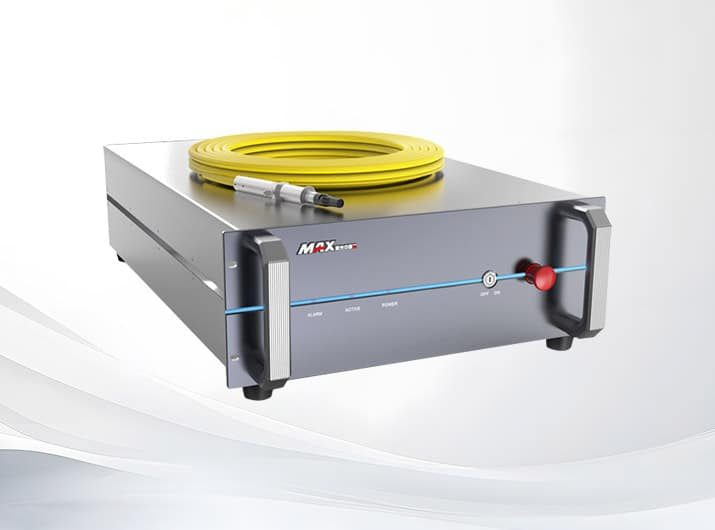

Portable Continuous Laser Cleaning Machine

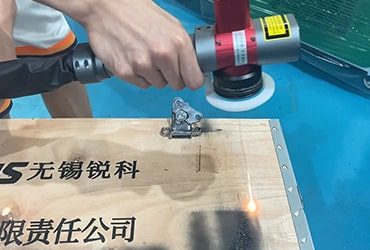

The portable continuous laser cleaning machine offers high-efficiency, non-contact cleaning with a lightweight design, handheld laser head, and powerful performance for flexible, on-site applications.

4 reviews for Portable Continuous Laser Cleaning Machine

Penelope –

Our team uses the laser cleaning machine daily for paint and rust removal. It’s fast, accurate, and doesn’t damage the base material. The settings are easy to adjust for different surfaces. We’ve seen a major improvement in work speed, and we no longer need to use harsh chemicals.

Xavier –

This machine is powerful yet easy to handle. We use it for rust removal on large steel parts, and the results are outstanding. It saves us labor hours and gives a cleaner finish than traditional methods. The handheld design makes it easy to clean difficult angles without much effort.

Bentley –

This laser cleaning machine has been a great addition to our tool lineup. It removes surface rust and old coatings efficiently without grinding or sanding. It’s much safer for our workers and reduces dust in the shop. Maintenance is simple, and it’s very energy efficient compared to other methods.

Faith –

I love how effective this laser cleaning machine is on tough jobs. We use it on construction equipment parts, and it cleans up years of buildup without any damage. It’s easy to move and simple to operate. We no longer need to rely on messy blasting methods.