Understanding The Odors Associated With Laser Cutting

Laser cutting is widely valued for its precision, speed, and ability to process a wide range of materials, from metals and plastics to wood and textiles. However, one often-overlooked aspect of this advanced manufacturing process is the distinct odor it produces. Understanding the odors associated with laser cutting is essential for operators, facility managers, and anyone working near laser cutting systems, as these smells are more than just a nuisance—they can signal important information about material behavior, air quality, and potential health or safety concerns.

When a laser cuts through a material, it does so by applying intense heat that melts, burns, or vaporizes the surface. This thermal interaction releases fumes and gases that carry characteristic odors depending on the material being processed. For example, cutting natural wood produces a burnt, smoky smell, while certain plastics may emit sharp or chemical-like odors. These smells are the result of complex chemical reactions and byproducts formed during high-temperature decomposition.

Recognizing and understanding these odors helps users identify materials correctly, detect improper settings, and ensure that ventilation and filtration systems are working effectively. More importantly, it supports safer working environments by reducing exposure to potentially harmful fumes. By becoming familiar with the causes and implications of laser cutting odors, professionals can improve both operational efficiency and workplace safety.

Table of Contents

What Odors Mean in Laser Cutting

In laser cutting, odors function as real-time indicators of the physical, chemical, and operational conditions occurring during the cutting process. When a laser beam strikes a material, temperatures rise rapidly—often to thousands of degrees—causing the material to melt, burn, or vaporize. This intense thermal reaction breaks down the material’s molecular structure and releases a mixture of gases, vapors, and fine particulates. The human nose detects these byproducts as distinct odors, each carrying a specific meaning. Far from being incidental, these smells provide valuable insight into material composition, cutting efficiency, machine setup, and the adequacy of ventilation systems.

Understanding these odors is especially important because laser cutting involves a wide variety of materials, each reacting differently under heat. Odors can serve as early warning signs of hazardous materials, poor process control, or equipment-related issues. Experienced operators often rely on smell—alongside visual cues like flame color and smoke density—to quickly assess whether a cut is proceeding as expected or if intervention is required.

Material Decomposition and Odor Formation

Odors originate from thermal decomposition, oxidation, and combustion. Organic materials such as wood, rubber, leather, and textiles break down into carbon-based compounds, producing familiar burnt or smoky smells. While these odors may seem mild, they often include VOCs and ultrafine particles that can irritate the respiratory system if not properly extracted.

Plastics and polymers generate more complex and sometimes more dangerous odors. Acrylic typically produces a relatively clean, sweet smell because it vaporizes efficiently under correct laser settings. Other plastics, however, can emit sharp, acrid, or acidic odors. These smells often indicate the release of toxic gases formed when chemical bonds break under high heat. A strong, biting odor may signal chlorine, sulfur, or nitrogen compounds, which pose health risks and can corrode internal machine components.

Metals usually produce minimal odor from the base material itself, but this changes when surface treatments are involved. Oils, paints, adhesives, or protective coatings can burn off during cutting, producing metallic, chemical, or oily smells. These odors suggest additional contaminants in the fume stream and may require stronger filtration or pre-cleaning of the material.

Operational and Environmental Signals

Odors also reflect cutting quality and system performance. Excessively strong or unpleasant smells can indicate incorrect laser parameters, such as too much power, slow cutting speeds, or improper focus, all of which cause excessive burning rather than clean separation. Persistent odors lingering in the workspace often point to inadequate airflow, failing exhaust fans, or saturated filters in the fume extraction system.

Sudden changes in odor during operation may signal inconsistent material composition, accidental use of the wrong material, or the presence of hidden coatings. These sensory changes provide immediate feedback that something has shifted and requires attention.

Odors in laser cutting are meaningful diagnostic cues that reveal how materials respond to laser energy, how efficiently the process is running, and how well harmful byproducts are being controlled. By understanding and interpreting these smells, operators can identify hazardous materials, fine-tune cutting parameters, verify ventilation performance, and prevent long-term health or equipment issues. In essence, odors act as an invisible communication channel—one that, when properly understood, contributes to safer operations, higher-quality cuts, and a more controlled laser cutting environment.

The Basic Science Behind Laser Cutting Odors

The odors produced during laser cutting are rooted in fundamental principles of physics and chemistry. At its core, laser cutting is a high-energy thermal process. A focused laser beam delivers intense energy to a very small area, rapidly raising the material’s temperature to the point of melting, burning, or vaporization. This sudden and extreme heat disrupts molecular bonds within the material, transforming solid matter into gases, vapors, and microscopic particles. The combination of these byproducts forms fumes, and the chemical makeup of those fumes is what the human nose detects as odor.

Understanding the science behind these odors helps explain why different materials smell so different when cut and why some odors are mild while others are sharp, irritating, or even dangerous. The smell is not caused by the laser itself, but by the chemical compounds released as materials undergo thermal decomposition and oxidation in the presence of heat and air.

Thermal Decomposition and Molecular Breakdown

When a laser interacts with a material, the energy input is far greater and more concentrated than in conventional cutting methods. This causes rapid thermal decomposition, meaning complex molecules break apart into simpler chemical compounds. In organic materials, such as wood or fabrics, carbon-based molecules break down into gases like carbon monoxide, carbon dioxide, aldehydes, and various organic vapors. These compounds are responsible for smoky or burnt odors.

Plastics and synthetic materials undergo even more complex reactions. Polymers are long chains of repeating molecules, and laser heat snaps these chains into smaller fragments. Some of these fragments are volatile organic compounds, which easily become gases and carry strong, distinctive smells. The exact odor depends on the polymer’s chemical structure and any additives, such as plasticizers, dyes, or flame retardants.

Combustion, Oxidation, and Vaporization

Odor formation is also influenced by how the material reacts with oxygen. If sufficient oxygen is present, combustion occurs, producing smoke and strong burnt smells. In low-oxygen conditions, vaporization dominates, creating finer fumes with different chemical signatures. Oxidation reactions further alter the chemical makeup of the fumes, often intensifying odors and increasing their irritant properties.

In metals, the base material typically vaporizes without much smell, but surface contaminants oxidize or burn, releasing metallic oxides and chemical vapors. These reactions explain why cleaned metal smells different from coated or oily metal during cutting.

The science behind laser cutting odors lies in rapid heating, molecular breakdown, and chemical reactions triggered by intense laser energy. As materials decompose, burn, or vaporize, they release specific combinations of gases and particles that create recognizable smells. These odors reflect material composition, reaction pathways, and cutting conditions. By understanding the basic science behind odor formation, operators gain deeper insight into why certain smells occur, what they indicate about the process, and how to better control air quality and safety in laser cutting environments.

