Product Introduction

Material Routing Capability

| Material Type | 1.5 kW | 2.2 kW | 3.0 kW | 3.2 kW | 3.5 kW | 4.5 kW | 5.5 kW | 6.0 kW | 7.5 kW | 9.0 kW |

|---|---|---|---|---|---|---|---|---|---|---|

| Softwood | Light Cutting | Standard Cutting | Fast Cutting | Fast Cutting | Fast Cutting | High-Speed Cutting | Heavy-Duty Cutting | Heavy-Duty Cutting | Industrial Cutting | Industrial Cutting |

| Hardwood | Light Duty | Standard Cutting | Stable Cutting | Stable Cutting | High-Precision | Heavy-Duty | Heavy-Duty | High-Torque Cutting | Industrial Cutting | Industrial Cutting |

| Plywood/MDF | Basic Cutting | Smooth Cutting | Fast, Clean Cutting | Fast Cutting | High-Precision | Heavy-Duty | Heavy-Duty | Industrial Smooth Cuts | High-Volume Cutting | High-Volume Cutting |

| HDF/Particle Board/Melamine | Light Cuts | Standard Cuts | Clean Cuts | Clean Cuts | High-Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Acrylic(PMMA) | Thin Sheets | Clean Cutting | Fast, Clean Edges | High Clarity | High Clarity | Smooth Finishing | Smooth Finishing | Industrial Clarity | Industrial Clarity | Industrial Clarity |

| Polycarbonate/PETG | Thin Sheets | Clean Cutting | Stable Cutting | Stable Cutting | Precision Cutting | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| ABS/PVC Foam Board | Light Duty | Standard | Fast Cutting | Fast Cutting | High Stability | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| HDPE/LDPE/PP/Nylon | Light Cuts | Standard Cuts | Stable Cuts | Stable Cuts | Deep Routing | Heavy-Duty | Heavy-Duty | High-Torque | Industrial | Industrial |

| Delrin/UHMW | Light Duty | Standard | Accurate Routing | Accurate Routing | High-Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Solid Surface (Corian) | Very Light | Standard | Strong Cutting | Clean Cutting | High-Precision | Heavy-Duty | Heavy-Duty | Industrial Cutting | Industrial Cutting | Industrial Cutting |

| Fiberglass/Carbon Fiber Sheet | Light Trimming | Standard | Precise Routing | Precise Routing | High-Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Phenolic/Bakelite | Limited | Standard | Clean Routing | Clean Routing | Precision Routing | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Foam(EVA, XPS, EPS, PU) | Very Easy | Very Easy | Fast Cutting | Fast Cutting | Ultra-Fast | Ultra-Fast | Ultra-Fast | High-Speed | High-Speed | High-Speed |

| Rubber/Leather/Cork | Light Duty | Standard | Clean Edges | Clean Edges | Faster Routing | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

| Cardboard/Paperboard | Easy | Easy | Fast Cutting | Fast Cutting | Ultra-Fast | Ultra-Fast | Ultra-Fast | Industrial | Industrial | Industrial |

| ACP/ACM (Surface Routing Only) | Very Light | Standard | Clean Grooves | Clean Grooves | High Precision | Heavy-Duty | Heavy-Duty | Industrial | Industrial | Industrial |

