Product Introduction

Types of Textile Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Textile

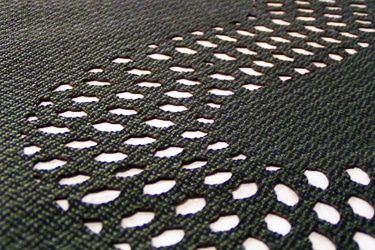

Clean and Precise Edges

Oscillating knife cutting ensures smooth, fray-free edges, even on delicate or complex fabrics. Unlike traditional cutting, it avoids jagged lines, ensuring garments, upholstery, and technical textiles meet exact design specifications with consistent, professional-quality finishes.

Cold-Cutting Technology

The process generates no heat, eliminating risks of fabric distortion, discoloration, or melting. This preserves the material’s natural properties, making it safe for synthetic, natural, and composite textiles without altering their functional or visual characteristics.

Versatility Across Textiles

From lightweight fabrics like silk and polyester to heavy-duty materials like denim, canvas, and technical composites, oscillating knife cutting machines can process diverse textiles, allowing manufacturers to handle multiple product lines with a single solution.

High Production Efficiency

With CNC automation and nesting software, oscillating knife cutting machines maximize fabric utilization, reduce setup times, and accelerate workflows. They can handle both prototypes and bulk production with consistent accuracy, helping businesses lower costs and improve turnaround times.

Reduced Material Waste

Precise cutting patterns and optimized layouts minimize fabric waste. Manufacturers benefit from significant material savings, lower production costs, and a more sustainable process that aligns with eco-friendly manufacturing initiatives.

Consistency and Repeatability

Every cut is uniform, even across large production runs. This repeatability ensures garments, upholstery, and industrial textile products meet strict quality standards, reducing rework and improving reliability for manufacturers serving competitive global markets.

Compatible Textile Materials

- Cotton

- Organic Cotton

- Linen

- Hemp

- Wool

- Cashmere

- Silk

- Bamboo Fabric

- Rayon

- Modal

- Lyocell

- Polyester

- Recycled Polyester

- Nylon

- Spandex

- Acrylic Fabric

- Acetate Fabric

- Denim

- Canvas

- Twill Fabrics

- Jersey Knit

- Fleece

- Felt

- Velvet

- Suede

- Leather

- Faux Leather

- Upholstery Fabrics

- Carpeting Textiles

- Nonwoven Fabrics

- Geotextiles

- Aramid Fabrics

- Carbon Fiber Textiles

- Glass Fiber Textiles

- PTFE-Coated Fabrics

- Technical Laminated Textiles

- Mesh Fabrics

- Netting Fabrics

- Protective Textiles

- Composite Fabrics

Application of Textile Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Waterjet Cutting | Hot Knife Cutting | Laser Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | High-pressure water jet | Electrically heated blade melts fabric | Laser beam burns through fabric |

| Cut Edge Quality | Smooth, clean, no fraying | Clean, but edges may absorb water | Melt-sealed edges, risk of distortion | Burnt, hardened, or discolored edges |

| Material Compatibility | Works with natural, synthetic, and technical textiles | Works on many textiles, not ideal for delicate fabrics | Limited to thermoplastic textiles | Limited—natural fibers burn, synthetics melt |

| Accuracy | High precision, ±0.1 mm | Very high accuracy | Moderate, less precise | High, but risk of heat distortion |

| Cutting Speed | Fast and efficient | Moderate, slower on thicker layers | Fast on simple cuts | Fast, but damaging for many fabrics |

| Design Complexity | Handles intricate patterns easily | Excellent for 2D shapes | Limited to straight/simple cuts | Handles complex shapes but burns fine details |

| Material Waste | Minimal with nesting optimization | Minimal, but water issues | Some waste from melted edges | Some waste from vaporization |

| Surface Finish | Natural fabric finish | Clean but may need drying | Glossy melt line, uneven | Burnt or charred edge |

| Heat Damage | None (cold cutting) | None | High—edges melt and warp | High—burning and shrinking |

| Tool Wear | Low, blades are replaceable | Nozzle requires upkeep | Heating element degrades | Optics require cleaning and alignment |

| Noise Level | Low noise | High (pump system) | Low | Low |

| Dust & Debris | Minimal | Water slurry, requires disposal | Minimal but melted residue | Hazardous fumes and smoke |

| Energy Consumption | Moderate | Very high | Moderate | High |

| Maintenance | Simple, low maintenance | Complex, pump/nozzle service | Regular element replacement | Frequent optics and ventilation care |

| Best Use Cases | Apparel, upholstery, composites, technical fabrics | Thick composites, industrial textiles | Sealing and cutting thermoplastic fabrics | Engraving or marking, not ideal for cutting fabrics |

