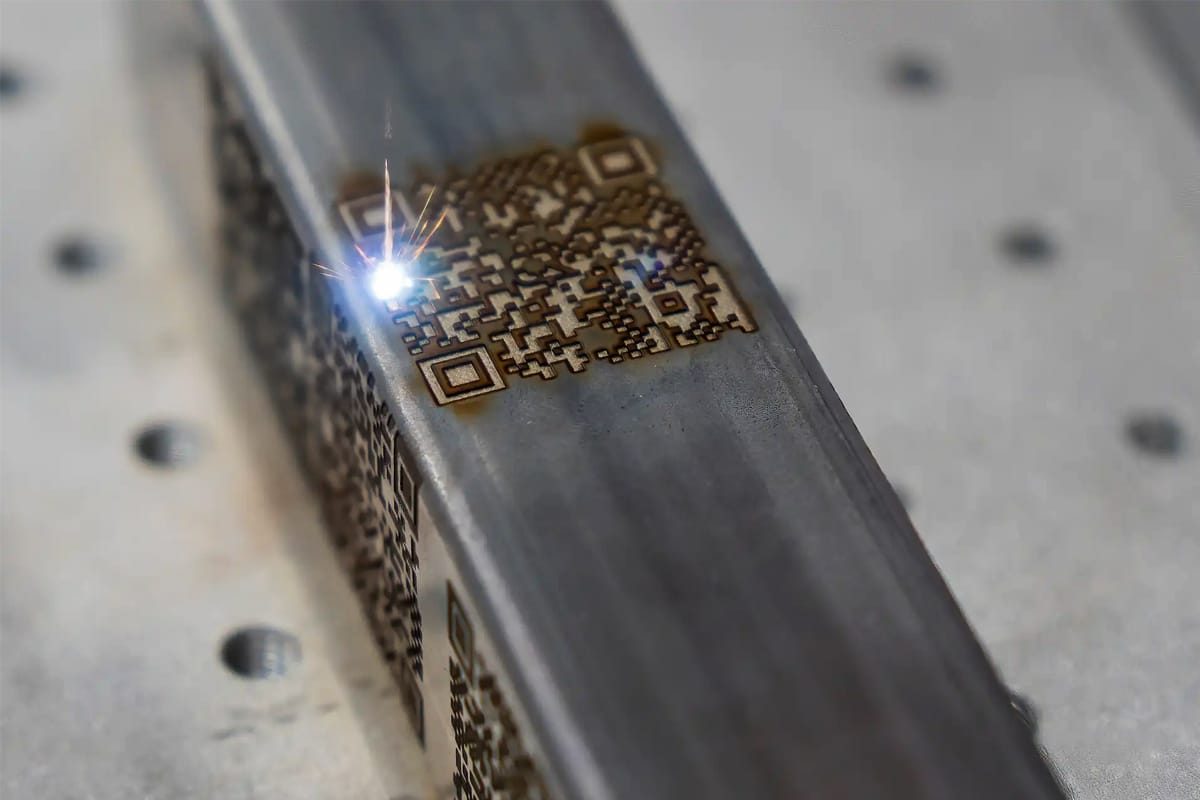

The basic principle behind laser marking involves focusing a high-powered laser beam onto the surface of a material. The laser’s energy causes localized heating, which in turn leads to various reactions, such as melting, vaporization, oxidation, or chemical changes, depending on the type of marking being performed and the material being marked. There are several marking processes commonly used:

- Laser Engraving: This method uses the laser to remove material from the surface, creating a permanent, deep mark. Engraving is often used for creating bold, visible markings that can withstand wear and tear.

- Laser Etching: A less intense process than engraving, laser etching modifies the surface of the material without removing significant amounts of material. The result is a shallow mark that still maintains permanence and clarity.

- Laser Ablation: In this technique, the laser removes the surface layer of the material, often exposing a contrasting layer beneath. It is commonly used for marking coated materials, such as anodized aluminum or painted surfaces.

- Laser Coloring: This technique changes the surface color of certain materials, such as metals, without removing material. The laser causes oxidation or other reactions that produce a color shift, offering a decorative or subtle marking solution.

Applications of Laser Marking

Laser marking technology has found widespread use across many industries due to its versatility, precision, and ability to produce durable, high-quality markings. Some of the most common applications include:

- Automotive Industry: Laser marking is essential for engraving serial numbers, part identifiers, and logos onto car components, helping manufacturers ensure traceability, regulatory compliance, and brand consistency.

