Does Laser Welding Require Gas

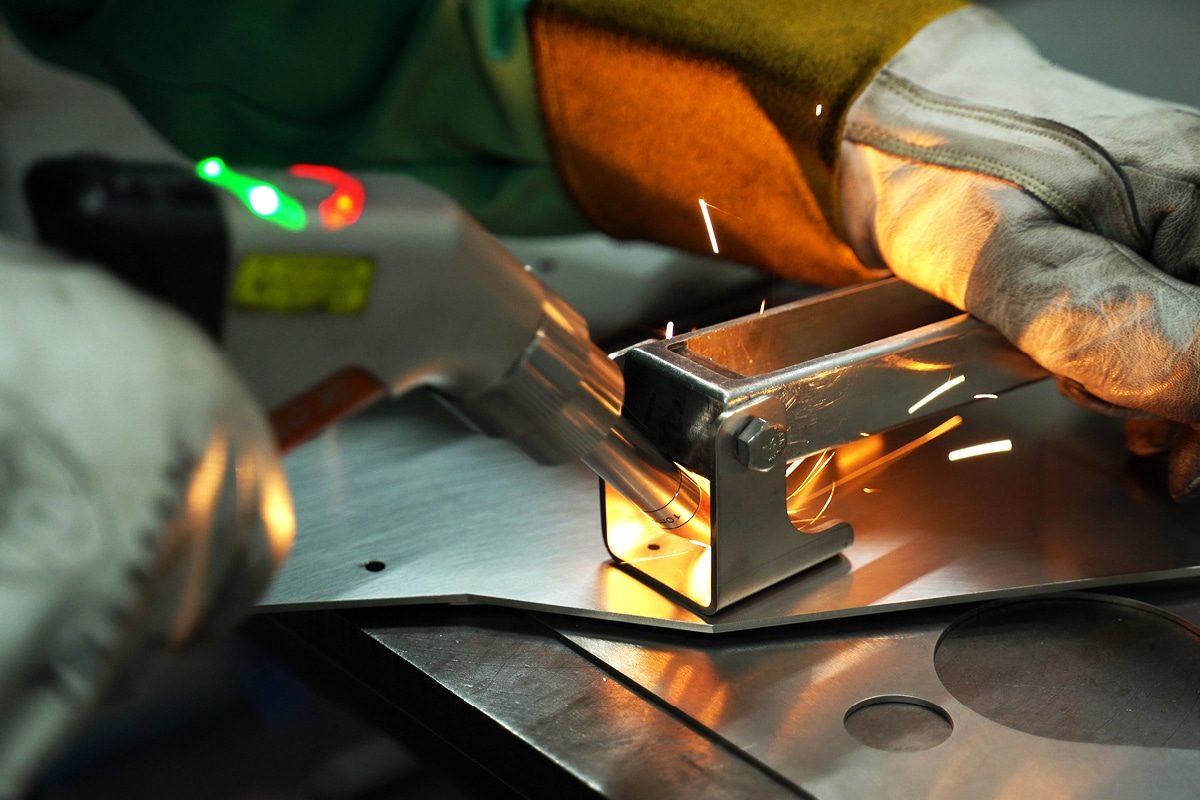

Laser welding is a high-precision joining process that uses a concentrated beam of light to fuse materials, commonly metals, with exceptional accuracy and minimal heat-affected zones. It’s widely used in industries like automotive, aerospace, medical device manufacturing, and electronics due to its speed, depth of penetration, and ability to produce clean, strong welds. But one question that often arises—especially among engineers new to the process—is whether laser welding requires the use of shielding gas.

The answer isn’t always straightforward. While some laser welding applications can technically be performed without gas, most require a shielding gas to ensure optimal results. The gas plays a critical role in protecting the weld pool from atmospheric contamination, stabilizing the welding process, improving energy transfer, and preventing oxidation or other defects. The type of gas, its flow rate, and how it’s applied can all affect weld quality, making gas selection and delivery an essential part of process design.

In this article, we’ll explore when and why laser welding needs gas, what types of gases are typically used, and how gas parameters impact performance and quality. Whether you’re refining an existing process or evaluating laser welding for a new application, understanding the role of gas is key to success.

