Product Introduction

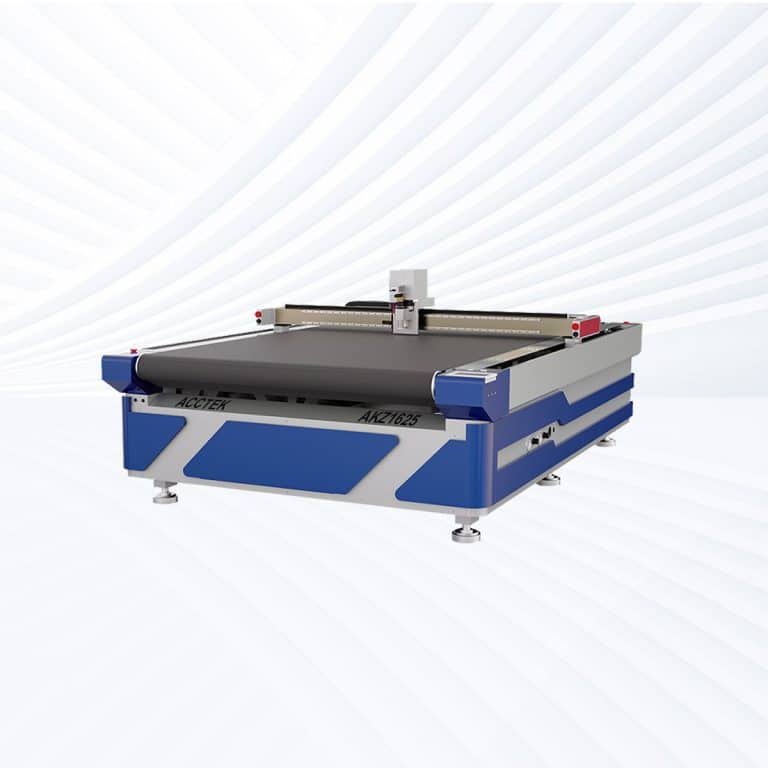

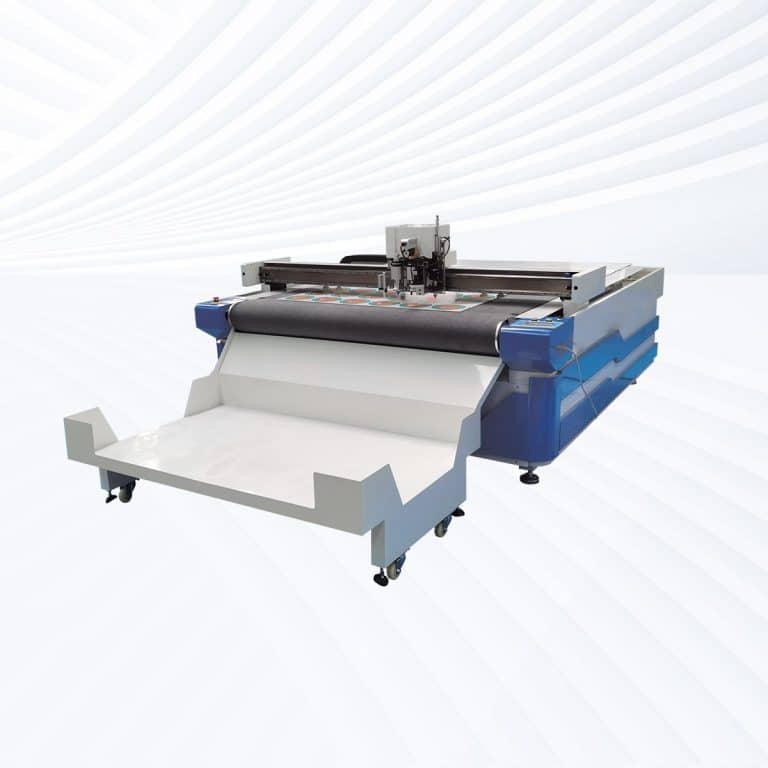

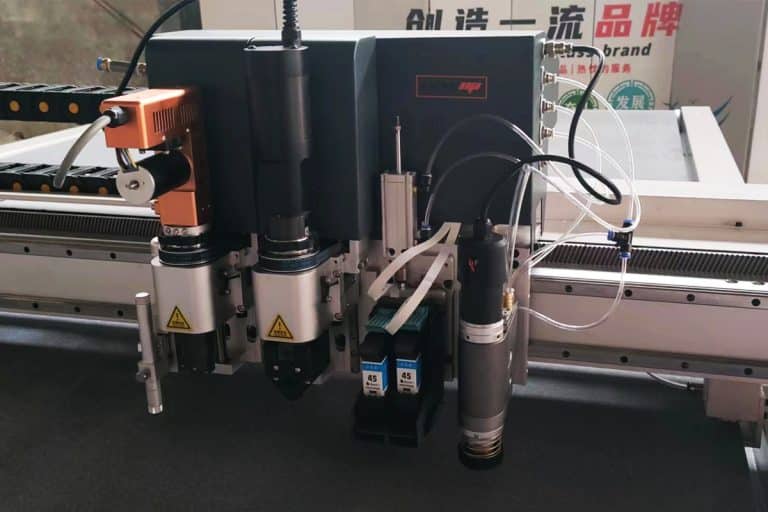

Types of Plastic Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Plastic

Clean and Accurate Edges

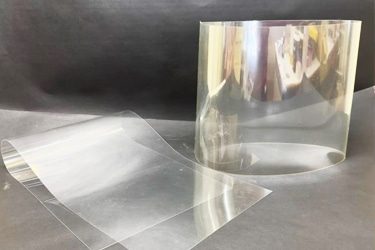

Oscillating knife cutting machines deliver precise cuts with smooth, clean edges. Unlike thermal cutting, they avoid melting, burning, or warping plastic surfaces, ensuring that every part meets exact specifications and maintains its professional appearance for end-use applications.

Cold-Cutting Technology

Because the blade operates without heat, the material’s structure and surface finish are preserved. This eliminates problems like discoloration, hardened edges, or toxic fumes, making it a safe and effective solution for processing a wide range of plastic types.

Compatibility with Multiple Plastics

From thin films and foils to rigid sheets and layered composites, oscillating knife cutting machines handle diverse plastic materials. This versatility allows manufacturers to streamline operations by using one machine for multiple products and production requirements.

High Production Efficiency

Equipped with CNC automation and intelligent nesting software, these machines optimize material usage and minimize setup times. Manufacturers can process both prototypes and large production runs efficiently, reducing operating costs while boosting output and maintaining consistent product quality.

Minimal Material Waste

By producing highly accurate cuts and maximizing sheet utilization, oscillating knife cutting machines significantly reduce scrap rates. Lower waste not only saves money but also contributes to more sustainable, environmentally friendly production practices across industries.

Consistency and Repeatability

Each cut is uniform and reliable, even during high-volume production runs. This repeatability ensures product quality, reduces rework, and helps businesses meet strict industry standards for precision and consistency in plastic component manufacturing.

Compatible Plastic Materials

