Product Introduction

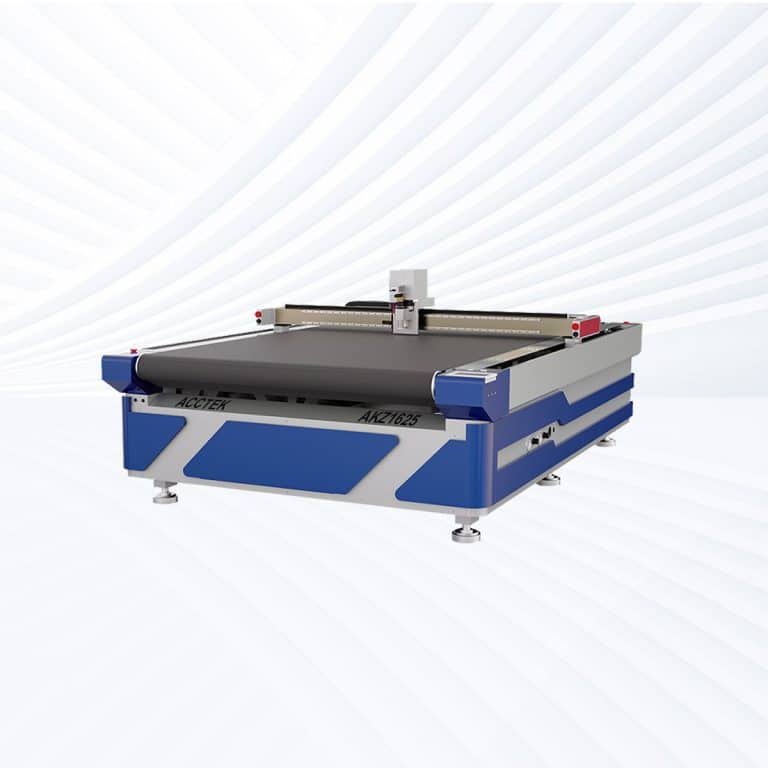

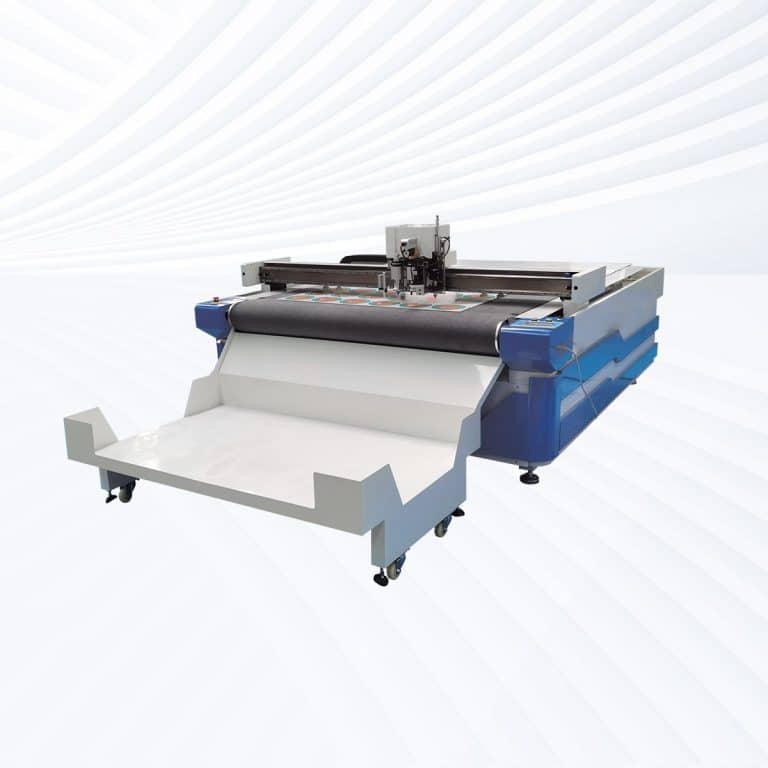

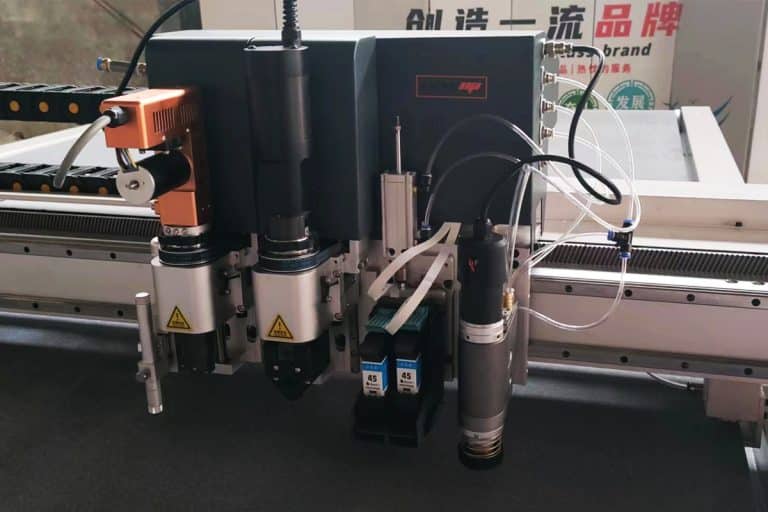

Types of Rubber Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Rubber

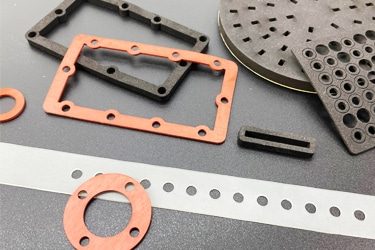

Clean and Accurate Cuts

Oscillating knife machines deliver sharp, precise cuts without tearing or stretching the rubber. This ensures clean edges, accurate dimensions, and consistent quality across every piece, making them ideal for industries that demand high precision and repeatable results.

Cold-Cutting Process

Unlike thermal cutting, the oscillating blade generates no heat, so the rubber does not burn, harden, or lose flexibility. This preserves the material’s original properties, ensuring components maintain their durability, elasticity, and long-term performance in demanding applications.

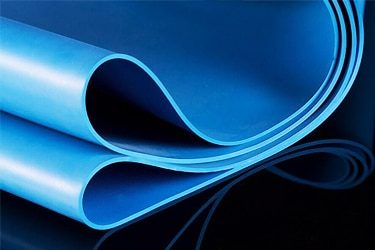

Versatility Across Rubber Types

From soft natural rubber to dense synthetic compounds like NBR, EPDM, or silicone, oscillating knife cutting machines handle a wide variety of rubber materials and thicknesses. This versatility makes them suitable for multiple industries and specialized product requirements.

High Efficiency and Productivity

With CNC automation and advanced nesting software, operators can cut complex designs quickly and accurately. Reduced setup times, optimized material use, and the ability to handle both prototypes and mass production increase overall efficiency and lower operating costs.

Reduced Material Waste

By delivering precise, optimized cuts, oscillating knife machines minimize offcuts and scrap. Better material utilization means lower production costs, improved sustainability, and a leaner manufacturing process that benefits both manufacturers and their customers.

Consistency and Repeatability

Every cut remains uniform, even in large production runs. This repeatable accuracy eliminates errors, reduces rework, and ensures rubber components meet strict quality standards, making these machines ideal for industries where reliability and consistency are critical.

