What Are the Risks of Using Oscillating Knife Cutting Machines

Oscillating knife cutting machines have become indispensable in industries that demand precision cutting—such as textiles, packaging, automotive, and composites manufacturing. These machines use a rapidly moving blade that vibrates at high speed to slice through materials cleanly and efficiently, offering better accuracy and versatility than traditional cutting tools. However, while their benefits are clear, the potential risks associated with oscillating knife cutting systems are often underestimated. Improper handling, inadequate maintenance, or lack of safety measures can lead to serious injuries, equipment damage, or production downtime. Operators face hazards such as lacerations, entanglement, and exposure to high noise or vibration levels. In addition, issues like poor calibration or worn blades can compromise cutting quality and cause costly material waste. Understanding these risks is crucial not only for worker safety but also for maintaining consistent production quality and extending machine life. This article explores the key dangers linked to oscillating knife cutting machines, why they occur, and the best practices for mitigating them. By addressing these risks proactively, manufacturers can ensure that these high-precision tools deliver their full potential—safely, reliably, and efficiently.

Table of Contents

Understanding Oscillating Knife Cutting Machines

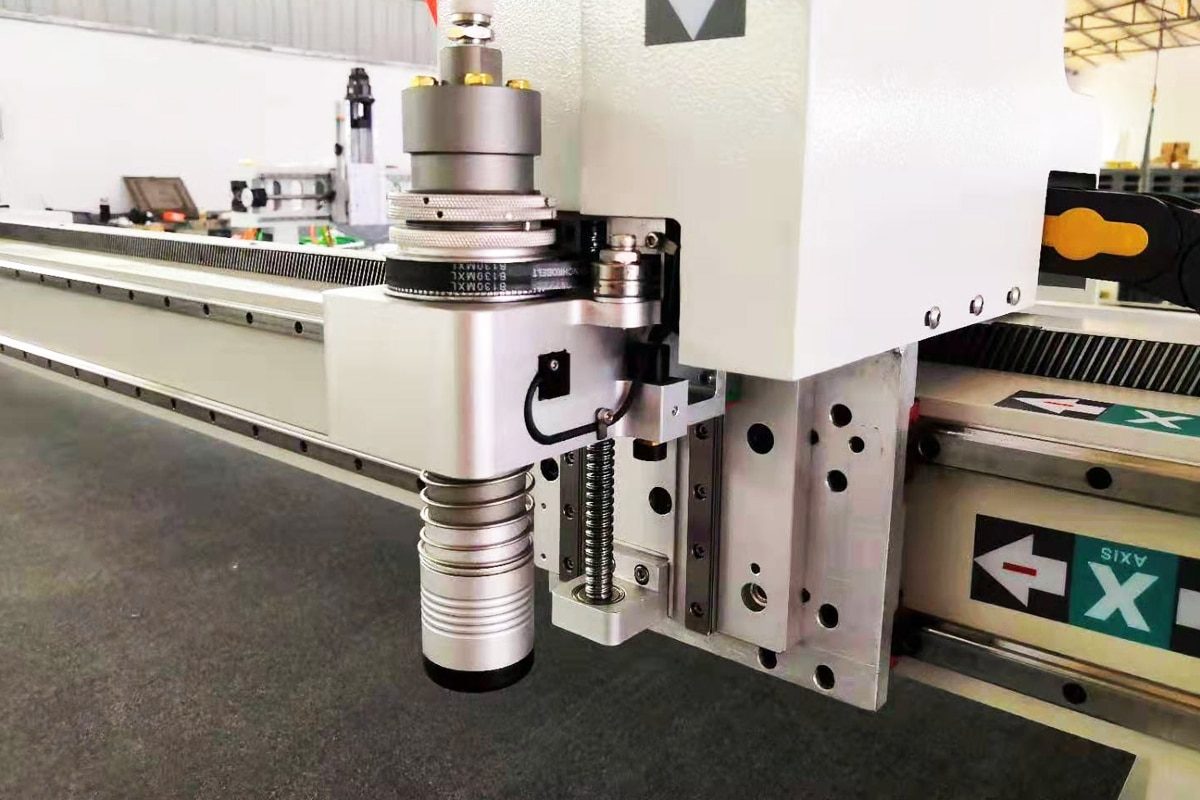

Oscillating knife cutting machines are precision cutting systems that use a rapidly vibrating, straight-edged blade to slice through a wide range of materials with high accuracy. Unlike rotary cutters or laser cutting systems, which rely on continuous motion or heat, oscillating knife cutting machines use a mechanical up-and-down motion—oscillating thousands of times per minute—to create clean, controlled cuts without burning, melting, or fraying the material. This makes them ideal for applications where material integrity and edge quality are critical.

These machines are commonly found in industries such as textiles, leather goods, foam packaging, signage, automotive interiors, aerospace composites, and gasket manufacturing. They are capable of handling diverse materials, including fabrics, rubber, cardboard, plastic sheets, and multilayer composites. The blades can vary in shape, size, and oscillation frequency depending on the material type and thickness. Some advanced models feature automated tool-changing systems, vacuum tables for material stabilization, and computer numerical control (CNC) technology for precise digital cutting.

In operation, a motor drives the blade’s oscillation while a CNC controller guides its movement along programmed cutting paths. The result is a system that can produce highly intricate designs with tight tolerances, consistent repeatability, and minimal material waste. However, these advantages also come with technical and operational complexities. The combination of sharp blades, high-speed motion, and automated components means that users must have a solid understanding of the machine’s mechanics, maintenance requirements, and safety protocols.

Oscillating knife cutting machines represent a balance between power and precision. They are engineered to deliver efficiency and accuracy across a range of materials and applications, but their performance—and safety—depend heavily on correct setup, regular maintenance, and trained operation. A clear understanding of how these machines work is the first step toward recognizing and managing the risks they pose in an industrial setting.

Risk Overview

Oscillating knife cutting machines are powerful precision tools, but their effectiveness comes with inherent risks that can’t be ignored. The combination of high-speed oscillation, razor-sharp blades, and automated motion makes these machines both highly efficient and potentially dangerous. Without proper safety procedures and maintenance routines, even minor oversights can lead to severe injuries, equipment failure, or production losses.

The primary risks stem from the machine’s moving components. The oscillating blade can easily cause deep lacerations if operators come into contact with it during operation, cleaning, or setup. Accidental activation of the machine—especially when guards or safety sensors are bypassed—poses one of the greatest hazards. In addition, vibrations and repetitive motions can create ergonomic stress for workers over time, leading to fatigue or strain injuries. Noise exposure is another often-overlooked factor, as prolonged use without adequate hearing protection can result in hearing loss.