Primary Sources of Odors Inside Laser Cutting Systems

Odors in a laser cutting environment do not originate from a single point; instead, they are generated and influenced by multiple interconnected areas within and around the laser cutting system. While the cutting process itself is the primary driver of odor formation, secondary components such as support structures, airflow pathways, and filtration units play a major role in how those odors develop, intensify, or linger. Understanding where these smells come from helps operators trace odor problems back to their source, improve system maintenance, and create a safer, more controlled working environment.

Each part of the laser cutting system interacts with fumes differently. Some areas generate odors directly, while others absorb, redistribute, or even re-release them over time. Recognizing these primary sources allows for more effective odor control and better overall process management.

The Cutting Zone

The cutting zone is the most immediate and intense source of odors. This is where the laser beam contacts the material, producing extreme heat that causes melting, burning, or vaporization. As the material breaks down, it releases gases, smoke, and fine particles directly into the surrounding air. The odor profile here is strongly influenced by the material type, laser power, cutting speed, and focus. Improper settings can lead to excessive burning, generating harsher and more persistent smells. Because fumes are most concentrated at this point, efficient localized extraction near the cutting zone is critical.

The Cutting Bed and Support Structure

The cutting bed and its support structure can become secondary odor sources over time. Molten residue, soot, and debris often fall through the cut and accumulate on slats, honeycomb beds, or supports. These residues can continue to off-gas when reheated during subsequent jobs, even if a different material is being cut. As buildup increases, odors may become stronger and less predictable. Regular cleaning of the cutting bed helps reduce lingering smells and prevents cross-contamination between materials.

Ductwork and Exhaust Channels

Ductwork and exhaust channels transport fumes away from the cutting area, but they can also trap odor-causing particles. Over time, sticky residues and fine dust can coat the interior surfaces of ducts. When warm air flows through, these deposits may release odors back into the airstream. Poorly designed or poorly maintained ductwork can cause odors to circulate within the system or re-enter the workspace, making smells more noticeable and persistent.

Filtration Units

Filtration units are designed to capture particles and neutralize odors, but they can become odor sources themselves if not maintained. Saturated filters, especially activated carbon filters, lose their ability to absorb gases and may begin to emit trapped odors back into the airflow. Mechanical filters clogged with debris can also restrict airflow, allowing fumes to build up and intensify smells near the machine.

The Surrounding Workspace

The surrounding workspace plays a subtle but important role in odor perception. Odors that escape the extraction system can settle into walls, floors, clothing, and nearby equipment. Poor ventilation in the room allows smells to linger long after cutting has stopped. Temperature, humidity, and air circulation all influence how odors disperse or persist within the space.

Odors in laser cutting systems originate from multiple sources, beginning at the cutting zone and extending through support structures, airflow pathways, filtration units, and the surrounding workspace. Each component can generate, store, or redistribute odor-causing compounds. By understanding these primary sources, operators can better diagnose odor issues, improve maintenance practices, and implement more effective ventilation and filtration strategies to maintain a cleaner, safer laser cutting environment.

Odor Characteristics by Material Type

Odors produced during laser cutting are closely tied to the chemical makeup and manufacturing processes of each material. When exposed to the extreme, localized heat of a laser beam, materials undergo rapid thermal decomposition, combustion, or vaporization. This releases a complex mixture of gases, vapors, and fine particulates, each contributing to a distinctive odor profile. These smells are not only sensory experiences but also practical indicators of material composition, cutting efficiency, and potential health risks. By understanding odor characteristics by material type, operators can better identify unsafe materials, anticipate ventilation needs, and recognize abnormal conditions during cutting.

- Wood and Plywood: Solid wood typically produces a warm, smoky, or campfire-like odor caused by the breakdown of cellulose, hemicellulose, and lignin. Hardwoods and softwoods may differ slightly, with resin-rich woods producing sharper, pine-like notes. Plywood, in contrast, often generates a harsher and more chemical smell. This is due to the synthetic adhesives used to bond layers, which release additional fumes when heated. These adhesive-related odors can linger and may irritate if ventilation is insufficient.

- MDF: MDF is one of the strongest-smelling wood-based materials when laser cut. It contains finely processed wood fibers combined with high concentrations of urea-formaldehyde or similar resins. When exposed to laser heat, these binders decompose rapidly, releasing pungent, acrid fumes that can irritate the eyes, nose, and throat. The odor is often described as sharp, sour, or chemically burnt and tends to persist in the workspace.

- Paper and Cardboard: Paper and cardboard emit a light, charred-paper odor similar to burning leaves. While generally mild, the smell can intensify if the edges scorch or if the material ignites slightly during cutting. Printed, coated, or laminated paper adds complexity to the odor, as inks, toners, and surface coatings can release additional chemical vapors.

- Leather: Laser-cutting leather produces a strong burnt-hair or burnt-protein odor. This smell comes from the thermal breakdown of collagen and natural fats within the hide. Vegetable-tanned leather tends to smell more organic, while chrome-tanned or dyed leather can emit sharper chemical odors due to tanning agents, dyes, and surface finishes.

- Acrylic (PMMA): Acrylic is known for its relatively clean and predictable odor profile. When cut properly, it releases a sweet, slightly fruity or ester-like smell, indicating efficient vaporization. Excessive heat, however, can shift the odor toward a harsher plastic scent, signaling suboptimal settings.

- ABS Plastic: ABS produces a strong, acrid plastic odor dominated by styrene compounds. The smell is often described as sharp, unpleasant, and lingering. It can cause headaches or respiratory discomfort if fumes are not adequately extracted, making robust ventilation essential.

- Polycarbonate: Polycarbonate tends to char rather than vaporize cleanly, resulting in a burnt, bitter plastic smell. The odor often accompanies discoloration and rough edges, serving as a sensory cue that the material is not well-suited for laser cutting or that settings are incorrect.

- PVC and Vinyl Materials: PVC and vinyl materials emit a highly distinctive, acidic, chlorine-like odor. This smell is an immediate red flag, as it indicates the release of hydrogen chloride gas and other toxic byproducts. These fumes are hazardous to health and corrosive to laser components, making PVC unsuitable for laser cutting.

- Polyethylene (PE) and Polypropylene (PP): PE and PP release a waxy, candle-like, or paraffin odor. Because these plastics melt rather than vaporize efficiently, odors may be accompanied by sticky residues and uneven cuts. The smell is usually mild but can linger due to incomplete combustion.

- Foam: Foams vary widely in odor depending on their chemical base. Polyurethane foams often produce strong chemical or sweet odors, while other foams may release burnt or acrid smells. Some foams emit toxic gases when cut, making material identification critical before processing.

