Product Introduction

Types of Multi-Head CNC Routers

-

AKM1325-4 CNC Router

Rated 4.50 out of 5$7,300.00 This product has multiple variants. The options may be chosen on the product page -

AKM1530-4 CNC Router

Rated 4.75 out of 5$7,900.00 This product has multiple variants. The options may be chosen on the product page -

AKM2030-4 CNC Router

Rated 5.00 out of 5$8,500.00 This product has multiple variants. The options may be chosen on the product page -

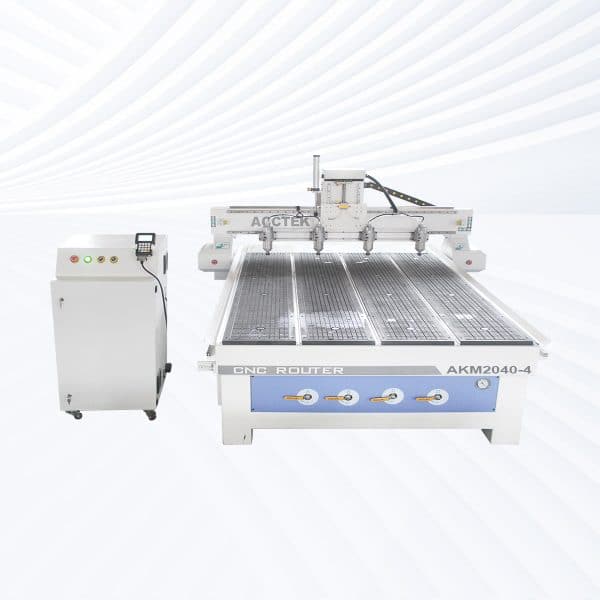

AKM2040-4 CNC Router

Rated 5.00 out of 5$9,000.00 This product has multiple variants. The options may be chosen on the product page -

AKM1325-4R CNC Router

Rated 4.75 out of 5$7,700.00 This product has multiple variants. The options may be chosen on the product page -

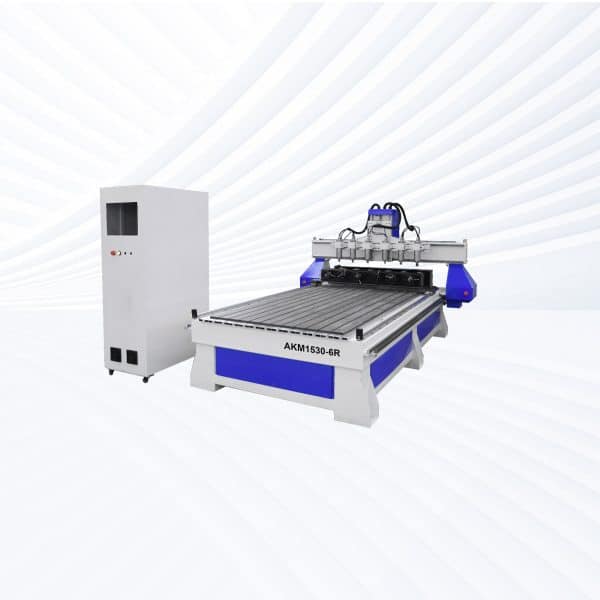

AKM1530-4R CNC Router

Rated 4.75 out of 5$8,300.00 This product has multiple variants. The options may be chosen on the product page -

AKM2030-4R CNC Router

Rated 5.00 out of 5$8,900.00 This product has multiple variants. The options may be chosen on the product page -

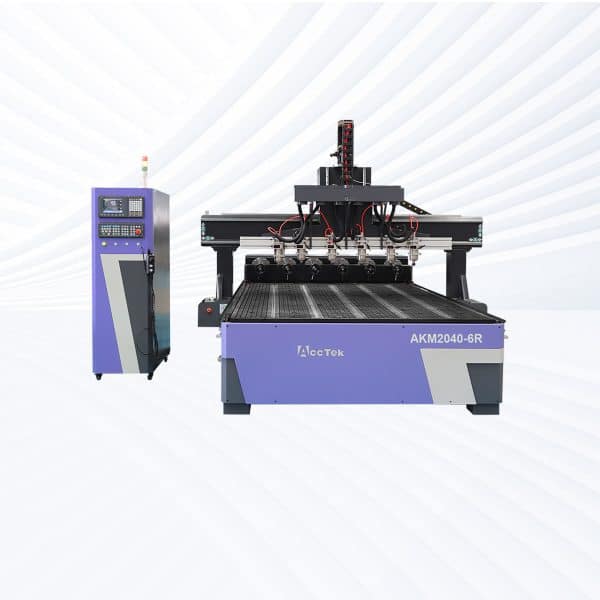

AKM2040-4R CNC Router

Rated 4.75 out of 5$9,100.00 This product has multiple variants. The options may be chosen on the product page

