Understanding Pad Printing

What Is Pad Printing

Pad printing (also known as tampography) is a printing technique where a soft silicone pad transfers ink from an etched plate to the object’s surface. The flexibility of the silicone pad allows it to conform to surface irregularities, enabling printing on:

- Spherical, cylindrical, concave, or convex objects

- Textured, rough, or delicate materials

- Small, detailed areas that require precision

History and Development

Pad printing evolved from techniques used in watchmaking in the mid-20th century, where delicate watch dials required precise marking. Early systems used gelatin pads and were entirely manual. Key milestones include:

- 1960s–1970s: Industrial adaptation of the process for toys, electronics, and automotive components.

- 1980s: Introduction of silicone rubber pads, which improved durability, flexibility, and ink transfer quality.

- 1990s: Automation and semi-automation made pad printing viable for mass production.

- 2000s–Present: Advancements in ink chemistry, pad materials, and CNC-etched plates increased print quality and adhesion. Integration with robotics and automated feeders allows pad printing to be part of high-speed production lines.

Working Principle

Pad printing transfers an image in several stages:

- Plate Preparation: The image is etched into a flat steel or photopolymer plate (cliché).

- Ink Application: Ink is spread over the plate, filling the etched image area.

- Doctoring: A doctor’s blade removes excess ink, leaving ink only in the etched recess.

- Ink Pick-up: A silicone pad presses onto the plate, compressing to pick up the ink from the etched image.

- Ink Transfer: The pad moves to the substrate and presses down, releasing the ink and forming the printed image.

- Curing: Depending on the ink type, the print may air-dry, heat-cure, or UV-cure.

Key Components

- Pad: Made of silicone rubber; available in different shapes, hardness levels, and sizes to suit the product surface.

- Cliché (Printing Plate): Steel or photopolymer plate with the image etched into it; determines the design’s detail and sharpness.

- Ink Cup / Doctor Blade System: Holds the ink and removes excess from the plate; can be open-ink well or sealed ink cup systems.

- Ink: Formulated for specific substrates; may require pre-treatment for adhesion.

- Printing Machine: Manual, semi-automatic, or fully automatic pad printing systems.

- Curing Equipment: Air-drying racks, infrared heaters, or UV curing systems.

Advantages of Pad Printing

- Prints on Complex Shapes: Can decorate surfaces that are spherical, cylindrical, textured, or recessed.

- Versatility in Materials: Works on plastic, metal, glass, ceramics, rubber, wood, and more.

- Fine Detail and Precision: Capable of reproducing intricate patterns, small fonts, and sharp lines.

- Multi-Color Printing: By sequentially printing with different pads and plates, complex multi-color designs can be achieved.

- Cost-Effective for Small to Medium Runs: Especially for items that cannot be printed by other methods.

- Gentle on Substrates: Low pressure prevents damage to delicate or fragile items.

Disadvantages of Pad Printing

- Limited Print Area: Not ideal for large surface coverage compared to screen or digital printing.

- Slower for High-Volume Large-Format Work: Multiple passes are required for multi-color prints.

- Pad Wear and Maintenance: Pads eventually degrade and must be replaced; ink cups and clichés require regular cleaning.

- Ink Limitations: Adhesion may require pre-treatment (e.g., flame or corona treatment for plastics).

- Less Durable than Laser Marking: Prints can wear off over time, especially under heavy use or exposure to harsh environments.

Applications of Pad Printing

Pad printing is used across numerous industries, including:

- Consumer Goods: Logos on promotional items, toys, sports equipment (e.g., golf balls).

- Electronics: Labels on buttons, keyboards, and control panels.

- Medical Devices: Markings on syringes, vials, and surgical instruments.

- Automotive: Symbols and labels on dashboards, knobs, and gear shifts.

- Industrial Equipment: Scale markings on gauges and tools.

- Packaging: Decorative and branding prints on caps, bottles, and containers.

- Household Items: Patterns on kitchenware, appliances, and decorative objects.