Table of Contents

Fundamentals of Laser Welding

Laser welding is a thermal joining process that uses a high-powered laser beam to fuse materials at the joint. The laser beam serves as a concentrated heat source, delivering energy with pinpoint accuracy. This allows for deep penetration welds, minimal distortion, and high-speed operation—especially advantageous in automated and precision-driven industries like automotive, aerospace, and electronics.

There are two primary modes of laser welding: conduction welding and keyhole welding.

- In conduction welding, the laser heats the surface of the material, and heat is conducted into the joint. This produces shallow, smooth welds and is typically used for thin materials or where an aesthetic surface finish is important.

- In keyhole welding, the laser’s power density is high enough to vaporize the material, creating a small cavity (or “keyhole”) that allows the beam to penetrate deeper. This method is used for thicker materials and creates narrow, deep welds with strong fusion.

Laser welding can be performed using different types of lasers—such as fiber lasers, CO2 lasers, or Nd:YAG lasers—each with unique properties affecting absorption, depth, and speed. The process is highly controllable and can be precisely tailored to a wide range of materials, including steels, aluminum, titanium, and even dissimilar metals.

One of the standout benefits of laser welding is its low heat input relative to other fusion welding methods. This means less warping, smaller heat-affected zones, and faster cooling, which in turn leads to better mechanical properties and minimal post-processing.

While the laser itself is central, several other elements contribute to the overall success of the process, including joint design, beam focus, travel speed, and the use (or absence) of shielding gas.

Why Gas Matters in Modern Laser Welding

Shielding gas plays a crucial role in laser welding, directly impacting the quality, consistency, and appearance of the final weld. While the laser beam provides the energy to fuse materials, the gas ensures the weld environment remains stable and uncontaminated. Without it, defects, discoloration, and structural weaknesses can occur, especially in high-precision or high-strength applications. Here’s why gas is more than just a side consideration in modern laser welding:

Oxidation Prevention

During welding, molten metal is highly reactive with elements in the surrounding air, particularly oxygen and nitrogen. If left unshielded, the weld pool can oxidize, resulting in porosity, brittleness, or surface discoloration. Shielding gases like argon or helium displace atmospheric air around the weld zone, creating an inert or semi-inert environment that protects the molten metal from contamination. This is essential for materials like aluminum, titanium, and stainless steel, which are especially sensitive to oxidation.

Plasma Suppression

In high-power laser welding, the interaction between the laser beam and metal vapor can form a bright plasma cloud. If not controlled, this plasma absorbs or deflects part of the laser energy, reducing penetration and weld quality. Certain shielding gases—particularly helium or helium-rich mixtures—help suppress this plasma plume, allowing maximum laser energy to reach the material.

Keyhole Stabilization

In keyhole welding mode, the laser creates a deep cavity in the material. This keyhole must remain stable for consistent penetration and fusion. Shielding gas helps stabilize the keyhole by balancing internal pressure and shielding the vaporized metal from collapse or turbulence. An unstable keyhole can lead to voids, spatter, or incomplete fusion.

Bead Shaping and Penetration Control

Shielding gas also influences the way the molten metal flows and solidifies. The type and flow rate of gas affect bead width, depth, and shape. For example, helium promotes deeper penetration due to its higher thermal conductivity, while argon provides better arc stability and a smoother surface finish. By adjusting the gas composition and delivery method, operators can fine-tune the weld profile to meet specific requirements.

Post-Weld Cleanliness

Clean welds reduce the need for post-processing like grinding or polishing. Shielding gas minimizes oxidation and spatter, producing a smoother, brighter surface. This is particularly important in industries where aesthetics or hygiene matter, such as medical devices, food processing equipment, and consumer electronics.

Shielding gas is not just a peripheral element—it’s an integral part of the laser welding process. It affects everything from weld quality and appearance to efficiency and reliability. Understanding its functions helps manufacturers optimize their processes and avoid costly defects or rework.

Types of Gases and Their Characteristics

The choice of shielding gas in laser welding isn’t one-size-fits-all—it directly influences weld quality, penetration depth, bead shape, and even the risk of defects. Different gases offer different advantages, depending on the base material, laser type, and welding conditions. Some gases are inert, providing passive protection, while others are active and can alter the weld chemistry or heat transfer. Below is a detailed breakdown of the most commonly used gases in laser welding and how they perform.