Why Choose Us

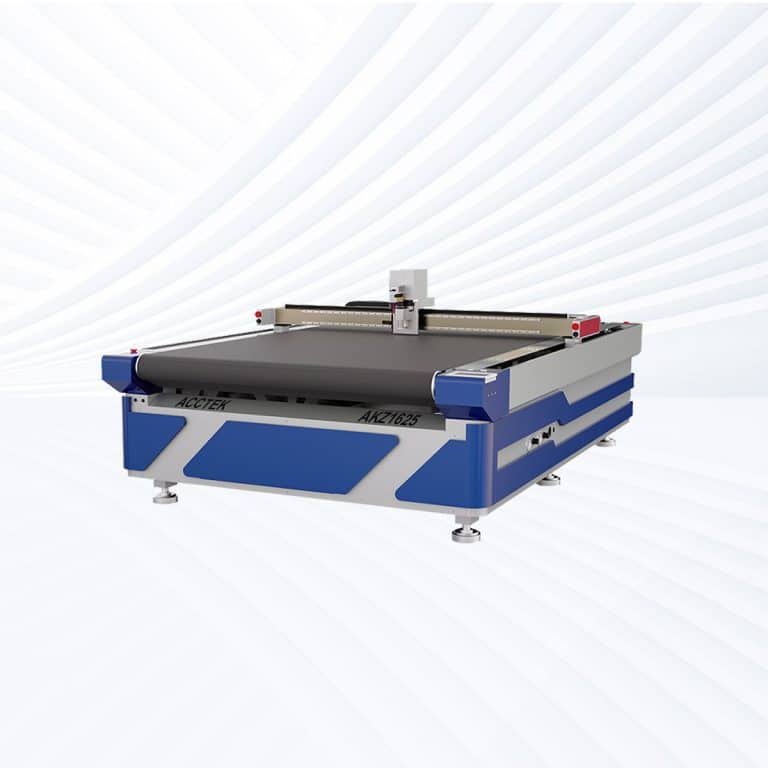

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

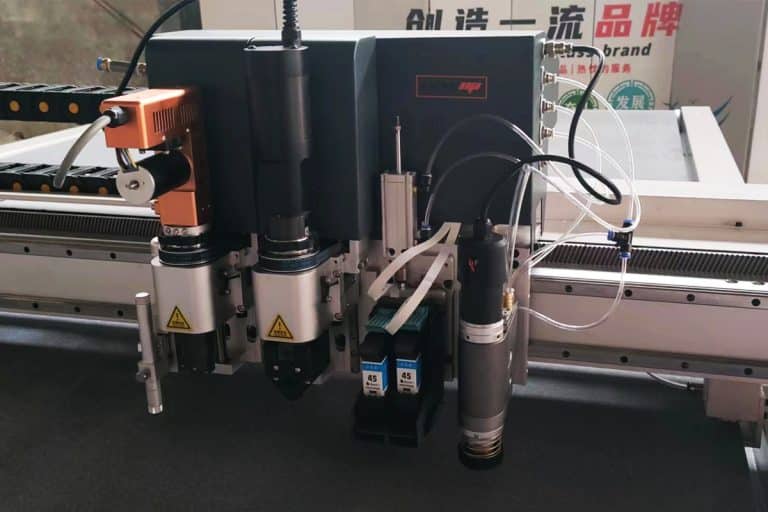

Customizable Configurations for Any Industry

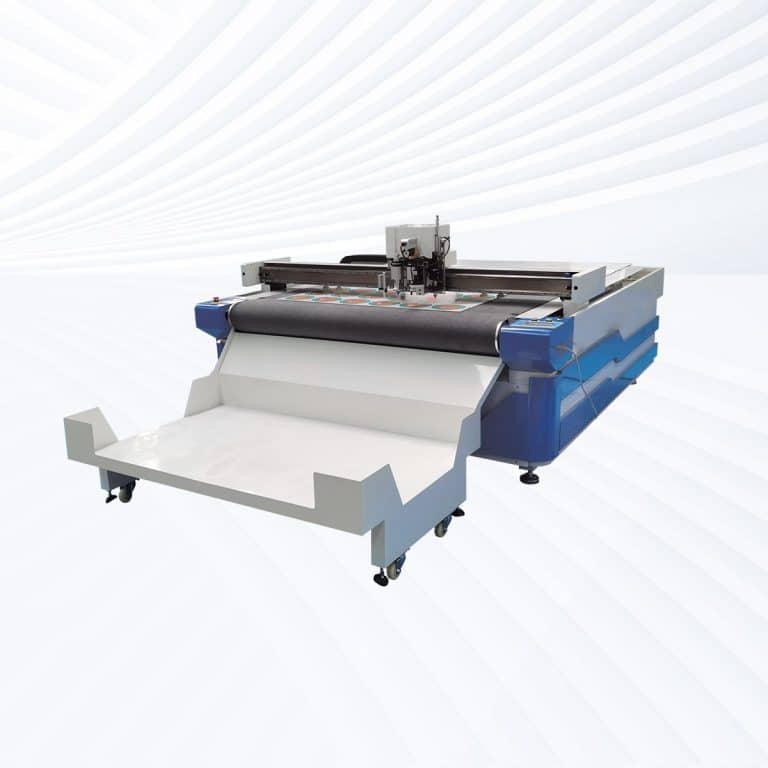

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Textile Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000–$10,000): Compact machines designed for small workshops, sampling, or light-duty production. They are best for cutting single-layer fabrics like cotton, polyester, or felt. While cost-effective, they usually have smaller cutting beds and fewer automation options.

- Mid-Range Machines ($10,000–$14,000): These systems offer larger cutting beds, stronger oscillation drives, and more advanced software. They can cut multiple layers of fabric with precision, making them suitable for medium-scale garment production, signage textiles, or upholstery materials. CAD/CAM integration and nesting functions improve material efficiency.

- High-End Machines ($14,000–$18,000): Industrial-grade cutting machines built for continuous, high-volume textile processing. These often include conveyor systems for roll-to-roll cutting, automatic feeding, multi-tool heads (oscillating knives, rotary blades, creasing tools), and advanced nesting software. They are capable of handling thick or technical fabrics such as denim, canvas, composites, or multilayer upholstery stacks.

What Is The Edge Quality Of Film Cut With An Oscillating Knife?

- Thin Plastic Films (Polypropylene, Polyethylene, PET): These materials cut with sharp, smooth edges. Since no heat is applied, there is no shrinkage, curling, or melting, which often occurs with laser cutting. The result is a crisp, distortion-free edge ideal for packaging or protective applications.

- Laminated Films (Multi-Layer Packaging Films, Adhesive-Backed Films): Oscillating knives maintain neat, controlled edges across laminated layers. However, adhesive-backed films may leave slight residue on the blade, which can reduce edge quality if not cleaned regularly. Proper maintenance ensures consistently clean edges.