Mechanical and electrical risks are equally critical. Faulty wiring, poor grounding, or improper calibration can lead to malfunctions or electrical shocks. Over time, worn or improperly tensioned blades can snap, sending fragments flying at high speed. Dust, debris, and material residue can also accumulate inside the machine, affecting performance, overheating components, and increasing the likelihood of mechanical failure.

Regular maintenance plays a key role in preventing these hazards. Routine inspections help identify issues like dull blades, loose fasteners, sensor failures, or lubrication problems before they escalate. Safety training ensures operators know how to use emergency stops, handle blades safely, and follow lockout/tagout procedures during maintenance. Together, these practices not only protect workers but also extend the life of the machine, maintain cutting precision, and minimize costly downtime.

Safety and maintenance are not optional—they are fundamental to operating oscillating knife cutting machines responsibly. When neglected, the risks extend beyond physical harm to include reduced productivity, product defects, and expensive repairs. A well-maintained machine, operated by trained personnel under strict safety standards, ensures both optimal performance and a safe working environment.

Mechanical Hazards

Mechanical hazards are the most immediate and visible risks associated with oscillating knife cutting machines. These dangers arise from the machine’s moving parts—especially the oscillating blade, which operates at high speed and exerts significant cutting force. Without proper safeguards, training, and maintenance, even a momentary lapse in attention can result in serious injury or equipment damage. Understanding the main mechanical hazards is essential for minimizing these risks and ensuring safe operation.

Blade Contact Injuries

The most obvious and severe hazard comes from direct contact with the oscillating blade. These blades move thousands of times per minute, and even a brief touch can cause deep cuts or amputations. Such injuries often occur during setup, cleaning, or maintenance, when operators may reach into the cutting area without proper lockout/tagout procedures. Dull or damaged blades can also increase danger, as they may require greater pressure to cut materials and behave unpredictably. Effective safety measures include fixed or interlocked guards, emergency stop switches, and clear operator zones. Training workers to handle and replace blades correctly—and only when the machine is fully powered down—is essential for preventing accidents.

Pinch Points and Moving Components

Beyond the blade itself, oscillating knife cutting machines have multiple moving parts that can trap or crush fingers, clothing, or tools. Pinch points commonly exist around the tool head, drive mechanisms, and material feed areas. Automated cutting tables, conveyors, and gantry systems can also move suddenly and with enough force to cause serious injury. Operators must remain vigilant, keeping their hands and loose items away from motion zones. Regular inspection of guards, sensors, and limit switches helps ensure that automatic shutdown systems function correctly when something obstructs the machine’s movement.

Ejected Material and Debris

Another significant hazard is flying debris or ejected material. When cutting dense or layered materials—such as foam, rubber, or composites—small fragments can break loose and be propelled outward at high speed. Worn or improperly installed blades can increase this risk by chipping or shattering under stress. Debris can cause eye or facial injuries and, in extreme cases, damage surrounding equipment. To mitigate this danger, operators should always wear appropriate personal protective equipment (PPE), such as safety glasses or face shields, and ensure the workspace is fitted with transparent protective barriers. Proper maintenance—particularly checking blade condition and material hold-down systems—helps reduce the likelihood of materials being thrown or displaced during operation.

Mechanical hazards in oscillating knife cutting machines are serious but manageable with proper precautions. Blade contact, pinch points, and ejected debris each pose unique risks that demand consistent attention and adherence to safety protocols. The key to prevention lies in a combination of physical safeguards, regular maintenance, and disciplined operator behavior. When these elements are in place, manufacturers can maintain productivity without compromising worker safety or equipment integrity.

Electrical and Control Risks

Oscillating knife cutting machines rely on complex electrical systems and computerized control units to deliver precision and consistency. While these systems enhance performance and automation, they also introduce a range of electrical and control-related risks. Faulty wiring, poor grounding, software errors, or power fluctuations can compromise both operator safety and machine reliability. Understanding these risks is critical to preventing accidents, ensuring continuous operation, and protecting valuable equipment from costly damage.

Power Overloads

Power overloads occur when the electrical demand of the machine exceeds the system’s rated capacity. This can happen due to faulty wiring, damaged power supplies, or the simultaneous operation of multiple high-load devices. Overloads can cause circuit breakers to trip, disrupt production, or, in severe cases, overheat components and start fires. To prevent overloads, machines should always be connected to properly rated circuits, and operators should avoid using extension cords or unverified power sources. Regular electrical inspections, combined with surge protection and voltage stabilizers, help safeguard both the equipment and operators from power-related disruptions.

Electrical Shock and Fire Hazards

Electrical shock is one of the most serious risks in any powered machinery environment. Damaged cables, exposed conductors, or improperly grounded components can deliver high-voltage shocks capable of causing severe injury or death. Moisture near electrical panels or cutting areas—especially when cutting water-absorbent materials—further increases the danger. In addition, accumulated dust, faulty insulation, or overloaded components can ignite and cause electrical fires. Preventive measures include using insulated tools, keeping panels sealed and dry, and ensuring that all electrical systems meet industrial safety standards (such as IP-rated enclosures and grounding continuity). Maintenance personnel should always disconnect power before performing any electrical or mechanical service.

Control System Failures

Modern oscillating knife cutting machines rely heavily on CNC or digital control systems for accuracy and automation. A control failure—whether from software corruption, sensor malfunction, or communication loss—can lead to dangerous, unpredictable movements. In such cases, the blade may continue operating even after an emergency stop command or fail to follow programmed paths, resulting in collisions, material waste, or injury. Regular calibration, firmware updates, and diagnostics help ensure reliable operation. It’s also essential to maintain backups of machine programs and verify that all emergency stop buttons, interlocks, and override systems are functioning properly at all times.

Electromagnetic Interference (EMI)

Electromagnetic interference can disrupt sensitive control signals within the machine’s electronics, leading to erratic operation or false readings. EMI can originate from nearby welding equipment, radio transmitters, or even other industrial machines operating on the same power grid. In severe cases, this interference can cause miscommunication between sensors and controllers, halting operations or triggering safety systems unnecessarily. To mitigate EMI risks, proper cable shielding, grounding, and physical separation between signal and power lines should be maintained. Using certified components and adhering to electromagnetic compatibility (EMC) standards ensures stable and interference-free operation.