- Electronics: Small, delicate electronic components such as microchips and circuit boards require precise, permanent identification. Laser marking enables manufacturers to print serial numbers, logos, and other information without damaging these sensitive components.

- Medical Devices: In the medical sector, laser marking ensures that surgical instruments, implants, and devices are clearly marked with identification numbers and regulatory codes. These permanent marks are vital for traceability, quality control, and patient safety.

- Aerospace: The aerospace industry relies on laser marking for labeling parts that require high durability and resistance to extreme conditions. Marks on critical components help ensure safety and meet strict regulatory standards.

- Packaging: Laser marking is commonly used in the packaging industry for creating batch codes, expiration dates, and barcodes on product packaging. It offers a clean, durable, and permanent marking solution that won’t fade or rub off over time.

Importance of Safety

To mitigate these risks, it is essential to implement strict safety protocols, including:

- Personal Protective Equipment (PPE): Operators should always wear appropriate protective eyewear designed to filter out harmful wavelengths of light. Gloves and protective clothing may also be necessary, depending on the material being marked.

- Laser Enclosures and Shields: Laser marking systems should be equipped with enclosures, safety shields, or barriers to prevent accidental exposure to the laser beam. These safeguards contain the laser’s energy and help protect those working nearby.

- Fume Extraction Systems: Many materials release hazardous fumes when exposed to the laser, particularly plastics, rubbers, and coatings. Effective ventilation and fume extraction systems are essential to remove potentially dangerous particles from the air and maintain a safe environment.

- Training and Standard Operating Procedures (SOPs): Operators must be thoroughly trained in laser safety protocols, ensuring they understand the risks and how to handle emergencies. Standard operating procedures should be in place to guide operators through the safe use of the equipment and establish protocols for dealing with accidents or malfunctions.

Types of Lasers Used in Marking Systems

CO2 Lasers

Fiber Lasers

UV Lasers

MOPA Lasers

Laser Marking Hazards and Risks

Laser Radiation

One of the most significant risks associated with laser marking is exposure to laser radiation. Lasers emit concentrated beams of light that can cause serious eye and skin damage if safety precautions are not strictly followed. The severity of the injury depends on the laser’s wavelength, power, and exposure duration.

- Eye Hazards: The most dangerous aspect of laser radiation is its potential to cause eye damage. Depending on the wavelength of the laser, exposure can lead to temporary or permanent vision impairment. For instance, infrared and ultraviolet lasers are particularly hazardous because they are invisible to the human eye, and people may unknowingly be exposed. The light energy can burn the retina, leading to permanent blindness or severe eye damage.

- Skin Hazards: Direct contact with the laser beam or even reflected laser light can result in serious burns. Skin exposure can cause superficial burns or deep tissue damage, depending on the intensity of the laser.

Burns and Skin Injuries

Fire Hazards

Toxic Fumes and Gases

Toxic Fumes and Gases

Key Features:

- High power efficiency: Fiber lasers convert over 30–40% of electrical energy into laser energy, making them more efficient than CO2

- Faster cutting speeds: Especially for thin and medium-thickness metals.

- Minimal maintenance: No moving mirrors or gas tubes, resulting in lower maintenance costs.

- Compact design: Requires less space compared to CO2 laser cutting systems.

- Long lifespan: Fiber laser diodes last significantly longer (50,000+ hours) than CO2 laser tubes.

- Low operational costs: No consumable gases or costly components.

Noise Hazards

Noise Hazards

Electrical Hazards

Laser Marking Equipment Safety Standards

International Safety Standards

Laser Classifications and Labeling

The IEC 60825-1 standard categorizes lasers into several classes, ranging from Class 1 (the safest) to Class 4 (the most hazardous):

- Class 1: These lasers are considered safe under normal operating conditions because they are either incapable of causing damage or are enclosed in a way that eliminates exposure. Common examples include low-powered lasers used in barcode scanners and CD players.

- Class 2: Lasers in this class emit visible light and are considered safe for brief exposure (up to 0.25 seconds) due to the natural blink reflex of the human eye. However, prolonged exposure can be hazardous.

- Class 3R: These lasers pose a greater risk and can cause eye injury if viewed directly. Proper protective eyewear should be worn when operating or working near these lasers.

- Class 3B: Class 3B lasers can cause eye damage if viewed directly or with reflected light. These lasers are typically used in more powerful industrial applications, such as laser marking. Protective equipment and enclosures are required for safety.

- Class 4: These are high-powered lasers capable of causing serious eye or skin damage, even from scattered or reflected light. Class 4 lasers are used in more powerful industrial settings, such as laser cutting and engraving. Strict safety measures, including full protective enclosures, eyewear, and warning systems, are essential.