Understanding Laser Marking

What Is Laser Marking

Laser marking involves the direct application of a laser beam to the surface of a material to create text, codes, graphics, or images. The energy from the laser induces thermal, chemical, or physical changes to the substrate. Depending on the material and laser parameters, this can result in:

- Color change (oxidation, carbonization, or foaming)

- Surface removal (ablation of coatings or layers)

- Depth marking (engraving for tactile marks)

- Texture modification (matte vs. glossy finishes)

History and Development

The concept of laser marking became possible after Theodore Maiman invented the first working laser in 1960. Early systems were bulky, expensive, and limited to research and military applications. Key milestones in development include:

- 1970s–1980s: CO2 lasers were adapted for industrial marking, primarily on plastics, wood, and certain metals.

- 1990s: Fiber lasers revolutionized marking with high beam quality, longer lifespans (up to 100,000 hours), and lower maintenance needs. This enabled mass production applications in electronics, automotive, and medical device industries.

- 2000s onward: UV lasers allowed cold marking, essential for delicate materials like glass and certain plastics. Software-controlled galvo scanning heads made high-speed, high-resolution marking possible.

- Today: Laser marking integrates with Industry 4.0 systems, allowing automated, traceable, and real-time marking in fully connected production lines.

Working Principle

The laser marking process involves energy transfer from the laser beam to the workpiece. Steps include:

- Laser Generation: The laser source (fiber, CO2, UV) emits coherent light at a specific wavelength (e.g., fiber lasers at ~1064 nm).

- Beam Guidance: Mirrors and galvanometer scanners steer the beam precisely.

- Focusing: Lenses condense the beam into a tiny spot (often <30 μm in diameter) to maximize energy density.

- Material Interaction: Depending on the laser settings:

- Annealing: Controlled heating causes surface oxidation for a visible mark without removing material.

- Etching/Engraving: Melts or vaporizes the surface for depth marking.

- Ablation: Removes coatings or surface layers without damaging the substrate.

- Mark Formation: The pattern, text, or image is shaped by the scanning head based on digital input from the control software.

Key Components

- Laser Source: Determines wavelength and suitability for different materials.

- Fiber lasers for metals and high-contrast plastics.

- CO2 lasers for organics, glass, and ceramics.

- UV lasers for sensitive materials, cold marking.

- Beam Delivery System: Galvanometer mirrors for fast beam steering, focusing lenses, and protective glass windows.

- Control System: Software for layout design, marking parameters, and automation integration.

- Cooling System: Air-cooled for lower power; water-cooled for high-power continuous operation.