Electrical and control risks in oscillating knife cutting machines are often less visible than mechanical hazards, yet their impact can be just as severe. Power overloads, electrical shocks, control malfunctions, and electromagnetic interference can all compromise both safety and productivity. The key to prevention lies in proactive maintenance, regular system testing, and strict adherence to electrical safety standards. When managed properly, these precautions protect not only workers but also the reliability and lifespan of the machine itself.

Operational and Process Risks

Beyond the obvious mechanical and electrical dangers, oscillating knife cutting machines also present significant operational and process-related risks. These hazards often stem from human error, poor setup, improper material handling, or process inefficiencies rather than equipment defects. Even with advanced automation, the performance and safety of these machines depend heavily on correct operation and careful workflow management. Understanding and controlling these risks is crucial for maintaining consistent quality, preventing damage, and minimizing production downtime.

Setup and Calibration Errors

Incorrect setup or calibration is one of the most common sources of operational failure. Oscillating knife cutting machines rely on precise alignment, blade depth, and oscillation frequency to produce clean, accurate cuts. A miscalibrated blade can cause uneven edges, material tearing, or complete part rejection. In extreme cases, it can overload the motor or cause the blade to break, endangering the operator. These issues often arise when operators rush the setup process, use outdated parameters, or neglect to verify tool alignment after maintenance. Preventing such errors requires strict adherence to setup protocols, proper documentation of cutting parameters, and the use of calibration tools or sensors to verify accuracy before each production run. Operator training and experience play a key role in ensuring that the machine performs within its intended tolerances.

Material Handling and Fixture Risks

Improper material handling and poor fixturing can create serious operational and safety problems. If materials are not securely held in place during cutting, they can shift unexpectedly, leading to inaccurate cuts, blade binding, or even projectile hazards. Flexible or layered materials—like fabrics, foams, or composites—are particularly prone to movement if not properly clamped or vacuum-secured. Handling large or heavy sheets can also expose operators to lifting injuries or pinch points between the material and the machine bed. To mitigate these risks, operators should always use the correct fixtures, vacuum tables, or clamping systems designed for specific material types. Additionally, clear handling procedures and teamwork during material loading and unloading help prevent strain injuries and accidental collisions.

Machine Downtime and Fatigue

Extended machine use without adequate rest periods or maintenance can lead to both equipment fatigue and operator exhaustion. Continuous operation can cause components such as bearings, belts, and motors to overheat or wear prematurely, increasing the likelihood of mechanical failure. For operators, long shifts spent monitoring or adjusting machines can result in fatigue-related errors, slower reaction times, and decreased situational awareness—conditions that heighten the risk of accidents. Preventive maintenance schedules, periodic inspections, and automated monitoring systems help keep the machine running within safe limits. Rotating operators and implementing rest breaks can reduce human fatigue, ensuring sustained attention and safer operation throughout production cycles.

Operational and process risks in oscillating knife cutting machines often emerge from human factors and procedural shortcomings rather than from the technology itself. Setup mistakes, improper material handling, and fatigue-induced oversights can compromise both safety and product quality. Effective risk management in this area depends on three pillars: skilled training, consistent operational discipline, and proactive maintenance. By integrating these practices into daily workflows, manufacturers can reduce process variability, extend machine lifespan, and ensure both safe and efficient cutting operations.

Ergonomic and Human Factors Risks

While much of the focus on oscillating knife cutting machines centers around mechanical and electrical dangers, the risks related to ergonomics and human factors are equally important—and often overlooked. Operators working with these machines must perform repetitive tasks, maintain precise movements, and interact closely with large, automated systems. Over time, poor ergonomics, awkward postures, and repetitive motions can lead to chronic health issues, reduced efficiency, and a higher likelihood of operational mistakes. Recognizing and addressing these risks is key to maintaining both workforce safety and long-term productivity.

Repetitive Motion Injuries

Operating or supervising an oscillating knife cutting machine often involves repetitive hand and arm movements—loading materials, adjusting fixtures, monitoring cuts, or removing finished parts. Over time, these motions can strain muscles, tendons, and joints, leading to conditions such as carpal tunnel syndrome, tendonitis, or muscle fatigue. Workers who perform these tasks for long periods without adequate rest breaks or ergonomic support are especially vulnerable. Additionally, vibration from the cutting process can exacerbate discomfort and contribute to long-term musculoskeletal issues. Preventive strategies include rotating tasks among team members, introducing adjustable workstations, and scheduling regular rest intervals. Anti-vibration gloves and ergonomically designed tools can also help minimize physical stress. Proper training on posture, lifting techniques, and safe movement patterns ensures that operators can perform their work safely and comfortably.

Poor Machine Layout and Accessibility

The physical layout of oscillating knife cutting machines can greatly influence operator safety and efficiency. When machines are positioned too high, too low, or too close to other equipment, workers may be forced into awkward or unsafe postures to reach controls, load materials, or perform maintenance. Limited access to emergency stops, cramped workspaces, and poorly designed control panels can all increase the risk of strain injuries or slow response times during emergencies. Additionally, inadequate lighting or cluttered floor areas can lead to slips, trips, and falls—especially when handling large sheets of material. A well-designed workspace prioritizes accessibility and comfort. Adjustable table heights, strategically placed controls, and clear, unobstructed walkways help reduce unnecessary movements and improve reaction time. Periodic ergonomic assessments can identify and correct layout problems before they lead to injury.

Ergonomic and human factors risks may not cause immediate injury, but their effects accumulate over time, impacting both worker well-being and operational reliability. Repetitive motion injuries and poor machine layout are two of the most common—and preventable—issues in facilities using oscillating knife cutting machines. By prioritizing ergonomics in workstation design, task scheduling, and operator training, manufacturers can create a safer, more comfortable working environment. In turn, this leads to improved concentration, reduced absenteeism, and higher long-term productivity—proving that protecting people is not just a safety measure, but a performance advantage.

Maintenance and Cleaning Risks

Maintenance and cleaning are essential to keeping oscillating knife cutting machines running efficiently and safely—but these tasks carry their own set of serious risks. Because maintenance often involves working close to sharp blades, electrical systems, and moving parts, even minor lapses in procedure can lead to severe injuries or costly equipment damage. Likewise, improper cleaning or neglecting upkeep can cause mechanical deterioration, calibration drift, and unexpected breakdowns. Understanding and managing these risks is crucial to maintaining both operator safety and machine reliability.