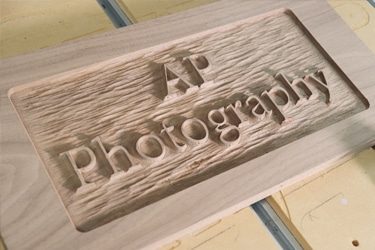

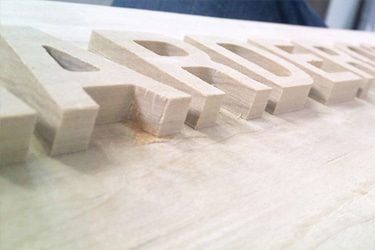

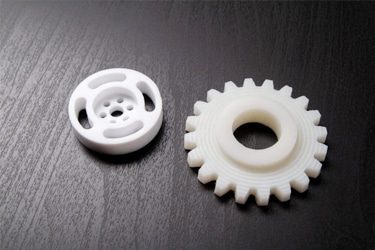

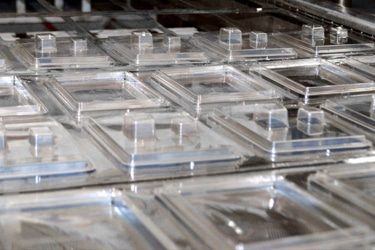

Application of Multi-Head CNC Routers

Customer Testimonials

Multi-Head CNC Routers VS Other Engraving Machines

| Comparison Item | Multi-Head CNC Router | Laser Engraving Machine | CNC Milling Center | CNC Lathe |

|---|---|---|---|---|

| Cutting Method | Rotary cutting with multiple spindles | Focused laser beam (non-contact) | Rigid rotary tool cutting | Rotating workpiece, fixed tool |

| Multi-Part Production | Yes, cuts multiple parts at once | No | No | No |

| Material Compatibility | Wood, MDF, acrylic, plastic, foam | Wood, plastic, coated metals | Metals, composites, plastics | Metals, plastics |

| Ideal Use | Mass production of identical parts | Surface marking, engraving | Precision metal part fabrication | Cylindrical part shaping |

| Axes of Movement | 3 axes | 2 to 3 axes | 3 to 5 axes | 2 axes (X, Z) |

| Tool Changes | Manual or semi-automatic | Not required | Manual or automatic | Manual |

| Setup Complexity | Moderate | Low | High | Medium |

| Machining Speed | Fast (parallel processing) | Very fast for surface jobs | Moderate | Fast for symmetrical work |

| Cutting Depth Capability | Moderate to deep | Shallow | Deep | Deep |

| Automation Compatibility | High | High | High | High |

| Tool Wear | Moderate | None | High | Medium |

| Maintenance Requirements | Medium | Low | High | Medium |

| Operating Cost | Low to moderate | Low | High | Moderate |

| Production Efficiency | Very high for batch work | Moderate | Moderate | Moderate |

| Application Range | Furniture, signage, and panel production | Tags, logos, surface graphics | Aerospace, automotive, molds | Shafts, bushings, cylindrical parts |

Why Choose Us

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

What Are The Risks of Using CNC Routers?

This article explores the various risks associated with using CNC routers, including mechanical, electrical, environmental, and human factors, along with ways to mitigate them.

What Are 4-Axis CNC Routers?

This article explains what 4-axis CNC routers are, how the swing-head A-axis works, and what advantages, applications, and considerations come with this advanced technology.

What Are 3-Axis CNC Routers?

This article explains what 3-axis CNC routers are, how they work, their key components, typical applications, benefits, limitations, and how to choose the right machine.

What Is CNC Routing?

Discover the fundamentals of CNC routing, its applications, advantages, challenges, and how advanced CNC technology enhances precision and efficiency across industries.

Frequently Asked Questions

How Do Multi-Head CNC Routers Work?

- Multiple Spindles on One Gantry: The CNC router has two or more spindles mounted on the same gantry, aligned in parallel. These spindles move together along the X, Y, and Z axes, but each can cut a separate part or area of the workpiece.

- Synchronized Operation: In most setups, all heads perform identical actions at the same time. For example, if you’re cutting four parts out of one sheet, each head mirrors the same toolpath across different zones.