Compatible Materials

- Low-Density EVA Foam

- Medium-Density EVA Foam

- High-Density EVA Foam

- Extra-Firm EVA Foam

- Soft EVA Foam

- Closed-Cell EVA Foam

- Open-Cell EVA Foam

- Colored EVA Foam Sheets

- Black EVA Foam

- White EVA Foam

- Multicolor EVA Craft Foam

- Textured EVA Foam Sheets

- Printed EVA Foam Sheets

- Glitter EVA Foam

- Laminated EVA Foam

- Adhesive-Backed EVA Foam

- EVA Foam Rolls

- Thick EVA Blocks

- EVA Puzzle-Mat Foam

- EVA Cosplay Foam

- Heat-Formable EVA Sheets

- Shock-Absorbing EVA

- High-Resilience EVA

- EVA Foam for Packaging Inserts

- EVA Footwear-Grade Foam

- EVA Sports Equipment Foam

- EVA Yoga-Mat Material

- EVA Helmet-Liner Foam

- EVA Marine Flooring Sheets

- UV-Resistant EVA Sheets

- Flame-Retardant EVA Foam

- Anti-Static EVA

- Conductive EVA Foam

- Perforated EVA Sheets

- Embossed EVA Sheets

- EVA–Rubber Composite Foam

- EVA–PE Blended Foam

- EVA–PVC Composite Material

- Cross-Linked EVA Foam

- High-Precision EVA for Model-Making

Application of EVA Foam CNC Routers

Customer Testimonials

Comparison VS Other Engraving Technologies

| Comparison Item | EVA Foam CNC Routing | Laser Engraving | Chemical Etching | EDM Engraving |

|---|---|---|---|---|

| Working Principle | Mechanical cutting with rotating tools | Burns/vaporizes material with laser | Chemical reaction dissolves material | Uses electrical discharge to remove material |

| Material Suitability | Excellent for EVA foam and soft foams | Works but may melt or burn foam | Not suitable for foam | Not suitable for foam |

| Edge Quality | Clean edges with proper tooling | Can leave melted or scorched edges | Not usable on foam | Not usable on foam |

| Depth Control | Full-depth cutting and profiling | Mostly shallow marking | Shallow, chemical-controlled | Very precise but only on metals |

| Precision Level | High for foam routing | High for engraving | Moderate | Extremely high |

| Speed of Production | Fast for thick foam | Fast for surface engraving | Slow | Slow |

| Heat Impact | No heat damage | High heat risk on foam | No heat, but requires chemicals | Generates heat but only on metals |

| Complexity of Shapes | Great for 2D/3D contours | Good for fine surface details | Limited pattern shapes | Good but only on conductive materials |

| Cutting Capability | Excellent | Limited on foam | No cutting | No cutting |

| Setup Difficulty | Medium | Easy | High (chemicals, masks) | High (conductive workpiece needed) |

| Operating Cost | Low | Low–medium | Medium (chemical use) | High (tool wear + infrastructure) |

| Maintenance Needs | Tool changes + lubrication | Optics cleaning, filter changes | Chemical disposal, tank cleaning | Electrode wear, dielectric fluid care |

| Safety Concerns | Dust and tool safety | Laser radiation & fumes | Chemical exposure | Electrical discharge hazard |

| Best Applications | Foam inserts, packaging, cosplay, padding | Surface marking & engraving | Industrial metal texturing | Precision metal molds & dies |

| Ideal Use Case | High-quality foam cutting & shaping | Fine marking, not deep cutting | Metal surface treatments | High-precision metal engraving only |