Argon

Argon is the most widely used shielding gas in laser welding due to its affordability, availability, and high density, which helps it blanket the weld area effectively. Being chemically inert, it protects the weld pool from atmospheric contamination without reacting with the base material. Argon also helps produce smooth surface finishes and is ideal for materials like stainless steel, aluminum, and titanium. However, its relatively low thermal conductivity can limit penetration compared to other gases.

Helium

Helium is another inert gas, but with much higher thermal conductivity and ionization potential than argon. This allows more laser energy to reach the weld pool, resulting in deeper penetration and improved keyhole stability. It’s especially useful for high-speed welding and materials with high thermal conductivity, such as copper and aluminum. The downside is its higher cost and lower density, which makes it less effective at shielding unless used at higher flow rates.

Nitrogen

Nitrogen is a semi-inert gas that can act as a cost-effective alternative to argon in some cases. It works well with austenitic stainless steels, where it can even enhance mechanical properties by forming nitrides. However, nitrogen can cause porosity or embrittlement in reactive metals like titanium or aluminum, so it must be used selectively. It’s often used in applications where cost savings are critical and where the base metal is compatible.

Oxygen & CO2 (Active Additions)

Although oxygen and carbon dioxide are reactive gases, they can be added in small amounts to inert shielding gases to modify the weld behavior. A small addition of oxygen (typically <1%) to argon can increase fluidity in the weld pool, improve wetting, and promote smoother bead formation. CO2 is less common but may be used in hybrid laser-arc processes. These active additives must be carefully controlled to avoid oxidation, spatter, or brittleness.

Mixed and Sequential Shielding

Advanced laser welding setups often use gas mixtures or switch between different gases during various stages of the weld. For example, a helium-argon mix can combine the penetration of helium with the arc stability of argon. In some automated systems, one gas may be used for root passes and another for capping passes, optimizing performance at each phase. Sequential shielding or dual-gas nozzles can also be used to target both the front and back of the weld zone, especially in thick or sensitive materials.

Each shielding gas brings its own set of properties and trade-offs. Argon is reliable and versatile, helium boosts penetration and heat transfer, nitrogen offers cost advantages with limitations, and oxygen/CO2 can fine-tune weld dynamics when used sparingly. Gas selection should be based on the material, weld geometry, and quality requirements. Understanding these characteristics allows engineers to customize the welding environment for maximum efficiency and performance.

Gas Delivery Hardware

In laser welding, it’s not just the type of shielding gas that matters—the way the gas is delivered to the weld zone is equally critical. Proper delivery ensures the gas forms a consistent protective envelope around the molten metal, prevents turbulence, and enhances overall weld quality. The right hardware setup reduces oxidation, improves stability, and maximizes the effectiveness of the shielding gas. Depending on the application, weld geometry, and material, various gas delivery configurations are used. Here’s a breakdown of the most common systems:

Coaxial Nozzle

The coaxial nozzle delivers shielding gas concentrically around the laser beam. This is one of the most common configurations in laser welding, especially in automated or robotic setups. The gas flows through a ring-shaped nozzle that surrounds the beam path, ensuring even coverage of the weld area. Coaxial nozzles are ideal for deep penetration welds and high-speed processes, as they maintain a steady gas envelope regardless of torch orientation. They are particularly effective in keyhole welding, where gas stability directly influences weld penetration and keyhole consistency.

Side Jet or Cross-Jet

Side jets, also known as cross-jets, introduce shielding gas from the side, at an angle to the laser beam and weld seam. This configuration is often used in situations where the main focus is plasma suppression rather than full shielding. The side jet deflects metal vapor and plasma out of the laser path, allowing more beam energy to reach the material. It’s frequently used in conjunction with a primary shielding system or when the laser beam must remain unobstructed by bulky hardware. It’s useful for high-power laser applications and fine welding where beam clarity is essential.

