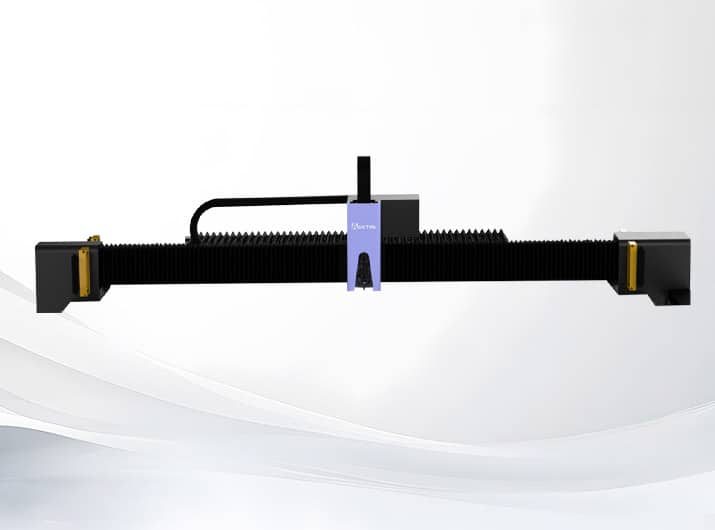

Ground Rail Fiber Laser Cutting Machine

The Ground Rail Fiber Laser Cutting Machine is a high-precision, large-format laser system designed for cutting oversized and thick metal sheets with exceptional stability, speed, and accuracy.

An advanced CNC control system integrates motion control and process management. It supports real-time monitoring, automatic edge detection, and optimized path planning to improve cutting efficiency and material utilization. The user-friendly interface allows operators to easily adjust cutting parameters and monitor performance in real time.

Equipped with high-power fiber laser sources from leading brands such as Raycus or MAX, the system offers power levels ranging from 3 kW to 40 kW. The high beam quality ensures smooth edges and minimal thermal distortion even in thick plates.

The machine uses an auto-focusing laser cutting head that automatically adjusts focal length according to material thickness. Equipped with collision protection and real-time height sensing, it maintains a constant distance between the nozzle and the material surface. This guarantees precise cuts even on uneven or warped sheets, while preventing damage to the cutting head.

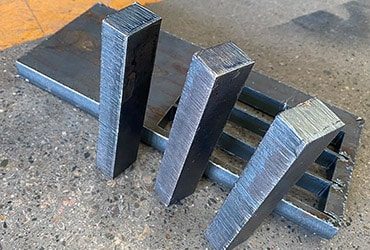

The machine adopts a ground rail installation, where precision rails are anchored directly to the workshop floor. This structure significantly lowers the center of gravity, improving stability and minimizing vibration during high-speed operation. It also allows for longer cutting lengths, commonly 12 m, 16 m, or even 20 m.

A double-driven gantry system, supported by precision rack and pinion transmission and linear guide rails, ensures smooth, synchronized movement for consistent cutting accuracy over long distances.

The heavy-duty bed is welded from high-strength steel plates that undergo stress relief annealing and gantry milling to ensure long-term structural stability. This robust bed design resists deformation under heavy loads and thermal stress, making it suitable for thick-plate cutting.

A precision industrial water chiller maintains a stable operating temperature for both the laser source and cutting head. The cooling system ensures consistent performance, protects optical components, and extends the overall service life of the equipment, even under continuous high-power operation.

The ground rail fiber laser cutting machine is equipped with high-performance servo motors to ensure smooth, precise, and efficient motion control throughout the cutting process. Servo motors can ensure precise motion control even during high-speed cutting or complex contour movements.

| Model | AKJ20120F | AKJ25120F | AKJ30200F |

|---|---|---|---|

| Cutting Range | 2000*12000mm | 2500*12000mm | 3000*20000mm |

| Laser Type | Fiber Laser | ||

| Laser Power | 3000-40000W | ||

| Laser Generator | Raycus / Max | ||

| Laser Cutting Head | Au3tech / Boci | ||

| Transmission System | Gantry Double Drive Structure | ||

| Linear Guide Rail | Hiwin | ||

| Control System | Au3tech | ||

| Servo Motor | Delta / Yaskawa (X Axis:1800W, Y Axis:2900W, Z Axis: 850W) | ||

| Transmission System | XY Axis: Rack and Pinion; Z axis: Leadscrew | ||

| Gearbox | French MOTOREDUCER | ||

| Computer & Cantilever | Yes | ||

| Voltage and Frequency | 380V 50Hz | ||

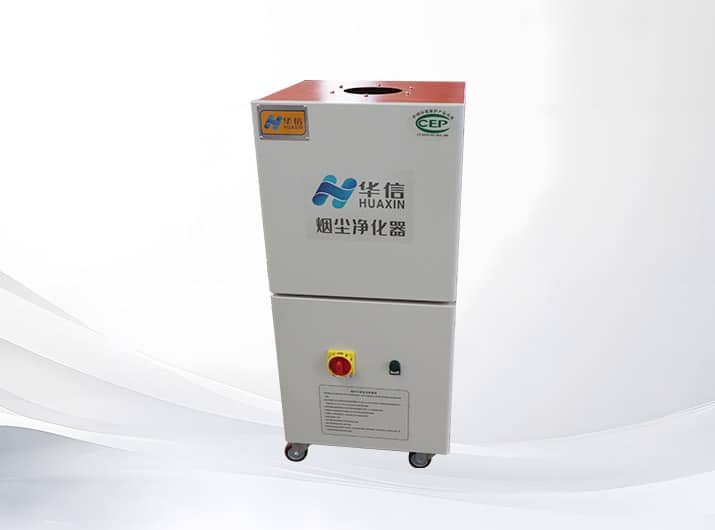

The smoke purifier is an optional configuration for fiber laser cutting machines, designed to effectively filter and remove harmful fumes and particles generated during cutting. With advanced filtration technology, it improves air quality, ensures a cleaner work environment, and complies with safety and environmental standards, enhancing both operator health and machine longevity.