Why Choose Us

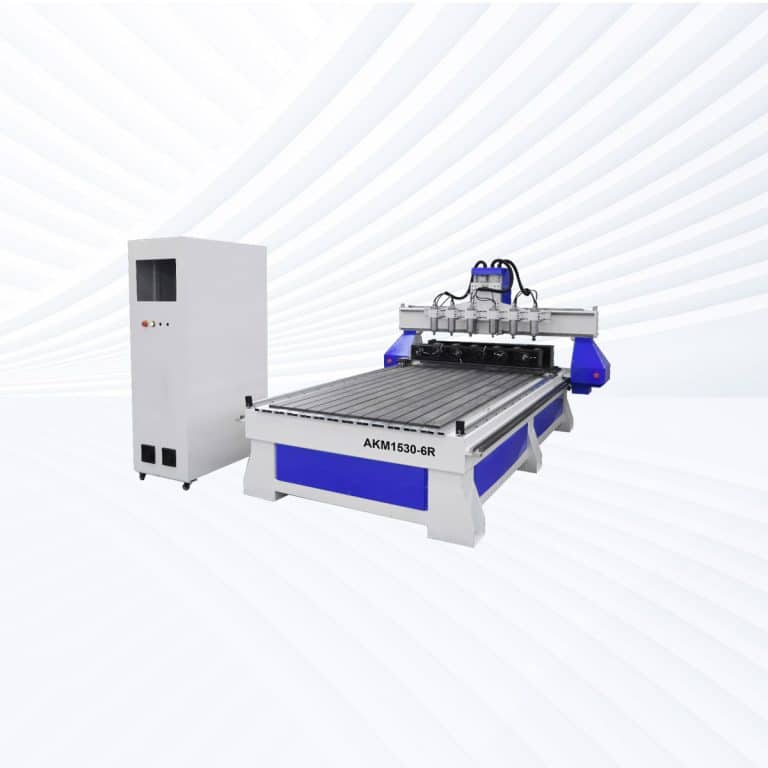

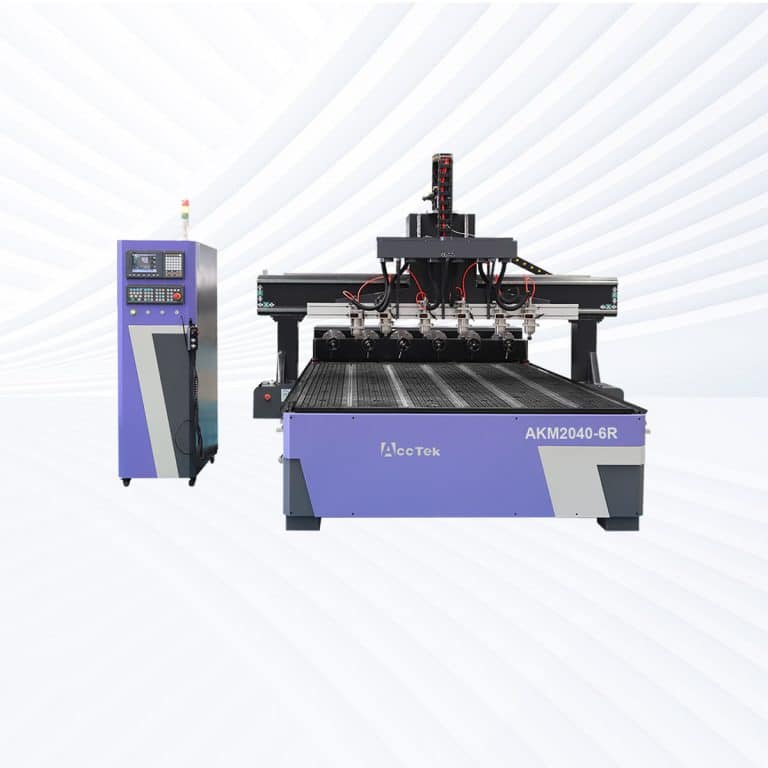

High Precision & Efficiency

AccTek CNC routers deliver fast, accurate results with minimal errors, supporting intricate designs and mass production across the woodworking, plastic, and metal industries.

Robust and Durable Design

Our machines are built with high-quality frames and components, ensuring long service life, high load-bearing capacity, and stability during high-speed operations.

Intelligent Control Systems

Equipped with user-friendly interfaces and smart controllers, our routers offer smooth motion control, automatic toolpath optimization, and easy integration with various CAD/CAM software.

Flexible Customization

From machine size to spindle power and motor type, we offer flexible configurations to suit different production needs, budgets, and material requirements.

Related Resources

How To Maintain CNC Routers

This article provides a comprehensive guide on how to maintain CNC routers, covering essential tasks, troubleshooting tips, upgrades, and best practices to ensure optimal performance and longevity.

What Is The Accuracy Of CNC Routers

This article is a comprehensive guide that explains the precision of CNC routers, the key factors affecting precision, expected performance, and how to improve machining results.

