Understand How Oscillating Knife Cutting Systems Create Risk

Oscillating knife cutting machines are powerful tools, but their design and operating environment introduce multiple categories of risk. Recognizing these hazards is the first step in building effective safety measures. Each source of danger stems from either the blade itself, the supporting systems, or the workplace conditions.

- Cut and Puncture Hazards: The rapidly oscillating blade is the most obvious danger. Even brief contact can cause deep lacerations or puncture wounds. Because the blades are sharp enough to slice through composites, textiles, and foam, they can easily penetrate skin, gloves, or clothing.

- Impact and Entanglement Hazards: Moving components such as drive belts, gantries, or conveyor systems can trap hands, hair, or loose clothing. A moment of inattention can result in crushing injuries or entanglement.

- Ejection and Flying Fragments: Workpieces, offcuts, or broken blades can be ejected at high speeds. Without barriers or guards, these fragments pose serious risks to the operator’s eyes and face.

- Vacuum Hazards: Many oscillating knife cutting systems use vacuum tables to hold materials in place. Sudden release of suction or improper use can cause material shifts or even unexpected drawing of clothing or small objects toward the cutting area.

- Electrical and Pneumatic Energy Hazards: These machines rely on electrical circuits and pneumatic pressure. Faulty wiring, leaks, or improper lockout/tagout during maintenance can result in shocks, burns, or high-pressure release injuries.

- Noise and Vibration: Oscillating knives produce significant noise levels and constant vibration, especially in continuous operation. Long-term exposure without hearing protection or anti-vibration measures can lead to hearing loss and musculoskeletal strain.

- Ergonomic Risks: Operators often work for extended periods with repetitive tasks such as loading, unloading, and positioning materials. Poor workstation setup, awkward postures, and manual handling of heavy sheets can cause fatigue and musculoskeletal disorders.

- Housekeeping Hazards: Scrap materials, dust, and debris can accumulate quickly around cutting stations. Slips, trips, and obstructed access routes not only increase accident risk but also interfere with safe machine operation.

- Fire and Thermal Hazards: Cutting certain composites, foams, or plastics generates heat and fine particles. Inadequate ventilation, sparks, or overheated equipment can trigger fire hazards.