Laser Enclosures and Safety Features

One of the most effective ways to mitigate laser-related hazards is through the use of laser enclosures and safety features. These systems are designed to physically restrict access to the laser beam and contain any harmful radiation, ensuring that operators and bystanders are not exposed to hazardous laser energy.

- Laser Enclosures: These are protective barriers or casings that fully enclose the laser marking system or the work area to prevent direct or reflected exposure to the laser. Enclosures are particularly important for higher-class lasers, such as Class 3B and Class 4 lasers, where there is a significant risk of eye injury or skin burns. These enclosures should be made from materials that can withstand the laser’s energy and prevent penetration by laser beams.

- Safety Interlocks: Laser marking systems must be equipped with interlock mechanisms to ensure that the laser cannot operate if the enclosure is opened or if access to the laser beam is unprotected. These interlocks automatically shut off the laser if safety barriers are breached, providing an additional layer of protection for operators and workers in the vicinity.

- Beam Stops and Safety Shields: To protect against accidental exposure to laser radiation from reflected beams, laser marking systems should be fitted with beam stops or safety shields. These shields deflect or absorb stray laser energy and prevent it from reaching the operator or any other unintended targets. These features are particularly important when working with reflective materials, such as metals, which can redirect the laser beam.

- Warning Systems: Visual and audible warning systems, such as flashing lights, sirens, or warning labels, should be installed to alert personnel when the laser is in operation or when hazardous conditions exist. These systems help ensure that everyone in the vicinity is aware of potential risks and can take necessary precautions.

- Protective Eyewear: Protective eyewear tailored to the wavelength of the laser is a critical component of any laser safety system. Operators and anyone in the laser marking area must wear appropriate goggles to filter out harmful wavelengths. The use of appropriate protective eyewear depends on the laser’s class and the environment in which the laser is operating.

Essential Personal Protective Equipment (PPE)

Laser Safety Glasses

Protective Clothing

Face Shields

Hearing Protection

Fire-Resistant Clothing

Laser Marking Equipment Safety Protocols

Proper Laser Enclosure

Emergency Shutoff Systems

Maintenance and Calibration

Cooling Systems

Workplace Safety Considerations for Laser Marking

Laser Safety Zones

Signage and Warnings

Fire Safety Procedures

Ventilation Systems

Laser Safety Training

Work Area Cleanliness

Laser Marking for Different Materials and Safety Concerns

Metals

Metals are one of the most commonly marked materials using laser technology, particularly in industries such as automotive, aerospace, and electronics. Laser marking on metals involves high-powered lasers that etch or engrave permanent marks such as serial numbers, logos, and barcodes.

- Safety Concerns: The primary safety concern when marking metals is the risk of high temperatures. Laser marking systems, especially fiber lasers, can generate significant heat during operation. This heat can cause burns if operators come into direct contact with the laser equipment or the metal surface. Additionally, reflective metals like aluminum and stainless steel can reflect laser beams, potentially causing accidental exposure to harmful radiation. The risk of fires also increases, especially when working with thin metals that can heat up quickly and potentially ignite.

- Safety Precautions: To mitigate these risks, operators should wear heat-resistant gloves and proper eye protection designed for the specific wavelength of the laser being used. Using laser marking systems with appropriate enclosures or safety barriers can help reduce the risk of accidental exposure to reflected beams. Regular inspection of the equipment and ensuring that laser marking systems are properly grounded can help prevent dangerous reflections. Fire extinguishers and appropriate cooling systems should also be in place to manage potential fire risks.

Plastics

Laser marking on plastics is a popular application in industries such as packaging, electronics, and medical devices. Plastic materials can be marked through engraving, etching, or coloring, depending on the type of plastic and the desired result.

- Safety Concerns: One of the main risks when marking plastics is the emission of toxic fumes and gases, particularly when working with materials that contain chlorine, such as PVC. When exposed to laser energy, these plastics can release harmful substances, including hydrogen chloride gas, which can be hazardous to the respiratory system. In addition to the health risks posed by fumes, plastics can also melt or catch fire if exposed to high heat for extended periods.

- Safety Precautions: Proper ventilation systems and fume extraction units are crucial when laser marking plastics to prevent the accumulation of toxic fumes. Operators should wear respirators if necessary and ensure that the workspace is well-ventilated. In addition, using laser marking systems with temperature controls to avoid overheating the plastic and causing burning is essential. Fire extinguishers or suppression systems should be readily available when working with flammable materials like plastic.