Compatible Rubber Materials

- Natural Rubber

- Styrene-Butadiene Rubber

- Nitrile Rubber

- Hydrogenated Nitrile Rubber

- Ethylene Propylene Diene Monomer

- Ethylene Propylene Rubber

- Butyl Rubber

- Halobutyl Rubber

- Halobutyl Rubber

- Chloroprene Rubber

- Silicone Rubber

- Fluorosilicone Rubber

- Fluoroelastomers

- Perfluoroelastomers

- Polyurethane Rubber

- Thermoplastic Polyurethane

- Thermoplastic Elastomers

- Isoprene Rubber

- Polybutadiene Rubber

- Chlorosulfonated Polyethylene Rubber

- Epichlorohydrin Rubber

- Acrylic Rubber

- Ethylene-Acrylic Rubber

- Styrene-Ethylene-Butylene-Styrene

- Styrene-Isoprene-Styrene

- Hydrogenated Styrene Block Copolymers

- Polyisoprene

- Polychloroprene Rubber

- Urethane Rubber

- Reclaimed Rubber

- Conductive Rubber

- Anti-Static Rubber

- Sponge Rubber

- Foam Rubber

- Hard Rubber

- Latex Rubber

- Medical-Grade Silicone Rubber

- High-Temperature Silicone Rubber

- Oil-Resistant Rubber Compounds

- Custom Blended Rubber Compounds

Application of Rubber Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Waterjet Cutting | CNC Routing | Laser Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | High-pressure water (with or without abrasive) | Rotating spindle with cutting bit | High-powered laser beam burns material |

| Cut Edge Quality | Smooth, clean edges, no heat damage | Clean, but may cause water absorption/swelling | Rough, tool marks visible | Hard/burnt edges, risk of charring |

| Material Compatibility | Wide range of natural and synthetic rubbers | Works with most rubbers but water-sensitive materials can be affected | Can cut rubbers, but tool wear is high | Limited—rubber burns, melts, or emits toxic fumes |

| Accuracy | High precision, ±0.1 mm possible | Very high accuracy | Good, but vibration affects detail | High precision but inconsistent with flexible rubber |

| Cutting Speed | Fast for sheets and patterns | Moderate; slower on thick materials | Moderate | Fast, but not ideal for rubber |

| Design Complexity | Handles intricate shapes easily | Excellent for complex 2D patterns | Can cut 3D contours | Handles complex shapes, but burns foam/rubber |

| Material Waste | Minimal due to nesting optimization | Minimal waste | Moderate waste from tool paths | Some waste from burning/vaporization |

| Surface Finish | Clean and natural | Very clean, but edges may be wet | Rough, needs finishing | Burnt or hardened surface |

| Heat Damage | None (cold cutting) | None | Low (mechanical stress only) | High (burning, melting, fumes) |

| Tool Wear | Low, blades easily replaced | Low, nozzle maintenance required | High, bits dull quickly on rubber | None, but optics require maintenance |

| Noise Level | Low noise operation | High noise from pump system | High noise from spindle | Low noise |

| Dust & Debris | Minimal | Water slurry, requires disposal | High dust, extraction required | Hazardous smoke and fumes |

| Energy Consumption | Moderate, efficient | Very high (intense pumps) | High (spindle power) | High (laser power) |

| Maintenance | Simple, low-maintenance | Complex, requires pump/nozzle care | Frequent bit changes, lubrication | Optics cleaning, ventilation system |

| Best Use Cases | Rubber sheets, gaskets, seals, footwear, industrial parts | Metals, composites, stone, some rubber | Plastics, wood, rubber prototypes | Plastics, thin sheets, engraving—not rubber |

Why Choose Us

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

Customizable Configurations for Any Industry

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Rubber Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000–$10,000): Compact cutting machines are suited for small workshops or low-volume production. They handle basic rubber sheets and rolls with clean, consistent edges. While affordable, these models may have smaller cutting areas and fewer automation options.

- Mid-Range Machines ($10,000–$14,000): More versatile machines equipped with stronger motors, larger cutting beds, and improved blade oscillation. They can process thicker or denser rubbers, including natural rubber, silicone rubber, and some composites. Many come with user-friendly CAD/CAM integration for more complex patterns.

- High-End Machines ($14,000–$18,000): Industrial-grade systems built for continuous, high-volume cutting. These often include conveyor-fed tables, multi-tool heads (oscillating knives, rotary cutters, creasing tools), and advanced nesting software. They excel at cutting complex gasket designs, footwear components, and production runs where speed, precision, and repeatability are critical.