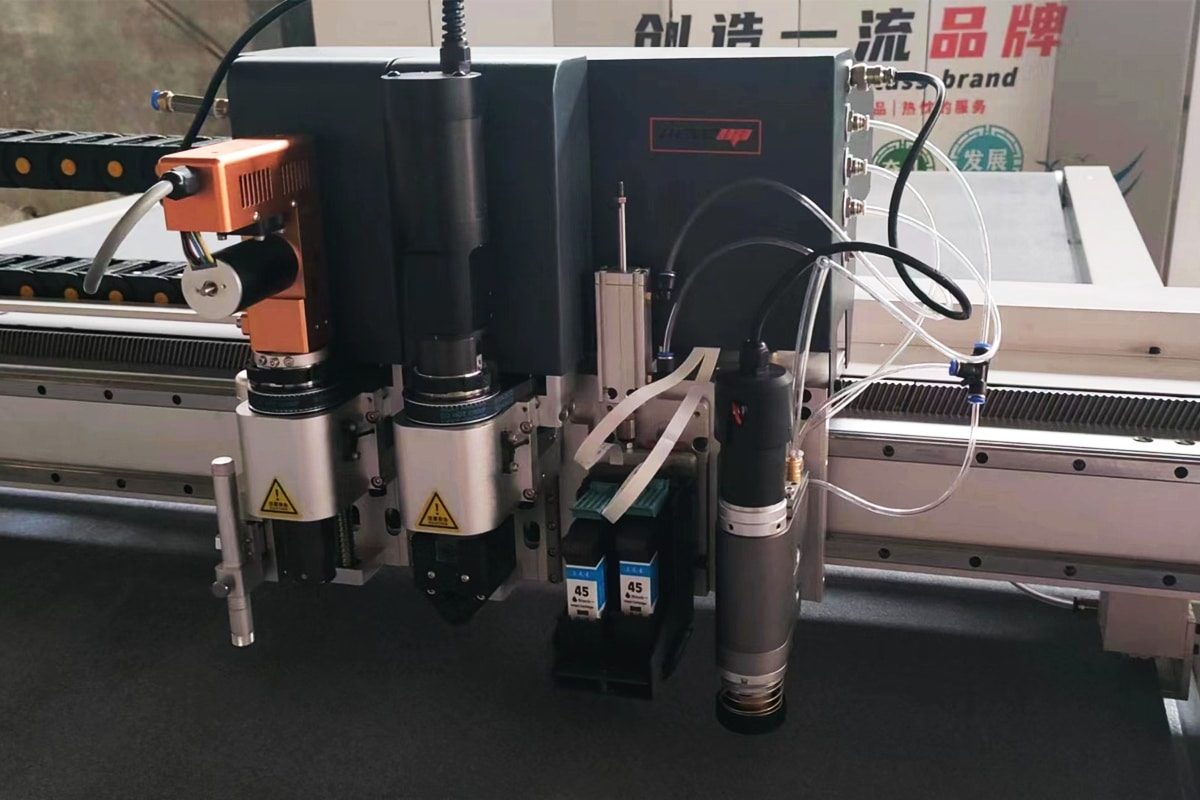

Fundamentals of Laser Cutting

Regulatory & Standards Landscape

Operating oscillating knife cutting machines safely isn’t just good practice—it’s a compliance issue spanning global and local frameworks. Start with a formal risk assessment: ISO 12100 lays out the lifecycle approach to identifying hazards and reducing risk through inherently safe design, technical safeguards, and information for use. In the EU, the new Machinery Regulation (EU) 2023/1230 replaces the Machinery Directive and becomes applicable on January 20, 2027, reinforcing manufacturer and operator duties around safety by design and documentation.

- Safety of Machinery: Guarding and interlocking are core controls around the blade and motion system. ISO 14120 defines how fixed and movable guards must be designed and constructed; ISO 14119 covers interlocking devices and how to minimize defeat. For safety-related control functions (e.g., emergency stop, light curtains, door interlocks), ISO 13849-1 sets methodology and performance levels for control system reliability.

- Electrical Safety of Machines: The electrical cabinet, cabling, protective bonding, overcurrent protection, emergency stopping circuits, and testing fall under IEC/EN 60204-1—the group standard for the electrical equipment of machines. It ties electrical measures back to the risk assessment and defines requirements up to 1000 VAC/1500 VDC.

- Lockout/Tagout (LOTO): For servicing, cleaning, blade changes, and troubleshooting, US employers must follow OSHA 29 CFR 1910.147, covering control of hazardous energy (electrical, pneumatic, vacuum). It requires machine-specific procedures, training, and verification of isolation before work begins.

- Noise Exposure: Oscillating knives can exceed action levels. OSHA 29 CFR 1910.95 sets the Hearing Conservation trigger at an 8-hr TWA of 85 dBA and a PEL of 90 dBA; programs must include monitoring, audiometry, training, and protection. For machine noise declarations and workstation checks, ISO 11201 specifies measurement methods.

- Dust/FiberControl: Cutting foams, textiles, and composites can generate fine particulates. OSHA highlights combustibility risks; NFPA 652 requires a Dust Hazard Analysis (DHA) to identify fire, flash-fire, and explosion hazards and prescribe controls (containment, ventilation, housekeeping, ignition control).

Pre-Installation Planning

Safe operation of oscillating knife cutting machines starts long before the first blade moves. The planning and preparation phase—where the machine will be located, how utilities will be provided, and how the environment is controlled—sets the foundation for safety, efficiency, and long-term reliability. A poorly planned installation can lead to cramped workspaces, unstable power supply, excessive operator strain, and even hazards that persist throughout the machine’s lifecycle. Proper pre-installation planning ensures that risks are minimized, workflows are optimized, and safety standards are met from day one.

- Location and Layout: Choose a space that allows free movement of operators, materials, and maintenance staff. The machine should be positioned to avoid bottlenecks, with clear access to emergency exits, fire extinguishers, and control panels. Adequate clearance around the cutting area also reduces collision risks during loading and unloading.