- Technical and Specialty Films (Optical Films, Electronics Films, Coated Films): These require high precision. Oscillating knives produce clean cuts with tight tolerances, ensuring coatings remain intact. There is no risk of discoloration or surface damage, which is a key advantage over thermal cutting methods.

- Very Thin or Delicate Films: Ultra-thin films cut smoothly, though at reduced speeds to prevent wrinkling or static-related misalignment. Edges are crisp and free from fraying or tearing, provided proper hold-down systems and anti-static controls are used.

What Is The Accuracy Of Textile Oscillating Knife Cutting Machines?

- Single-Layer Fabrics (Cotton, Polyester, Felt): When cutting light, single-layer fabrics, oscillating knife cutting machines typically achieve ±0.1–0.25 mm accuracy. Edges remain smooth with no fraying, making the technology ideal for fashion samples, signage, textiles, or protective covers where fine details matter.

- Multi-Layer Fabrics (Garment Stacks, Upholstery, Denim): Accuracy remains high even when cutting multiple layers, though tolerance may widen slightly to ±0.25–0.5 mm depending on fabric thickness and stack height. Precision hold-down systems like vacuum beds ensure material stability during high-speed cutting.

- Technical Textiles (Kevlar, Composites, Reinforced Fabrics): Tough, dense, or coated textiles require slower cutting speeds to maintain precision. With proper blade selection, machines can still achieve ±0.3–0.5 mm accuracy. These applications often demand consistent repeatability rather than decorative precision, which oscillating knives provide reliably.

- Stretchable and Elastic Fabrics (Lycra, Spandex, Knits): Elastic textiles pose greater challenges because they can shift, stretch, or contract during cutting. Accuracy depends on tension control systems and vacuum suction, with tolerances typically in the range of ±0.5 mm.

What Are The Disadvantages Of Using An Oscillating Knife To Cut Film?

- Blade Wear and Adhesive Buildup: Films, particularly laminated or adhesive-backed types, dull blades faster than many other materials. Adhesive residue can accumulate on the blade, reducing edge smoothness and requiring frequent cleaning or replacement. This adds to ongoing maintenance costs.