Accidental Start-Up

One of the most dangerous risks during maintenance or cleaning is accidental start-up. When a machine is powered but not properly locked out, it can unexpectedly activate, causing the blade to oscillate or the head to move suddenly. This can result in serious lacerations, crushing injuries, or even fatalities. These incidents often occur when workers skip lockout/tagout procedures, assume the machine is off, or miscommunicate during multi-person maintenance tasks. To prevent accidental start-up, strict adherence to lockout/tagout protocols is mandatory. Power sources must be fully disconnected, residual energy discharged, and machine status clearly tagged before any service begins. Visual and audible warning indicators should also be used to alert personnel when maintenance is in progress.

Blade Replacement Hazards

Replacing or adjusting blades is among the most hazardous maintenance activities. Oscillating blades are extremely sharp and can cause deep cuts even when stationary. The risk increases if operators handle blades without proper tools, gloves, or training. Additionally, incorrectly installed blades can loosen or break during operation, creating projectile hazards. Safe blade replacement requires cut-resistant gloves, secure blade holders, and adherence to manufacturer torque specifications. The area around the cutting head should be cleared of obstructions to avoid accidental contact, and used blades must be disposed of in designated sharps containers to prevent secondary injuries.

Slips, Trips, and Cleaning Hazards

Cleaning the machine and the surrounding workspace may seem routine, but it carries several hidden dangers. Cutting residues such as dust, fibers, lubricants, and fragments can accumulate on the floor, creating slippery or uneven surfaces. Liquid cleaning agents and compressed air can also scatter debris, increasing the chance of slips or inhalation hazards. In addition, reaching into tight spaces to remove debris can expose workers to sharp edges or moving components. To reduce these risks, cleaning should only be done when the machine is fully powered down, with guards in place. Spill-resistant flooring, proper ventilation, and non-slip footwear further enhance safety. Regular housekeeping should be integrated into daily operations to prevent buildup that could interfere with sensors, airflow, or cutting accuracy.

Lubrication Neglect and Wear

Oscillating knife cutting machines rely on proper lubrication to ensure smooth motion, reduce friction, and prevent premature wear. Neglecting lubrication schedules or using the wrong type of lubricant can cause overheating, part failure, and increased vibration—all of which contribute to safety hazards and product defects. Conversely, over-lubrication can lead to excess residue, which attracts dust and debris, impairing sensors and moving mechanisms. A disciplined lubrication plan—using manufacturer-recommended oils and intervals—helps maintain optimal performance. Maintenance logs should track lubrication points, frequency, and any observed anomalies such as noise or irregular motion.

Calibration and Alignment Drift

Over time, even well-maintained oscillating knife cutting machines can experience calibration and alignment drift. Continuous vibration, material stress, and component wear gradually affect blade positioning, cutting depth, and oscillation accuracy. If not detected early, this drift can lead to poor-quality cuts, blade damage, or machine misoperation. Misalignment can also cause uneven load distribution on mechanical parts, accelerating wear and increasing the chance of mechanical failure. Regular calibration checks, performed with precision instruments, ensure that the machine continues to operate within safe and accurate tolerances. Automated diagnostic systems or built-in calibration tools can help detect alignment issues before they cause operational or safety problems.

Maintenance and cleaning tasks, though routine, pose substantial risks when working with oscillating knife cutting machines. Accidental start-ups, blade handling injuries, cleaning-related slips, lubrication errors, and calibration drift can all compromise both safety and efficiency. The key to mitigating these hazards lies in disciplined maintenance protocols, proper protective equipment, and consistent operator training. A structured maintenance schedule not only minimizes safety risks but also extends machine lifespan, improves cutting accuracy, and ensures uninterrupted productivity. In short, safe maintenance practices protect both the operator and the investment in high-precision cutting technology.

Noise, Vibration, and Environmental Risks

Oscillating knife cutting machines are known for their precision and versatility, but they also generate environmental and ergonomic challenges that can impact both workers and the surrounding workspace. Prolonged exposure to noise, vibration, and airborne particles doesn’t just reduce comfort—it can lead to serious health issues and degrade overall productivity. Understanding these environmental risks and taking proactive measures to control them is essential to maintaining a safe, compliant, and sustainable workplace.

Noise Exposure

The rapid oscillation of the knife blade, combined with air compression systems and cutting friction, produces significant noise levels. In high-speed industrial environments, sound levels can easily exceed 85 decibels—the threshold where long-term hearing damage becomes a concern. Continuous exposure to this noise can cause not only hearing loss but also fatigue, stress, and reduced concentration, which increases the likelihood of accidents. Factors such as machine type, material density, and room acoustics influence how loud the operation becomes. To mitigate these risks, facilities should implement noise control strategies such as installing acoustic barriers or sound-absorbing panels around cutting stations. Regular noise level monitoring and enforcing the use of hearing protection, like earmuffs or earplugs, help safeguard operators’ hearing health. Additionally, scheduling quieter operations during maintenance or shift changes can reduce cumulative exposure for workers.

Vibration and Fatigue

Vibration is another inherent byproduct of oscillating knife cutting machines. The high-frequency movement of the blade transmits vibrations through the machine’s frame and, in some cases, into the work surface or operator’s hands. Prolonged exposure to vibration can lead to hand-arm vibration syndrome (HAVS), joint pain, or muscle fatigue. It can also loosen mechanical components over time, affecting calibration and cut accuracy. For operators, even low-level vibration exposure throughout a workday can contribute to physical discomfort and cognitive fatigue, reducing performance and situational awareness. Vibration-damping mounts, isolation pads, and properly maintained bearings can significantly reduce transmission. Routine machine inspections ensure that worn or unbalanced components—common vibration culprits—are promptly repaired or replaced. Workers should also rotate between tasks and use anti-vibration gloves when prolonged machine contact is unavoidable.

Air Quality and Dust

While oscillating knife cutting machines do not produce smoke or fumes like laser cutting machines, they can generate fine dust and airborne particles depending on the materials being processed. Cutting textiles, foams, leathers, or composites can release fibers and particulate matter that linger in the air, potentially causing respiratory irritation or allergic reactions. Over time, this buildup can affect both human health and machine performance by clogging sensors, filters, or ventilation systems. Effective dust control begins with proper extraction systems, such as localized vacuum units or overhead air filtration. Regular cleaning of ducts, filters, and cutting surfaces helps maintain a clean workspace and consistent airflow. Operators should also wear appropriate respiratory protection when cutting materials known to shed fibers or particulates. In environments where dust accumulation is heavy, continuous air quality monitoring ensures compliance with occupational health standards.

