The journey of CNC technology began with simple numerical control (NC) systems in the late 1940s, when early machines were driven by punch cards and rudimentary servomechanisms. These early systems allowed for programmable tool paths but required significant manual setup and input.

In the 1970s, the advent of affordable microprocessors led to true computer numerical control—machines guided by digital instructions created through computer-aided design (CAD) and manufacturing (CAM) software. This leap allowed for the automation of increasingly complex tasks with a high degree of accuracy.

By the 1990s and 2000s, CNC machines became more user-friendly and connected. Features like touchscreen interfaces, real-time feedback, and integration with networked production systems became standard. CNC technology evolved from an industrial luxury into a mainstream necessity, accessible to everyone from large-scale manufacturers to hobbyist makers.

CNC technology has evolved from mechanical punch-card systems into advanced, software-driven machines that dominate modern fabrication. Within this landscape, 3-axis CNC routers hold a unique and essential role. They offer a powerful mix of precision, accessibility, and affordability, making them indispensable across a wide range of industries. While not as complex as multi-axis machines, they cover a vast amount of machining needs and continue to be a crucial step in the evolution of digital manufacturing.

To understand how a 3-axis CNC router operates, it’s essential to grasp the basic mechanical and mathematical principles that define its movement. At the heart of this lies the Cartesian coordinate system, which guides toolpaths across three spatial dimensions. Understanding what a 3-axis CNC router is—and how it moves—provides a strong foundation for working with or investing in this technology.

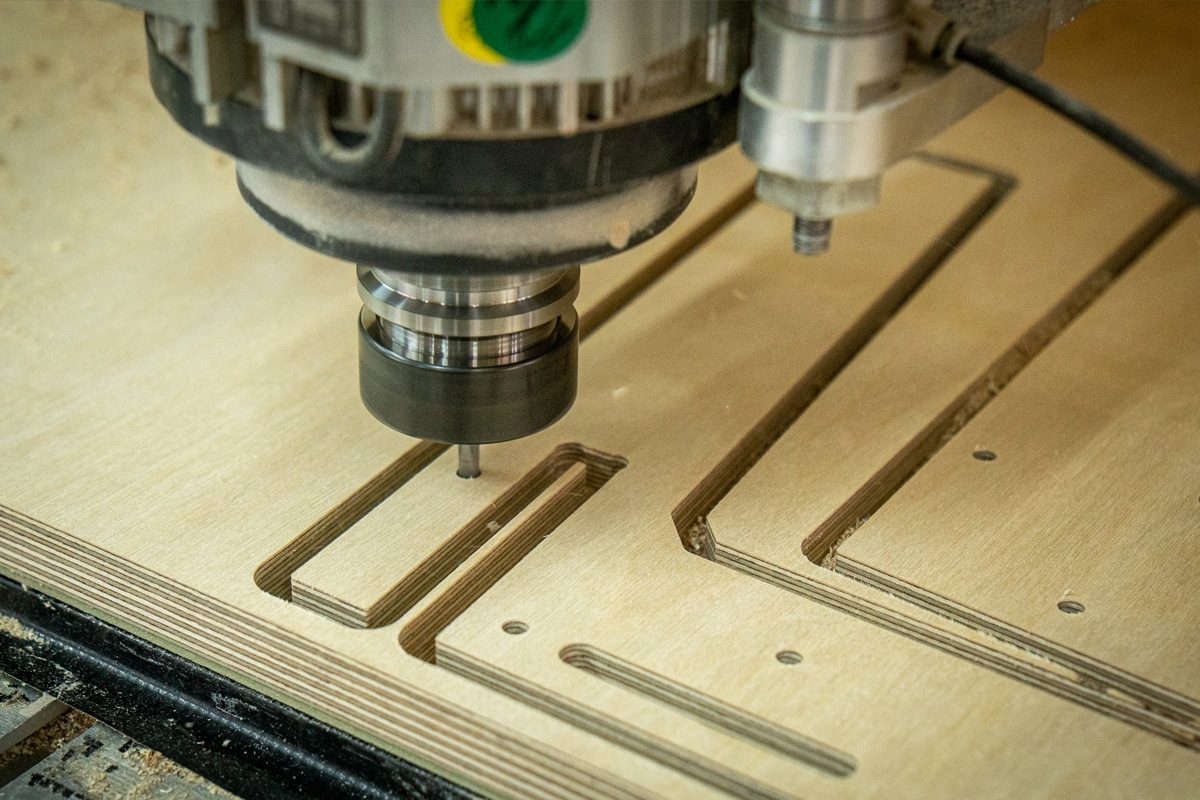

3-axis CNC routers are a computer-controlled cutting machine that operates along three linear axes: X (left-right), Y (front-back), and Z (up-down). The tool, typically a spindle holding a bit or cutter, moves through these axes to cut or shape materials like wood, plastic, aluminum, or foam. The machine interprets digital design files (usually generated through CAD software) and executes precise tool movements based on programmed G-code instructions.