- Power, Air, and Vacuum: Oscillating knife cutting machines depend on stable electricity, compressed air, and vacuum systems. Electrical supply should meet machine specifications with grounding and surge protection. Air and vacuum systems must be properly filtered and sized to avoid sudden pressure loss, which could disrupt material handling or create hazards.

- Lighting and Visibility: Cutting precision and operator safety rely on clear visibility. Install bright, shadow-free lighting above work zones, especially around the cutting head and loading area. Supplement with task lighting where detailed adjustments are made.

- Data and Software: Modern cutters integrate with CAD/CAM software and production networks. Plan for secure data connections and a robust IT infrastructure to prevent interruptions or errors that could cause unsafe cutting operations. Access controls and software updates also reduce cybersecurity risks.

- Flooring and Ergonomics: Non-slip, level flooring is critical for preventing slips and trips. Consider anti-fatigue mats for operators who stand for extended periods. The layout should minimize awkward reaching, bending, or heavy lifting, and provide proper height for material handling surfaces.

- Environmental Controls: Cutting processes often generate dust, fibers, or noise. Ventilation systems should capture airborne particles before they spread, while acoustic treatments can reduce ambient noise levels. Temperature and humidity should also be regulated to ensure both material stability and operator comfort.

Engineering Controls

Engineering controls are the backbone of machine safety. Unlike administrative measures or personal protective equipment (PPE), these controls are built directly into the design and function of oscillating knife cutting machines. Their purpose is to physically prevent accidents, reduce exposure to hazards, and minimize operator reliance on constant vigilance. Properly implemented engineering controls transform the cutting station from a high-risk environment into a managed workspace where risks are predictable and contained.

- Physical Guards: Fixed and movable guards shield operators from direct contact with the oscillating blade and other moving components. Guards should be designed to withstand impact, resist tampering, and allow visibility where necessary. Transparent polycarbonate guards or enclosures around the cutting head are common, providing both protection and line-of-sight for operators.

- Interlocks & Safety Devices: Interlocks ensure that access doors, hoods, or covers cannot be opened while the blade is in motion. Safety devices such as light curtains, pressure-sensitive mats, and area scanners further protect the operator by automatically halting machine motion when a person enters a hazardous zone. These systems are vital to prevent bypassing or human error.

- Emergency Stop (E-Stop) System: Every oscillating knife cutting machine must have prominently placed, easily accessible emergency stop buttons. The E-stop should override all other controls and halt dangerous movements immediately. To be effective, E-stop systems must be tested regularly and located within arm’s reach at key points around the machine.

- Safe Motion and Tool Management: Engineering controls also govern the safe operation of the moving gantry, tool head, and cutting path. Speed limits, controlled acceleration/deceleration, and collision detection reduce the risk of sudden impacts. Automatic blade retraction or parking positions when idle ensure the knife is not exposed unnecessarily.

- Electrical & Pneumatic Safety: Electrical and pneumatic systems require built-in protections such as circuit breakers, residual current devices, and pressure relief valves. Proper grounding and bonding minimize electrical shock risk, while pressure regulators and fail-safe valves prevent hazardous pneumatic release. Lockout/tagout compatibility should be integrated into the design for safe servicing.

- Vacuum Table Safety: Vacuum systems are critical for holding material in place, but they also present risks. Engineering controls should include fail-safes to prevent sudden loss of suction, which could release workpieces unexpectedly. Filters and silencers should be installed to reduce noise and prevent dust or debris from entering the system.

Administrative Controls

While engineering controls provide the first line of defense, the safe operation of oscillating knife cutting machines also depends heavily on administrative controls. These are policies, procedures, and organizational practices that govern how people interact with machines and the work environment. Administrative controls ensure that safety is not left to chance but embedded into daily routines, responsibilities, and accountability systems. Without them, even the best-designed machine can become hazardous due to human error, miscommunication, or poor oversight.

- Authorization & Training: Only trained and authorized personnel should operate oscillating knife cutting machines. Training must cover machine functions, hazard awareness, emergency procedures, and safe material handling. Regular refresher sessions and competency checks ensure skills remain sharp, while records of authorization help supervisors confirm who is cleared for operation.