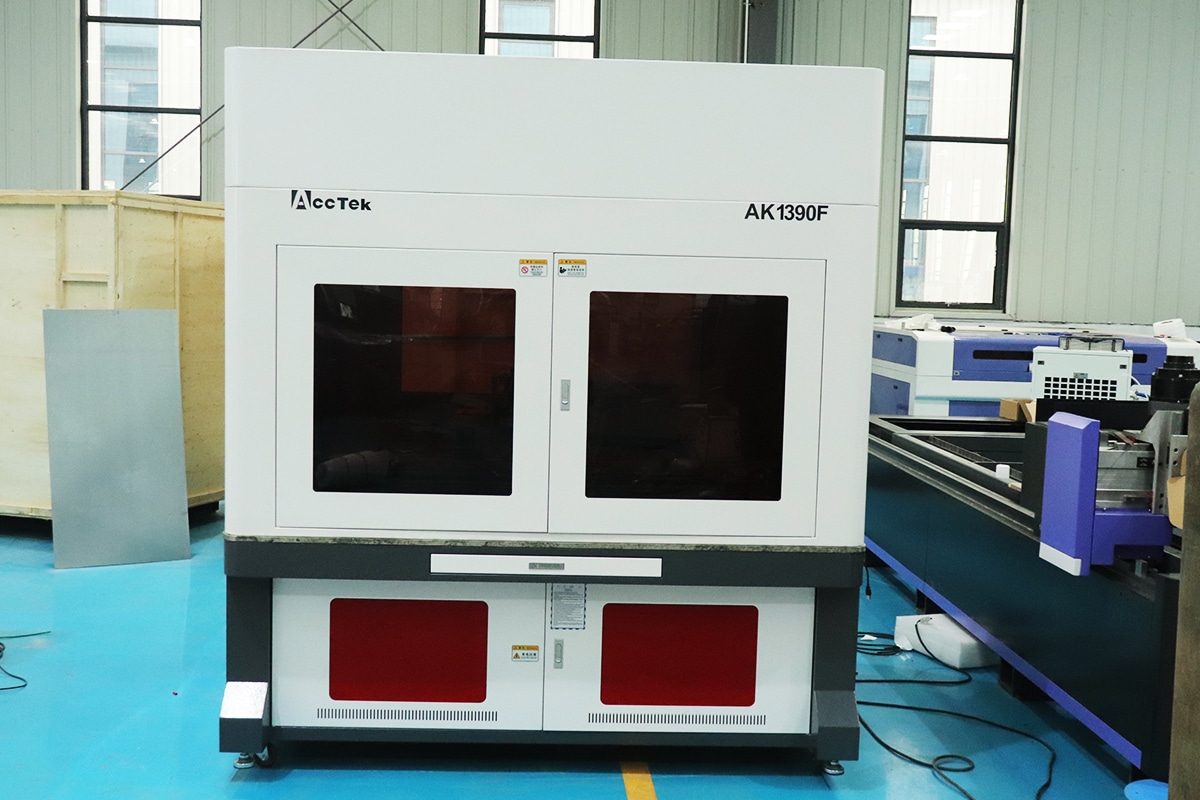

- Safety Enclosure: Shields operators from harmful radiation; may include fume extraction.

Types of Laser Marking

- Laser Engraving: Deep material removal for tactile, wear-resistant marks; ideal for metal tools and plaques.

- Laser Etching: Shallow melt and resolidification; faster than engraving; used for product identification.

- Laser Annealing: Color change via oxide layer creation, mainly for stainless steel and titanium, without damaging the surface.

- Laser Foaming: Creates raised, light-colored marks on plastics through micro-bubble formation.

- Carbonization: Produces dark marks by burning away lighter elements, common in organic materials.

- Ablation: Selectively removes thin layers like paint, anodizing, or plating to reveal a contrasting layer.

Advantages of Laser Marking

- Extreme Precision: Micron-level accuracy for fine details and microtext.

- Permanent and Durable: Resistant to fading, chemicals, heat, and abrasion.

- Wide Material Range: From stainless steel and aluminum to plastics, ceramics, and glass.

- High Speed and Automation: Suited for mass production with minimal downtime.

- Eco-Friendly: No inks, solvents, or consumables; low waste.

- Minimal Maintenance: Especially with fiber lasers, which have no moving parts in the laser source.

Disadvantages of Laser Marking

- High Initial Cost: Entry-level fiber laser systems often start at several thousand dollars.

- Material Limitations: Some reflective metals (e.g., copper, gold) require specific wavelengths or surface preparation.

- Possible Heat Effects: Can cause micro-cracking, warping, or discoloration if parameters are not optimized.

- Training Requirements: Operators must understand laser safety, software, and maintenance.

Applications of Laser Marking

- Electronics: QR codes, barcodes, and serial numbers on circuit boards, microchips, and housings.

- Automotive: VINs, component tracking, and branding on engine parts.

- Medical Devices: Non-toxic, sterilizable marks on surgical tools, implants, and instruments.

- Aerospace: High-contrast marks on turbine blades, fasteners, and control panels.

- Jewelry & Luxury Goods: Intricate engraving on precious metals and anti-counterfeit micro-marking.

- Packaging Industry: Expiration dates, batch codes on food, beverage, and pharmaceutical packaging.

- Industrial Tools: Deep engraving for permanent identification of cutting tools and dies.

- Creative Design: Customized gifts, promotional items, and decorative patterns.

Marking Quality and Resolution

Pad Printing

Pad printing can achieve fine detail and intricate designs due to the precision of the etched plate (cliché) and the flexibility of the silicone pad.

- Resolution: Typical resolution can reach up to 150–200 lines per inch (LPI), which is sufficient for small text, logos, and complex graphics. Very fine lines (~0.05 mm) are possible under ideal conditions.

- Quality Influences: Image sharpness depends on:

- Pad hardness and shape: Softer pads conform better to irregular shapes but may slightly reduce sharpness.