These CNC routers are commonly used in fabrication, woodworking, sign making, prototyping, and light metalworking. While limited to three degrees of freedom, they can perform highly accurate operations like engraving, pocketing, contouring, drilling, and profile cutting.

These three directions represent the machine’s degrees of freedom—each axis allows the tool to move independently in one direction. Together, these axes enable the machine to follow complex toolpaths across flat and moderately contoured surfaces. This model is simple yet powerful, forming the basis for how CNC machines interpret and execute cutting instructions.

These motion types work together to give 3-axis CNC routers the flexibility to handle both simple and intricate tasks, even though the machine is limited to three linear directions.

The fundamental operation of a 3-axis CNC router is grounded in the Cartesian coordinate system, with each axis representing one degree of motion. These machines use digital instructions to guide precise tool movements along the X, Y, and Z axes, allowing for a wide variety of 2D and 3D machining processes. With a firm grasp of concepts like degrees of freedom, coordinate systems, and motion types (continuous, incremental, and simultaneous), users can better understand how these routers operate—and how to maximize their capabilities for any given project.

3-axis CNC router is more than just a cutting machine—it’s an integrated system made up of mechanical, electrical, and software-driven components working together to deliver precision and repeatability. Each part has a specific role in ensuring accuracy, speed, and reliability. Understanding the function of each major component gives insight into how the machine operates, how it can be optimized, and how different configurations affect performance and cost. Below is a breakdown of the essential elements that make up 3-axis CNC routers.

The machine frame is the structural backbone of the CNC router. It supports the entire system and determines the machine’s overall rigidity. A sturdy frame made from welded steel or heavy-duty aluminum minimizes vibration and improves cutting accuracy. The gantry, which spans across the frame, holds the spindle and moves along one axis, typically the Y-axis. Its rigidity and weight distribution are critical for smooth, precise motion.

Linear guideways and bearings allow the machine’s moving parts to glide smoothly along their respective axes. High-quality linear guides reduce friction, support high loads, and ensure precise alignment. Bearings within these guides help maintain motion accuracy over long travel distances and extended use. The smoother and more precise the movement, the better the surface finish and dimensional accuracy of the final product.

The drive system directly affects how smoothly and accurately the machine moves along its axes.

The spindle is the heart of the cutting process. It holds the tool and rotates it at high speeds to cut, carve, or engrave materials. Spindles come in air-cooled or water-cooled configurations and vary in power output, typically ranging from 1 HP to over 10 HP. The spindle’s speed, torque, and durability directly influence cutting quality and the range of materials the router can handle.

The motion controller acts as the brain of the machine, converting digital design files into precise motor commands. It determines acceleration, speed, path accuracy, and error correction. Control software like Mach3, UCCNC, or proprietary systems handles the interface between the user, the G-code, and the controller hardware. Together, they manage the machine’s real-time behavior and job execution.

Choosing between stepper and servo motors often comes down to the balance of cost, performance, and application needs.

Poor workholding leads to chatter, shifting, and ruined parts, so this system is critical to performance.

Investing in safety and cleanliness protects both the operator and the equipment.

3-axis CNC routers are a complex machine built from a range of integrated systems, each playing a crucial role in performance, precision, and safety. From the rigidity of the frame to the sensitivity of the motors and the intelligence of the controller, every component matters. Understanding how these parts work together helps users maintain the machine, troubleshoot issues, and select the right system for their specific needs. Whether you’re a hobbyist or a production engineer, knowing what goes into the machine is key to getting the most out of it.

At a glance, a 3-axis CNC router seems simple: a tool moves across three directions to cut material. But behind each cut lies a highly structured workflow and a deep integration of software, hardware, and motion control principles. To understand how these machines turn digital designs into physical parts, we need to examine the steps from design to execution—and the specific codes, motions, and machining strategies used in between.