Trailing Shield Shoe

Trailing shields are attachments that follow behind the laser head, applying shielding gas to the hot weld zone immediately after the beam passes. This is especially important in materials like titanium or zirconium, where even brief exposure to air during cooling can cause severe oxidation or embrittlement. The trailing shield shoe helps maintain a protective environment over the cooling weld pool, improving surface finish and preventing post-weld contamination. It’s often used in aerospace and medical applications where weld integrity and appearance are critical.

Double Shield

Double shielding involves two separate gas streams: one for primary shielding and one for secondary or auxiliary coverage. The primary stream may be delivered coaxially, while the secondary stream could be a trailing shield or side jet. This configuration is used to enhance protection and control multiple aspects of the welding environment, such as shielding the keyhole area with one gas and cooling the surrounding heat-affected zone with another. Double shielding is ideal for thick materials, complex joints, or reactive metals where a single gas stream may be insufficient.

Gas delivery hardware is more than just a means of transporting gas—it directly affects weld quality, gas efficiency, and process stability. Coaxial nozzles provide balanced coverage, side jets control plasma, trailing shields protect the cooling weld, and double shields offer advanced protection for demanding applications. Choosing the right configuration is essential for maximizing the performance of both the laser and the shielding gas, especially in precision or high-spec welding environments.

Process Optimization

Shielding gas in laser welding isn’t just about choosing the right type or delivery method—how the gas is managed and maintained is just as important. Process optimization ensures the gas performs effectively, consistently protects the weld pool, and contributes to high-quality results. Poor gas control can lead to weld defects, surface contamination, and inefficient gas usage. Key optimization factors include volumetric flow rate, gas velocity, gas purity, and the condition of delivery hardware. Managing these variables is essential for maintaining stable welds and avoiding costly rework.

Volumetric Flow Rate

This refers to the amount of gas delivered per unit of time, typically measured in liters per minute (L/min). An inadequate flow rate can result in insufficient shielding, exposing the molten metal to atmospheric gases. On the other hand, an excessive flow rate may cause turbulence, pulling air into the weld zone and leading to contamination or porosity. Optimizing flow rate requires balancing the material type, welding speed, nozzle design, and joint configuration. Flow meters and pressure regulators are essential tools for keeping this parameter in check.

Gas Velocity

Velocity—the speed at which the gas exits the nozzle—affects how well the gas displaces air and maintains coverage over the weld pool. Too low, and the gas may not shield effectively; too high, and it may create turbulence or blow molten metal, causing weld irregularities. Unlike flow rate, velocity depends heavily on nozzle geometry and gas line pressure. Smooth, laminar flow is ideal, and test runs should be performed to fine-tune this parameter, especially when welding sensitive or thin materials.

Moisture & Purity

Even trace levels of moisture or impurities in the shielding gas can severely affect weld quality. Water vapor and contaminants like hydrocarbons or oxygen can cause porosity, discoloration, and even embrittlement in reactive materials. For high-spec industries such as aerospace or medical device manufacturing, using ultra-high-purity gas (typically 99.999%) is critical. Inline gas purifiers and moisture traps may be necessary to maintain purity, especially in humid environments or when working with materials like titanium, where contamination is unforgiving.

Nozzle Wear

Nozzle condition is often overlooked but has a direct impact on gas coverage and distribution. Worn, deformed, or partially blocked nozzles can cause uneven gas flow, reducing shielding effectiveness and introducing variability into the weld. Regular inspection and replacement of nozzles are essential to maintain consistent performance. In automated systems, nozzle wear monitoring can be integrated as part of a preventive maintenance program to avoid unexpected drops in weld quality.

Optimizing shielding gas performance in laser welding is a combination of science and fine-tuning. It’s not just what gas you use, but how you deliver it, how clean it is, and how well your system maintains control over time. Paying attention to flow rate, gas velocity, purity, and equipment condition can significantly improve weld consistency, reduce defects, and increase overall process efficiency. For any operation that values reliability and repeatability, gas optimization is not optional—it’s essential.

Material-Specific Guidelines

Not all metals behave the same under a laser beam, and neither should your approach to shielding gas. The type of material being welded significantly influences whether gas is required, what type of gas to use, and how it should be delivered. Different metals have different thermal conductivities, reactivity levels, and weld pool dynamics. Matching your shielding strategy to the material is critical to achieving strong, defect-free welds. Below are detailed guidelines for handling various common and specialized materials.