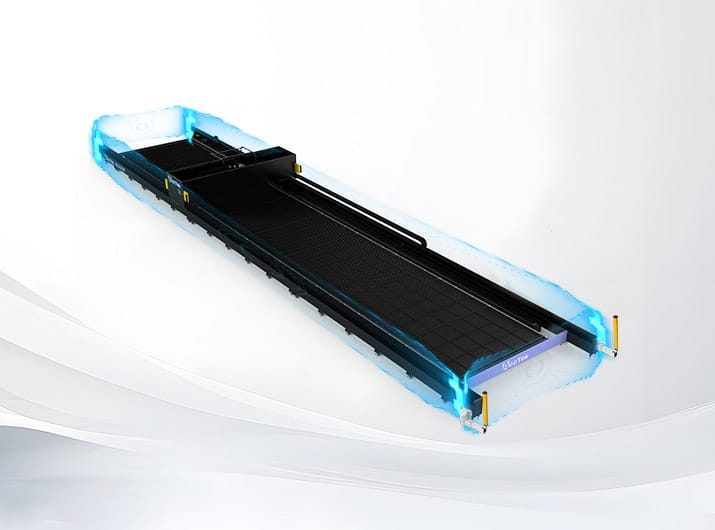

This enclosure surrounds the gantry and cutting head components, offering protection against external contaminants, such as dust, metal particles, and debris generated during the cutting process. Additionally, the enclosure serves to shield operators from light exposure, particularly the intense laser light emitted during cutting, ensuring compliance with safety standards and improving workplace safety.

The integrated air compressor is an optional configuration for fiber laser cutting machines, providing a reliable and efficient air supply for cutting operations. It ensures consistent air pressure, enhancing cutting quality and speed. Compact and easy to integrate, it reduces the need for external compressors, offering a space-saving and cost-effective solution.

The safety light curtain is an optional configuration for fiber laser cutting machines, providing enhanced operator safety. It uses infrared sensors to detect movement, automatically stopping the machine if an obstruction is detected within the safety zone. This feature ensures a secure working environment, reducing the risk of accidents and improving workplace safety.

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Its widths often range from 2–4 m, and lengths can extend 12–20 m or more, depending on the modular bed configuration. Highlight that the modular design allows expansion to meet future production requirements.

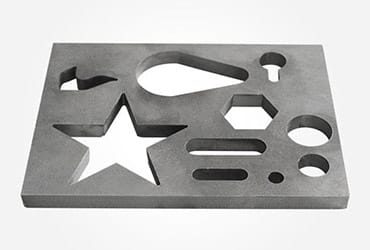

The ground rail fiber laser cutting machine is capable of cutting a wide range of metal materials with high precision and efficiency. Its primary cutting materials include:

Thanks to its high-power fiber laser source and intelligent control system, the machine delivers clean, precise cuts across these materials, even on thick plates and oversized sheets, making it highly versatile for industrial manufacturing.

The ground rail fiber laser cutting machine offers a variety of power options to meet different cutting needs: 3000W, 4000W, 6000W, 12000W, 20000W, 30000W, and 40000W. These options allow flexibility for various materials and thicknesses, depending on your production requirements.

Our laser cutting machine package includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser cutting machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-cutting machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

Yes, all our laser cutting machines are equipped with an auto-focus feature to enhance cutting precision and ease of operation.

The auto-focus capability automatically adjusts the focal distance of the laser beam based on the material thickness and type. This feature is especially beneficial for users who work with various materials or need to switch between different thicknesses frequently. By automatically optimizing the focus, the machine ensures consistent, high-quality cuts without the need for manual adjustments, which saves time and minimizes errors.

Additionally, the auto-focus function enhances cutting efficiency, allowing for faster processing speeds and reducing setup time. This feature is ideal for both intricate designs and high-volume production, ensuring precise results across all types of materials. If you have specific applications in mind, we would be happy to discuss how the auto-focus feature can improve your workflow.

Our laser-cutting machine system supports a variety of file formats, including DXF, AI, PLT, SVG, PDF, and DWG. These formats ensure compatibility with popular design and CAD software, making it easy to import and work with detailed drawings, vector designs, and technical files. If you have any additional format requirements, feel free to let us know, and we can verify compatibility.

4 reviews for Ground Rail Fiber Laser Cutting Machine

Mason –

The speed and accuracy of this laser cutter exceeded my expectations. It delivers clean edges with almost no need for finishing. The machine is well-built, and support has been great whenever we’ve needed it.

Isabella –

We use this machine for both small and large cutting jobs, and it performs flawlessly. The accuracy is consistent, and it handles intricate patterns with ease. It’s reliable and simple for our team to operate.

Ella –

This is one of the best pieces of equipment we’ve added to our shop. It cuts a variety of metals quickly and precisely, with minimal maintenance. The system runs smoothly and produces consistent results.

Natalie –

This machine has improved our production speed dramatically. It delivers precise cuts and requires very little post-processing. We’ve also noticed reduced material waste, which saves us money in the long run.