- Material Handling Challenges: Thin films are prone to wrinkling, shifting, or misalignment during cutting. Without strong vacuum suction or static-control systems, films may move, resulting in uneven or inaccurate cuts.

- Static Electricity Issues: Films such as PET and polypropylene generate static during processing, causing sheets to cling together or attract dust. This can reduce cut accuracy and create handling difficulties, especially in high-speed production.

- Speed Limitations with Delicate Films: Although oscillating knives can cut films quickly, very thin or fragile materials often require slower cutting speeds to avoid tearing or distortion. This can limit throughput compared to tougher materials like rubber or textiles.

- Noise and Vibration: The rapid oscillation of the blade generates noise and mechanical vibration, particularly in large-scale or continuous-use environments. Operators may require hearing protection, and vibration can contribute to operator fatigue.

- Limited Polished Edge Finish: Unlike lasers, which can leave polished or glossy edges (albeit with risk of melting), oscillating knives produce sharp but matte edges. For applications requiring a decorative or polished finish, secondary processing may be necessary.

- Ongoing Maintenance Needs: To maintain consistent quality, these machines require regular blade replacement, lubrication, and calibration. Ignoring maintenance increases wear and reduces cutting precision.

How Should I Choose Textile Oscillating Knife Cutting Machines?

- Fabric Types and Thickness: Different textiles are cut differently. Lightweight fabrics like cotton, polyester, or silk require less power, while heavy-duty materials such as denim, canvas, upholstery textiles, or technical fabrics like Kevlar demand stronger oscillating drives. Choose a machine that supports both the fabrics you use most often and any specialty materials you may need in the future.

- Single-Layer vs. Multi-Layer Cutting: If your production involves cutting multiple fabric layers at once (e.g., garment stacks, upholstery, or automotive interiors), select a machine with strong vacuum hold-down systems and high oscillation speeds. For single-layer cutting, a smaller, less powerful system may be sufficient.

- Cutting Bed Size and Layout: Machines come in various bed sizes. Small beds suit prototyping or sample making, while large beds or conveyor systems are better for continuous roll-to-roll textile cutting. Ensure your workspace can accommodate the machine and allow efficient material handling.

- Automation Features: Advanced models include automatic feeding systems, conveyor beds, tool-changing heads (oscillating knives, rotary blades, creasers, punches), and smart nesting software. These features reduce labor, increase throughput, and minimize fabric waste, making them valuable for medium- to large-scale production.

- Software Integration: CAD/CAM compatibility is essential for pattern-driven industries like fashion, upholstery, or technical textiles. Ensure the machine integrates with your design workflow and supports nesting optimization for maximum fabric efficiency.

- Accuracy and Precision Needs: For industries like fashion or technical textiles, where tolerances are tight, look for machines with ±0.1–0.25 mm accuracy. High-end models maintain consistent precision even on stretchable or elastic fabrics by combining vacuum suction with advanced motion control.

- Maintenance and Blade Management: Oscillating knife cutting machines require routine blade changes, cleaning, and lubrication. Machines that provide easy access to blade replacement and built-in maintenance diagnostics will reduce downtime and improve long-term reliability.

- After-Sales Support and Training: Select a machine from a manufacturer or distributor that offers strong technical support, spare parts availability, and operator training. This ensures your team can fully utilize the system and keep it running at peak efficiency.

- Budget vs. ROI: Entry-level machines ($8,000–$10,000) are suitable for small workshops and sample making. Mid-range models ($10,000–$14,000) balance features and cost for medium-scale production. High-end systems ($14,000–$18,000) deliver industrial-grade performance with automation and continuous production capabilities.

What PPE Do Operators Need When Cutting Film With An Oscillating Knife?

- Safety Glasses or Goggles: Protective eyewear shields operators from small particles, dust, or static-related debris when films are cut at high speeds. Laminated films may shed tiny flakes or coatings that could irritate the eyes if unprotected.

- Cut-Resistant Gloves (for Blade Handling Only): Operators should not wear gloves while working near moving blades, but cut-resistant gloves are essential when changing or cleaning blades. They protect against accidental cuts during maintenance or blade replacement.

- Hearing Protection: Oscillating knives produce mechanical noise and vibration, especially at high oscillation speeds in large-scale production. Earplugs or earmuffs may be required in environments where machines run continuously.

- Dust Masks or Lightweight Respirators: While cutting films does not generate fumes, laminated, adhesive, or coated films can release fine particles. Lightweight dust masks provide adequate protection in most cases, while respirators may be required when processing technical films in sensitive environments.