- Standard Operating Procedures (SOPs): Written SOPs provide step-by-step instructions for every phase of operation—from startup and cutting to cleaning and maintenance. These documents reduce variability, eliminate guesswork, and ensure consistency across shifts and operators. SOPs should be readily available at the workstation and updated whenever new risks, tools, or processes are introduced.

- Permits & Change Control: Certain activities, such as blade changes, maintenance involving energy isolation, or process modifications, should require a permit-to-work system. Change control procedures ensure that new materials, software updates, or workflow adjustments are risk-assessed before implementation, preventing unintended hazards.

- Contractors & Visitors: Third-party contractors and visitors must be managed carefully. Contractors performing service or maintenance need documented safety clearances, while visitors should be restricted to safe zones and provided with clear briefings on hazards and protective requirements. Uncontrolled access increases the risk of accidents.

- Housekeeping: Clean, organized work areas directly contribute to safety. Scrap buildup, dust accumulation, or misplaced tools can cause slips, trips, or interference with machine function. Administrative programs should establish housekeeping as a daily responsibility, supported by inspections and corrective action when standards are not met.

Personal Protective Equipment (PPE)

Even with engineering and administrative controls in place, operators of oscillating knife cutting machines remain exposed to certain residual risks. Personal Protective Equipment (PPE) serves as the last line of defense, protecting workers from hazards that cannot be eliminated at the source. PPE requirements must be tailored to the tasks performed, the materials being cut, and the overall work environment. Importantly, PPE is only effective when properly selected, fitted, and consistently used, supported by training and regular inspections.

- Eye Protection: Safety glasses or goggles are essential to shield against ejected fragments, dust, or debris. When cutting composites or brittle materials that may splinter, impact-rated eye protection with side shields is strongly recommended. For environments with high dust loads, sealed goggles provide additional defense.

- Cut-Resistant Gloves: Operators handling blades, offcuts, or material edges should wear cut-resistant gloves made from high-performance fibers like Kevlar or Dyneema. These gloves reduce the risk of lacerations during handling but should be chosen carefully—thin enough for dexterity, yet strong enough for protection. Gloves should never compromise the operator’s grip or control of the workpiece.

- Hearing Protection: Oscillating knives generate continuous noise, often exceeding safe exposure limits during prolonged operation. Earplugs or earmuffs rated for the measured sound levels in the work area are necessary. Hearing protection should be part of a broader hearing conservation program with regular monitoring.

- Safety Footwear: Steel-toe or composite-toe safety shoes protect against dropped materials, tooling, or fixtures. Slip-resistant soles are critical in environments where scrap, dust, or fluids may create slippery surfaces, reducing the risk of falls.

- Respiratory Protection: Cutting foam, textiles, or composites often produces fine airborne particles or fibers. Where ventilation alone is insufficient, operators should use respirators fitted with appropriate filters (e.g., P2/P3 or N95/HEPA, depending on particle size and type). Respiratory PPE must be fit-tested to ensure a proper seal.

- Tight-Fitting Clothing: Loose clothing, jewelry, and long hair can easily become entangled in moving parts. Operators should wear close-fitting garments designed for industrial work, with sleeves and hems secured. Long hair must be tied back or covered with a cap or net.

- Antistatic Measures: When cutting materials that generate static electricity, operators should wear antistatic clothing, footwear, or grounding devices. These measures help prevent electrostatic discharge, which could damage sensitive materials or, in rare cases, ignite combustible dust.

Pre-Start and Setup

Daily Pre-Start Checklist

Operators should follow a standardized checklist at the beginning of every shift. This typically includes:

- Inspecting physical guards, interlocks, and emergency stop buttons to confirm they are functional and unobstructed.

- Checking the blade and tool head for wear, cracks, or improper installation.

- Verifying that electrical and pneumatic connections are secure, with no leaks or frayed wiring.

- Ensuring dust extraction, vacuum systems, and ventilation are switched on and operational.

- Confirming that PPE is worn and that the work area is free from debris or obstructions.