- Polyethylene

- High-Density Polyethylene

- Low-Density Polyethylene

- Polypropylene

- Polyvinyl Chloride – Rigid

- Flexible PVC

- Polyethylene Terephthalate

- PETG

- Acrylonitrile Butadiene Styrene

- Polystyrene

- High Impact Polystyrene

- Expanded Polystyrene Sheets

- Extruded Polystyrene Sheets

- Polycarbonate

- Acrylic

- Cellulose Acetate

- Nylon

- Polyoxymethylene

- Polytetrafluoroethylene

- Polyetheretherketone

- Polyphenylene Oxide

- Polysulfone

- Polyetherimide

- Thermoplastic Polyurethane

- Thermoplastic Elastomers

- Expanded Polypropylene Sheets

- Polyethylene Foam Sheets

- PVDF

- Polyisocyanurate Plastics

- Acrylic Laminates

- Composite Plastic Sheets

- Co-Extruded Plastic Films

- Biodegradable Plastics

- Engineering Plastics Blends

- Transparent Plastic Films

- Plastic Laminated Boards

- Plastic Insulation Sheets

- Specialty Packaging Plastics

- Recycled Plastic Sheets

- Custom Plastic Composites

Application of Plastic Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Waterjet Cutting | CNC Routing | Laser Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | High-pressure water (with or without abrasives) | Rotating spindle with cutting bit | High-powered laser beam burns material |

| Cut Edge Quality | Smooth, clean edges, no melting | Clean, but edges may absorb moisture | Rough, tool marks visible | Burnt, melted, or hardened edges |

| Material Compatibility | Works with flexible and rigid plastics, films, laminates | Works with thick plastics but risk of delamination | Effective for rigid plastics, poor on thin films | Limited—plastics may burn, melt, or release toxic fumes |

| Accuracy | High precision, ±0.1 mm | Very high accuracy | Good, but vibration reduces detail | High, but heat distortion possible |

| Cutting Speed | Fast for sheets and patterns | Moderate, slower on thick plastics | Moderate | Fast, but not ideal for many plastics |

| Design Complexity | Handles intricate shapes easily | Excellent for complex 2D cuts | Can cut 3D contours | Handles fine detail but risks heat damage |