Wood

Laser marking on wood is commonly used for engraving logos, text, and intricate designs, particularly in the furniture and crafting industries. Wood marks easily with lasers, and the process creates a clean, smooth finish without physical contact.

- Safety Concerns: One of the most significant hazards when marking wood is the potential for fire. Wood is highly combustible, and the laser’s high temperatures can ignite the material, particularly if it is not adequately monitored. Additionally, the laser can generate wood dust, which, if accumulated, poses an explosion risk in the presence of heat.

- Safety Precautions: To prevent fire hazards, the laser marking system should be equipped with an automatic shut-off system that activates if the wood overheats. Fire-resistant barriers or enclosures can help prevent fire from spreading. Proper dust collection systems should also be in place to minimize the risk of dust accumulation, and operators should regularly clean the work area to avoid combustible dust buildup. Fire extinguishers must be located nearby, and operators should be trained in emergency procedures in case of a fire.

Glass

Glass is a delicate material that can be marked using lasers to create etched designs or surface texturing. Laser marking on glass is often used for decorative purposes, as well as for marking serial numbers on glass bottles or containers.

- Safety Concerns: The primary safety concern when laser marking glass is the risk of shattering. Glass is brittle and can break or crack when exposed to concentrated laser energy, leading to potential injuries from flying shards. Additionally, laser marking glass can generate sharp edges and small fragments that can pose physical hazards to operators.

- Safety Precautions: Laser marking systems used for marking glass should be equipped with precise controls to ensure that the laser energy is distributed evenly across the surface. This helps avoid localized overheating, which can cause cracks or breakage. Operators should wear protective gloves and face shields to protect against flying shards, and the work area should be equipped with barriers or shields to contain any debris. Using tempered or specially treated glass for marking can also reduce the risk of breakage.

Rubber

Rubber materials, such as those used in seals, gaskets, or tires, can be laser marked to provide permanent text, logos, or product information. The process is often used in the automotive and manufacturing industries.

- Safety Concerns: The laser marking process on rubber can release potentially harmful fumes, including hazardous chemicals such as carbon monoxide and volatile organic compounds (VOCs). These fumes can be toxic if inhaled in significant quantities, leading to respiratory issues and long-term health problems. Rubber materials are also highly flammable, and there is an increased risk of fire, especially when using high-powered lasers.

- Safety Precautions: Effective ventilation and fume extraction systems are essential when working with rubber to eliminate toxic fumes and gases. Operators should wear proper respiratory protection, including masks or respirators, to minimize inhalation risks. Fire safety protocols should be in place, including fire extinguishers, and operators should monitor the laser marking process to prevent excessive heat buildup.

Paper

Laser marking on paper is widely used for printing barcodes, QR codes, text, and intricate designs in industries such as packaging and publishing.

- Safety Concerns: The primary hazard when marking paper is the risk of fire. Paper is highly combustible, and the intense heat from the laser can easily ignite the material, particularly if the paper is thin or stacked in large quantities. In addition to fire risks, paper dust generated during the marking process can accumulate and create a fire or explosion hazard if not properly managed.

- Safety Precautions: To prevent fires, operators should ensure that paper is handled carefully during the marking process, avoiding the buildup of excessive heat. Fire-resistant barriers and sprinkler systems should be installed to help contain any fires that might occur. It is also essential to implement a dust collection system to remove paper dust and minimize the risk of dust explosions. Operators should be vigilant in monitoring the laser marking process and maintain an organized work area to reduce fire risks.

Laser Marking Machine Safety Controls

Laser Power Control

Laser power control is one of the most essential safety features of a laser marking system. The power output of a laser determines the intensity of the beam, which, in turn, affects the marking process. If the laser is too powerful, it can cause unintended damage to the material or even result in hazardous situations such as fire or excessive heat. Conversely, insufficient power can lead to poor-quality markings or ineffective results.

- Safety Concerns: The primary safety concern with laser power is the risk of uncontrolled radiation exposure, which can be dangerous to operators or anyone in the vicinity. High-powered lasers, especially those used for marking metals or thick materials, can generate excessive heat, posing a significant risk of burns, fires, and even damage to the laser marking system itself. Therefore, controlling the power output of the laser is vital for maintaining both safety and quality.