- Rubber: Rubber generates a powerful, sulfurous, burnt-rubber odor that is immediately recognizable. This smell comes from sulfur compounds, fillers, and additives used in rubber manufacturing. The odor is persistent, often clinging to surfaces and ventilation systems.

- Fabrics and Textiles: Natural fabrics like cotton, linen, and wool produce smoky or burnt-fiber odors. Synthetic textiles such as polyester and nylon emit sharper, chemical smells due to polymer breakdown. Blended fabrics can create mixed and unpredictable odor profiles, complicating fume management.

- Metals: Metals generally produce minimal odor from the metal itself. Any noticeable smell typically originates from oils, lubricants, paints, or protective coatings on the surface. These substances burn off during cutting, producing chemical or oily odors that vary based on surface condition.

Odor characteristics in laser cutting are highly material-dependent, shaped by chemical composition, additives, and surface treatments. From the smoky scent of wood and the pungency of MDF to the sweet vapor of acrylic and the dangerous acidity of PVC, each odor tells a story about what is happening at the molecular level. Understanding these differences enables operators to make safer material choices, adjust cutting parameters more effectively, and ensure proper ventilation and filtration for a healthier laser cutting environment.

Chemical Families Responsible for Laser Cutting Odors

The distinctive odors encountered during laser cutting are not random or mysterious—they originate from well-defined chemical families formed when materials are exposed to extreme, localized heat. A laser beam delivers energy rapidly enough to fracture molecular bonds, rearrange atomic structures, and create new compounds in fractions of a second. As solids transition into gases and vapors, these newly formed chemicals disperse into the air and stimulate the human sense of smell. Each chemical family has characteristic odor traits, volatility, persistence, and health implications. Understanding these families allows operators to interpret what they smell as chemical information, providing insight into material composition, cutting conditions, and potential hazards long before visual or mechanical issues appear.

Aldehydes and Ketones

Aldehydes and ketones are among the most common contributors to laser cutting odors, especially when processing organic materials, engineered woods, and many plastics. These compounds form when carbon-based molecules undergo partial oxidation rather than complete combustion. Aldehydes such as formaldehyde and acetaldehyde are highly volatile and have sharp, biting, or sweet-pungent odors that are easily detected even at very low concentrations. Ketones often add solvent-like or fruity notes to the overall smell. These compounds are notorious for causing eye irritation, dryness in the throat, and headaches, which explains why some laser cutting odors feel immediately uncomfortable despite appearing mild.

Phenols and Aromatic Compounds

Phenols and aromatic compounds are released from materials containing complex ring-shaped molecular structures, including resins, phenolic adhesives, rubber, and certain plastics. These compounds tend to produce heavy, smoky, tar-like, or medicinal odors that linger in the air and cling to surfaces. Phenols are particularly noticeable because they have low odor thresholds and high persistence. In laser cutting environments, they often accumulate in ductwork, filters, and enclosure walls, contributing to long-term odor buildup. Their presence is a strong indicator of resin-rich or adhesive-bound materials being processed.

Organic Acids

Organic acids form when materials oxidize under high heat but do not fully burn. Acetic acid, formic acid, and related compounds are common byproducts when cutting wood, paper, cardboard, and some plastics. These acids are responsible for sour, sharp, or vinegar-like odors that can feel irritating to the nose and lungs. Even when concentrations are relatively low, organic acids can make the air feel harsh and corrosive, particularly in poorly ventilated systems. Over time, these compounds can also contribute to corrosion inside exhaust systems.

Nitrogen-Containing Compounds

Nitrogen-containing compounds arise from materials that include proteins, amines, nitriles, or nitrogen-based stabilizers. Leather, ABS plastic, certain foams, and synthetic textiles are common sources. These compounds often produce pungent, fishy, ammonia-like, or bitter odors that are immediately noticeable. Chemically, they result from the breakdown of nitrogen-carbon bonds under intense heat. In addition to being unpleasant, nitrogen-based fumes can cause respiratory irritation and nausea, and their presence may indicate excessive thermal stress or incomplete vaporization during cutting.

Chlorinated Compounds (High Alert)

Chlorinated compounds represent one of the most serious odor-related hazards in laser cutting. When chlorine-containing materials such as PVC or vinyl are exposed to laser heat, they release hydrogen chloride gas and other chlorinated byproducts. These compounds produce a sharp, acidic, choking odor that is unmistakable and should trigger immediate cessation of cutting. Beyond the immediate health risks—such as respiratory injury and chemical burns—chlorinated gases are highly corrosive to metal components, optics, and electronics inside the laser cutting system. Even brief exposure can cause long-term equipment damage.

Sulfur Compounds

Sulfur compounds are responsible for some of the strongest and most persistent odors encountered during laser cutting. These compounds are released primarily from rubber and sulfur-cured materials. Their smells are often described as burnt rubber, rotten eggs, or skunky. Sulfur compounds have extremely low odor thresholds, meaning they are detectable at very small concentrations, and they tend to adhere strongly to surfaces. Once present, they can contaminate ductwork, filters, and the surrounding workspace, making odor control particularly challenging.

Laser cutting odors originate from specific chemical families formed during rapid thermal decomposition. Aldehydes and ketones create sharp, solvent-like sensations; phenols and aromatic compounds produce heavy, smoky persistence; organic acids add sour, irritating notes; nitrogen-containing compounds contribute pungent, ammonia-like smells; chlorinated compounds signal severe danger; and sulfur compounds generate some of the most intense and lingering odors. By understanding these chemical families, operators can interpret odors as meaningful signals, recognize hazardous conditions quickly, and implement appropriate material choices, ventilation strategies, and safety measures to maintain a healthier laser cutting environment.

Influence of Cutting Parameters on Odor Generation

Odor generation during laser cutting is not solely a material-driven phenomenon; it is highly sensitive to how laser energy is applied and controlled. Cutting parameters determine whether a material cleanly vaporizes, partially decomposes, or burns excessively. Each of these outcomes produces different chemical byproducts and, therefore, different odor profiles. Even when cutting the same material, changes in power, speed, focus, or gas flow can transform a relatively mild smell into a harsh, lingering, or irritating one. Understanding how each cutting parameter influences odor formation enables operators to fine-tune the process for both performance and air quality, reducing unnecessary fume production and improving overall safety.

Power and Speed

Laser power and cutting speed work together to control the energy density delivered to the material. When power is too high relative to speed, the material absorbs more heat than necessary, leading to excessive combustion and deep thermal degradation. This produces darker smoke and stronger odors rich in aldehydes, phenols, and other irritating compounds. On the other hand, too little power or excessive speed can cause incomplete cuts, forcing the laser to dwell longer or make multiple passes. These repeated heating cycles also increase odor generation by prolonging material breakdown. Properly matched power and speed allow rapid vaporization with minimal residual burning, resulting in cleaner cuts and lighter odors.