Is It Safe To Cut Rubber With An Oscillating Knife?

- Natural Rubber and Soft Rubber Sheets: Safe to cut with oscillating knives, producing smooth, accurate edges without scorching or smoke. These are commonly used for seals, mats, and footwear components, where clean edges are essential.

- Silicone Rubber: Also safe to process. Silicone cuts cleanly without releasing harmful byproducts, unlike when exposed to high heat from lasers. Proper blade selection ensures minimal drag or deformation during cutting.

- EPDM, Nitrile, and Industrial Rubbers: Safe when cut with oscillating knives, though denser rubbers may require slower cutting speeds to maintain accuracy. Mechanical cutting prevents the release of fumes that would occur with thermal methods.

- Reinforced or Composite Rubbers (Fabric-Backed, Layered, or Gasket Materials): Safe to cut, but may produce more blade wear due to embedded fibers or dense layers. Operators should monitor for blade dulling and replace tools regularly to maintain cut quality.

- PVC or Chlorine-Containing Rubbers: Unlike laser cutting, which is dangerous due to toxic chlorine gas, oscillating knives can safely cut these materials since they do not rely on heat. Still, users should handle the material itself safely, as some rubbers may contain additives that produce dust or particles during cutting.

What Is The Accuracy Of Rubber Oscillating Knife Cutting Machines?

- Soft Rubber Sheets (Natural Rubber, Neoprene, Sponge Rubber): These are cut with very high precision, typically achieving tolerances within ±0.1–0.3 mm. The blade slices cleanly, leaving smooth edges with no thermal damage. This level of accuracy is ideal for seals, mats, and custom-shaped components.

- Silicone Rubber: Silicone cuts accurately and consistently because it doesn’t resist blade motion the way denser rubbers do. Oscillating knives can reproduce fine details and complex geometries, making them suitable for medical, food-grade, or specialty silicone parts.

- Medium to High-Density Rubbers (EPDM, Nitrile, Industrial Rubbers): Accuracy remains strong, though dense rubbers may require slower feed rates to maintain precision. Tolerances are generally within ±0.2–0.5 mm, depending on thickness and machine configuration. CAD/CAM integration ensures that digital gasket designs translate directly into physical parts with minimal deviation.

- Reinforced or Fabric-Backed Rubbers (Composite Gaskets, Automotive Seals): Still accurate, though blade wear can slightly impact precision over time. Operators may need to monitor blade condition more closely when working with fabric inserts or reinforced layers. When properly maintained, machines still hold tight tolerances suitable for demanding industrial uses.

What Are The Environmental Requirements For Using Rubber Oscillating Knife Cutting Machines?

- Stable Power Supply: Machines depend on precise motor control for accurate blade oscillation. A stable power source, ideally supported by surge protection or an uninterruptible power supply (UPS), prevents voltage fluctuations that could affect cut quality or damage electronics.

- Clean and Dust-Controlled Workspace: Unlike laser cutting machines, oscillating knife cutting machines don’t generate smoke or fumes, but cutting reinforced or composite rubbers can produce fine dust or particles. A clean workspace with dust extraction or localized vacuum systems ensures consistent accuracy, protects moving parts from buildup, and improves operator safety.

- Ventilation: Heavy ventilation is not required as with lasers, but good airflow is recommended. This helps disperse any light odors or dust from certain rubber types and creates a more comfortable environment for operators during extended runs.

- Temperature and Humidity Control: Maintaining a stable environment prevents material distortion and machine wear. Excessive humidity can affect rubber sheets by making them tacky or harder to handle, while extreme cold may make some rubbers brittle. Optimal conditions are typically in the standard industrial range of 18–26℃ (65–79℉) with moderate humidity.

- Floor Space and Layout: Machines require a level, vibration-free surface for accurate cutting. Large-format or conveyor-fed systems need clear floor space for loading and unloading rubber sheets or rolls. A well-organized layout reduces material handling risks and maximizes workflow efficiency.

