What Precautions Should Be Taken During Laser Cleaning

This article explains key precautions for safe laser cleaning, covering equipment setup, operator protection, ventilation, maintenance, and compliance with safety standards.

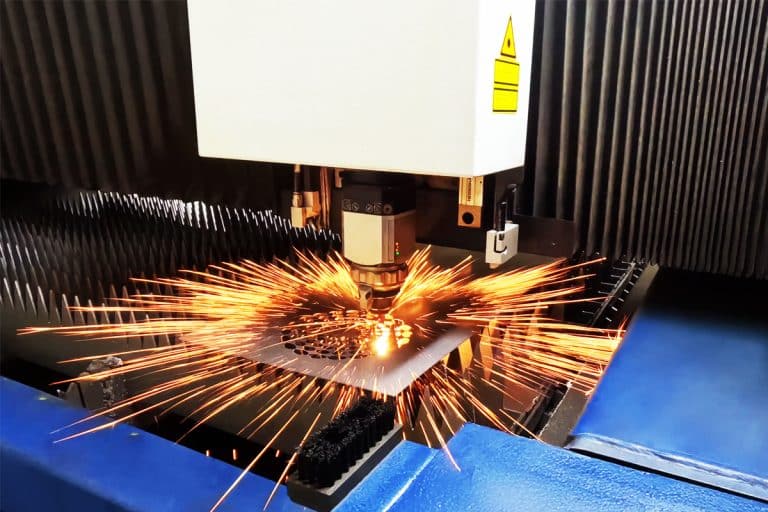

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

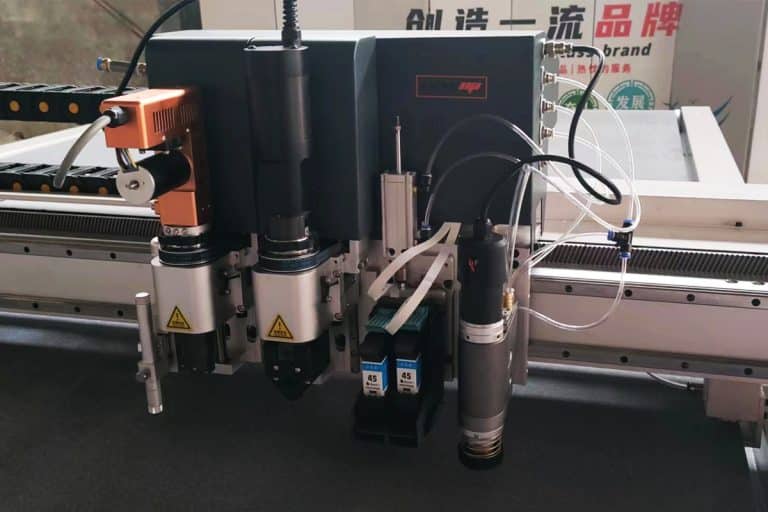

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

How To Choose Laser Marking Machines

A comprehensive guide to selecting the right laser marking machine—covering materials, mark quality, laser types, software, integration, compliance, and total cost of ownership.

Laser Welding Copper Guide

A detailed guide to laser welding copper, outlining process modes, parameters, challenges, joint designs, and industrial applications for efficient and high-quality copper welding.

What Factors Affect Laser Cleaning Performance

This article explains the key factors that influence laser cleaning performance, including laser parameters, material properties, process control, and environmental conditions.

Does Laser Cutting Use Gases

This article explains the role of assist gases in laser cutting, outlining how oxygen, nitrogen, and air influence cutting performance, quality, and material compatibility.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are Vacuum Tables

This article explains vacuum tables in CNC routing, covering their components, types, benefits, applications, and maintenance, offering insights into their role in enhancing machining precision and efficiency.

What Precautions Should Be Taken During Laser Cleaning

This article explains key precautions for safe laser cleaning, covering equipment setup, operator protection, ventilation, maintenance, and compliance with safety standards.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

How to Choose the Right CNC Router Spindle

This article explains how to choose the right CNC router spindle by detailing key factors such as power, torque, speed range, cooling type, precision, and machine compatibility.

How To Choose Laser Marking Machines

A comprehensive guide to selecting the right laser marking machine—covering materials, mark quality, laser types, software, integration, compliance, and total cost of ownership.

Laser Welding Copper Guide

A detailed guide to laser welding copper, outlining process modes, parameters, challenges, joint designs, and industrial applications for efficient and high-quality copper welding.

What Factors Affect Laser Cleaning Performance

This article explains the key factors that influence laser cleaning performance, including laser parameters, material properties, process control, and environmental conditions.

Does Laser Cutting Use Gases

This article explains the role of assist gases in laser cutting, outlining how oxygen, nitrogen, and air influence cutting performance, quality, and material compatibility.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are Vacuum Tables

This article explains vacuum tables in CNC routing, covering their components, types, benefits, applications, and maintenance, offering insights into their role in enhancing machining precision and efficiency.