Pulse Frequency (For Some Lasers)

In pulsed laser systems, pulse frequency and pulse duration control how energy is distributed over time rather than continuously. High pulse frequencies can cause cumulative heat buildup, especially in thermally sensitive materials, leading to smoldering and persistent odors. Lower frequencies with sufficient cooling intervals between pulses reduce sustained thermal stress and limit the formation of pungent decomposition products. Inconsistent or fluctuating odors during cutting often indicate unstable pulse settings, where the material alternates between vaporization and burning.

Air Assist and Gas Type

Air assist and assist gases play a major role in odor control by influencing combustion, oxidation, and fume removal. Compressed air helps blow molten material and fumes away from the cut zone, reducing charring and preventing odor-causing gases from stagnating near the surface. In metal cutting, oxygen assist increases cutting efficiency but also promotes oxidation and combustion, which can intensify odors from coatings and contaminants. Nitrogen, by contrast, creates an inert environment that limits oxidation and generally results in reduced odor formation. Insufficient gas flow allows fumes to linger and concentrate, amplifying odor intensity.

Focus and Spot Size

Laser focus directly affects energy concentration. A properly focused beam delivers maximum energy to a small, controlled area, enabling rapid material separation with minimal heat spread. When the beam is out of focus, energy is dispersed over a larger area, increasing the heat-affected zone and causing unnecessary burning. This leads to stronger odors and more smoke. Spot size also influences how quickly material vaporizes; smaller spots promote clean cuts, while larger spots encourage prolonged heating and odor production. Gradual focus drift can explain increasing odors over extended cutting sessions.

Cutting Path Strategy

Cutting strategy determines how heat accumulates across the workpiece. Tight corners, dense patterns, and overlapping paths can trap heat in localized areas, causing smoldering and sudden spikes in odor. Sequential cutting in adjacent regions without allowing cooling time increases overall thermal load and fume generation. Well-planned cutting paths that distribute heat evenly and allow cooling intervals help reduce excessive decomposition and associated odors.

Material Thickness

Material thickness directly affects odor generation by increasing the amount of material exposed to high temperatures. Thicker materials require longer dwell times and higher energy input, resulting in greater volumes of gases and particulates. If parameters are not adjusted for thickness, the material may char internally, producing strong, lingering odors even after cutting is complete. Thinner materials, while requiring less energy, can scorch easily if parameters are not reduced accordingly.

Cutting parameters shape the chemical pathways through which materials decompose during laser cutting, directly influencing odor intensity, composition, and persistence. Power, speed, pulse frequency, assist gases, focus, cutting strategy, and material thickness all determine whether cutting is clean or excessively thermal. By carefully optimizing these variables, operators can significantly reduce odor generation, improve air quality, and maintain consistent cutting performance while creating a safer and more comfortable laser cutting environment.

Odor as a Troubleshooting Tool

In a laser cutting environment, odor functions as a real-time diagnostic signal that reflects changes in materials, machine condition, cutting parameters, and ventilation performance. Because fumes are generated instantly at the cutting interface, the human sense of smell often detects problems before visual defects, alarms, or sensor readings appear. Each laser setup develops a “normal” odor profile based on material type, power settings, and airflow design. When that profile shifts—either in strength, sharpness, duration, or location—it usually indicates a measurable change in the system. Treating odor as a troubleshooting tool helps operators identify issues early, minimize downtime, protect equipment, and reduce exposure to harmful fumes.

It Suddenly Smells Much Stronger Than Usual

A sudden increase in odor intensity is one of the clearest warning signs in laser cutting. This often points to excessive thermal input, where the material is burning rather than cleanly vaporizing. Causes may include increased laser power, reduced cutting speed, misfocus, or repeated passes over the same area. However, odor strength can also spike due to airflow problems. A partially blocked duct, clogged pre-filter, or saturated carbon filter reduces fume removal efficiency, allowing odor-causing compounds to accumulate inside the enclosure and escape into the workspace. In some cases, stronger odors indicate a change in the material itself, such as higher resin content, hidden laminates, or surface treatments that were not present in previous batches.

The Smell Is Sharper and More Irritating Today

When odors become sharper, more acrid, or irritating to the eyes and throat, the issue is often chemical rather than thermal. This change may signal the release of more aggressive compounds, such as aldehydes, organic acids, or nitrogen-containing byproducts. Contributing factors include altered assist gas flow, increased oxygen exposure, or higher humidity that intensifies oxidation reactions. Environmental conditions also play a role—warmer air can hold more vapors, while stagnant airflow concentrates irritants. A sharper smell can also indicate that a different material or adhesive is being cut, even if it appears visually similar to previous stock.

There’s a Sweet Plasticky Smell Even When Not Cutting

Odors present when the machine is idle almost always point to secondary sources rather than active cutting. Saturated activated carbon filters are a common cause, as they can release previously captured vapors back into the airflow once their adsorption capacity is exceeded. Residues on the cutting bed, slats, or duct walls can also off-gas when warmed by ambient heat or residual machine warmth. Electrical components and enclosures may trap fumes that slowly leak out over time. This symptom indicates that cleaning, filter replacement, or deeper system maintenance is required.

Smell Is Mostly Near the Machine, Not Near the Exhaust

When odors are strongest near the laser but weak at the exhaust outlet, fume capture is failing at the source. This often results from air leaks, loose duct connections, damaged seals, or insufficient negative pressure inside the enclosure. Poor hood or intake placement can allow fumes to escape before entering the exhaust stream. In some cases, fans may be running but not generating adequate airflow due to worn motors or incorrect sizing. This condition increases operator exposure and suggests that airflow balance and containment need immediate attention.

Odor serves as an effective and immediate troubleshooting tool in laser cutting operations. Sudden increases in strength, sharper irritation, lingering smells during idle periods, or odors concentrated near the machine each point to specific issues involving heat input, material chemistry, filtration performance, or airflow design. By learning to recognize and interpret these odor-related signals, operators can diagnose problems earlier, reduce health risks, prevent equipment damage, and maintain a safer, more controlled laser cutting environment.

The Biggest Red Flags

Not all laser cutting odors are equal. While many smells are expected byproducts of normal material processing, certain odors represent immediate and serious danger. These red-flag odors signal the release of highly toxic gases, catastrophic ventilation failure, or electrical faults that can escalate rapidly into health emergencies or fires. Unlike routine cutting smells, these odors are intense, unnatural, and often provoke instant physical reactions such as coughing, eye-watering, or chest tightness. Recognizing these warning signs—and knowing that production must stop immediately when they appear—is essential for protecting both personnel and equipment.