How to Choose the Right Router Bits for CNC Routers

This article explains how to select the right router bit for your CNC router, including cutter type, material, coating, and tip, to achieve precise, efficient, and durable cutting performance.

Stepper Motor VS Servo Motor

This article compares stepper motors and servo motors, detailing their working principles, performance characteristics, applications, and key differences in modern automation.

Frequently Asked Questions

What Is The Price Of EVA Foam CNC Routers?

What Is The Working Range Of EVA Foam CNC Routers?

- Small and Medium Working Areas: Sizes such as 700mm×900mm and 900mm×1500mm are ideal for detailed EVA foam cutting, prototype development, model-making, and small-batch production. These compact formats fit easily into limited workshop spaces while providing precise contour cutting for craft items, inserts, and custom foam pieces.

- Full-Sheet and Standard Production Sizes: Popular models like 1300mm×2500mm and 1500mm×3000mm are designed for processing full EVA foam sheets used in packaging, yoga mats, protective padding, and industrial components. These sizes deliver efficient nesting layouts, allowing operators to maximize material usage and reduce waste in mid- to large-scale production.

- Large-Format Industrial Sizes: Working ranges such as 2000mm×3000mm, 2000mm×4000mm, and 2000mm×6000mm serve high-volume manufacturers handling oversized EVA foam blocks, multi-layer laminations, or long components. These machines provide extended cutting areas suitable for automotive liners, sports flooring, and industrial cushioning substrates.

- Ultra-Large Custom Configurations: Very large setups like 3000mm×6000mm support specialized manufacturing, including stage design, aerospace foam components, packaging for oversized equipment, and multi-panel foam fabrication. Their expansive work surfaces are ideal for continuous-sheet production or large integrated parts.

- Custom Working Ranges: EVA foam CNC routers can also be customized according to specific industry needs. Custom sizes accommodate non-standard foam sheet dimensions, conveyor-fed production lines, or additional processing area for multi-station workflows.

What Type Of Spindle Do EVA Foam CNC Routers Use?

- Air-Cooled Spindles: Air-cooled spindles use internal fans to dissipate heat and are widely used in small to medium EVA foam CNC routers. They are easy to install, require minimal maintenance, and operate reliably for foam routing tasks such as packaging inserts, cosplay armor, sports mats, and custom foam prototypes. Air-cooled designs are well-suited for workshops needing simple, plug-and-play operation, although they may generate more noise during high-RPM cutting.

- Water-Cooled Spindles: Water-cooled spindles offer superior cooling and quieter operation, making them ideal for continuous or industrial-scale EVA foam machining. These spindles maintain consistent temperature even under long run times, reducing wear on bearings and ensuring smooth cutting performance. Their stable thermal control is particularly beneficial when producing large foam sheets, deep 3D contours, or precision-cut foam components. They do require an external chiller or water pump.

What Type Of Motor Do EVA Foam CNC Routers Use?

- Stepper Motors: Stepper motors are widely used in entry-level and mid-range EVA foam CNC routers. They operate in defined steps, providing repeatable and reliable motion for general foam cutting tasks such as packaging inserts, cosplay armor pieces, cushioning materials, or sports-gear components. Stepper motors offer good low-speed torque, which is suitable for the gentle cutting forces required for EVA foam. While they may lose steps under high-speed loads, they remain cost-effective and precise enough for most light-duty foam applications.

- Easy Servo Motors (Closed-Loop Steppers): Easy servo motors enhance stepper performance by adding closed-loop feedback, allowing the system to automatically correct missed steps and maintain smooth motion. This is particularly beneficial when cutting large EVA foam sheets or executing intricate shapes that require high accelerations and tight curves. Easy servos reduce vibration, improve path precision, and ensure consistent depth control—important for EVA foam, where clean edges and uniform thickness are essential.