| Material Waste | Minimal due to nesting optimization | Minimal | Moderate from tool paths | Some waste from burning/vaporization |

| Surface Finish | Clean, natural finish | Smooth, but may be wet | Rough, often requires finishing | Burnt or discolored surface |

| Heat Damage | None (cold cutting) | None | Low (mechanical stress only) | High—melting, burns, or fumes |

| Tool Wear | Low, blades easily replaced | Low, nozzle requires maintenance | High, bits wear quickly on plastics | None, but optics need cleaning |

| Noise Level | Low noise operation | High noise from pump | High noise from spindle | Low noise |

| Dust & Debris | Minimal | Water slurry, requires disposal | High dust, requires extraction | Hazardous smoke and fumes |

| Energy Consumption | Moderate, efficient | Very high (intense pumps) | High (spindle power) | High (laser power) |

| Maintenance | Simple, low-maintenance | Complex, pump and nozzle care | Frequent bit replacement and lubrication | Optics cleaning, ventilation system |

| Best Use Cases | Plastic sheets, films, laminates, prototypes, mass production | Metals, stone, thick composites, some plastics | Rigid plastics, structural prototypes | Engraving thin plastics, not recommended for cutting |

Why Choose Us

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

Customizable Configurations for Any Industry

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Plastic Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000–$10,000): Compact models suited for light-duty or small-scale production. They are ideal for cutting thin plastics such as polypropylene, polyethylene sheets, and films. While affordable, they often come with smaller cutting beds and limited automation features.

- Mid-Range Machines ($10,000–$14,000): These machines handle a wider range of plastics, including ABS, PVC-free foams, acrylic films, and laminated plastics. They usually feature larger cutting beds, faster oscillation speeds, and improved software for precision cutting. CAD/CAM integration allows them to cut more complex geometries for signage, displays, and protective packaging.

- High-End Machines ($14,000–$18,000): Industrial-grade systems designed for high-volume production and demanding applications. They can handle thicker, more rigid plastics such as high-density polyethylene (HDPE) or acetal sheets. These models often include conveyor feeding systems, multi-tool heads (oscillating knives, rotary blades, creasing tools), and advanced nesting software for maximum material efficiency.

How Fast Does An Oscillating Knife Cut Rubber?

- Soft Rubber Sheets (Natural Rubber, Neoprene, Sponge Rubber): These materials can be cut quickly, often at speeds ranging from 800 to 1,200 mm/s (about 31–47 in/s). The knife moves smoothly through softer rubbers without significant resistance, allowing for faster throughput in gasket, mat, or footwear applications.

- Silicone Rubber: Silicone is soft but slightly tacky, which can slow down feed rates compared to natural rubber. Typical speeds fall around 600 to 1,000 mm/s (24–39 in/s), depending on thickness. The clean slicing action ensures precise, heat-free edges.

- Medium-Density Rubbers (EPDM, Nitrile, Industrial Sheets): Cutting speed decreases as material hardness increases. For these rubbers, oscillating knife cutting machines typically operate at 400 to 800 mm/s (16–31 in/s) to maintain edge accuracy and prevent blade deflection.

- High-Density and Reinforced Rubbers (Fabric-Backed, Composite Gaskets): These materials require slower feed rates, often between 200 and 500 mm/s (8–20 in/s). Reinforcement layers add resistance and wear down blades faster, so slower speeds are necessary to preserve accuracy and reduce stress on the machine.

How Can I Purchase Plastic Oscillating Knife Cutting Machines?

- Direct from Manufacturers: Many machine builders sell directly via company websites or sales representatives. This option often provides access to the latest models, custom configurations, and factory-level technical support. Lead times may be longer if machines are built to order, but direct purchase ensures authenticity and full warranty coverage.

- Authorized Distributors and Dealers: Distributors represent multiple brands and can recommend machines suited to different plastic types and production volumes. They often provide demonstrations, installation, and training, along with localized service support. Purchasing through a distributor can speed up delivery while ensuring strong after-sales service.

- Online Marketplaces and Industrial Platforms: Websites such as Alibaba, Made-in-China, and ThomasNet list a wide selection of oscillating knife cutting machines. This route offers competitive pricing and easy access to international suppliers. However, buyers must carefully evaluate certifications, supplier reputation, and after-sales support to avoid reliability issues.

- Trade Shows and Industry Exhibitions: Manufacturing, packaging, and plastics expos often showcase oscillating knife cutting technology. Attending allows buyers to see live demonstrations, compare machines side by side, and negotiate directly with manufacturers or authorized dealers. This is one of the best ways to evaluate machines before investing.