The process begins with CAD (Computer-Aided Design), where the part is modeled in 2D or 3D software like Fusion 360, SolidWorks, or SketchUp. This design is then passed to CAM (Computer-Aided Manufacturing) software, which defines the machining operations—what tool to use, how fast to cut, and the path to follow.

The CAM software generates G-code, a machine-readable language consisting of movement instructions, speed settings, and commands for tool changes or spindle control. This G-code is sent to the CNC router’s motion controller, which interprets and executes the commands.

Before machining begins, the router performs a homing routine to locate its origin or “machine zero” using limit switches. Operators then set a datum—the “work zero” or reference point on the material. This could be the top-left corner, the center, or the bottom surface of the stock, depending on the setup.

Modern CNC routers support multiple work coordinate systems, typically labeled G54 to G59. These allow operators to define and switch between different datums within a single project, useful when machining multiple parts on one table.

Understanding when and how the machine uses these movement types is crucial to programming efficient and safe toolpaths.

These values must be dialed in carefully for each job to avoid poor finishes or tool damage.

These strategies can be combined in a single project to achieve complex geometries.

3-axis CNC routers operate through a highly structured workflow, starting with digital design and ending with precise, automated cutting. The CAD → CAM → G-code pipeline translates ideas into machine instructions, while systems like homing, coordinate setting, and toolpath programming ensure repeatable accuracy. Motion commands such as G00 and G01 define how the machine moves, and machining parameters like feed rate and depth of cut determine efficiency and finish quality. With a range of toolpath strategies, 3-axis CNC routers can tackle diverse tasks, making them versatile tools for both simple and complex parts.

One of the major strengths of 3-axis CNC routers lies in their versatility across a wide range of materials. From dense hardwoods to lightweight foams and durable plastics, these machines are capable of cutting, carving, and shaping materials used in everything from cabinetry and signage to aerospace prototypes and art installations. The key to successful machining lies in pairing the right tooling and parameters with the specific properties of each material.

3-axis CNC routers are perhaps most famously associated with woodworking. They excel at cutting and carving solid hardwoods like oak, maple, walnut, and cherry, as well as softwoods like pine and cedar. These machines also handle engineered wood products such as plywood, particleboard, and oriented strand board (OSB).

Another staple is MDF (Medium-Density Fiberboard), which is favored for its consistent density and smooth surface, making it ideal for detailed engraving, cabinetry components, and furniture panels. However, dust extraction is crucial when cutting wood products, as materials like MDF generate fine particulate matter that can be harmful when inhaled.

While not as robust as a vertical machining center, many 3-axis CNC routers can process non-ferrous metals like aluminum, brass, and copper, especially if they’re equipped with a rigid frame, strong spindle, and appropriate cooling or lubrication.

Aluminum is the most commonly machined metal on these CNC routers, used in parts for electronics, automotive, and aerospace applications. Key considerations include chip evacuation, tool wear, and vibration damping. Slower feed rates and higher spindle speeds with small-diameter cutters yield the best results.

Emerging applications span sectors like green construction, medical prototyping, and maker-space innovation. With new tooling and spindle configurations, 3-axis CNC routers are pushing into areas once reserved for high-end machining centers.

When evaluating or operating 3-axis CNC routers, performance isn’t just about how fast it cuts—it’s about how precisely and consistently it can produce parts over time. Understanding the core performance metrics helps users make informed decisions about machine selection, setup, and optimization.

Accuracy refers to how closely the machine can cut to a specified dimension—how close the final part is to the intended design. High accuracy is essential in applications like mold-making, precision prototyping, and complex joinery.

Repeatability is the machine’s ability to produce the same result repeatedly under the same conditions. CNC routers might hit a dimension correctly once (accuracy), but repeatability determines whether it can hit that same mark across dozens or hundreds of parts. Mechanical rigidity, backlash in the drive system, thermal expansion, and even table flatness can affect repeatability.

Industrial-grade 3-axis CNC routers often offer repeatability within ±0.01 mm (±0.0004 in), though hobbyist or entry-level models may have looser tolerances.

The surface finish is determined by tool geometry, feed rate, spindle speed, and stepover settings. A smoother finish requires slower feeds, tighter stepovers, and sharper tools—but this increases machining time. Roughing passes typically leave visible tool marks, while finishing passes refine the surface.