- Ink viscosity and formulation: Affects line definition and edge clarity.

- Surface preparation: Untreated or contaminated surfaces can cause blurring or incomplete ink transfer.

- Environmental conditions: Temperature and humidity can influence ink behavior during transfer.

- Visual Appearance: Pad printing produces vivid, opaque colors and can print multi-color designs by using sequential passes. Colors can be matched to Pantone standards, making it ideal for branding.

- Limitations: Although the initial print quality is high, edge definition may degrade over time with repeated printing, and printed marks can wear off in harsh environments. Achieving microtext or high-resolution QR codes is challenging because the ink transfer process can cause slight spreading or distortion.

Laser Marking

Laser marking delivers exceptionally high resolution and consistent quality because it directly modifies the material surface without using ink or physical contact.

- Resolution: Modern fiber and UV laser systems can achieve resolutions up to 1,000 DPI or higher, with line widths as small as 10–20 microns. This makes it possible to produce microtext, high-density barcodes, and intricate vector graphics.

- Quality Influences: Mark’s quality depends on:

- Laser type and wavelength: UV lasers excel at fine detail on plastics; fiber lasers are optimal for metals.

- Focusing optics: High-quality lenses and precise beam alignment maintain sharpness.

- Material properties: Some materials yield higher contrast marks (e.g., anodized aluminum vs. polished stainless steel).

- Parameter optimization: Power, pulse frequency, and scanning speed must be tuned to avoid overheating or poor contrast.

- Visual Appearance: Laser marks have crisp edges and high contrast, especially on metals and coated surfaces. They are permanent, wear-resistant, and chemical-resistant. While multi-color printing is not possible, certain lasers can produce color annealing effects on metals for decorative purposes.

- Limitations: Lasers generally cannot replicate the same full-color graphics achievable with pad printing. On certain reflective or transparent surfaces, additional treatment may be needed for optimal readability.

Material Compatibility

Pad Printing

Pad printing is one of the most material-flexible printing methods because it is an indirect transfer process using specially formulated inks.

- Compatible Materials

- Plastics: ABS, polycarbonate, polypropylene, polyethylene, PVC, acrylic, nylon (often with surface pretreatment such as flame, corona, or plasma to improve adhesion).

- Metals: Aluminum, stainless steel, brass, steel (with or without coatings).

- Glass and Ceramics: Requires appropriate ink systems and curing methods.

- Rubber and Silicone: Specialized inks for flexible or low-surface-energy substrates.

- Wood and Leather: Can be printed with proper ink formulation and drying techniques.

- Advantages in Compatibility

- Works well on coated or painted surfaces.

- Can handle delicate or flexible materials without distortion.

- Performs reliably on curved, textured, or irregular shapes where direct printing or engraving methods fail.

- Limitations

- Ink adhesion may be poor on very smooth, non-porous materials without pretreatment.

- Exposure to heat, solvents, or abrasion can degrade print quality.

- Different inks are needed for different substrates, which can increase production complexity.

Laser Marking

Laser marking relies on direct interaction between a focused laser beam and the substrate to alter its surface. Compatibility depends on the laser type, wavelength, and material properties.

- Compatible Materials

- Metals: Stainless steel, aluminum, brass, copper, titanium, gold, silver, and more; suitable for deep engraving, annealing, or color marking (with specific parameters).

- Plastics: ABS, polycarbonate, polyethylene, polypropylene, acrylic, and others; certain additives or pigments can improve contrast.

- Ceramics and Glass: With proper laser type (often UV lasers) to prevent cracking.

- Coated or Painted Surfaces: Can ablate the top layer to reveal a contrasting underlayer.

- Advantages in Compatibility

- Produces high-contrast, permanent marks on metals without additional consumables.

- Works well on coatings and layered materials for precise logo or code removal.

- Can mark delicate materials without mechanical stress.

- Limitations

- Transparent or highly reflective materials (e.g., glass, copper) can require special wavelengths, coatings, or pretreatment to achieve high contrast.

- Some heat-sensitive plastics may discolor or deform if parameters are not carefully optimized.

- Limited in producing multi-color marks compared to pad printing.