Noise, vibration, and air quality risks often go unnoticed in the daily operation of oscillating knife cutting machines, yet they have long-term effects on both human health and production efficiency. Excessive noise can impair hearing and focus; vibration can lead to physical strain and machine wear; and poor air quality can threaten respiratory health and precision cutting performance. Addressing these environmental hazards through engineering controls, personal protective equipment, and regular monitoring not only ensures regulatory compliance but also promotes a safer, more comfortable, and more productive work environment.

Fire and Explosion Risks

While oscillating knife cutting machines are not inherently high-temperature systems like laser or plasma cutting machines, they can still pose serious fire and explosion risks under certain operating conditions. These hazards typically arise from a combination of mechanical friction, electrical faults, combustible materials, and poor environmental control. Even a small ignition source—such as a spark from static discharge or a short circuit—can trigger a fire if flammable materials or dust are present. Understanding how these risks develop and how to prevent them is critical to maintaining a safe and compliant production environment.

Sources of Ignition and Combustion

The primary ignition risks in oscillating knife cutting machines stem from electrical faults, overheated components, and friction-related heat buildup. If the blade or drive system becomes misaligned or jammed, excessive friction can generate localized heat capable of igniting nearby dust or fibers. Faulty wiring, overloaded circuits, and damaged insulation can also produce electrical sparks that ignite flammable materials. Machines cutting foams, rubber, or composite materials are particularly vulnerable since these materials can emit flammable particles or vapors when abraded. Static electricity is another hidden danger, especially when cutting lightweight or synthetic materials that accumulate charge. Without proper grounding and static dissipation systems, this charge can discharge suddenly, causing a spark capable of igniting fine dust or fumes.

Flammable Dust and Material Accumulation

Dust buildup is one of the most overlooked fire and explosion hazards in oscillating knife operations. Materials such as polyurethane foam, fabric fibers, paper, or composite dust can create a combustible atmosphere when suspended in air. In enclosed areas, these particles can ignite explosively if exposed to an ignition source. The risk is especially high in cutting rooms with poor ventilation or inadequate dust extraction systems. Regular cleaning, vacuum-based dust collection, and anti-static flooring can significantly reduce the likelihood of combustible dust accumulation. Air filtration and ventilation systems should be inspected regularly to ensure they effectively remove airborne particles and do not themselves become sources of ignition.

Electrical and Control Failures

Electrical malfunctions are a common contributor to fire incidents. Short circuits, poor grounding, or overloaded power supplies can overheat wiring and ignite nearby materials. Inadequate maintenance of control cabinets or failure to inspect electrical connections can allow small faults to escalate into dangerous conditions. To minimize risk, all machines should comply with industrial electrical standards, and regular thermal imaging inspections can be used to detect overheating components before failure occurs. Emergency shutdown mechanisms and circuit protection devices (such as fuses and overload relays) should always be functional and tested as part of routine safety checks.

Preventive Measures and Safe Practices

Preventing fire and explosion risks requires a layered safety approach that includes engineering controls, preventive maintenance, and operator awareness. Machines should be installed in well-ventilated areas with minimal combustible materials nearby. Dust collection systems must be properly grounded to prevent static buildup. Operators should never use compressed air to blow debris off the machine, as this can suspend dust in the air and increase explosion potential. Instead, vacuum systems equipped with spark-proof filters should be used. Regular cleaning schedules, electrical inspections, and monitoring for unusual noises, smells, or vibrations can help detect early warning signs of overheating or malfunction. Fire extinguishers rated for electrical and combustible dust fires should be readily accessible, and all personnel should be trained in emergency procedures.

Fire and explosion risks in oscillating knife cutting machines may not be immediately apparent, but they can develop quickly under the wrong conditions. Friction, electrical faults, static discharge, and combustible dust all have the potential to ignite fires or cause explosions in confined environments. Effective prevention depends on maintaining clean, grounded, and well-ventilated workspaces—supported by disciplined maintenance routines and vigilant operator training. By taking these precautions, manufacturers can ensure that high-speed cutting operations remain both efficient and safe from the devastating consequences of fire-related incidents.

Software, Automation, and Cybersecurity Risks

As oscillating knife cutting machines evolve into smarter, more automated systems, their reliance on software and networked technologies introduces a new category of risks—those rooted in programming errors, system failures, and cybersecurity vulnerabilities. These machines often operate through computer numerical control (CNC) systems and integrate with digital production lines or cloud-based management platforms. While automation enhances precision and efficiency, it also increases exposure to software malfunctions, data corruption, and even cyberattacks. Understanding these risks is vital for maintaining safe, reliable, and secure cutting operations.

CNC Programming Errors

CNC programming governs every movement of the oscillating knife—its path, speed, depth, and sequence. A single error in programming or code input can result in catastrophic outcomes. Incorrect tool paths might cause the knife to collide with fixtures, cutting tables, or even itself, damaging expensive equipment and endangering nearby operators. Overly aggressive cutting parameters can also lead to overheating, blade breakage, or material tearing. Such issues often stem from manual coding mistakes, outdated post-processors, or poor file conversion between design and machine software. To minimize this risk, operators should validate cutting programs through simulation before running live operations. Regular software updates, standardized naming conventions, and operator training on CNC programming best practices ensure consistency and prevent costly errors.

Cybersecurity Threats

Modern oscillating knife cutting machines frequently connect to local networks, production servers, and sometimes cloud-based systems for data sharing and remote monitoring. This connectivity, while convenient, exposes them to cybersecurity threats such as malware, ransomware, and unauthorized access. A successful cyberattack could disable machine functions, alter control parameters, or corrupt stored cutting programs—causing operational disruptions and potential safety hazards. In extreme cases, hackers could exploit vulnerabilities in industrial control systems (ICS) to manipulate machine behavior remotely. Protecting these systems requires implementing robust firewalls, secure user authentication, regular software patching, and restricted access privileges. Manufacturers should treat their cutting machines as part of their broader IT infrastructure, applying the same cybersecurity standards used for critical enterprise systems.