Carbon & Low-Alloy Steel

These materials are relatively forgiving and can often be laser welded with minimal shielding. However, using an inert gas like argon is still recommended to prevent oxidation and maintain bead appearance. For higher-strength low-alloy steels, shielding becomes more important to reduce the risk of cracking or porosity. Flow rate and gas coverage should be consistent, especially in high-speed or deep-penetration applications. Side jets or coaxial nozzles typically suffice.

Stainless Steel

Stainless steel is more reactive than carbon steel, particularly with oxygen and nitrogen at elevated temperatures. Argon is the go-to shielding gas for most stainless steel welding, offering clean, oxidation-free welds. For thicker sections or higher power welding, a helium-argon mixture can improve penetration. Nitrogen can also be used for austenitic grades to enhance corrosion resistance, but only in tightly controlled environments. A trailing shield is often used to protect the hot metal as it cools, especially for cosmetic or hygiene-sensitive applications.

Aluminum & Magnesium

Both metals are highly conductive and prone to oxidation, making proper gas shielding essential. Argon is typically used, although helium or helium-rich mixtures are preferred for thicker sections due to their ability to transfer more heat. Magnesium is even more reactive than aluminum and may require additional shielding or trailing gas to prevent oxidation and burn-through. Nozzle placement and flow control are critical here—too much velocity can create turbulence, while too little allows air contamination.

Copper & Precious Metals

Copper has high reflectivity and thermal conductivity, which makes laser welding challenging. Helium is often preferred due to its high ionization potential and better heat transfer, which helps achieve sufficient penetration. For precious metals like gold, silver, and platinum, shielding gas also helps prevent oxidation and discoloration. Given the value of the material, even minor defects can be costly. A coaxial nozzle and carefully controlled flow are standard, with ultra-clean gas to avoid contamination.

Titanium & Reactive Alloys

Titanium, zirconium, and other reactive metals are extremely sensitive to air exposure at high temperatures. Even brief contact with oxygen or nitrogen can ruin a weld, leading to embrittlement, porosity, or surface contamination. These materials require shielding gas—typically high-purity argon—and often use both primary and trailing shields. In some cases, an enclosed or inerted chamber is used for critical welds. Gas purity (99.999% or higher) is essential, and special attention must be paid to moisture and nozzle condition.

There is no universal rule for gas use in laser welding—it depends entirely on the material. Carbon steels may allow some flexibility, but reactive metals like titanium demand rigorous shielding. Choosing the right gas and delivery system, and tailoring them to the material’s properties, is the difference between a clean, strong weld and one riddled with flaws. Material-specific guidelines aren’t just recommendations—they’re requirements for success.

When Gas Is Not Required

While shielding gas is essential in most laser welding scenarios, there are specific situations where it can be reduced or even eliminated. These exceptions are not the norm, but they exist—thanks to specialized environments, component design, or ultra-precise processes that control or eliminate exposure to air. In these cases, the need for shielding gas is replaced by alternative protective strategies such as vacuum conditions, physical barriers, or enclosure systems. Understanding when gas can be skipped safely is important for minimizing cost, simplifying setups, or addressing unique application constraints.

Vacuum Laser Welding (VLW)

Vacuum laser welding is performed inside a sealed chamber where air is completely removed, creating a low-pressure or high-vacuum environment. With no oxygen or nitrogen present, oxidation and atmospheric contamination are no longer a concern, removing the need for shielding gas. VLW is particularly useful for materials like titanium or magnesium that are extremely reactive at high temperatures. It also allows for precise welds with minimal porosity. The drawback is the cost and complexity of vacuum systems, which limits their use to high-value, low-volume applications such as aerospace components or scientific instruments.

Hermetic or Closed-Cell Welding

In some cases, components are designed to be self-shielding. For example, hermetic enclosures—such as battery cells, sensors, or sealed electronic modules—may be welded within a closed system where the internal atmosphere is controlled (e.g., inerted or evacuated). During the weld, the joint design and enclosure prevent outside air from reaching the weld zone. In these setups, external shielding gas may not be necessary. Precision is still critical, as the joint must be airtight, and any oxidation or contamination could compromise the entire sealed unit.