In terms of material compatibility, pad printing offers unmatched flexibility across an extremely wide range of substrates, including delicate, flexible, or irregularly shaped objects. It adapts well to different surfaces with the right ink and curing method, though adhesion and durability can vary. Laser marking, while slightly more selective in material choice, excels on metals, coated surfaces, and certain plastics—producing permanent, high-contrast marks without consumables. The choice ultimately depends on the production needs:

- For a broad substrate variety and complex geometries, pad printing is generally more adaptable.

- For permanent, high-contrast marking on metals and specific plastics, laser marking is the superior option.

Process Characteristics

Pad Printing

Pad printing is an indirect offset printing process that transfers an image from an etched plate (cliché) to a substrate using a silicone pad.

- Nature of the Process

- Contact Method: The silicone pad physically touches both the cliché and the substrate, transferring ink.

- Ink-Based: Uses solvent-based, UV-curable, or specialty inks tailored to the substrate.

- Two-Step Transfer: Ink is first picked up from the plate, then deposited on the workpiece.

- Adaptability

- Can print on curved, textured, or recessed surfaces.

- Easily handles multi-color graphics by using multiple pads or passes.

- Pad shape, hardness, and size can be customized for different applications.

- Setup and Operation

- Requires plate engraving, ink mixing, and pad alignment before production.

- Changeovers between designs or colors require pad and ink system cleaning, which adds downtime.

- Key Process Traits

- Excellent for small to medium production runs.

- Can achieve fine detail but may face slight resolution loss on highly contoured surfaces.

- Dependent on ink adhesion and curing for long-term mark quality.

Laser Marking

Laser marking is a non-contact process that uses concentrated laser energy to modify the surface of a material.

- Nature of the Process

- Non-Contact Method: The beam does not physically touch the substrate, eliminating tool wear.

- Direct Material Interaction: Marking is achieved by engraving, annealing, foaming, ablation, or color change, depending on parameters and material.

- Computer-Controlled: Highly programmable for pattern design, positioning, and variable data (e.g., serial numbers, QR codes).

- Adaptability

- Capable of marking flat, slightly curved, or coated surfaces with precision.

- Handles variable data marking without physical retooling.

- Not ideal for very deep recesses or extremely irregular surfaces due to focus limitations.

- Setup and Operation

- Minimal setup—designs are loaded via software, and the machine requires little adjustment between jobs.

- Changeovers between designs are instantaneous with digital file changes.

- Key Process Traits

- High repeatability and precision with micron-level control.

- Works efficiently for low to high production volumes, especially in automated lines.

- Produces permanent, wear-resistant marks without consumables.

In terms of process characteristics, pad printing offers unmatched flexibility for multi-color, irregular surface, and decorative applications, but requires more manual preparation, consumables, and downtime for changeovers. Laser marking, on the other hand, delivers fast, precise, and permanent marks with minimal setup and no consumables, making it ideal for high-volume or variable-data production. The decision comes down to priorities:

- Pad Printing: Best for colorful designs, complex geometries, and moderate runs.

- Laser Marking: Best for permanent, high-precision, and automated marking with minimal operational interruption.

Quality and Durability

Pad Printing

Pad printing is valued for its color versatility and adaptability to complex shapes, making it ideal for decorative and branding purposes.

- Quality

- Can reproduce fine details, gradients, and multi-color images.

- Capable of printing small text, logos, and intricate patterns on flat or irregular surfaces.

- Color matching can be tailored to Pantone or custom specifications, allowing precise brand consistency.

- Durability

- Durability depends on the bond between ink and substrate.

- Susceptible to scratching, chipping, or fading from mechanical abrasion or UV exposure.

- Performance can degrade in harsh environments (e.g., outdoors, chemical exposure) unless protected.

Laser Marking

Laser marking delivers exceptional precision and permanence because the mark is formed by directly modifying the material’s surface.

- Quality

- Produces ultra-sharp edges and micron-level detail, ideal for microtext, barcodes, and data matrix codes.

- High contrast on metals, coated materials, and certain plastics.

- Fully computer-controlled for consistency across production runs.

- No risk of smudging, bleeding, or misalignment.