- Servo Motors: Servo motors represent the highest-precision option for EVA foam CNC routers. They provide continuous closed-loop control, high torque at all speeds, faster acceleration, and very smooth motion. Servo-driven systems excel in industrial environments where high production speed, long-term reliability, and complex cutting patterns are required. Their precision ensures clean edges without tearing, especially in multi-layer EVA foam or deep-contour routing applications.

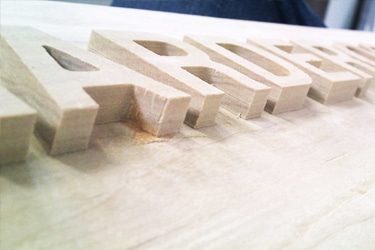

Are The Routing Edges Of EVA Foam CNC Routers Clean?

- Material Characteristics and Cut Quality: EVA foam is naturally soft and uniform in density, allowing CNC routers to cut it cleanly without chipping or splintering. Unlike wood-based materials, EVA foam does not crack or tear under mechanical cutting, making it highly compatible with CNC routing tools.

- Tool Selection: Clean edges depend heavily on using sharp, appropriate tools such as single-flute or spiral-flute bits designed for foam. These bits minimize friction and produce smooth, consistent cuts. Dull tools may deform or compress the foam, creating uneven edges, so proper tool maintenance is essential.

- Feed Rate and Spindle Speed: EVA foam requires balanced machining parameters. High feed rates combined with low to moderate spindle speeds help prevent melting or edge distortion. When correctly calibrated, CNC routers produce crisp edges with no burning, warping, or surface fuzzing.

- Vacuum Hold-Down and Stability: EVA foam is lightweight and flexible, so effective hold-down—typically via a vacuum table—is important for maintaining clean edges. Stable material positioning ensures accurate toolpaths and prevents shifting that could cause rough or uneven finishes.

- Edge Finish on Complex Shapes: CNC routers excel at cutting curves, contours, pockets, and multi-layer patterns in EVA foam. Even intricate designs maintain clean edges without tearing or material drag, provided the compression of the foam is minimized during cutting.

- Dust and Debris: EVA foam produces far less dust than wood materials. Most chips are soft, lightweight particles that do not scratch or damage the cut surface. A clean cutting environment supports better edge quality and reduces the chance of recutting debris.

- Post-Processing Requirements: In most cases, EVA foam components do not require secondary sanding or trimming. When cut with optimized parameters, the edges are production-ready, smooth, and uniform.

What Problems Might Occur When Using EVA Foam CNC Routers?

- Foam Deformation During Cutting: Because EVA foam is soft and compressible, it may flex or deform under the pressure of the cutting tool. This can cause inconsistent depths, distorted contours, or slightly widened cuts. Using sharp bits and proper feed rates reduces deformation and helps maintain dimensional accuracy.

- Edge Fuzzing or Fraying: EVA foam can produce fuzzy edges if the bit is dull or the spindle speed is too low. Incorrect feed or plunge settings can also tear the foam rather than slice it cleanly. Switching to high-RPM cutting and using sharp, single-flute or specialty foam bits improves edge quality significantly.

- Material Melt or Burn Marks: Although EVA foam is low-density, excessive spindle speeds or slow feed rates can generate heat and cause melting. Melted foam may cling to the bit, reducing cutting efficiency and creating rough surfaces. Proper parameter balancing and frequent chip clearing prevent thermal buildup.

- Poor Vacuum Holding Power: EVA foam sheets are lightweight and often porous, making them less responsive to vacuum hold-down systems. Air leakage through the foam may reduce suction strength. Using sacrificial layers, masking tape, or T-slot clamps helps stabilize the material during machining.

- Chip and Dust Accumulation: Foam chips are light and static-prone, which causes them to scatter or cling to machine components. Insufficient dust extraction can lead to buildup around the spindle, rails, or electronics. An effective dust collection system and regular cleaning are essential for smooth operation.