Tolerance stacking becomes critical in assemblies where multiple parts must align or fit together. Each small error—from tool deflection to fixture misalignment—can compound over multiple dimensions. Understanding how these tolerances accumulate helps engineers adjust toolpaths, material allowances, or machining order to maintain fit and function.

Increasing cutting speed can improve throughput, but often comes at the cost of tool wear, finish quality, or positional accuracy. High speeds can also introduce chatter (vibration marks) or heat buildup, which degrades both tools and material.

Every job has an optimal material removal rate (MRR)—the sweet spot between productivity and quality. CNC Routers must be tuned for each material and application to find this balance, which involves dialing in feed rates, spindle speeds, and depth of cut while monitoring tool life and cut quality.

In production environments, this trade-off directly impacts profitability. Faster isn’t always better—smart routing balances speed with long-term consistency.

The spindle drives the cutting tool, and its performance is defined by both power (measured in horsepower or kilowatts) and torque (rotational force). High-speed spindles are great for light materials like foam or plastic, but cutting hardwood or aluminum requires a motor with strong, low-end torque.

A spindle’s torque curve indicates how torque behaves at different RPMs. Some spindles lose torque at low speeds, which can limit their effectiveness with larger cutters or deeper cuts. A flat, consistent torque curve allows better versatility across materials and operations.

Duty cycle refers to how long the spindle can operate at a given load without overheating. Entry-level spindles may be rated for light-duty or intermittent use, while industrial spindles are built for continuous, high-volume operation. Understanding the duty cycle is critical for avoiding overheating, premature wear, or system failure in demanding workflows.

The performance of 3-axis CNC routers hinges on much more than speed. Accuracy, repeatability, and surface quality define the machine’s capability to deliver reliable, professional results. Meanwhile, trade-offs between cutting speed and precision must be managed carefully, and the power and torque of the spindle play a major role in handling different materials and workloads. By understanding and optimizing these performance metrics, users can get the most out of their machines, whether they’re fabricating one-offs, short runs, or full-scale production batches.

3-axis CNC routers remain the workhorses of digital fabrication for good reason. While they lack the complex motion of multi-axis machines, their simplicity is a strength in many workflows. For shops, educators, hobbyists, and small manufacturers, 3-axis systems offer an ideal balance of capability, cost, and ease of use.

A major appeal of 3-axis CNC routers is their mechanical and operational simplicity. With only three linear axes (X, Y, and Z), the machine is easier to design, build, maintain, and troubleshoot. This streamlined setup translates directly to a lower cost of entry, both in terms of initial purchase price and long-term ownership.

Compared to 5-axis or industrial-grade CNC routers, 3-axis CNC routers are dramatically more affordable, making them accessible for startups, schools, and small fabrication businesses. Replacement parts, service, and upgrades are also generally cheaper and easier to source.

The popularity of 3-axis CNC routers has created a thriving ecosystem of compatible tooling, accessories, and software. From standard end mills and engraving bits to specialized cutters for plastics or composites, the market offers countless options tailored for 3-axis use.

On the software side, users benefit from a wide range of mature and user-friendly CAD/CAM packages—from professional suites like Fusion 360 and VCarve Pro to open-source or entry-level tools. The widespread support ensures that users can find resources, tutorials, and upgrades without being locked into proprietary platforms.

Unlike multi-axis systems that require a deep understanding of rotational kinematics and advanced toolpath programming, 3-axis CNC routers are relatively easy to learn and operate. Beginners can master the basics of tool setup, workholding, and G-code interpretation within days, not months.

The simplicity of the 3-axis motion also makes it easier to predict tool behavior and avoid crashes or programming mistakes. This makes these CNC routers perfect for educational environments, prototyping labs, and any operation where time-to-competence matters.

When it comes to cutting 2D profiles and 2.5D shapes (flat parts with varying depths), 3-axis CNC routers shine. Their rapid movement along flat planes and efficient toolpath strategies make them ideal for mass production of items like signs, cabinetry panels, inserts, molds, and components with pockets or stepped features.

Thanks to the streamlined workflow and lower cycle times, these CNC routers can deliver high throughput with consistent quality. For many applications, especially in woodworking, signage, and plastics, there’s simply no need for more complex motion systems.