- Protective Clothing or Aprons: Operators should wear close-fitting work clothing or lightweight aprons to protect against static cling and dust buildup. Loose clothing should be avoided to reduce the risk of entanglement in moving components.

- Safety Footwear: Protective shoes with reinforced toes help guard against injury when handling large rolls of film or moving heavy machine parts. Non-slip soles also reduce the risk of accidents in production areas.

- Anti-Static Protection (Optional in Some Workplaces): When cutting films prone to static buildup, anti-static wristbands, mats, or grounding devices may be used to prevent shocks and improve material handling safety.

What Problems Might Be Encountered During Film Cutting With An Oscillating Knife?

- Material Shifting and Wrinkling: Films are lightweight and can move during cutting, especially if not held down securely. Without strong vacuum suction or clamping systems, sheets may wrinkle or misalign, leading to uneven edges.

- Static Electricity Build-Up: Thin plastic films such as PET and polypropylene generate static charges that cause sheets to cling together or attract dust. This can reduce accuracy, contaminate the cutting bed, and complicate handling during high-speed production.

- Blade Wear and Adhesive Residue: Adhesive-backed or laminated films can leave sticky residue on blades, dulling them more quickly and reducing cut smoothness. Frequent blade cleaning or replacement is required to maintain precision.

- Edge Tearing or Fraying on Delicate Films: Ultra-thin or fragile films may tear if the cutting speed is too high or if blades are not sharp enough. Lowering the cutting speed and ensuring regular blade maintenance helps prevent edge damage.

- Accuracy Loss with Multi-Layer Films: When cutting laminated or reinforced films, the blade may drift slightly or produce inconsistent edges, especially if layers shift during the process. Proper hold-down systems and slower feed rates improve accuracy.

- Dust and Particle Accumulation: Although films do not produce fumes like plastics or rubbers, coated or laminated varieties may shed fine particles. Without regular cleaning, these can build up in the cutting bed and interfere with machine movement.

- Noise and Vibration: Oscillating blades generate noticeable vibration and noise, particularly in continuous-use environments. Over time, this can cause operator fatigue and may require noise management strategies.

- Software and Nesting Errors: Inefficient nesting setups or file preparation can waste material. Since films are often used in packaging and graphics, optimizing software usage is critical to minimizing production waste.

What Are The Environmental Requirements For Using Textile Oscillating Knife Cutting Machines?

- Clean and Dust-Free Workspace: Textile cutting produces lint, fibers, and fine dust that can accumulate in the machine’s moving parts and reduce accuracy. A clean workspace with regular housekeeping prevents buildup on the cutting bed, blade, and vacuum system. Dust extraction or filtration systems are recommended in high-volume fabric processing.

- Stable Temperature and Humidity: Textiles respond to environmental changes. High humidity can cause natural fibers like cotton or wool to swell, while low humidity increases static buildup in synthetic fabrics like polyester. A controlled environment—typically 18–26°C (64–79°F) with 40–60% relative humidity—helps maintain material stability and consistent cut quality.

- Anti-Static Control: Synthetic and blended fabrics generate static electricity during cutting, which can cause misalignment or material sticking. Anti-static devices such as grounding mats, ionizers, or humidifiers help reduce this problem and keep material feeding smooth.

- Adequate Ventilation and Airflow: Although oscillating knives do not produce harmful fumes, proper airflow is important to clear airborne fibers and maintain operator comfort. In busy textile facilities, localized air extraction near the cutting bed improves cleanliness and safety.

- Flat, Stable Flooring: Oscillating knife cutting machines are large, heavy systems. They require level, vibration-free flooring to ensure smooth operation of linear guides and oscillating drives. Uneven floors can lead to misalignment over time.

- Lighting and Visibility: Bright, shadow-free lighting around the cutting area allows operators to inspect fabric alignment, nesting, and cut quality. Good visibility also supports safe blade changes and machine maintenance.

- Electrical Supply and Grounding: Machines require a stable electrical supply, often with three-phase power for industrial models. Proper grounding reduces electrical risks and helps prevent static buildup in fabrics.

- Noise Management: Oscillating knife cutting machines generate mechanical vibration and noise during operation. Facilities should consider acoustic dampening or provide operators with hearing protection, especially in large-scale production environments.

- Space for Material Handling: Sufficient space is needed around the machine for loading rolls, handling cut pieces, and moving fabric stacks. Conveyor-fed systems especially require extended clearance for roll-to-roll processing.