- Incomplete Cuts on Thick Foam: Thick EVA foam may require multiple passes to avoid deformation or inconsistency. Deep single-pass cuts risk uneven depths or tearing. Multi-pass toolpaths with optimized step-downs ensure stable and accurate machining.

- Tool Wear or Bit Clogging: Although EVA foam is soft, melted particles or dust buildup may clog the bit, reducing cutting performance. Regular tool inspection and cleaning help maintain cutting efficiency.

Is It Safe To Use EVA Foam CNC Routers?

- Material Handling Safety: EVA foam is lightweight and easy to position on the worktable, reducing the risk of strain or mishandling. However, it must be secured properly using a vacuum table or clamps to prevent shifting during high-speed routing. Material movement can cause inaccurate cuts or kickback of loose foam pieces.

- Dust and Particle Control: While EVA foam produces less hazardous dust compared to MDF or hardwood, it still generates fine particles and lightweight chips. Dust extraction is necessary to keep the workspace clean and maintain operator visibility. Good ventilation reduces floating foam particles that may irritate the eyes or respiratory system.

- Tool and Spindle Safety: EVA foam cuts at high feed rates, meaning spindle and bit speeds remain fast. Operators must keep their hands away from the cutting area and avoid adjusting tools or foam sheets while the machine is running. Sharp bits are safer than dull ones because they minimize tearing and reduce machine strain.

- Fire Risk Precautions: EVA foam is generally safe and does not ignite easily under normal routing conditions. However, friction from an overheated or damaged bit could cause localized melting. Maintaining proper spindle speeds and ensuring adequate cooling helps prevent thermal buildup.

- Noise and Vibration Safety: CNC routers can be noisy at high speeds, so hearing protection is recommended for prolonged operation. Stable machine placement and proper maintenance reduce vibration and unexpected mechanical movement.

- Electrical and Operational Safety: Operators should follow standard CNC safety rules—checking wiring, grounding, emergency stop function, and ensuring all protective covers are in place. Training helps prevent incorrect toolpaths, collisions, or unsafe feed rate settings.

- PPE Requirements: Basic personal protective equipment, such as safety glasses, dust masks, and hearing protection, enhances overall safety during EVA foam machining.

How To Choose EVA Foam CNC Routers?

- Working Area Selection: EVA foam CNC routers are available in multiple sizes, such as 700mm×900mm, 1300mm×2500mm, 2000mm×4000mm, and custom dimensions. The working range should match the maximum EVA sheet size you plan to process. Large-format CNC routers benefit packaging, sports equipment, protective inserts, and custom foam prototyping.

- Spindle Type and Power: EVA foam requires high-speed, low-resistance cutting. Both air-cooled and water-cooled spindles are suitable, but water-cooled options offer quieter performance and better long-term stability during long cutting cycles. Power levels ranging from 3.0kW to 6.0kW are typically sufficient, though higher power is preferred for thicker foam or high-volume production.

- Motor System: Stepper motors are adequate for simple EVA machining, but easy servo or full servo motors deliver smoother motion and higher precision when processing complex contours or fast cutting patterns. Servo systems are recommended for industries requiring consistent accuracy and minimal vibration.

- Worktable Type: EVA foam cutting benefits from vacuum tables that firmly hold soft material without clamps. T-slot tables are also useful for fixing jigs or special fixtures for thick foam blocks. A combination vacuum and T-slot design provides the highest flexibility across various foam shapes and densities.

- Cutting Tools and Compatibility: Ensure the CNC router supports high-RPM cutting tools suitable for soft materials. Specialized foam-cutting bits reduce drag and prevent deformation of the foam edges. Tool length and diameter should match the thickness of your EVA foam sheets.

- Dust and Chip Extraction: Although EVA foam produces lightweight chips rather than heavy dust, a proper extraction system keeps the surface clean and ensures smooth toolpath motion.

- Control System and Software: User-friendly controllers such as Mach3 or Syntec improve accuracy and ease of operation. CAM compatibility should support high-speed contouring and nesting.