Chlorine, Acidic, or Pool-Like Smell

A sharp chlorine-like, acidic, or swimming-pool odor is one of the most critical danger signals in laser cutting. This smell almost always indicates the release of chlorine-based gases, typically hydrogen chloride, which are produced when chlorine-containing materials such as PVC, vinyl, faux leather, or certain laminates are exposed to laser heat. These gases are extremely hazardous: even brief exposure can cause severe irritation to the lungs, chemical burns to the airways, and long-term respiratory damage. Beyond health risks, chlorine-based fumes are highly corrosive and can rapidly damage mirrors, lenses, metal structures, and electronic components inside the laser cutting system. The moment this odor is detected, the laser must be stopped, the area evacuated if necessary, and the material source identified and removed. Ventilation should continue running to clear residual gases before anyone re-enters the space.

Strong Ammonia-Like or Extremely Eye-Watering Fumes

Odors that resemble ammonia or cause immediate eye-watering, throat burning, or choking sensations are another urgent stop signal. These smells often indicate the release of aggressive nitrogen-containing compounds, high concentrations of aldehydes, or acidic vapors formed through extreme thermal degradation. Such fumes can arise from cutting unsuitable materials, overheating resins or adhesives, or severe airflow failure that allows gases to concentrate. Physiological reactions occur quickly and can include coughing, nausea, dizziness, and shortness of breath. Continued exposure under these conditions can lead to chemical irritation or injury to the respiratory tract. If these fumes appear, cutting should cease immediately, and ventilation systems should be checked for blockages, fan failures, or saturated filters before operations resume.

Sudden Burnt Electrical Smell

A sudden burnt electrical odor—often described as melting plastic, hot insulation, or ozone-like—is a serious equipment-related red flag. This smell is not caused by material decomposition and typically indicates overheating wiring, failing power supplies, damaged connectors, or internal electrical shorts. Electrical fires often begin with this odor before smoke or visible flames appear. Continuing to operate the laser under these conditions poses a severe fire risk and can result in catastrophic equipment damage. The machine should be shut down immediately, power isolated if safe to do so, and the system inspected by qualified maintenance personnel before restarting.

Some odors in laser cutting are not warnings—they are stop signs. Chlorine or acidic smells signal the release of toxic, corrosive gases; ammonia-like or intensely irritating fumes indicate severe chemical exposure risks or ventilation failure; and burnt electrical odors warn of imminent equipment failure or fire. Treating these odors as non-negotiable red flags protects workers, prevents irreversible equipment damage, and ensures that safety always takes precedence over production.

Materials Management

In laser cutting operations, many odor-related problems are often blamed on ventilation or machine settings, when in reality they originate from poor materials management. Because laser cutting applies extreme heat at a very localized point, any uncertainty in material composition can instantly result in strong, unpleasant, or dangerous odors. Contaminants, additives, coatings, or improper storage conditions all influence how a material decomposes under laser energy. By managing materials proactively—long before they reach the cutting bed—operators can prevent many odor issues, reduce health risks, and maintain consistent cutting performance.

Confirm Material Identity

Accurate material identification is the foundation of odor prevention. Many materials that appear similar can behave very differently when laser cut. For example, acrylic and polycarbonate may look nearly identical but produce very different odors and cutting results. Operators should never rely solely on visual inspection or assumptions. Supplier documentation, material labels, safety data sheets, and purchase records should be used to confirm composition. When documentation is missing or unclear, materials should be treated as unknown and tested cautiously or rejected. Proper identification allows operators to anticipate odor characteristics and confirm that the material is suitable for laser processing.

Avoid Hazardous Categories

Some materials should be categorically excluded from laser cutting due to their odor toxicity and equipment risk. Chlorine-containing plastics, certain synthetic foams, and poorly defined composites can release highly toxic, corrosive gases when heated. These fumes not only pose immediate health dangers but can also contaminate filtration systems and permanently damage internal machine components. Establishing and enforcing a clearly defined list of prohibited materials helps prevent dangerous situations and removes guesswork from daily operations. Training staff to recognize warning signs and material red flags is equally important.

Watch for Hidden Layers

Hidden layers are a common source of unexpected odor problems. Engineered woods, laminates, faux leathers, coated metals, and multi-layer plastics often contain adhesives, fillers, or surface treatments that are not obvious from appearance alone. These hidden components can dramatically change the odor profile, producing sharper, more irritating fumes than expected. Even small adhesive layers can introduce nitrogen, sulfur, or aromatic compounds into the fume stream. Reviewing material construction details and cutting small test sections helps identify potential issues before full production begins.

Store Materials Properly

Material storage conditions directly affect odor generation during cutting. Materials stored in damp environments may absorb moisture, leading to increased steam, incomplete vaporization, and stronger odors when cut. Exposure to oils, solvents, or airborne contaminants can introduce additional compounds that burn off under laser heat. Prolonged exposure to heat or sunlight can degrade plastics and resins, altering their chemical behavior. Storing materials in clean, dry, temperature-controlled areas and keeping them sealed or covered helps preserve their original properties and ensures more predictable odor behavior.

Effective materials management is a proactive strategy for controlling laser cutting odors before they become a problem. By confirming material identity, avoiding hazardous categories, staying alert to hidden layers, and storing materials under proper conditions, operators can dramatically reduce unexpected fumes and odor intensity. These practices protect worker health, preserve equipment, and create a safer, more controlled laser cutting environment long before the laser is ever turned on.

Engineering Controls

Engineering controls are the backbone of effective odor management in laser cutting operations. Unlike administrative controls or personal protective equipment, engineering solutions physically remove odor-causing contaminants from the air before workers inhale them. Odors in laser cutting are not abstract sensations; they are the result of airborne gases, vapors, and ultrafine particles created at the moment a laser interacts with material. A well-designed ventilation and extraction system controls how these contaminants are captured, transported, filtered, and replaced with clean air. Understanding these mechanisms clarifies why some systems virtually eliminate odors while others merely circulate them.

Capture at the Source

Capturing fumes at the source is the single most important factor in odor reduction. Odor-causing compounds are most concentrated immediately above and below the cutting zone, where material decomposition occurs. Enclosed laser cabinets, downdraft tables, and strategically placed extraction ports create localized negative pressure that pulls fumes directly into the exhaust system before they can disperse into the room. The closer the capture point is to the source, the less energy is required to control the fumes and the more effective the system becomes. Poor enclosure sealing or improperly positioned intakes allow fumes to escape, spreading odors throughout the workspace and overwhelming downstream filtration.