Job Setup Protocol

Vacuum and Hold-Down

Safe Operating Practices During Production

Once production begins, the oscillating knife cutting machine becomes a high-energy system where hazards are active and continuous. Safe operation during this stage depends on vigilance, adherence to procedures, and respect for both machine capabilities and limitations. Even small lapses—such as reaching into the cutting zone or ignoring warning signals—can quickly escalate into accidents or equipment damage. The goal during production is to maintain smooth, controlled workflows while minimizing direct operator exposure to risks.

- Maintaining Operator Positioning: Operators should never reach into the cutting area while the blade is moving. Safe zones should be clearly marked, and operators must stand clear of the moving gantry, tool head, and ejection paths. Observing the process from designated positions prevents accidental contact and keeps escape routes open.

- Monitoring Machine Status: During operation, operators must keep an eye on displays, warning lights, and system alarms. Any irregular sound, vibration, or error message should trigger an immediate pause for inspection. Continuing production under abnormal conditions increases the likelihood of blade failure, material ejection, or system breakdown.

- Handling Materials Safely: Material loading and unloading should only occur when the blade has stopped and the machine is in a safe state. Sharp or heavy materials should be handled with appropriate tools or lifting aids, not bare hands, to prevent cuts and musculoskeletal injuries. Offcuts and scrap should be cleared periodically, but only when the machine is idle and isolated.

- Communication and Coordination: When multiple workers are involved, clear communication is essential. Hand signals, radios, or standard verbal cues should be used to coordinate actions like restarting, clearing jams, or adjusting material. No one should re-enter the cutting zone without confirmation that the machine has been stopped and secured.

- Avoiding Distractions: Operators must stay focused throughout production. Mobile phone use, side conversations, or multitasking can divert attention at critical moments. Production areas should be treated as controlled environments where concentration is mandatory.

- Emergency Preparedness: All operators should remain aware of the location of emergency stops and know how to use them without hesitation. If an unsafe condition arises—whether a jam, material shift, or abnormal noise—stopping the machine is always safer than attempting to fix the issue on the fly.

Blade Handling and Tooling Safety

Tool Selection and Limits

Blade Change SOP

Changing blades is one of the highest-risk activities for operators. A standardized procedure (SOP) should always be followed:

- Power down and isolate the machine (lockout/tagout if applicable).

- Wait for all motion to stop and secure the tool head in a safe, stable position.

- Use proper tools (e.g., torque wrenches, clamps) instead of improvising.

- Handle blades with cut-resistant gloves and never touch sharp edges directly.

- Dispose of worn or broken blades in puncture-resistant containers.

- Verify blade alignment and locking mechanisms before restarting.

Tool Storage & Control

Vacuum Table, Fixturing, and Small-Part Management

Vacuum Table Safety

Vacuum tables use suction to hold materials steady during cutting, but they must be properly inspected and maintained:

- Seal Integrity: Damaged or worn seals reduce suction, causing material to lift or slip unexpectedly. Regular inspection and replacement are essential.

- Pump Performance: Operators should verify that vacuum pumps are producing sufficient negative pressure before every job. Low vacuum pressure may not provide adequate hold.

- Airflow Management: Dust, fibers, or debris can clog vacuum channels. Cleaning the table surface and filters prevents suction loss and reduces fire risk from accumulated particles.

- Emergency Release: Operators must understand how to safely release suction to remove materials without sudden shifts or strain.

Fixturing for Irregular or Porous Materials

Some materials, such as open-cell foam, perforated sheets, or textured composites, resist stable hold-down through suction alone. In these cases, mechanical fixturing or auxiliary methods are required:

- Clamps, pins, or frames to stabilize large sheets.

- Adhesive mats or tapes for lightweight or porous materials.

- Custom jigs for irregularly shaped workpieces.

Small-Part Management

Cutting small parts introduces unique hazards. Once cut free, parts may shift, tip, or become airborne due to suction loss or airflow. To manage these risks:

- Use sacrificial layers or holding tabs to keep small parts in place until the full job is complete.

- Program cutting paths that minimize rapid knife direction changes on small parts, reducing vibration and ejection risks.

- Employ collection systems, such as mesh overlays or vacuum-assisted part retainers, to secure finished pieces.

