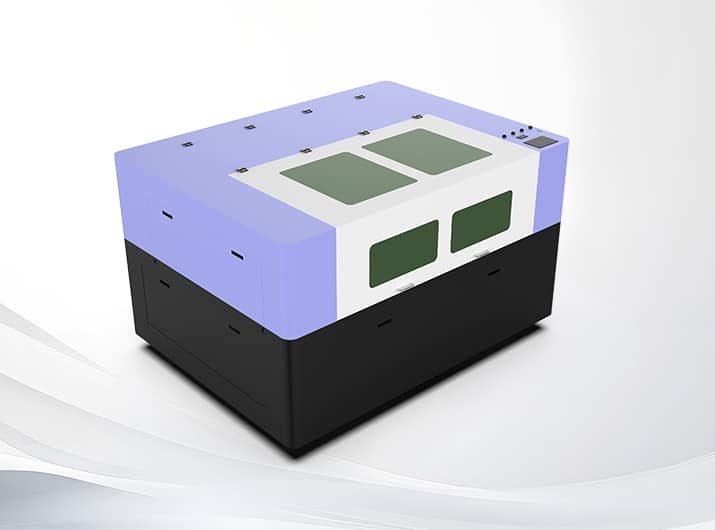

6 In 1 Laser Welding Cutting Cleaning Making Machine

The 6-in-1 machine integrates fiber and CO2 laser systems for versatile metal and non-metal processing, combining cutting, welding, marking, and cleaning functions in one efficient, compact unit.

4 reviews for 6 In 1 Laser Welding Cutting Cleaning Making Machine

Michael –

I’ve been using the 6-in-1 laser welding cutting cleaning machine for over six months, and it has become a core part of our shop. Welding seams are clean and strong, and switching to cutting or cleaning takes only minutes. This saved us time and floor space since we no longer need separate machines. The controls are simple enough for new operators, yet precise for detailed work. Build quality feels solid, and daily maintenance is minimal. Overall, it helped us improve output without adding extra staff.

Linda –

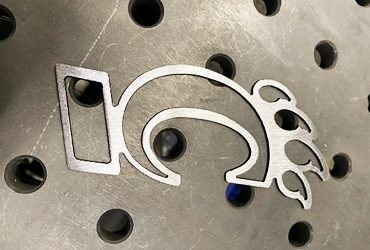

From an engineer’s point of view, the design of this 6-in-1 laser welding cutting cleaning machine is well thought out. The laser output remains stable across different modes, which is not always easy to achieve. I’ve tested it on stainless steel and carbon steel with good results. The interface is clear, and parameter adjustments are logical. I used to worry about precision loss when switching functions, but that hasn’t been an issue. It fits well into both testing and small-batch production work.

Sarah –

As someone who manages daily production, I care most about reliability and ease of use. This 6-in-1 laser welding cutting cleaning machine has performed steadily during long shifts. My team uses welding and cleaning functions the most, and both give consistent results. The cleaning mode removes rust and oil without damaging the surface, which reduces rework. Training new workers was faster than expected. I like that one machine now handles tasks that once required three separate units, making scheduling much simpler.

Daniel –

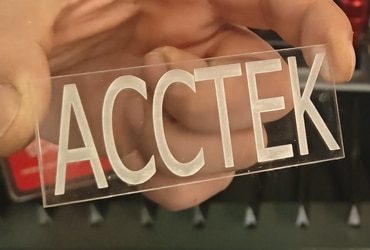

I purchased this machine last year to upgrade my small metal shop. At first, I was unsure about an all-in-one system, but it exceeded my expectations. Cutting accuracy is good, welding is smooth, and the cleaning function helped us restore old parts for reuse. It also reduced power use compared to our older tools. AccTek Group provided clear setup guidance, which helped a lot. For a business trying to grow without overspending, this machine proved to be a smart investment.