Maintain Adequate Airflow (Not Just “a Fan”)

Effective odor control depends on maintaining sufficient airflow volume, velocity, and pressure. Simply adding a fan does not guarantee proper fume extraction. The system must move enough air to overcome thermal buoyancy, as hot fumes naturally rise and spread. Undersized fans, excessive duct length, sharp bends, or leaks can dramatically reduce airflow efficiency. Over time, filter loading and residue buildup further restrict flow. Properly engineered systems maintain stable negative pressure within the laser enclosure, ensuring consistent capture even as cutting conditions change. Routine airflow monitoring and maintenance are essential to prevent gradual odor increases.

Filtration Types and What They Do

Laser cutting fumes contain both particulate matter and gaseous compounds, each requiring different filtration approaches. Pre-filters and mechanical filters capture larger debris and dust, protecting finer filters downstream. High-efficiency particulate filters remove ultrafine particles that contribute to respiratory risk and odor persistence. Activated carbon filters address odor directly by adsorbing volatile organic compounds and other gases responsible for smell. The effectiveness of carbon filtration depends on filter quality, contact time, and saturation level. Once saturated, carbon filters can release trapped odors back into the air, making timely replacement critical for odor control.

Make-Up Air

Ventilation systems cannot function properly without adequate make-up air. As contaminated air is removed, an equal volume of clean air must replace it to maintain pressure balance and airflow. Without make-up air, extraction performance drops, capture efficiency declines, and odors may be drawn back into the workspace through unintended openings. Properly designed make-up air systems ensure steady airflow, prevent drafts, and maintain comfortable working conditions. They also help stabilize temperature and humidity, which can influence odor perception and fume behavior.

Ventilation and extraction systems reduce laser cutting odors by controlling the entire lifecycle of airborne contaminants: capturing them at the source, moving them with sufficient airflow, removing particles and gases through appropriate filtration, and replacing exhausted air with clean make-up air. These engineering controls do not mask odors—they remove their chemical causes. When properly designed, balanced, and maintained, ventilation systems dramatically improve air quality, protect worker health, and create a safer, more controlled laser cutting environment.

Housekeeping

In laser cutting operations, odor control is often approached as a technical problem requiring better fans, larger filters, or more advanced extraction systems. While engineering controls are essential, they cannot perform effectively without consistent housekeeping. Odors are not generated only during active cutting; they are also released from residues that accumulate throughout the machine and exhaust system over time. These residues slowly off-gas, are repeatedly reheated, and mix with new fumes, creating persistent and often worsening odor problems. Good housekeeping removes these hidden sources, stabilizes odor levels, and allows ventilation systems to operate at their intended efficiency.

Clean the Bed and Cutting Area

The cutting bed, slats, honeycomb structures, and enclosure walls are prime locations for residue buildup. During cutting, vaporized material condenses into fine soot, sticky films, and charred particles that settle on every surface inside the machine. Each time the laser operates, these deposits are reheated, releasing odors even if a different material is being processed. Over time, layers of residue from multiple materials can interact chemically, producing more complex and unpleasant smells. Regular cleaning of the bed and enclosure removes these secondary odor sources, improves airflow through the cutting area, and reduces the baseline odor level inside the machine. Clean surfaces also reduce fire risk and improve cutting consistency.

Maintain Ductwork

Ductwork is often overlooked because it is out of sight, yet it plays a major role in long-term odor behavior. As fumes travel through ducts, sticky vapors and ultrafine particles adhere to the interior walls, particularly at bends, transitions, and low-velocity sections. These deposits restrict airflow and act as odor reservoirs, slowly releasing absorbed compounds back into the exhaust stream. Warm exhaust air can intensify this off-gassing effect, making odors more noticeable even when cutting has stopped. Periodic inspection and cleaning of ductwork help maintain airflow efficiency, prevent odor carryover, and reduce the risk of combustible residue accumulation.

Maintain Filters

Filters are the final barrier between odor-causing contaminants and the workspace or external environment. Mechanical filters trap dust and particulates, while activated carbon filters adsorb gaseous compounds responsible for smell. Both types have finite capacity. As filters load with contaminants, airflow resistance increases, reducing extraction efficiency. Once carbon filters become saturated, they can no longer hold odors and may begin to release them back into the airflow, leading to persistent smells even during idle periods. Regular inspection, timely replacement, and proper disposal of filters are essential to prevent odor breakthrough and maintain consistent air quality.

Housekeeping is an essential, though often underestimated, component of laser cutting odor control. By routinely cleaning the cutting bed and enclosure, maintaining ductwork, and replacing filters before they fail, operators eliminate hidden odor sources that ventilation alone cannot resolve. Consistent housekeeping stabilizes odor levels, improves system performance, reduces fire risk, and creates a cleaner, safer, and more predictable laser cutting environment.

Material-by-Material Odor Reduction Strategies

Odor generation in laser cutting is highly material-dependent, which means odor control must also be material-specific to be truly effective. Different materials decompose through different chemical pathways, producing distinct combinations of gases, vapors, and particulates. Applying the same settings, airflow, and housekeeping practices to every material often leads to unnecessary odor problems and increased health risks. By tailoring cutting parameters, preparation steps, ventilation strategies, and maintenance routines to each material type, operators can significantly reduce odor intensity while improving cut quality and extending equipment life.

Wood, Plywood, and MDF

Solid wood typically produces a predictable smoky odor that can be managed by minimizing charring. This is best achieved through proper focus, balanced power-to-speed ratios, and sufficient air assist to prevent prolonged burning. Plywood introduces additional odor challenges due to synthetic adhesives between layers. These adhesives release sharper, more persistent fumes, making strong source capture and effective carbon filtration essential. MDF is the most odor-intensive of the three because it contains finely processed fibers and high concentrations of resin and formaldehyde-based binders. For MDF, using the lowest effective power, higher cutting speeds, and aggressive ventilation helps limit excessive decomposition. Frequent cleaning of the cutting bed and enclosure is critical, as MDF residues off-gas strongly when reheated.

Acrylic (PMMA)

Acrylic is often considered one of the cleanest laser-cut materials, but only when parameters are optimized. Sufficient power and precise focus promote clean vaporization rather than melting, which reduces lingering plastic odors. Air assist plays a key role by quickly removing vapors before they condense on surfaces. While acrylic odors are typically mild and sweet, long production runs can still overwhelm poorly maintained filtration systems. Activated carbon filtration helps prevent odor accumulation in enclosed spaces, especially when multiple machines operate simultaneously.

Rubber

Rubber presents some of the greatest odor control challenges due to sulfur compounds, fillers, and curing additives. These materials inherently produce strong, persistent smells that can contaminate ductwork and filters. Rubber cutting should be performed only in fully enclosed systems with high-capacity extraction and robust carbon filtration. Reducing laser power and increasing cutting speed can help limit excessive burning, but odors will still be significant. Dedicated filtration or separate exhaust paths for rubber cutting are often necessary to prevent cross-contamination with other materials.