- Remove small parts only when the cutting head has stopped and the vacuum system is safely released.

Ergonomics & Manual Handling

Workstation Design and Reach Zones

Lifting and Material Handling

Repetitive Tasks and Fatigue

Posture and Operator Movement

Environmental Factors

Energy Control (LOTO) and Safe Servicing

Hazardous Energy Sources

Oscillating knife cutting machines involve multiple forms of stored or active energy:

- Electrical: High-voltage circuits, drives, and control panels pose shock and arc-flash risks.

- Pneumatic: Compressed air lines can release sudden bursts of high pressure.

- Vacuum: Loss of suction can cause abrupt material movement or backflow of debris.

- Mechanical: Stored energy in moving gantries, springs, or drive belts can release unexpectedly.

- Thermal: Some components may retain heat from motors or cutting processes.

Lockout/Tagout (LOTO) Procedures

A formal LOTO procedure should be in place and enforced for all servicing tasks:

- Preparation: Identify all energy sources and notify affected personnel.

- Shutdown: Power down the machine using normal operating controls.

- Isolation: Physically disconnect energy sources (e.g., main electrical disconnect, pneumatic shutoff valve, vacuum isolation).

- Lockout: Apply locks and tags to each isolation device. Only the individual performing the service should hold the key.

- Release Stored Energy: Bleed off residual air pressure, discharge capacitors, and lower any moving components to a safe state.

- Verification: Test that the machine is de-energized by attempting a controlled start or using proper instruments.

- Servicing: Perform maintenance only after verifying zero-energy state.

- Re-energization: Remove tools, reinstall guards, clear personnel, and remove locks/tags before restoring power.

Safe Servicing Practices

Beyond LOTO, servicing requires additional precautions:

- Use only trained and authorized personnel for maintenance tasks.

- Follow manufacturer-recommended servicing intervals and checklists.

- Keep service logs to track maintenance activities and detect recurring issues.

- Provide adequate lighting and stable platforms for accessing machine components.

- Ensure spare blades, tools, and cleaning materials are stored safely to avoid secondary hazards.

Noise, Dust, and Air Quality

Noise Control

The rapid oscillation of blades, combined with suction systems and compressed air, produces sustained noise that often exceeds safe exposure limits. Prolonged exposure without protection can cause hearing loss or fatigue. Controls should include:

- Engineering measures: acoustic enclosures, sound-dampening panels, and quieter pump technologies.

- Administrative measures: rotating staff to limit individual exposure times and enforcing hearing conservation programs.

- PPE: properly fitted earmuffs or earplugs matched to the measured decibel levels in the work area.

Dust and Fiber Management

Dust and fibers generated during cutting can irritate the respiratory system, contaminate products, and create housekeeping challenges. Effective dust management includes:

- Local Exhaust Ventilation (LEV): extraction points placed near the cutting head to capture dust at the source.

- Filtration Systems: HEPA or equivalent filters to remove fine particles before air is recirculated.

- Machine Maintenance: keeping blades sharp to reduce dust generation and regularly cleaning vacuum lines and filters.

- Housekeeping Protocols: scheduled sweeping or vacuuming (never dry sweeping of combustible dust) to keep floors and surfaces free from buildup.

Air Quality and Ventilation

Fire and Explosion Considerations

Fine particulates from some materials can be combustible. If dust accumulates in air systems or surfaces, it increases the risk of fire or explosion. Preventive measures include:

- Conducting dust hazard analyses (as required in many regulatory frameworks).

- Using grounded and antistatic ducting to prevent ignition.

- Installing spark detection and suppression systems in high-risk environments.

Special Materials

Foams (EVA, PU, PE)

Foams can compress and rebound, making a stable hold-down difficult. Polyurethane (PU) foams, in particular, may generate fine dust and potentially hazardous fumes if frictional heat builds up. Controls include:

- Strong vacuum hold-down or adhesive mats to prevent shifting.

- Sharp blades to reduce tearing and dust generation.

- Dust extraction and filtration systems, especially when cutting PU.

- Fire prevention measures are necessary since foam dust can be combustible.