- Durability

- Marks are permanent and resist abrasion, chemicals, solvents, heat, and UV light.

- Ideal for medical, aerospace, automotive, and industrial components where traceability and safety compliance are critical.

- Longevity is tied to the durability of the base material itself—if the material remains intact, so does the mark.

- On softer or heat-sensitive plastics, depth and energy settings must be optimized to prevent degradation or fading under extreme wear.

When comparing quality and durability, the core trade-off is between visual flexibility and long-term resilience:

- Pad Printing: Best for color-rich, decorative, and multi-surface designs, with excellent initial visual quality but limited durability under extreme conditions without protective measures.

- Laser Marking: Delivers unmatched permanence and precision, maintaining legibility for the product’s lifetime, but is limited in color variety and suited mainly for single-color or high-contrast designs.

Color Capability

Pad Printing

Pad printing is renowned for its full-color versatility and precise color-matching capabilities.

- Color Range

- Can reproduce solid colors, gradients, and halftones.

- Capable of matching brand-specific shades using Pantone Matching System (PMS) or custom color mixing.

- Supports opaque, metallic, fluorescent, and specialty inks.

- Multi-Color Printing

- Multiple colors can be applied in sequence using separate clichés (plates) and pads.

- Complex designs with three or more colors are achievable with proper registration and alignment.

- Multi-station pad printing machines can automate multi-color application for higher efficiency.

- Quality and Consistency

- Produces rich, vibrant prints on a variety of materials, including plastics, metals, ceramics, and glass.

- Consistency depends on careful ink mixing, viscosity control, and pad condition.

- Limitations

- Color alignment (registration) must be precisely controlled; misalignment can occur if pads or substrates shift.

- Requires additional time and setup for each color, increasing production complexity.

- Printed colors may fade over time without protective coatings, especially under UV exposure.

Laser Marking

Laser marking generally offers limited color capability because it does not apply pigments—it modifies the material’s surface to create contrast.

- Color Range

- Most commonly produces single-color marks—black, gray, white, or shades created by varying depth and texture.

- The exact color depends on material type, laser wavelength, and marking method (e.g., engraving, annealing, ablation).

- Special Color Effects

- Certain materials, like stainless steel and titanium, can produce oxide-layer interference colors (blues, golds, purples) using precise annealing.

- Some plastics can yield contrasting or dark marks if additives or pigments are present in the substrate.

- These effects require high process control and may not be practical for high-volume multi-color requirements.

- Quality and Consistency

- Laser marks are extremely consistent in tone and sharpness because they are digitally controlled.

- No ink means no color fading due to pigment breakdown, though contrast may vary depending on material surface changes over time.

- Limitations

- Not suitable for full-color photographic images or designs requiring multiple vibrant colors.

- True multi-color output is limited to specific materials and specialized processes, which can be slower and more expensive.

Speed and Throughput

Pad Printing

Pad printing is well-suited for medium to high-volume production, but its speed is influenced by the number of colors and the required setup for each run.

- Marking Speed

- Simple, single-color designs can be applied in less than a second per item on high-speed machines.

- Multi-color prints require multiple passes or stations, which increases cycle time.

- Throughput Potential

- Multi-station pad printing systems can print multiple colors in quick succession, reaching several hundred to over a thousand pieces per hour, depending on complexity.

- Highly adaptable to semi-automated and fully automated lines, especially for products requiring alignment fixtures.

- Changeover Time

- Color changes and design swaps require pad cleaning, cliché replacement, and ink mixing, which can take several minutes to over an hour depending on complexity.

- Limitations

- Each additional color slows the process.

- Ink curing (air, heat, or UV) may add extra time before handling or packaging.

- Physical contact between pad and substrate limits maximum speed compared to fully non-contact processes.

Laser Marking

Laser marking excels in fast, consistent marking, especially for single-color, variable-data, or high-detail applications.

- Marking Speed

- Can mark simple text or codes in fractions of a second.

- High-speed galvanometer scanning systems can process dozens to hundreds of items per minute, depending on mark size and content.

- Throughput Potential

- Non-contact process eliminates delays from mechanical alignment or ink transfer.