Micro-Welding Under Cover Slides

In micro-welding applications—such as bonding small sensors, optical components, or MEMS devices—laser energy may be applied through a transparent cover slide or encapsulation layer. The weld zone is physically isolated from air, which can reduce or eliminate the need for shielding gas. This technique is common in medical and electronic packaging, where minimal heat input and extreme precision are required. The sealed environment under the slide acts as a natural barrier to contamination. However, this only works for small-scale applications with tight control over materials and conditions.

While shielding gas is vital in most laser welding processes, certain controlled or enclosed environments can eliminate the need for it. Vacuum laser welding removes atmospheric gases entirely, closed-cell designs block external air, and micro-welding under cover slides offers passive protection. These cases are exceptions, not standard practice, and typically involve specialized equipment or part designs. Knowing when you can safely skip shielding gas—and when you absolutely can’t—is key to making smart, application-specific decisions.

Environmental and Economic Considerations

While shielding gas is often essential for laser welding, its use carries both environmental and economic consequences that manufacturers can’t afford to overlook. From the extraction and delivery of gases to their long-term operating costs, gas use introduces both resource demands and carbon footprints. At the same time, process inefficiencies—such as overuse, leakage, or improper gas selection—can quietly erode profitability and sustainability. Balancing performance with responsibility means weighing the real-world costs and environmental impact of gas usage in your laser welding process.

Environmental Impact

Shielding gases like argon, helium, and nitrogen are naturally occurring, but their industrial production, purification, compression, and transport require significant energy. Helium, in particular, is a finite resource extracted during natural gas processing and is increasingly expensive and scarce. Excessive or wasteful use contributes to unnecessary emissions and resource depletion.

In high-volume manufacturing, minimizing gas usage can significantly reduce a facility’s environmental footprint. This is especially relevant for companies striving to meet ESG (Environmental, Social, and Governance) goals or seeking certification for sustainable operations. Advanced gas delivery systems, process enclosures, and optimized flow rates can all contribute to lower consumption and cleaner operation.

Cost of Gases

Shielding gases vary widely in cost. Argon is generally affordable and readily available, making it a go-to for many applications. Helium, on the other hand, is costly and subject to supply fluctuations. Nitrogen is inexpensive, but only suitable for select materials. Misusing a high-cost gas when a lower-cost alternative would suffice leads to unnecessary expense.

In some cases, switching to gas mixtures or minimizing flow rates through better nozzle design and process control can lead to major savings without compromising weld quality. Manufacturers should evaluate total cost of ownership, factoring in not just the price per cylinder, but also flow rate, frequency of replacement, downtime for refills, and system maintenance.

Efficiency and Waste Reduction

Many welding operations overuse gas due to conservative settings, outdated equipment, or a lack of real-time monitoring. Flow meters, pressure regulators, and flow optimization software can help dial in the right amount of shielding for each application. Preventive maintenance—like inspecting for leaks, replacing worn nozzles, and calibrating gas delivery systems—can significantly reduce waste and lower operational costs.

Gas use in laser welding comes with real environmental and economic trade-offs. While necessary in most cases, it should be managed with efficiency and sustainability in mind. Choosing the right gas, using only what’s needed, and investing in proper equipment and maintenance can minimize both carbon impact and operational cost. In today’s competitive and environmentally conscious manufacturing landscape, responsible gas management is as much about performance as it is about long-term viability.

Best-Practice Checklist

To ensure consistent, high-quality results in laser welding, especially when shielding gas is involved, it’s essential to follow a disciplined set of best practices. These practices help prevent defects, reduce waste, and maximize both weld performance and operational efficiency. Whether you’re setting up a new process, troubleshooting issues, or optimizing existing operations, this checklist serves as a practical guide to getting the most out of your laser welding system—technically, economically, and environmentally.

Select the Right Gas for the Material

Match the shielding gas to the base material and application.

- Argon for general-purpose use with stainless steel, aluminum, and titanium.

- Helium for deep penetration and high-conductivity metals like copper.

- Nitrogen for austenitic stainless steels (if compatible).