Rubber and Cork

Rubber sheets may produce frictional heat, leading to smoke or odor, while cork tends to generate fine particulate dust. Both materials can be tough on blades. Controls include:

- Selecting blades designed for elastic or abrasive materials.

- Reduce cutting speed to minimize heat buildup.

- Using localized exhaust ventilation to capture cork dust.

- Regular blade checks to prevent premature wear or breakage.

Textiles and Leather

Textiles may fray, and multilayer stacks can slip if not properly secured. Leather is dense, variable in thickness, and may produce fine fibers. Hazards include hand injuries during manual handling and airborne fibers. Controls include:

- Adequate clamping or vacuum strength to hold flexible layers.

- Blades are designed for fibrous or dense material.

- PPE such as cut-resistant gloves and respiratory protection for dusty fabrics.

- Housekeeping to prevent fiber buildup around the machine.

Composites (Glass/Carbon Fabrics, Prepregs)

Composite materials pose some of the highest health risks. Glass and carbon fabrics release fine fibers that can irritate the skin, eyes, and lungs. Prepregs contain resins that may emit harmful fumes when disturbed. Controls include:

- HEPA-filtered dust extraction at the source.

- Respiratory PPE (P3/N100 filters recommended).

- Protective clothing and eye protection to reduce skin and eye irritation.

- Strict housekeeping to prevent airborne fibers from spreading.

- Fire-safe waste disposal, as some resin-impregnated offcuts may be flammable.

Honeycomb Cardboard and Laminates

These materials can delaminate or eject fragments, especially if blade angles or speeds are not optimized. Honeycomb structures may also trap dust inside cells. Controls include:

- Using slower feed rates to reduce delamination.

- Employing sacrificial layers to support the honeycomb material.

- Strong vacuum systems to capture fragments and debris.

- Regular surface cleaning to prevent buildup in vacuum channels.

Adhesive-Backed Sheets

Adhesive layers can gum up blades, leading to poor cut quality and increased maintenance. They may also release fumes if frictional heat builds up. Controls include:

- Use non-stick or coated blades designed for adhesive materials.

- Slower speeds to reduce heat and adhesive transfer.

- Regular cleaning of blades with appropriate solvents.

- Adequate ventilation to capture fumes from adhesives.

Preventive Maintenance for Safety

Daily / Shift Tasks

At the start and end of each shift, operators should:

- Inspect blades and tooling for wear, cracks, or improper seating.

- Verify that guards, interlocks, and emergency stops function correctly.

- Check vacuum pressure and seals for leaks or debris.

- Clean the cutting surface, removing offcuts, dust, and adhesives.

- Confirm pneumatic and electrical connections are secure, with no visible damage.

- Record observations in a logbook to track issues across shifts.

Weekly Tasks

Technicians or trained operators should carry out more detailed checks each week:

- Lubricate moving components per manufacturer guidelines (rails, bearings, gantry systems).

- Inspect belts, pulleys, and drive components for wear or misalignment.

- Test vacuum and dust extraction filters, replacing them if clogged.

- Confirm software settings, job libraries, and control panels are functioning correctly.

- Conduct a test of the machine’s safe-stop and reset sequences.

Monthly / Quarterly Tasks

These intervals allow for deeper inspections and minor adjustments:

- Inspect the electrical cabinet for loose terminals, overheating, or dust buildup.

- Test the integrity of pneumatic lines and valves; replace worn hoses or seals.

- Check alignment of cutting heads and calibration of tool positioning.

- Evaluate noise and vibration levels, addressing excessive changes that may indicate imbalance or wear.

- Review training logs to ensure operators are up to date on machine use and maintenance protocols.

Annual Tasks

A thorough safety and performance review should be conducted annually by qualified maintenance staff or the machine manufacturer:

- Replace critical wear parts (e.g., bearings, drive belts, high-use tooling).

- Test full compliance of electrical and pneumatic systems with relevant safety standards.

- Inspect vacuum pumps, motors, and exhaust systems for efficiency and safety.

- Conduct a risk assessment update, factoring in any changes in materials, processes, or staffing.

- Review preventive maintenance records to identify recurring issues and implement long-term solutions.