- Capable of marking products while moving on conveyor systems (on-the-fly marking), maintaining continuous production flow.

- Changeover Time

- Instant changeovers—designs are switched digitally via software without hardware changes.

- Ideal for short runs, variable data, or serialized marking with no impact on speed.

- Limitations

- Marking time increases with larger areas, complex graphics, or deep engraving.

- For full-color or decorative marks, laser processes are generally slower and more complex than single-pass pad printing.

In speed and throughput, the choice depends on production requirements:

- Pad Printing: Highly efficient for simple, repetitive designs and multi-color decorative work, especially when integrated into multi-station setups. However, throughput drops with more colors and design changes due to setup time and curing needs.

- Laser Marking: Offers the fastest cycle times for single-color, variable-data, or high-detail applications with virtually no setup delays between jobs. Ideal for just-in-time manufacturing and serialized marking in continuous production lines.

Cost Considerations

Pad Printing

Pad printing is generally more accessible in terms of startup cost, but it comes with continuous consumables and labor expenses.

- Initial Investment

- Entry-level manual or semi-automatic machines start at a few thousand dollars, with industrial multi-color systems costing more.

- Additional investment for cliché-making equipment, pads, and curing systems may be required.

- Consumable Costs

- Inks, thinners, and additives must be replenished regularly.

- Pads and clichés wear over time and need replacement—lifespan varies with usage and substrate type.

- Protective coatings or varnishes may add extra cost for durability.

- Maintenance

- Requires routine cleaning of pads, ink cups, and plates to maintain print quality.

- Pad and plate replacement is a recurring operational cost.

- Operational Efficiency

- Setup time for color changes or new designs adds labor cost.

- Multi-color jobs consume more ink and increase per-unit labor cost.

- Cost Profile

- Best suited for low to medium-volume production or applications requiring multi-color branding.

- Lower machine cost but higher ongoing consumables and labor expenses compared to laser marking.

Laser Marking

Laser marking requires a larger upfront investment but offers significant savings over time due to its non-contact, consumable-free process.

- Initial Investment

- Industrial-grade fiber, CO2, or UV laser marking machines typically range from several thousand to tens of thousands of dollars, depending on power, wavelength, and automation features.

- Additional costs may include fume extraction systems, safety enclosures, and integration into production lines.

- Consumable Costs

- Virtually no consumables—no inks, pads, or plates.

- Occasional lens cleaning and rare replacement of optical components may be needed.

- Maintenance

- Fiber lasers have a lifespan of up to 100,000 hours with minimal servicing.

- Lower operator labor for cleaning or setup compared to pad printing.

- Operational Efficiency

- Instant design changes via software—no downtime for physical adjustments.

- High-speed marking reduces labor costs per unit in large production runs.

- Cost Profile

- Best suited for medium to high-volume production, especially where marks must be permanent.

- Higher capital cost but lower total cost of ownership over the machine’s life.

From a cost perspective:

- Pad Printing offers lower startup costs, making it attractive for smaller businesses or those with limited budgets. However, ongoing expenses for inks, pads, plates, and labor can make it more expensive in the long term—especially in high-volume production.

- Laser Marking requires a larger upfront investment but offers minimal recurring costs, reduced labor requirements, and high throughput, often delivering a better long-term ROI for large-scale or permanent marking applications.

Environmental and Safety Factors

Pad Printing

Pad printing involves inks, solvents, and physical contact, which have environmental and safety implications.

- Environmental Impact

- Chemical Use: Uses solvent-based or UV-curable inks that may emit volatile organic compounds (VOCs), contributing to air pollution.

- Consumable Waste:Pads, clichés, and excess ink create waste that requires proper disposal.

- Cleaning Agents: Solvent-based cleaning fluids may pose hazards if not handled and disposed of properly.

- Recycling Challenges: Ink-contaminated materials often cannot be recycled without specialized processing.

- Safety Considerations

- Chemical Exposure: Operators may be exposed to fumes and skin contact with inks or cleaning solvents.

- Protective Equipment: Gloves, masks, and adequate ventilation are essential to minimize health risks.

- Ergonomic Factors: Manual operations and repetitive motions can lead to strain injuries.