3-axis CNC routers offer a compelling mix of affordability, accessibility, and practical performance. Their straightforward design keeps costs down and reliability up, while the abundance of tooling and intuitive software options make them easy to integrate into any workflow. For 2D and 2.5D work, they deliver fast, precise, and repeatable results, making them a smart investment for anyone looking to enter or scale up in the world of digital fabrication.

While 3-axis CNC routers are incredibly versatile, they do come with mechanical and operational limits. These machines are restricted by their fixed-axis movement and inability to tilt or rotate tools dynamically. As a result, certain geometries—especially those involving deep pockets, undercuts, or angled surfaces—can be difficult or impossible to machine in a single setup. However, creative programming, fixturing, and machining strategies can often overcome these limitations.

A core limitation of any 3-axis CNC router is that the cutting tool always approaches the material from a perpendicular (orthogonal) angle. Unlike 4- or 5-axis machines, which can tilt or rotate the spindle to reach complex angles, 3-axis CNC routers are locked into vertical engagement along the Z-axis.

This restriction makes it difficult to machine features like beveled edges, angled holes, or contoured sidewalls unless they align exactly with the primary axes. Parts with intricate 3D geometry or sloped surfaces may require additional setups or entirely different machines.

Undercuts—features that sit beneath an overhang or require the tool to reach around a part—are unachievable with standard end mills on 3-axis CNC routers. Likewise, deep pockets pose challenges related to tool deflection, chip removal, and spindle clearance. Long tools needed to reach deep cavities often vibrate or flex, leading to chatter, poor surface finish, or tool breakage.

To mitigate these problems, users may employ stubby tools for initial passes and switch to long-reach tools only for final depths, though this increases machining time and complexity.

One of the most common workarounds for the limitations of fixed-axis machining is re-fixturing—removing the part from the table, rotating it, and re-aligning it to cut a different face. This process requires precise repositioning to maintain dimensional accuracy and avoid errors at the seams between operations.

Indexing plates, rotary jigs, and mechanical stops can help simplify this process by providing consistent alignment references. Some shops even design custom fixtures to hold parts at specific angles, effectively simulating limited multi-axis capabilities with 3-axis CNC routers.

CAM software now offers adaptive toolpaths that intelligently adjust stepovers, depths, and feeds based on tool engagement. These strategies reduce tool wear and increase efficiency when roughing deep cavities or working with difficult materials. Though not a direct fix for geometric limitations, adaptive machining extends the effectiveness of 3-axis CNC routers within their physical constraints.

Another technique is multi-side machining, where the workpiece is manually flipped or rotated to access different surfaces. For example, a part may be cut on the top face, then rotated 90° to cut features on the side. With careful setup and proper use of coordinate systems (G54–G59), this approach can replicate some of the capabilities of a 4- or 5-axis machine at a fraction of the cost.

While 3-axis CNC routers can’t match the flexibility of multi-axis machines, smart workflows and creative fixturing can bridge many of the gaps. Limitations like orthogonal-only tool angles and restricted access to undercuts or deep pockets are real, but not insurmountable. Re-fixturing, indexing, adaptive toolpaths, and strategic multi-side machining give skilled operators the tools to push beyond the machine’s base capabilities. Knowing these limits—and how to work around them—is what separates a good CNC operator from a great one.

The versatility of 3-axis CNC routers has made them indispensable across a wide spectrum of industries. Whether producing high-volume parts or crafting one-of-a-kind prototypes, these machines combine digital precision with material flexibility to support a range of creative and technical needs. From furniture workshops to aerospace labs, and from signage studios to classrooms, 3-axis CNC routers deliver reliable performance in both professional and educational environments.

One of the most common uses for 3-axis CNC routers is in cabinetmaking and millwork. These machines streamline the production of cabinet parts, drawer fronts, doors, face frames, and interior panels. CNC routers cut materials like plywood, MDF, and hardwoods with high accuracy, allowing for tight joinery and consistent sizing across hundreds of pieces.

Architectural millwork shops also use 3-axis CNC routers to produce moldings, trim details, wainscoting panels, corbels, and wall paneling systems. Intricate geometric patterns, inlays, and relief carvings that once required hours of skilled handwork can now be done in minutes.

In the furniture industry, 3-axis CNC routers are used to cut complex curves, mortise-and-tenon joints, and decorative elements. They enable consistent reproduction of chair backs, table legs, cabinet components, and custom veneers. Because the machines can execute both structural cuts and ornamental details, they’re well suited to modern, minimalist, or traditionally styled furniture alike.