Data Corruption and Communication Delays

Oscillating knife cutting systems depend on accurate and uninterrupted data exchange between control units, sensors, and software interfaces. Any corruption or delay in this data flow can disrupt synchronization between movement and blade oscillation, resulting in inaccurate cuts, wasted materials, or mechanical collisions. Communication failures may arise from faulty network cables, outdated firmware, or interference from other devices on the production floor. In networked environments, large data packets or slow server response times can further compound these issues. To prevent data-related risks, it’s essential to maintain stable and shielded network connections, use error-checking communication protocols, and regularly back up all machine configurations and cutting programs. Continuous monitoring tools can alert operators to latency or signal loss before it leads to operational errors.

Collision Detection Failures in Automated Cells

In facilities where oscillating knife cutting machines operate within automated cells—often alongside robotic arms, conveyors, or material feeders—collision detection becomes critical. These systems rely on sensors and software algorithms to recognize obstacles and stop movement when a collision risk is detected. If a sensor malfunctions, becomes misaligned, or the software fails to interpret data correctly, the machine may continue operating despite obstructions, leading to severe equipment damage or worker injury. Common causes of failure include sensor degradation, calibration drift, or interference from reflective surfaces and dust. Regular testing of collision detection systems, along with preventive maintenance and redundant safety sensors, ensures reliable obstacle recognition. Advanced monitoring systems with real-time diagnostics can also help identify issues early and prevent unplanned collisions.

Software, automation, and cybersecurity risks represent an increasingly complex challenge in the safe operation of oscillating knife cutting machines. CNC programming errors, data corruption, and control failures can cause mechanical damage and safety incidents, while cyber threats introduce new layers of vulnerability that extend beyond the physical workspace. As automation grows, maintaining rigorous control over both digital and physical systems becomes essential. This includes secure network practices, validated software workflows, consistent data management, and regular testing of automated safety features. By integrating these digital safeguards with traditional safety measures, manufacturers can achieve a resilient and secure production environment that balances innovation with protection.

Training, Supervision, and Organizational Risks

Even the most advanced oscillating knife cutting machines are only as safe as the people who operate and manage them. Human factors—such as insufficient training, weak supervision, and poor communication—are among the leading causes of accidents, inefficiency, and equipment damage in industrial environments. These risks are not tied to the machine itself, but to how organizations prepare, guide, and oversee their workforce. Without a strong safety culture and structured operational oversight, even minor procedural lapses can escalate into serious incidents.

Insufficient Training

Inadequate operator training is one of the most significant and widespread risks in facilities using oscillating knife cutting machines. These systems demand more than just basic mechanical skill—they require an understanding of CNC programming, safety interlocks, calibration processes, and emergency response procedures. When training is rushed, incomplete, or outdated, workers may not recognize early warning signs of malfunction, perform maintenance incorrectly, or bypass safety mechanisms to save time. Such mistakes can lead to severe injuries, poor cut quality, and machine damage. Comprehensive training programs should cover not only machine operation but also hazard recognition, lockout/tagout procedures, and emergency protocols. Refresher courses and periodic assessments ensure that both new and experienced employees remain competent as equipment and technology evolve. Hands-on sessions, supervised apprenticeships, and certification systems can further reinforce safe and consistent operational standards.

Poor Supervision and Enforcement

Even when workers are properly trained, poor supervision and a lack of enforcement can undermine safety practices. Supervisors play a critical role in ensuring that procedures are followed consistently—especially in high-paced production settings where shortcuts are tempting. Without active oversight, workers may neglect pre-use inspections, remove guards for convenience, or skip shutdown procedures. These behaviors, often motivated by production pressure or complacency, can create unsafe conditions and normalize risky habits across the workforce. Effective supervision means more than monitoring; it involves coaching, mentoring, and leading by example. Supervisors should perform regular audits, document compliance, and address safety violations immediately. Management must also support a culture where reporting hazards or errors is encouraged, not punished. When leadership models accountability and prioritizes safety over speed, employees are far more likely to maintain disciplined and safe work habits.

Communication Failures

Clear and consistent communication is essential to safe machine operation, particularly in multi-shift environments or teams sharing the same equipment. Misunderstandings about machine status, maintenance schedules, or software updates can result in improper operation or unexpected machine behavior. For instance, if one team fails to record a calibration adjustment or a blade replacement, the next shift might operate under false assumptions—potentially causing damage or injury. In larger facilities, communication failures can also occur between departments, such as maintenance, production, and safety management, leading to gaps in preventive actions or hazard tracking. To prevent such issues, companies should implement structured communication systems, including standardized handover reports, maintenance logs, and digital tracking tools. Safety meetings, pre-shift briefings, and open feedback channels allow workers to share observations and raise concerns before small issues escalate into serious risks.

Training, supervision, and communication form the human backbone of safe oscillating knife cutting machine operations. When these elements are weak or neglected, the likelihood of accidents, errors, and production inefficiencies increases dramatically. Properly trained operators understand both the capabilities and the limits of the machine; strong supervision ensures that safety standards are upheld; and clear communication keeps teams aligned and informed. Investing in these organizational foundations not only reduces risk but also enhances productivity, morale, and long-term operational stability. In essence, building a strong safety culture is not just about following rules—it’s about creating an environment where awareness, responsibility, and teamwork drive safe and efficient machine performance.

Legal and Regulatory Risks

Operating oscillating knife cutting machines involves not only technical and operational responsibilities but also significant legal and regulatory obligations. Employers and facility managers are required by law to ensure that these machines are installed, maintained, and operated in compliance with workplace safety standards. Failing to meet these requirements can lead to serious consequences, including fines, production shutdowns, reputational damage, and even criminal liability in cases involving injury or death. Legal and regulatory risks arise when companies overlook safety standards, fail to maintain proper documentation, or neglect ongoing risk assessments. Understanding and adhering to these legal frameworks is essential to maintaining both compliance and workplace safety.

Regulatory Requirements

Regulations governing oscillating knife cutting machines vary by region but share a common goal: to protect workers from mechanical, electrical, and ergonomic hazards. In most countries, these machines fall under general machinery safety standards such as OSHA (Occupational Safety and Health Administration) regulations in the United States, the EU Machinery Directive in Europe, or ISO/EN standards for industrial machinery worldwide. These standards dictate requirements for guarding systems, emergency stops, electrical safety, noise levels, and operator training. Employers must also comply with local workplace health and safety laws that mandate hazard assessments, personal protective equipment (PPE), and regular safety inspections. Noncompliance can result in citations, financial penalties, or enforced machine shutdowns until corrective measures are implemented.