- Noise Management: Oscillating knives generate vibration and noise, especially when cutting dense rubbers. Sound-dampening enclosures, barriers, or PPE such as earmuffs may be required in facilities where noise levels must be controlled.

- Safety Features and Operator Protection: Blade guards, emergency stops, and safety sensors should always be operational. Operators should also be equipped with personal protective equipment (PPE) such as gloves for material handling and protective masks when cutting dust-producing rubbers.

- Periodic Professional Maintenance Environment: To maintain peak performance, machines should be installed in a workshop where scheduled servicing can be carried out easily. Adequate access to the cutting bed and moving components is necessary for technicians to perform calibration, lubrication, and part replacement.

What Problems Will Be Encountered When Cutting Rubber With An Oscillating Knife?

- Blade Wear and Frequent Replacement: Cutting rubber, especially dense or reinforced varieties, dulls blades more quickly than softer materials. A worn blade produces rougher edges, reduces accuracy, and can increase machine vibration. Regular replacement and proper blade selection are essential.

- Difficulty with Dense or High-Durometer Rubbers: Very dense or stiff rubbers (like industrial EPDM or nitrile) require slower cutting speeds to maintain accuracy. Pushing the feed rate too high can result in incomplete cuts, jagged edges, or tool deflection.

- Challenges with Reinforced or Composite Rubbers: Rubbers backed with fabric, mesh, or embedded fibers increase blade resistance. This can lead to uneven cuts, blade chipping, or accelerated wear. Adjusting oscillation settings and using specialized blades helps mitigate this issue.

- Edge Deformation or Compression: Because oscillating knives apply downward pressure, softer rubbers may compress before cutting, causing slight edge distortion. Proper clamping, sharp blades, and optimized oscillation frequencies help reduce this effect.

- Material Slippage on the Cutting Bed:Rubber sheets are flexible and can shift during cutting, particularly on smooth cutting beds. Without adequate vacuum hold-down systems, clamps, or textured surfaces, slippage can compromise accuracy.

- Dust and Debris Generation: While rubber doesn’t produce fumes when cut mechanically, some grades shed dust or fine particles. This can build up on the cutting bed or inside machine components, requiring regular cleaning to maintain precision.

- Noise and Vibration: Oscillating knives generate mechanical vibration, which increases when cutting dense rubbers. This can contribute to operator fatigue or higher noise levels in production environments if not managed with sound-dampening systems.

- Software or Nesting Inefficiencies: Complex gasket or seal designs require precise digital nesting to minimize waste. Inexperienced operators may face challenges preparing files, leading to inefficient material usage or misaligned cuts.

What Training Is Required To Operate Rubber Oscillating Knife Cutting Machines?

- Basic Machine Operation: Operators must learn how to start, stop, and calibrate the system. This includes loading and securing rubber sheets or rolls, setting cutting depth, adjusting oscillation speed, and selecting the correct blade type for the material being processed.

- Software and Digital File Preparation: Most oscillating knife cutting machines rely on CAD/CAM integration. Training covers how to import digital drawings, generate cutting paths, and apply nesting strategies to maximize material efficiency. Accurate file setup is especially important for gasket and seal production, where precision tolerances are critical.

- Blade Selection, Handling, and Maintenance: Rubber cutting requires specific blade types depending on thickness and reinforcement. Operators learn how to select the proper blade, replace worn tools safely, and align them correctly to maintain smooth, accurate cuts. Regular inspection helps prevent rough edges or blade breakage.

- Material Knowledge: Different rubbers (natural rubber, silicone, EPDM, nitrile, or reinforced composites) behave differently under the blade. Training ensures operators know how to adjust machine settings—like feed rate and oscillation frequency—to match the density and hardness of the rubber.

- Safety Protocols: Even though oscillating knives are safer than lasers, training emphasizes safe handling practices. Operators are instructed on using guards, emergency stops, and proper personal protective equipment (PPE). Dust management is also covered, especially for reinforced rubbers that shed fine particles.