Luthiers and musical instrument makers use CNC routers for roughing and shaping guitar bodies, fretboards, violin plates, and other precision components. While final assembly and tuning may still be done by hand, CNC technology ensures consistency and efficiency in the early stages of production.

CNC routers are heavily used in the sign-making and display fabrication sectors. Materials like acrylic, PVC, HDU foam, aluminum composite, and wood are cut and engraved to create channel letters, dimensional signs, backlit panels, and logo elements.

In the world of point-of-purchase (POP) displays, 3-axis CNC routers are employed to cut structural elements, support brackets, face panels, and decorative trims. These fixtures—found in retail stores, trade shows, and product launches—often require fast turnaround times and high visual impact, both of which CNC routing helps deliver.

While high-end aerospace components are often machined on 5-axis systems, 3-axis CNC routers still play a critical role in prototyping and low-load part fabrication. Engineers use them to create molds, form tools, brackets, jigs, templates, and custom enclosures. Lightweight materials like foam board, composites, and aluminum sheet are easily handled on 3-axis CNC routers.

In automotive prototyping, CNC routers are used to shape dashboards, door panels, interior trim components, and conceptual models for testing ergonomics and aesthetics. The speed and flexibility of CNC routers support fast iteration cycles and real-world testing of design ideas.

In schools, universities, and maker communities, 3-axis CNC routers serve as powerful learning tools. Educational institutions use them to teach design, engineering, and manufacturing principles, while fab-labs and maker spaces empower individuals to prototype and fabricate custom parts for robotics, art, and personal inventions.

The combination of hands-on learning and real-world application helps students and entrepreneurs bridge the gap between concept and production. With the ability to work on wood, plastics, and light metals, these CNC routers provide an affordable, approachable gateway into digital fabrication.

3-axis CNC routers are far more than entry-level machines—they’re production tools that support a diverse range of industries. From cabinetry and custom furniture to signage, aerospace prototyping, and educational projects, their ability to deliver accurate, repeatable results makes them invaluable across both high-volume and one-off applications. Their widespread adoption is a testament to their flexibility, efficiency, and importance in modern fabrication workflows.

Choosing the right 3-axis CNC router isn’t a one-size-fits-all decision. The ideal machine for a sign shop might be a poor fit for a luthier or an aerospace prototyping lab. Factors like table size, spindle power, rigidity, software compatibility, and workholding options all depend on the intended use.

Durability and throughput matter more here than ultra-tight tolerances, especially in high-volume environments.

A rigid frame and low-vibration design help produce better finishes on decorative and structural elements.

Edge quality and engraving precision are important for producing polished, customer-facing results.

Advanced probing systems and fixture plates can also reduce setup times between iterations.

CNC routers that support multiple materials and small projects encourage creativity without steep technical barriers.

Selecting the right 3-axis CNC router comes down to understanding your workflow, materials, and production goals. Cabinetmakers need large-format tables and nesting efficiency. Furniture builders require rigidity and precision. Sign shops benefit from fast tool changes and multi-material support. Prototype labs demand accuracy and flexibility. Educational and maker environments need safety, simplicity, and adaptability. Matching machine specs to real-world use cases ensures better outcomes, longer machine life, and a faster return on investment.

3-axis CNC routers are foundational tools in modern fabrication, offering a powerful blend of precision, versatility, and accessibility. Operating along the X, Y, and Z axes, these machines automate the cutting, carving, and shaping of materials ranging from wood and plastic to foam and non-ferrous metals. Their relatively simple design keeps costs down while still delivering high levels of accuracy and repeatability, making them ideal for applications in cabinetry, furniture making, signage, prototyping, and education.

From the CAD-to-G-code workflow to spindle performance and motion control, a 3-axis CNC router relies on a carefully integrated system of components. While limited to orthogonal tool paths and constrained by their inability to reach complex angles or undercuts, skilled operators can overcome these challenges with clever toolpath strategies, multi-side machining, and re-fixturing techniques.

Whether in a large-scale manufacturing environment or a community maker space, 3-axis CNC routers remain an essential asset. Their ease of use, short learning curve, and wide range of compatible software and tooling make them an excellent entry point into the world of digital manufacturing, without compromising capability. For users who need reliability, precision, and efficiency in 2D and 2.5D machining, a well-selected 3-axis CNC router is a smart, long-term investment.