Regulatory agencies often require that machines be equipped with certified safety components—such as interlocked guards, overload protection, and compliant control systems—to reduce the likelihood of injury. Manufacturers and operators share responsibility for ensuring that the machine’s design, installation, and usage meet legal safety thresholds. Importing or modifying oscillating knife systems without proper certification can void compliance status and expose a company to liability. Therefore, staying current with evolving safety regulations and ensuring continuous compliance is a core part of responsible machine ownership.

Documentation and Risk Assessment

Proper documentation and formal risk assessments are not just best practices—they are legal necessities. Regulatory bodies require employers to maintain detailed records of safety inspections, maintenance activities, operator training, and incident reports. Comprehensive documentation provides a traceable record that demonstrates due diligence in the event of an audit, inspection, or legal inquiry. It also serves as a foundation for continuous improvement in workplace safety practices.

Risk assessments play a critical role in identifying potential hazards before they result in harm. A thorough risk assessment for an oscillating knife cutting machine should cover mechanical dangers (like blade contact), electrical exposure, ergonomic strain, noise and vibration hazards, and even cybersecurity vulnerabilities in modern automated systems. Assessments must be updated regularly, especially when introducing new materials, modifying machine configurations, or integrating automation components. These evaluations help ensure that all foreseeable hazards are mitigated through engineering controls, administrative policies, and training.

Failure to conduct and document risk assessments can have severe legal implications. If an accident occurs and no records show that risks were properly evaluated or controlled, companies can face liability claims, insurance disputes, and potential legal prosecution. Beyond compliance, effective documentation and risk management foster a culture of accountability—demonstrating to regulators, employees, and clients that safety is an integral part of business operations.

Legal and regulatory risks associated with oscillating knife cutting machines extend far beyond paperwork—they directly influence workplace safety, operational continuity, and corporate reputation. Compliance with machinery safety standards, coupled with detailed documentation and risk assessment, ensures that both employers and operators meet their legal obligations. A well-documented safety system not only protects against legal penalties but also builds trust with employees, regulators, and customers. Ultimately, proactive compliance is more than a regulatory checkbox—it’s a strategic safeguard that supports safe, sustainable, and legally sound manufacturing operations.

Economic Risks

The risks of using oscillating knife cutting machines extend beyond safety and compliance—they also carry significant economic consequences. Mechanical failures, operator errors, and poor maintenance can quickly translate into financial losses through downtime, wasted materials, and increased operational expenses. Additionally, accidents or regulatory violations can lead to increased insurance premiums and trigger costly legal proceedings. Understanding the financial dimension of these risks helps businesses appreciate why preventive measures, training, and proper maintenance are not expenses but strategic investments in long-term profitability and reliability.

Downtime and Productivity Loss

Unplanned machine downtime is one of the most direct and costly economic risks associated with oscillating knife cutting machines. When a cutting machine malfunctions or requires emergency repairs, production can grind to a halt—disrupting schedules, delaying orders, and creating bottlenecks across the workflow. In industries like automotive, textiles, or packaging, where production lines are tightly synchronized, even a few hours of downtime can lead to missed delivery deadlines and dissatisfied clients. The costs go beyond lost production time; idle labor, rescheduling, and expedited shipping can further inflate expenses. Many of these interruptions stem from preventable causes such as inadequate maintenance, calibration errors, or improper machine setup. Implementing predictive maintenance systems, scheduling regular inspections, and training operators to detect early warning signs can significantly reduce downtime-related losses and improve overall equipment effectiveness (OEE).

Scrap Material and Tool Wear Costs

Poorly maintained or improperly calibrated oscillating knife cutting machines often produce defective cuts, leading to high scrap rates and material waste. This is particularly costly when working with expensive materials such as composites, technical textiles, or specialty foams. A dull or misaligned blade can cause frayed edges, inaccurate dimensions, or incomplete cuts—rendering entire batches unusable. In addition to material loss, excessive tool wear raises replacement costs and shortens the lifespan of key components like blades, bearings, and drive systems. Over time, these small inefficiencies compound into substantial financial drains. Establishing proper tool maintenance schedules, tracking blade life, and investing in high-quality cutting consumables can reduce these losses. Additionally, monitoring machine performance data can help identify patterns of excessive wear or process inefficiency, allowing for timely interventions before waste escalates.

Insurance and Legal Implications

Accidents involving oscillating knife cutting machines can have far-reaching financial repercussions. Workplace injuries, fires, or equipment damage often result in insurance claims, legal fees, and potential compensation payouts. Repeated incidents or evidence of negligence can drive up insurance premiums or even lead to loss of coverage. Noncompliance with safety regulations may also result in government fines, production suspensions, or lawsuits filed by affected employees. Beyond the immediate financial costs, legal proceedings can harm a company’s reputation and disrupt relationships with clients and suppliers. The best financial defense against these risks is proactive compliance and thorough documentation. Maintaining safety certifications, training records, and risk assessments demonstrates due diligence, which can reduce liability and strengthen a company’s position during insurance reviews or legal disputes.

Economic risks tied to oscillating knife cutting machines are multifaceted, affecting both short-term cash flow and long-term business sustainability. Downtime and productivity loss erode efficiency, material waste inflates production costs, and legal or insurance issues can drain financial resources and damage credibility. However, these risks are largely controllable through preventive maintenance, skilled training, and adherence to safety and quality standards. By viewing safety and maintenance not as overhead costs but as strategic investments, manufacturers can minimize financial exposure, protect profit margins, and maintain a stable, competitive operation. In essence, the economic stability of a cutting operation depends as much on smart risk management as on technological precision.

Risk Mitigation and Best Practices

While oscillating knife cutting machines present a range of mechanical, electrical, ergonomic, and operational hazards, nearly all of these risks can be effectively managed through well-structured risk mitigation strategies and adherence to industry best practices. Safety and efficiency go hand in hand: a properly managed cutting environment not only prevents injuries but also enhances productivity, extends machine lifespan, and improves product quality. Effective risk control requires a multi-layered approach—combining engineering solutions, administrative systems, personal protection, and a strong safety culture reinforced through technology and training.

Engineering Controls

Engineering controls are the first line of defense against machine-related hazards because they physically eliminate or isolate risks at their source. In oscillating knife cutting machines, these controls include features like blade guards, automated tool changers, vibration dampers, and precision control systems that limit operator exposure to moving parts. Proper ventilation and dust extraction systems also help control airborne particles, reducing respiratory hazards. In advanced systems, integrated sensors can automatically detect abnormal vibration, overload conditions, or blade wear—triggering alerts or halting operations before a failure occurs. These built-in safeguards should be maintained and periodically tested to ensure they function as intended.