Textiles

Textile odor behavior varies widely depending on fiber composition and finishing treatments. Natural fabrics such as cotton or wool benefit from faster cutting speeds and moderate power to prevent scorching, which intensifies burnt-fiber odors. Synthetic textiles require careful control to avoid melting and chemical vapor release. Pre-washing fabrics can remove sizing agents, dyes, and finishes that contribute to strong odors. Consistent airflow across the cutting area helps capture fumes before they disperse into the workspace, particularly when cutting large or layered textile pieces.

Metals (Especially with Coatings)

Bare metals generally produce minimal odor, but coatings, oils, and protective films are significant odor sources. Cleaning metal surfaces before cutting removes lubricants and residues that would otherwise burn off and generate fumes. Using inert assist gases such as nitrogen reduces oxidation and limits odor formation compared to oxygen-assisted cutting. Strong extraction is essential when cutting painted, anodized, or laminated metals, as coating fumes can be irritating and persistent. Regular maintenance of optics, ductwork, and filters is especially important to prevent residue buildup from coating vapors.

Reducing laser cutting odors effectively requires a material-by-material approach. Wood products benefit from minimizing charring and managing adhesive fumes; acrylic requires clean vaporization and airflow; rubber demands aggressive, often dedicated extraction; textiles need careful parameter control and preparation; and metals rely on surface cleaning and appropriate assist gases. By tailoring odor reduction strategies to the specific materials being processed, operators can achieve cleaner air, safer working conditions, and more predictable, high-quality cutting results.

Common Myths About Laser Cutting Odors

Laser cutting odors are often interpreted through personal experience rather than scientific understanding, which gives rise to persistent myths. These misconceptions can create a false sense of safety, delay corrective action, and expose operators to unnecessary health and equipment risks. Odor perception is subjective, influenced by sensitivity, fatigue, and environmental conditions, while the hazards associated with laser cutting fumes are chemical and physical in nature. Dispelling these myths is essential for building a realistic understanding of what laser cutting odors do—and do not—mean in terms of safety and control.

If It Smells Sweet, It’s Safe

A sweet or pleasant odor is one of the most misleading sensory cues in laser cutting. Acrylic (PMMA), for example, often produces a light, fruity smell when cut efficiently, which many operators associate with a “clean” process. However, sweet-smelling fumes can still contain volatile organic compounds and fine particulates that irritate the respiratory system over time. Some hazardous compounds also have deceptively mild or even pleasant odors at low concentrations. Relying on odor pleasantness rather than material identity and ventilation performance can lead to prolonged, unnecessary exposure.

If I Can’t Smell It, It’s Fine

The absence of odor is not evidence of safety. Many harmful substances have weak odors or are only detectable at concentrations higher than those that already pose health risks. Additionally, olfactory fatigue can quickly desensitize the nose, causing operators to stop noticing smells that are still present. Ultrafine particles generated during laser cutting are completely odorless yet capable of penetrating deep into the lungs. Ventilation systems may also dilute odors enough to make them undetectable while still allowing exposure. This myth encourages complacency and underestimates invisible hazards.

A Bigger Fan Always Fixes It

Increasing fan size or airflow alone rarely solves odor problems and can sometimes make them worse. Odor control depends on proper capture at the source, controlled airflow paths, and effective filtration. A larger fan without proper ducting or enclosure design may simply spread fumes more widely across the workspace. Excessive airflow can disrupt capture efficiency, create drafts, or pull contaminated air from unexpected locations. Effective odor control requires engineered systems that balance airflow, pressure, and filtration—not just more air movement.

Carbon Filters Last a Long Time, No Matter What

Activated carbon filters are often misunderstood as permanent solutions. In reality, their lifespan depends heavily on the type and volume of fumes they are exposed to. Materials rich in resins, sulfur compounds, or VOCs can saturate carbon filters rapidly. Once saturated, carbon no longer adsorbs odors and may begin releasing previously captured compounds back into the airflow. Assuming long filter life leads to unnoticed performance decline, persistent odors, and increased exposure. Regular monitoring and replacement are essential for reliable odor control.

Misconceptions about laser cutting odors can undermine safety and air quality. Sweet smells are not inherently safe; lack of odor does not mean lack of risk, larger fans do not replace proper ventilation design, and carbon filters are consumables—not permanent fixtures. Understanding and rejecting these myths enables more effective odor management, better health protection, and more reliable laser cutting operations.

A Step-by-Step Odor Reduction Plan

Persistent or severe odors in laser cutting rarely have a single cause. They are usually the cumulative result of material choices, thermal input, airflow design, filtration condition, machine cleanliness, and room ventilation. Addressing only one element often leads to temporary improvement, followed by a return of the problem. A structured, step-by-step odor reduction plan helps operators move from critical safety checks to fine-tuning everyday practices in a logical order. This approach not only reduces odors but also improves cutting quality, protects equipment, and creates a healthier working environment.

Verify Material Safety and Identity

Odor control starts with material verification. Operators should confirm the exact material type, composition, and any coatings or laminations before cutting. Supplier documentation and safety data sheets are essential, especially for plastics, engineered woods, and textiles. Materials with uncertain composition, recycled content, or unknown surface treatments should be treated as high risk. Verifying material safety prevents the accidental cutting of hazardous substances and eliminates unexpected odor spikes caused by hidden additives or chlorine-containing compounds.

Confirm Extraction Is Actually Working

Extraction systems must be evaluated based on performance, not assumptions. Operators should verify that fumes are being captured at the cutting zone rather than escaping into the enclosure or workspace. This includes checking enclosure seals, intake placement, and negative pressure consistency. Simple tests—such as observing smoke movement or feeling airflow direction—can quickly reveal capture failures. Poor extraction is one of the most common reasons odors persist despite having a ventilation system installed.

Check Filters

Filters determine whether extracted fumes are truly removed or merely redistributed. Mechanical pre-filters should be inspected for dust loading that restricts airflow. Activated carbon filters should be monitored for saturation, which varies based on material type and cutting volume. Resin-rich woods, rubber, and plastics can exhaust carbon capacity far faster than expected. Tracking filter usage and odor breakthrough helps prevent the false assumption that filters are still effective when they are not.

Clean the Machine

Residue inside the laser cutting system is a major secondary odor source. Charred debris, condensed vapors, and sticky films accumulate on cutting beds, slats, enclosure walls, and internal components. These residues off-gas whenever the machine heats up, even if no cutting is occurring. Regular, thorough cleaning reduces baseline odors, improves airflow, and minimizes cross-contamination between materials. A clean machine also makes it easier to identify new odor issues quickly.