- Increased Output: By machining multiple parts in one pass, multi-head CNC routers multiply production speed—ideal for batch production of identical parts like cabinet doors, signs, panels, or furniture components.

- Independent Tooling (Optional): Some advanced multi-head CNC routers have independent tool control, allowing each head to use a different bit or perform a different operation, useful for complex or multi-step jobs.

- Shared or Split Work Areas: The machine bed can be split into separate zones, each assigned to a spindle. This allows multiple parts to be cut from one large sheet or from separate materials loaded side-by-side.

- Programming and Setup: Toolpaths are programmed in CAM software, and then duplicated or assigned to different spindles in the machine control software. Some machines support manual spindle offset adjustment or automatic spacing calibration.

Multi-head CNC routers work by duplicating or dividing cutting tasks across multiple spindles—dramatically improving efficiency in high-volume or repetitive production. They’re ideal for businesses that need speed, consistency, and output without the complexity of multiple machines.

What Can Multi-Head CNC Routers Do?

- Cut Multiple Parts Simultaneously: Each spindle can perform the same operation on different sections of a single sheet or multiple smaller workpieces. Ideal for producing several identical parts in one pass—like signs, cabinet doors, or panels.

- Mass Production of Identical Designs: Multi-head CNC routers are perfect for batch manufacturing, where large quantities of the same part need to be made quickly and consistently.

- Mirror or Duplicate Toolpaths: The machine’s spindles follow the same G-code simultaneously, mirroring the motion across the machine bed. This saves time and ensures uniformity.

- Split-Zone Machining: Some machines can operate in independent work zones, allowing one zone to be loaded or unloaded while the other is cutting, minimizing downtime.

- Increase Output Without Extra Machines: A multi-head CNC router can replace several single-head machines, reducing the need for additional operators, space, and maintenance.

- Handle Wood, Plastics, and Some Metals: Depending on spindle power and rigidity, they can process a wide range of materials—wood, MDF, acrylic, PVC, and even soft metals like aluminum.

Multi-head CNC routers are productivity machines. They excel at making multiple identical parts quickly and accurately, making them ideal for woodworking shops, sign makers, furniture manufacturers, and any business focused on high-throughput fabrication.

How Much Do Multi-Head CNC Routers Cost?

This is a wise investment for shops that focus on high-volume, high-repeatability part production. They significantly reduce cycle time by increasing the output of a single operation without increasing labor or floor space.

What Materials Can Multi-Head CNC Routers Process?

- Wood

- Softwoods and Hardwoods: Pine, Oak, Maple, Walnut

- Engineered Wood: MDF, Plywood, Particleboard

- Plastics

- Acrylic

- PVC

- HDPE

- Polycarbonate

- Foam

- EVA Foam

- Rigid Foam

- Polyurethane Foam

- Composites (Light-Duty)

- Fiberglass

- Carbon Fiber

- Phenolic Panels

Multi-head CNC routers are best for cutting wood, plastic, foam, and light composites, with limited capability in non-ferrous metals like aluminum. Their strength lies in fast, repetitive processing—making them ideal for shops focused on batch production with consistent materials.

What Are The Disadvantages Of Multi-Head CNC Routers?

- Limited Flexibility: Most multi-head CNC routers are designed for synchronized cutting—all heads perform the same operation. This makes them great for batch production but not suitable for complex or varied jobs that require different toolpaths.

- Fixed Spindle Spacing (on basic models): Many models have fixed spacing between spindles, which limits the size and layout of workpieces. You’re locked into specific part dimensions unless the machine offers adjustable head positioning.

- Increased Machine Size: Adding more spindles increases the physical footprint of the machine. This can be a challenge in smaller workshops where space is limited.

- More Complex Setup and Calibration: You’ll need to align workpieces precisely under each spindle to avoid mismatches. Misalignment can lead to inconsistent cuts or part failure.

- Higher Upfront Cost: While more efficient long-term, multi-head CNC routers cost more than single-head machines, and may require more powerful control systems.

- Limited to Similar Operations: Because all heads typically use the same tool and cut the same path, you can’t perform multi-step machining (e.g., cut + engrave + drill) unless the machine is custom-configured or equipped with ATC.

- Maintenance Is Multiplied: More spindles = more parts to service. Bearings, belts, and collets wear out across all heads, and keeping everything in sync adds maintenance overhead.

Multi-head CNC routers are excellent for high-volume, repeatable jobs, but they sacrifice flexibility, require more space, and can be overkill for shops focused on custom or one-off work. Choose them when speed and part consistency outweigh the need for versatility.