- Safety Precautions: Modern laser marking machines are equipped with precise power control mechanisms that allow operators to adjust and regulate the laser’s output according to the material being marked and the desired result. Many systems feature automatic power adjustments that help optimize laser performance based on real-time data, such as the reflectivity of the material or the thickness of the workpiece. Additionally, laser marking systems should include power limiters that prevent the laser from exceeding safe operating thresholds, helping to ensure that it operates within safe parameters at all times. These power control systems are critical for minimizing risks and ensuring that the equipment functions safely without overexposing personnel to harmful radiation.

Beam Path Monitoring

Beam path monitoring refers to the continuous monitoring of the laser’s path from the source to the workpiece. The laser beam can be directed through various optical components such as mirrors, lenses, and focusing units. If any of these components malfunction or become misaligned, it can lead to unsafe conditions, such as beam leakage, misdirected radiation, or damage to the equipment.

- Safety Concerns: The main safety concern with beam path monitoring is the potential for unintentional exposure to laser radiation. If the beam is not properly aligned or if a component fails, the laser could leak radiation outside the designated working area, which could lead to serious eye injuries or skin burns.

- Safety Precautions: Laser marking systems are often equipped with beam path monitoring systems that continuously check the alignment and integrity of the laser beam. These systems track the laser’s movement and ensure that it remains within safe boundaries. If any irregularities are detected—such as misalignment or reflection issues—automatic alerts can be triggered, and the laser can be shut off immediately to prevent accidents. Additionally, protective covers or shields should be used to enclose the laser beam path to minimize exposure to stray radiation. Regular checks and maintenance of optical components, such as lenses and mirrors, are also essential for ensuring proper beam alignment and minimizing risks associated with beam misdirection.

Interlocks

Interlocks are safety mechanisms designed to prevent the laser marking system from operating under unsafe conditions. These devices are crucial in ensuring that the laser beam is only active when the work area is properly enclosed or when the necessary safety measures are in place.

- Safety Concerns: Without interlocks, there is a risk that the laser could be activated when the work area is not fully protected or the system is improperly configured, potentially exposing the operator to laser radiation or other hazards. For instance, if the machine enclosure is opened or a safety cover is removed while the laser is still active, the operator could be exposed to the dangerous laser beam, which could result in serious eye injury or skin burns.

- Safety Precautions: Interlocks are commonly used in laser marking machines to ensure that critical safety conditions are met before the laser is allowed to operate. Safety interlocks are typically integrated into the machine’s doors, enclosures, and safety covers. These interlocks automatically stop the laser from functioning if any part of the system is opened or compromised. Some laser marking systems also include dual or redundant interlocks to further increase safety. For example, a system may require multiple actions to be completed before the laser can be activated, such as confirming the machine’s enclosure is securely closed and that protective eyewear is in place. These interlocks can significantly reduce the likelihood of accidents caused by human error or equipment failure.

Positioning and Controls

Proper positioning and control systems are essential to ensure that the laser operates within the correct parameters and that the workpiece is accurately marked. Misalignment of the laser beam can lead to poor marking quality, equipment damage, or, in extreme cases, unintentional exposure to hazardous laser radiation.

- Safety Concerns: The risk associated with improper positioning includes accidental misdirection of the laser beam, which could potentially harm the operator or cause unintended damage to surrounding equipment. Inaccurate positioning of the workpiece itself can also lead to safety issues, particularly if the material moves during the marking process or if it interacts with the laser beam in unexpected ways.

- Safety Precautions: Modern laser marking systems typically feature precise positioning controls, such as CNC (computer numerical control) systems or robotic arms, that allow for accurate movement of the workpiece within the laser’s focal point. These systems help ensure that the laser marks the correct location on the material and that the material is securely positioned to avoid unintended movement during the marking process. Additionally, motion sensors and feedback loops are often incorporated into these systems to track the workpiece’s position in real-time and make any necessary adjustments automatically. Manual overrides and limit switches are also important for ensuring that the laser cannot operate outside the designated safety zones or parameters.

Laser Marking Operation Procedures

Pre-Operation Safety Checks

Key Safety Checks Include:

- System Inspection: Operators should visually inspect the entire laser marking system, including the laser head, lenses, mirrors, and beam path, to ensure that all components are in good working condition and free of debris or damage. Any damage to the optical components, such as cracked lenses or misaligned mirrors, should be immediately addressed to prevent improper beam delivery or exposure to stray radiation.

- Laser Alignment: Proper alignment of the laser beam is critical for ensuring that the laser focuses accurately on the material. Misalignment can result in poor-quality markings, equipment damage, or accidental exposure to harmful laser radiation. Operators should verify that the beam is correctly aligned and that any adjustments to the laser focusing system have been made before operation.