Administrative Controls

Administrative controls focus on policies, procedures, and organizational practices that reduce the likelihood of unsafe behavior. Clear operating procedures, job-specific training programs, and standardized safety checklists ensure that each operator understands how to use the machine safely and consistently. Implementing lockout/tagout (LOTO) procedures during maintenance, scheduling regular audits, and enforcing reporting of near-miss incidents all contribute to a stronger safety framework. Rotating personnel between tasks can reduce fatigue, while well-documented maintenance and inspection logs help track machine health over time. These systems not only prevent accidents but also demonstrate compliance with legal and regulatory standards.

Personal Protective Equipment (PPE)

Even with strong engineering and administrative controls, personal protective equipment remains an essential layer of protection. Operators should wear cut-resistant gloves, safety glasses or face shields, and hearing protection when working near oscillating knife cutting machines. Anti-slip footwear helps prevent accidents in areas where lubricant or material residue may accumulate. For operations involving dusty or fibrous materials, appropriate respiratory protection should be used. However, PPE should always be seen as a supplement to—not a substitute for—proper machine safety measures. Regular PPE inspections and proper storage ensure that gear remains effective and compliant with safety standards.

Machine Guarding and Safety Interlocks

Machine guarding and safety interlocks are critical in preventing accidental contact with moving blades or mechanical components. Fixed and interlocked guards ensure that cutting operations cannot begin until all protective barriers are securely in place. Modern oscillating knife systems often include light curtains, pressure-sensitive mats, and emergency stop buttons that immediately disable power when triggered. Regular testing of these interlocks is essential to ensure reliability. Any modification, bypass, or deactivation of guards should be strictly prohibited and met with corrective action, as these systems are fundamental to safe machine operation.

Continuous Training and Culture

A culture of safety begins with continuous education. Training should not be a one-time event but an ongoing process that evolves with technology and operational practices. Regular refresher courses keep employees up to date on new safety protocols, machine upgrades, and incident response procedures. Encouraging open communication about hazards and near-misses helps build trust and fosters proactive problem-solving. Supervisors and managers play a pivotal role in setting the tone—by modeling safe behaviors, recognizing good practices, and reinforcing the importance of safety over speed. Over time, this consistent reinforcement creates a workplace culture where safety is viewed as a shared responsibility rather than an imposed rule.

Predictive Maintenance and Monitoring

Predictive maintenance uses real-time data and analytics to identify potential equipment issues before they cause downtime or accidents. Sensors that monitor vibration, temperature, and motor performance can alert operators to early signs of wear or imbalance. Regular calibration checks ensure that cutting parameters remain accurate and within tolerance, reducing material waste and improving product quality. Maintenance schedules should be based on both usage data and manufacturer recommendations, ensuring that no component operates beyond its service life. By catching problems early, predictive maintenance not only prevents costly failures but also enhances operator safety by avoiding unexpected breakdowns.

Software Updates and IoT Integration

As oscillating knife cutting machines become increasingly digital, software and connectivity play a key role in risk mitigation. Regularly updating CNC software, firmware, and safety control systems ensures that vulnerabilities are patched and performance remains stable. Internet of Things (IoT) integration allows machines to communicate with centralized monitoring systems, providing real-time insights into operational status, energy use, and maintenance needs. These digital systems can also track compliance metrics and automatically log safety incidents or performance data for analysis. However, strong cybersecurity measures—such as network segmentation, encrypted communications, and access control—are essential to protect connected machines from unauthorized interference or cyberattacks.

Mitigating the risks of oscillating knife cutting machines requires a holistic approach that blends technology, process discipline, and human awareness. Engineering controls minimize exposure to hazards, administrative systems enforce consistent safe practices, and PPE provides personal defense. Complementing these are proactive maintenance, reliable safety interlocks, and continuous training—all supported by intelligent software and IoT-enabled monitoring. Together, these measures not only prevent accidents but also optimize machine performance, reduce downtime, and ensure compliance with safety regulations. The ultimate goal is a safe, efficient, and forward-thinking operation where every layer of protection works in harmony to sustain long-term productivity and safety.

Summary

Oscillating knife cutting machines are powerful, precise, and indispensable in modern manufacturing, but they also present a wide range of risks that must be carefully managed. From mechanical dangers such as blade contact, pinch points, and flying debris to electrical, ergonomic, and environmental hazards, every aspect of machine operation demands vigilance. Poor maintenance, improper calibration, and inadequate training can lead to injuries, costly downtime, and reduced productivity. Beyond physical safety, digital vulnerabilities—such as software errors, data corruption, and cybersecurity threats—introduce additional layers of risk in today’s increasingly automated production environments.

Legal, organizational, and economic consequences further amplify the importance of strong safety and maintenance programs. Failing to comply with regulations, neglecting documentation, or allowing unsafe practices can result in fines, reputational damage, and significant financial loss. To minimize these risks, companies must adopt a comprehensive safety strategy combining engineering controls, proper guarding, consistent operator training, predictive maintenance, and continuous monitoring.

Ultimately, the safe and efficient operation of oscillating knife cutting machines depends on the balance between technology, discipline, and culture. When workers are well-trained, equipment is well-maintained, and safety is embedded in daily practice, these machines can deliver exceptional precision and productivity—without compromising the well-being of the people who use them.

Get Oscillating Knife Cutting Solutions

At AccTek Group, we understand that precision, efficiency, and safety are equally important when it comes to cutting operations. As a professional manufacturer of intelligent laser and cutting equipment, AccTek Group offers advanced oscillating knife cutting solutions designed to meet the diverse needs of modern industries—from textiles and packaging to composites, foam, and automotive manufacturing. Our machines are engineered with cutting-edge technology that delivers clean, accurate cuts while maintaining the highest safety and reliability standards.

AccTek Group’s oscillating knife cutting systems feature high-speed servo motors, intelligent control software, and customizable tool heads that can handle a wide range of materials with ease. Safety is built into every stage of design, with features such as smart blade protection, emergency stop systems, and automated calibration to reduce human error. In addition, our equipment supports IoT connectivity and digital monitoring, allowing for predictive maintenance and real-time performance tracking.

Whether you need a standard machine or a fully customized cutting solution, AccTek Group’s team provides expert consultation, installation, and technical support to ensure long-term performance and safety. Partner with AccTek Group for reliable, high-precision oscillating knife cutting solutions that combine innovation, durability, and intelligent design—helping your business cut smarter, faster, and safer.