What Are The Dangers Of Using Multi-Head CNC Routers?

- Greater Risk Area: Each spindle moves in sync, but if you’re working near the machine, the chance of contact with moving parts increases. More heads mean more potential points of injury if safety zones are ignored.

- Tool Breakage Across Multiple Heads: If one bit breaks or gets misaligned, the others may keep cutting, damaging materials, or creating a safety hazard if the machine isn’t immediately stopped.

- Increased Chance of Setup Errors: Misalignment in fixture setup under any spindle can cause crashes, inconsistent cuts, or flying debris if the tool digs into an improperly placed part.

- Electrical and Motor Hazards Multiply: More spindles mean more wiring, more motors, and more chances for faults. Improper maintenance or overloads can cause overheating or short circuits.

- Loud Operation and Debris Ejection: Running multiple spindles at once produces high noise levels and generates chips or dust at a faster rate. Without proper hearing protection and dust extraction, this can be dangerous.

- Emergency Stop Dependency: In an emergency, you must stop all heads at once. A delayed reaction or hesitation can result in multiple parts—and tools—being damaged, or worse, an injury.

- Complex Maintenance Risks: Servicing one spindle while others are powered or active can lead to accidental activation if lockout/tagout procedures aren’t followed properly.

Multi-head CNC routers require strict attention to safety. The increased number of moving parts and higher-speed output come with a higher risk. Proper training, PPE, safety interlocks, and emergency protocols are essential to operate these machines safely.

What Is The Lifespan Of Multi-Head CNC Routers?

A well-maintained multi-head CNC router can last 8 to 12 years or longer. High-quality machines with steel frames and industrial-grade spindles often exceed this range with part replacements and routine servicing.

With consistent maintenance and smart operation, a multi-head CNC router can be a long-term asset, often running strong for over a decade. Spindles and wear parts may need replacing over time, but the core machine can deliver high-output performance for years.

What Maintenance Is Required For Multi-Head CNC Routers?

- Daily Maintenance

- Clean the Work Area: Remove dust, chips, and debris from the machine bed, rails, and around all spindles. This prevents buildup that can affect motion and accuracy.

- Inspect Each Spindle: Check for odd sounds, vibration, or heat. Make sure all spindles are aligned and running smoothly.

- Lubricate Rails and Ball Screws (if manual): Apply manufacturer-recommended lubricant to linear guides and ball screws, especially under heavy use.

- Check Tool Holders and Bits: Inspect all tools for wear or damage. Replace dull bits to avoid uneven cuts across heads.

- Weekly Maintenance

- Test Spindle Alignment and Sync: Verify that each spindle is cutting in the correct position and at the same depth to maintain consistent output across all heads.

- Check Pneumatics (if used for tool changes or spindle lifts): Look for leaks, pressure drops, or sluggish response in pneumatic systems.

- Clean and Inspect Dust Collection System: Ensure all heads are properly connected to dust ports and airflow is clear.

- Monthly Maintenance

- Tighten Bolts and Fasteners: Vibration from multi-spindle operation can loosen bolts over time. Check mounts, gantry bolts, and spindle brackets.

- Inspect Wiring and Connectors: Look for frayed cables, loose connections, or damage near moving parts like cable chains.

- Calibrate Z-Axis for All Heads: Ensure that each spindle cuts at the same depth. Use a tool height sensor or manual measurement to confirm.

- Annual or Long-Term Maintenance

- Replace Spindle Bearings (as needed): If any spindle starts to vibrate, overheat, or lose accuracy, it may need bearing replacement or a full spindle swap.

- Service Motion Components: Inspect linear rails, ball screws, couplers, and drive motors for wear. Replace or re-lubricate as needed.

- Update Control Software and Firmware: Keep your machine’s software current to ensure stable performance and compatibility with new toolpath strategies.

- Full Mechanical Inspection: Check gantry alignment, frame integrity, and all head assemblies for wear or fatigue.

Multi-head CNC routers demand consistent maintenance across all heads to ensure synchronized, accurate performance. Cleanliness, lubrication, and spindle alignment are critical for maximizing uptime and protecting your investment.

Get CNC Routing Solutions

If you have questions about our CNC routers, need a customized solution, or want to learn more about machine specifications, pricing, or delivery, we’re here to assist you every step of the way.

Simply fill out the contact form, email us, or reach out via phone. One of our knowledgeable representatives will get back to you promptly with the information you need. Partner with AccTek Group and take your manufacturing capabilities to the next level.