- Mixtures for fine-tuned control over penetration and bead shape.

Avoid using high-cost gases where simpler alternatives will suffice.

Optimize Gas Flow Rate and Velocity

Don’t assume “more is better.” Excessive flow creates turbulence; too little allows contamination.

- Use flow meters and pressure regulators.

- Target smooth, laminar flow.

- Adjust based on joint type, speed, and material thickness.

Ensure Gas Purity and Dryness

Moisture and impurities lead to porosity and surface defects.

- Use high-purity gases (especially for reactive metals like titanium).

- Install moisture traps and inline filters where necessary.

- Store gas cylinders in a dry, temperature-controlled environment.

Choose the Right Gas Delivery Hardware

Different weld geometries require different nozzle setups.

- Coaxial nozzles for balanced, all-around shielding.

- Side jets for plasma suppression in high-power setups.

- Trailing shields for reactive metals or cosmetic welds.

- Double shielding for advanced applications or large weld pools.

Maintain and Inspect Equipment Regularly

Check for leaks in hoses and fittings.

- Inspect nozzles for wear, blockage, or damage.

- Replace consumables before performance degrades.

- Calibrate gas flow systems periodically.

Consider Automation and Monitoring

Integrate sensors to monitor gas flow and pressure in real time.

- Use data logging to identify trends and prevent failures.

- Automate purging cycles for consistency.

Validate with Test Welds and Quality Checks

Before launching full production, run test welds under real conditions.

- Use visual inspections, metallographic analysis, or X-ray testing.

- Confirm bead shape, penetration, and cleanliness.

- Adjust gas parameters as needed to meet quality standards.

Laser welding is a precision process, and shielding gas management is a key variable in its success. Following a structured best-practice approach—covering gas selection, delivery, equipment care, and process control—ensures better weld quality, higher productivity, and lower costs. Whether you’re running a prototype lab or a full-scale production line, this checklist helps lock in reliability and repeatability every time you press “start.”

Summary

So, does laser welding require gas? In most cases, the answer is yes. Shielding gas plays a vital role in protecting the weld pool from atmospheric contamination, preventing oxidation, stabilizing the keyhole, suppressing plasma, and shaping the final weld. From common materials like stainless steel and aluminum to highly reactive metals like titanium, the right gas and delivery method can make or break the weld quality.

However, there are exceptions. Specialized processes such as vacuum laser welding, hermetically sealed components, and micro-welding under cover slides can eliminate or reduce the need for shielding gas. Still, these are niche scenarios requiring highly controlled environments.

Different gases—argon, helium, nitrogen, and gas mixtures—offer distinct advantages based on material type and weld objectives. Hardware configurations like coaxial nozzles, side jets, and trailing shields further tailor gas effectiveness. And optimizing variables such as flow rate, gas purity, and nozzle condition is essential for consistent results.

Ultimately, using shielding gas in laser welding is about more than just protection—it’s about control, repeatability, and performance. With careful selection and process optimization, manufacturers can achieve cleaner welds, lower defect rates, and more efficient operations. Gas might not always be required, but in modern laser welding, it’s almost always smart.

Get Laser Welding Solutions

At AccTek Group, we understand that successful laser welding is about more than just the laser—it’s about the complete system, from shielding gas strategy to precision control. As a professional manufacturer of intelligent laser equipment, we offer comprehensive solutions tailored to your specific materials, applications, and production goals.

Whether you’re working with stainless steel, aluminum, copper, or high-performance alloys, our laser welding systems are designed to integrate advanced shielding gas control, customizable delivery hardware, and real-time monitoring to ensure consistent, high-quality welds. From coaxial nozzles to trailing shields and vacuum-compatible setups, we help you choose the right configuration for optimal results—every time.

Our team of engineers and application experts will work closely with you to identify the best gas types, flow rates, and delivery techniques for your process. We also provide training, technical support, and on-site service to help your team get up to speed and stay productive.

Whether you’re building consumer electronics, automotive parts, medical devices, or precision aerospace components, AccTek Group delivers laser welding solutions that balance performance, reliability, and efficiency. Contact us today to learn how our intelligent laser systems can help you weld cleaner, faster, and smarter—without compromise.