- Safety Features Check: It is essential to ensure that all safety features, such as interlocks, emergency shutoffs, and beam enclosures, are functioning properly. These features are designed to stop the laser from operating if the system is unsafe or if the protective barriers are breached. Interlocks should be tested to ensure that the system will automatically shut down if an operator opens the protective enclosure or if any other safety condition is violated.

- Ventilation System: If the laser marking system requires a ventilation or fume extraction system, operators should verify that these systems are operational before starting the machine. Proper ventilation helps remove toxic fumes and particulates generated during the marking process, particularly when working with materials like plastics, rubber, or treated metals.

- Material Setup: Ensuring the correct placement and securing of materials on the laser bed is essential for both safety and marking quality. The material should be properly positioned to prevent accidental movement during the laser operation. Operators should also confirm that the correct parameters (e.g., power, speed, frequency) are set for the material being marked.

Operator Training

Key Aspects of Operator Training Include:

- Laser Safety Awareness: Operators should understand the potential hazards of laser radiation, including the risks to the eyes and skin. They must learn how to identify the laser class of the system and understand the appropriate safety measures for each class. This includes recognizing the importance of wearing proper laser safety glasses and using shielding to protect against exposure to laser light.

- Emergency Response Training: Operators should be familiar with the emergency procedures to follow in case of an accident or malfunction. This includes knowing how to quickly activate the emergency shutoff system, how to respond in the event of a fire, and how to use fire extinguishers and first-aid kits. In addition, operators should know the proper steps to take if toxic fumes are detected, including evacuating the area and using respiratory protection if necessary.

- Safe Machine Operation: Operators must be trained on how to safely operate the laser marking system. This includes learning how to set the correct laser power, speed, and focus for different materials, how to load and position materials on the marking bed, and how to initiate and monitor the marking process. They should also understand how to troubleshoot common issues, such as poor marking quality or system errors, and know when to contact maintenance personnel.

- Preventing Accidental Exposure: Operators must be educated on the risks of accidental exposure to laser radiation, particularly from reflected beams or during maintenance or cleaning activities. Understanding the importance of maintaining proper safety zones around the laser, using shields and barriers, and keeping the workspace free from reflective surfaces is critical.

- Use of Personal Protective Equipment (PPE): Operators should be thoroughly trained in the proper use and maintenance of PPE, including laser safety glasses, protective clothing, gloves, face shields, and hearing protection. Proper training ensures that operators know how to wear and maintain PPE for maximum protection during operations.

Laser Operation Safety

Key Laser Operation Safety Practices Include:

- Laser Area Restrictions: The laser marking area should be clearly marked and restricted to authorized personnel only. Access to the laser marking system should be controlled to prevent unauthorized individuals from entering the area during operation. This reduces the risk of accidental exposure to laser radiation.

- Supervision During Operation: During the marking process, the laser should be continuously monitored to ensure that the marking is proceeding as planned and that no safety hazards, such as overheating or equipment malfunction, arise. Operators should be vigilant and ready to stop the process immediately if any abnormalities occur.

- Avoiding Direct Exposure: Operators should never look directly into the laser beam or at the marked surface unless they are wearing appropriate laser safety goggles. Even with the proper equipment, operators should avoid unnecessary exposure to the laser beam, as it can still pose a risk, particularly in the case of reflected light.

- Preventing Overheating: High-powered lasers generate significant heat during operation, which can present a fire risk or damage the equipment. Operators should ensure that the laser marking system’s cooling systems are functioning properly and monitor for signs of overheating. If the laser marking system begins to overheat, it should be shut down immediately for inspection and cooling.

- Post-Operation Shutdown: After the marking process is completed, the laser marking system should be properly shut down, and all protective covers should be replaced. This prevents accidental exposure to the laser and ensures that the equipment is ready for the next operation. The work area should be cleaned and organized to reduce the risk of accidents in future operations.

Emergency Protocols

Laser Marking Accidents

Despite rigorous safety measures, accidents can still occur in the laser marking process, often due to human error, system malfunction, or external factors. Laser accidents may include eye injuries from unprotected exposure to the laser beam, skin burns from direct or reflected laser radiation, or fire outbreaks caused by excessive heat generated by the laser marking system.

- Types of Laser Marking Accidents Include:

- Laser Radiation Exposure: If operators or nearby personnel are exposed to high-powered laser radiation, it can cause severe eye damage or even permanent blindness, as well as skin burns if exposed for too long. Accidental exposure may occur if the laser is misaligned, if safety enclosures are improperly maintained, or if personnel are not using the appropriate protective gear.