- Troubleshooting and Quality Control: Training includes diagnosing issues like incomplete cuts, material slippage, blade wear, or edge deformation. Operators learn to fine-tune settings, recalibrate the cutting head, and perform quality checks to ensure consistent part accuracy.

- Manufacturer and Ongoing Training: Most suppliers provide installation-day training to cover the basics. Ongoing training sessions or refresher courses may be offered for advanced features such as automated feeding, multi-tool heads, or updated CAD/CAM software.

What Is The Service Life Of Rubber Oscillating Knife Cutting Machines?

- Average Service Life: High-quality rubber oscillating knife cutting machines typically have a service life of 8 to 12 years in standard industrial environments. In light-use workshops, machines can last even longer, while in 24/7 production environments, lifespan may lean toward the lower end of this range.

- Blade Service Life vs. Machine Service Life: Blades are consumables and wear much faster than the machine itself. Depending on the rubber type (soft sheets vs. reinforced composites), blades may last anywhere from a few hours to several weeks of use before requiring replacement. Regular blade changes ensure the core machine stays in peak condition.

- Impact of Material Type: Cutting softer rubbers, such as natural rubber or silicone, places relatively low stress on the machine, extending service life. In contrast, dense or reinforced rubbers (EPDM with fabric backing, nitrile composites) cause greater wear on blades and drive systems, requiring more frequent maintenance.

- Maintenance Influence: Routine care significantly extends machine lifespan. Regular cleaning, lubrication, calibration, and prompt blade replacement help prevent stress on motors and cutting assemblies. Neglecting maintenance shortens service life and increases repair costs.

- Component Longevity:

- Motors and Drive Systems: With proper lubrication, these can last over a decade.

- Control Electronics: Typically lasts 8–10 years, though upgrades may be needed as software evolves.

- Cutting Bed/Conveyor Systems: Service life depends on usage volume; high-volume production may require replacement belts or surfaces within 3–5 years.

- Manufacturer Support and Upgrades: Machines backed by strong manufacturer support often remain in service longer thanks to spare parts availability and software updates. Some systems can be upgraded with new tools or automation, extending their useful life.

How To Maintain The Rubber Oscillating Knife Cutting Machines?

- Blade Care and Replacement: Blades wear quickly when cutting rubber, especially dense or reinforced materials. Operators should inspect blades regularly for dullness or chipping, replace them when necessary, and ensure proper alignment. A sharp, well-installed blade improves cut quality and reduces strain on the machine.

- Cleaning the Cutting Bed and Conveyor System: Rubber cutting can generate fine particles and dust, especially with composites. Regular cleaning of the bed, conveyor belts, and clamping systems prevents material slippage, maintains accuracy, and protects moving components from buildup.

- Lubrication of Mechanical Components: Oscillating knife cutting systems rely on fast-moving drives, bearings, and guide rails. Scheduled lubrication reduces friction, minimizes wear, and prevents overheating. Using manufacturer-approved lubricants is essential for long-term reliability.

- Calibration and Software Checks: Accurate cutting requires periodic calibration of the cutting head, blade depth, and machine axes. Operators should also keep the software updated to benefit from improved nesting, efficiency features, and compatibility with CAD/CAM design files.

- Dust and Particle Control: While rubber cutting does not release fumes, certain industrial rubbers may shed particles. Machines should be fitted with dust extraction systems or cleaned frequently to prevent buildup inside housings and moving assemblies. This also improves operator health and machine precision.

- Inspection of Electrical and Safety Systems: Routine checks of wiring, sensors, emergency stop functions, and blade guards ensure the machine operates safely. Any worn cables or faulty connections should be repaired immediately to avoid downtime or hazards.

- Preventive Professional Servicing: In addition to daily and weekly maintenance by operators, periodic professional servicing is recommended. Technicians can inspect oscillation drives, motors, and control systems, replacing worn parts before they cause failures.