Optimize Cutting Parameters

Cutting parameters directly influence how much material decomposes and what byproducts are released. Excessive power, slow speeds, misfocus, or inefficient cutting paths increase burning and fume generation. Operators should optimize settings for each material to favor clean vaporization rather than prolonged heating. Adjusting parameters not only reduces odor intensity but also improves edge quality, reduces residue buildup, and lowers overall fume volume.

Improve Room Ventilation and Workflow

Local extraction works best when supported by good room ventilation. Adequate make-up air ensures that exhaust systems maintain proper airflow and prevent pressure imbalances that allow odors to linger. Workflow considerations—such as operator positioning, job sequencing, and cooling intervals—also affect odor exposure. Keeping personnel away from exhaust discharge points and allowing time for fumes to clear between jobs further reduces odor accumulation.

An effective odor reduction strategy in laser cutting requires a comprehensive, step-by-step approach. By verifying material safety, confirming extraction performance, maintaining filters, cleaning the machine, optimizing cutting parameters, and improving room ventilation and workflow, operators can systematically eliminate odor problems at their source. This integrated plan not only improves air quality and comfort but also enhances safety, equipment longevity, and overall operational reliability.

Summary

Odors produced during laser cutting are far more than an inconvenience—they are meaningful signals that reflect material chemistry, cutting conditions, ventilation performance, and overall workplace safety. Every smell generated during laser cutting originates from the thermal breakdown of materials into gases, vapors, and fine particles. These odors vary widely depending on material type, cutting parameters, and how effectively fumes are captured and filtered. Understanding what different odors mean allows operators to recognize unsafe materials, detect process problems early, and take corrective action before health or equipment risks escalate.

Throughout the laser cutting process, odor can serve as a powerful troubleshooting tool. Sudden changes in intensity, sharp or irritating smells, or lingering odors often point to issues such as improper settings, saturated filters, residue buildup, or inadequate airflow. Certain odors—such as chlorine-like, ammonia-like, or burnt electrical smells—are critical red flags that require immediate shutdown and investigation. Addressing these warnings promptly protects both people and machinery.

Effective odor control relies on a combination of smart materials management, optimized cutting parameters, engineered ventilation and filtration, and consistent housekeeping. No single solution is sufficient on its own. By taking a systematic, informed approach to odor reduction, laser cutting operations can create cleaner air, safer working conditions, and more reliable, high-quality results.

Get Laser Cutting Solutions

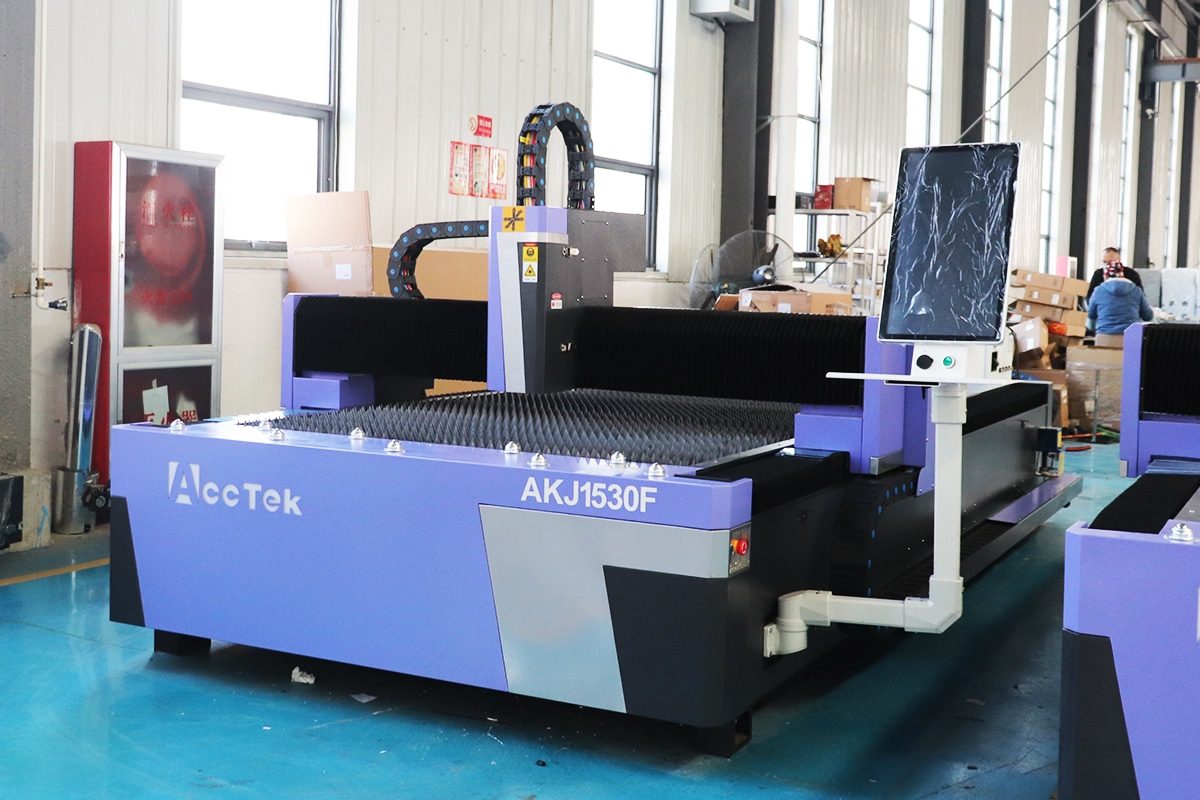

Understanding and controlling odors associated with laser cutting is an essential part of building a safe, efficient, and professional production environment. However, achieving reliable odor control requires more than good practices alone—it also depends on using well-designed, intelligently engineered laser equipment. This is where AccTek Group plays a vital role.

As a professional manufacturer of intelligent laser equipment, AccTek Group focuses on providing complete laser cutting solutions that prioritize performance, safety, and long-term reliability. AccTek Group laser cutting machines are engineered with optimized cutting stability, precise power control, and compatibility with advanced ventilation and fume extraction systems. These design elements help reduce excessive thermal degradation, minimize unnecessary fume generation, and support effective odor management at the source.

Beyond the machine itself, AccTek Group offers technical guidance to help users select appropriate materials, optimize cutting parameters, and integrate proper extraction and filtration systems into their workflows. This holistic approach ensures that odor issues are addressed proactively rather than reactively. Whether cutting metals, acrylic, wood products, or textiles, AccTek Group’s intelligent laser solutions help maintain cleaner air, safer working conditions, and consistent cutting quality.

By combining advanced laser technology with practical application support, AccTek Group empowers businesses to control laser cutting odors effectively while achieving high productivity and dependable results.