- Fire Hazards: Laser marking processes, particularly those using high-powered lasers on materials like plastics, metals, or wood, can generate heat and cause fires. Flammable materials in the vicinity can catch fire due to the intense heat from the laser or from sparks created during the process.

- Toxic Fumes: When marking certain materials, such as plastics or rubber, hazardous fumes or gases may be released. These can include toxic chemicals such as chlorine gas from PVC or carbon monoxide from burning plastic. Inhalation of these fumes can cause respiratory distress, eye irritation, or long-term health issues.

- Emergency Procedures for Laser Marking Accidents:

- Immediate First Aid: In the event of skin burns or eye injuries, immediate first aid must be administered. For eye injuries, rinse the eyes with clean water and seek medical attention immediately. For burns, cool the affected area with water, apply sterile dressings, and avoid further contact with the laser source.

- Fire Response: If a fire occurs, the operator should activate the fire suppression system if one is installed. If the fire is small and manageable, use an appropriate fire extinguisher. Otherwise, evacuate the area immediately, ensuring that the fire department or emergency responders are alerted.

- Toxic Exposure: If harmful fumes or gases are inhaled, evacuate the area and seek fresh air immediately. Personnel should be trained in the use of respirators or gas masks and should evacuate the area to a well-ventilated space. In the case of a severe release of toxic fumes, emergency medical assistance should be called.

Machine Malfunctions and Safety Shutdown

Laser marking systems are complex machines with many components that can fail or malfunction, potentially leading to safety hazards. These malfunctions can include system errors, electrical faults, cooling system failures, or malfunctions in the laser’s focusing system. When a malfunction occurs, it’s crucial to shut down the system quickly and safely to prevent further damage or hazards.

- Common Machine Malfunctions:

- Laser Beam Misalignment: If the laser beam becomes misaligned, it could potentially fire outside the intended area, posing a risk of accidental exposure to operators or damaging the workpiece or other equipment.

- Cooling System Failure: Laser marking machines generate substantial heat, especially with high-powered lasers. A malfunction in the cooling system can lead to overheating, which may cause the machine to shut down automatically or, worse, cause a fire or component failure.

- Electrical Failures or Power Surges: Laser marking systems rely on precise electrical systems to control various components. Any malfunction or power surge can result in erratic system behavior, failure to power off, or other safety risks.

- Safety Shutdown Procedures for Machine Malfunctions:

- Immediate Power Off: Upon noticing any malfunction, operators should immediately power off the laser marking system using the emergency shutoff button or the main power switch to cut off power to all components of the machine.

- Disconnect Power Supply: If an electrical malfunction is suspected or there is any risk of electrical shock, operators should ensure that the power supply is disconnected from the machine. Lock-out/tag-out procedures should be followed to ensure that the system cannot be inadvertently reactivated.

- Cooling System Inspection: In the event of a cooling system malfunction, operators should follow the manufacturer’s guidelines for safely shutting down the machine. Ensure that the system is allowed to cool down completely before any inspection or maintenance takes place.

- Notify Maintenance Personnel: After the system is powered down, maintenance or technical personnel should be notified immediately to assess the issue. No repairs or troubleshooting should be performed until the system has been safely shut down, and the area is secure.

Evacuation Procedures

Evacuation Protocols Include:

- Activate Alarm Systems: If the emergency is severe enough to require evacuation, the operator or designated personnel should activate the facility’s emergency alarm system to alert all workers of the need to evacuate. This system should be loud enough to be heard throughout the workplace.

- Follow Pre-Established Evacuation Routes: Facilities should have pre-established evacuation routes that are clearly marked and free of obstructions. Employees should be trained in these routes and know where to assemble once they have exited the building. Evacuation drills should be held regularly to ensure that everyone is familiar with the procedures.

- Evacuate Using Safe Exits: Operators and personnel should exit the building via designated safe exits. In case of fire, elevators should not be used, and personnel should instead take stairwells to avoid exposure to smoke or other hazards.

- Assembly Area: Once outside, personnel should proceed to a designated assembly area away from the building to ensure that everyone is accounted for. The assembly area should be a safe distance from the facility to avoid exposure to any ongoing hazards, such as toxic fumes or fires.

- Headcount and Reporting: A headcount should be conducted to ensure that everyone has evacuated the building. Any missing personnel should be immediately reported to emergency responders. Only trained personnel should attempt to re-enter the building or perform any hazardous activities after the emergency is under control.