- Regulatory Compliance

- Facilities may need to comply with VOC emission limits, hazardous waste handling rules, and chemical safety standards (e.g., OSHA, REACH).

Laser Marking

Laser marking is a non-contact, consumable-free process, making it more environmentally friendly overall, but it introduces other safety considerations.

- Environmental Impact

- No Inks or Chemicals: Eliminates VOC emissions and reduces waste.

- Minimal Consumables: No pads, clichés, or ink containers to dispose of.

- Energy Efficiency: Modern fiber lasers are highly efficient, though high-power systems consume more energy.

- Fume Generation: Material vaporization can release particulates or fumes, which must be captured by fume extraction systems to prevent environmental release.

- Safety Considerations

- Laser Radiation Hazard: Direct or reflected beams can cause severe eye or skin injury.

- Protective Measures: Requires enclosed systems or safety interlocks, laser safety eyewear, and trained operators.

- Fume and Particle Safety: Vapors from certain materials may be toxic (e.g., PVC), requiring proper filtration.

- Regulatory Compliance

- Must meet laser safety standards (e.g., IEC 60825, ANSI Z136) and local workplace health regulations.

- Some industries require proof of fume extraction efficiency and safe handling of hazardous emissions.

From an environmental and safety perspective:

- Pad Printing: Has a larger environmental footprint due to inks, solvents, VOC emissions, and consumable waste. Operator safety requires chemical handling precautions, ventilation, and PPE.

- Laser Marking: Is more eco-friendly due to its consumable-free nature, but requires strict laser safety controls and effective fume extraction.

Choosing Between Pad Printing and Laser Marking

When to Choose Pad Printing

Pad printing is the preferred solution when color versatility, surface adaptability, and decorative appeal are key priorities.

- Best For

- Multi-color graphics: Ideal for branding, decorative logos, and promotional products requiring vibrant, Pantone-matched colors.

- Complex shapes and textures: Works exceptionally well on spherical, cylindrical, concave, convex, or irregularly contoured surfaces.

- Mixed material runs: Flexible enough to print on plastics, metals, glass, ceramics, rubber, and more with appropriate inks and pretreatments.

- Small to medium production runs: Offers a cost-effective setup for runs where high initial equipment costs are a concern.

- Advantages in Context

- Ability to print fine details and artistic designs that lasers cannot reproduce in full color.

- Compatible with both smooth and textured finishes without compromising ink transfer.

- Considerations

- Requires consumables (inks, pads, plates) and more frequent maintenance.

- Marks are less durable in harsh environments without protective coatings.

- Longer changeover times for new designs or colors compared to laser marking.

When to Choose Laser Marking

Laser marking is the optimal choice when permanence, precision, and efficiency are the top priorities.

- Best For

- High-detail, high-precision marks: Perfect for serial numbers, barcodes, QR codes, microtext, and compliance markings.

- Permanent identification: Applications where marks must resist wear, chemicals, UV light, and extreme temperatures (e.g., medical, aerospace, automotive).

- High-volume, automated production: Digital control allows fast changeovers and on-the-fly marking for continuous manufacturing lines.

- Variable data: Easily handles sequential numbering, date codes, and custom patterns without slowing down production.

- Advantages in Context

- Consumable-free: Lower long-term operating costs and reduced environmental footprint.

- Consistent mark quality across thousands or millions of parts.

- Considerations

- Higher upfront cost for equipment.

- Limited in color variety, primarily producing high-contrast, single-color marks (unless specialized materials and techniques are used).

- Some materials require pretreatment or specific laser wavelengths for optimal results.

The decision between pad printing and laser marking hinges on whether the project prioritizes aesthetic flexibility or functional permanence:

- Choose Pad Printing if your design demands full-color graphics, branding flexibility, and the ability to print on complex, irregular surfaces. It’s an excellent option for decorative applications, promotional products, and smaller production runs where vivid visual presentation matters more than extreme durability.

- Choose Laser Marking if you need permanent, precise, and high-contrast marks that withstand harsh environments, or if your operation values speed, minimal downtime, and low long-term maintenance costs. It’s best for industrial, traceability, and compliance-driven applications where mark longevity is critical.