Maintenance and Safety Checks

Routine Safety Inspections

Key Aspects of Routine Safety Inspections:

- Laser Marking System Components: The laser’s key components, such as the laser source, beam path, optics (lenses and mirrors), and focusing system, should be inspected for wear, misalignment, or damage. These components are essential for proper beam delivery, and any irregularities or damage can lead to inefficient or unsafe operation. Misaligned components can cause beam leakage, poor marking quality, or hazardous radiation exposure.

- Protective Barriers and Enclosures: The enclosures around the laser marking system must be regularly inspected to ensure they are intact and secure. These barriers prevent exposure to the laser beam and protect operators from harmful radiation. Safety doors, shields, and windows should be checked for cracks, damage, or wear that could compromise their ability to contain the laser’s energy. Interlocks, which prevent the system from operating if the enclosure is open, should also be tested regularly to ensure they are functioning correctly.

- Cooling Systems: Laser marking systems, particularly high-powered lasers, generate substantial heat. Cooling systems, whether air-cooled or liquid-cooled, must be checked to ensure that they are functioning properly. Blockages in air vents, leaks in liquid cooling lines, or malfunctioning pumps can lead to overheating and equipment damage, and increase the risk of fire. Regular checks of coolant levels, temperature readings, and airflow should be conducted to avoid overheating.

- Electrical and Safety Circuits: Regular inspections of the electrical components, including wiring, power supplies, and safety circuits, are essential to prevent electrical malfunctions. Any exposed wires or damaged insulation should be repaired immediately. Circuit breakers, emergency shutoff switches, and fuses should be inspected to ensure they function correctly in the event of an emergency.

Laser System Maintenance

Key Maintenance Practices:

- Cleaning and Replacing Optical Components: Dust, debris, and contaminants can interfere with the laser’s beam quality and effectiveness. Regular cleaning of lenses, mirrors, and other optical components is necessary to prevent buildup that could affect the precision of the laser marking. Cleaning should be performed using appropriate tools and methods to avoid scratching or damaging delicate surfaces. Over time, optical components may degrade or become damaged, requiring replacement to maintain the system’s performance.

- Laser Source Maintenance: The laser source itself requires periodic checks and maintenance. Depending on the type of laser used, this may involve recalibration, cleaning, or even replacement of the laser diode or gas-filled tube. Regular checks for signs of degradation in the laser source, such as power drops or inconsistent marking, are necessary to prevent performance issues.

- Cooling System Maintenance: The cooling system, crucial for preventing overheating, should be regularly maintained by checking coolant levels, inspecting hoses for leaks, and cleaning air filters. For liquid cooling systems, the coolant should be replaced periodically, and the system should be flushed to remove any contaminants. Air-cooled systems require cleaning of fans and heat exchangers to maintain efficient heat dissipation.

- Moving Parts and Mechanical Systems: Laser marking systems often include mechanical parts such as motors, guides, and moving stages. These parts should be lubricated regularly and checked for wear or damage. Proper maintenance ensures smooth and precise movement of materials or the laser head, which is essential for high-quality marking.

- System Calibration: Periodically, the laser marking system should be recalibrated to ensure that it operates within the desired tolerances. Calibration includes checking the alignment of the laser beam, verifying the accuracy of the marking process, and ensuring that all settings, including laser power, speed, and frequency, are optimized for the materials being processed. Misalignment or incorrect settings can affect marking quality and lead to inefficiencies or safety hazards.

Documentation and Record-Keeping

Key Aspects of Documentation and Record-Keeping:

- Maintenance Logs: Every maintenance activity should be recorded in a maintenance log, including routine checks, repairs, replacements, and calibrations. This log provides a detailed history of the machine’s performance, helping operators and maintenance personnel track recurring issues or assess the overall condition of the equipment.

- Inspection Reports: Safety inspections should also be documented. Reports should include details of the inspections performed, any issues identified, and corrective actions taken. These reports are valuable for monitoring safety performance and ensuring that the laser marking system meets safety standards.

- Calibration Records: Calibration procedures should be logged to verify that the system is operating within the required parameters. These records help ensure that the laser continues to provide accurate and high-quality markings and that the system remains in compliance with industry standards.

- Compliance Documentation: In some industries, laser marking systems must comply with strict regulatory requirements. Keeping a record of compliance checks and safety certifications ensures that the system meets the necessary standards and helps avoid legal or regulatory issues.

- Operator Training Records: Ensuring that operators are properly trained is essential for maintaining safety and efficiency. Documentation of all training activities, including initial training, refresher courses, and certification, helps to ensure that all operators are qualified to use the system safely.