- Secondhand and Refurbished Equipment: Pre-owned oscillating knife cutting machines are available from equipment resellers and auction platforms. While cost savings can be substantial, buyers should inspect machine condition, verify parts availability, and confirm whether manufacturer support is still active for the model.

What Is The Edge Quality Of Plastic Oscillating Knife Cutting Machines?

- Thin Plastic Films (Polypropylene, Polyethylene, PET): Oscillating knives cut these cleanly with sharp, precise edges and no fraying or melting. Since there is no heat distortion, the edges remain stable, making this method ideal for packaging films, laminates, and protective sheets.

- Acrylic and Rigid Plastics (Acrylic Sheets, HDPE, ABS): Edges are smooth and accurate, though they lack the polished finish of laser-cut acrylic. Instead, the cut edges are matte and uniform, with no burn marks. This is excellent for applications where function matters more than aesthetic polish, such as prototypes, enclosures, and signage backings.

- Foamed Plastics (PVC-Free Foam Board, Polyethylene Foam Sheets): Edges remain clean and consistent, with no risk of melting or smoke release. Oscillating knives excel at cutting foam-core plastics, which often warp or discolor under laser cutting. The mechanical cut keeps shapes precise and edges well defined.

- Composite Plastics and Laminates: For multi-layered plastics, edges are neat and controlled, though blade wear can slightly affect smoothness over long runs. Proper blade selection and maintenance ensure crisp cuts even on reinforced plastics or adhesive-backed laminates.

- Very Thick or Dense Plastics: Edges remain accurate but may show slight tool marks depending on feed rate and material hardness. Slower speeds and sharper blades help maintain smooth edges across thicker sheets.

What Is The Lifespan Of Plastic Oscillating Knife Cutting Machines?

- Average Machine Lifespan: A well-maintained plastic oscillating knife cutting machine typically lasts 8 to 12 years in standard industrial use. In light-duty workshops, machines may last longer, while in high-volume, 24/7 production settings, service life may fall toward the lower end of the range.

- Blade Lifespan vs. Machine Lifespan: Blades are consumables and wear out much faster than the machine itself. Cutting plastics—especially rigid types like ABS, HDPE, or acetal—dulls blades relatively quickly. Depending on thickness and material hardness, blades may last anywhere from a few days to several weeks before replacement is required.

- Impact of Plastic Type on Longevity:

- Thin Films and Soft Plastics (PE, PP, PET): Low wear on blades and mechanical systems, extending machine life.

- Rigid Plastics (ABS, HDPE, acetal): Higher resistance causes greater blade wear and puts more strain on oscillating motors.

- Composite Plastics and Laminates: Added layers increase wear on blades and may require more frequent maintenance.

- Maintenance Influence: Consistent upkeep—such as blade replacement, lubrication of moving parts, cleaning of dust and debris, and periodic calibration—significantly extends machine life. Neglecting these tasks leads to premature wear and more costly repairs.

- Component Lifespan Breakdown:

- Motors and Drive Assemblies: Typically last 8–10 years with proper lubrication and care.

- Electronics and Control Systems: Often reliable for 8–12 years, though software updates may be required.

- Cutting Beds and Conveyor Systems: Depending on workload, beds and belts may need replacement after 3–5 years in heavy production.

- Manufacturer Support and Upgrades: Machines from established brands often remain in service longer because spare parts and software updates are readily available. Some systems can also be upgraded with additional tools or automation features, extending their working lifespan.

What PPE Do Operators Need When Cutting Rubber With An Oscillating Knife?

- Safety Glasses or Goggles: Operators should wear protective eyewear to shield against rubber dust, small particles, or accidental blade fragments during cutting. This is especially important when processing reinforced or fabric-backed rubbers that may release fibers.

- Cut-Resistant Gloves (for Handling, Not During Cutting): While gloves should not be worn when working near moving blades, cut-resistant gloves are important when handling sharp blades during installation or replacement. They also protect hands when moving rubber sheets or trimming excess material.

- Hearing Protection: Oscillating knife cutting machines generate vibration and noise, particularly when cutting dense rubbers at high speeds. Operators working in high-noise environments should wear earmuffs or earplugs to reduce long-term hearing risks.

- Dust Masks or Respirators: Cutting certain industrial rubbers can generate fine dust or fibers. Lightweight dust masks are sufficient for most cases, but respirators may be required when cutting reinforced rubbers or composites that release airborne particles.

- Protective Clothing or Aprons: Operators may wear durable clothing or lightweight aprons to protect against dust accumulation or incidental contact with rubber particles. In heavy-duty cutting environments, clothing should be close-fitting to avoid getting caught in moving parts.

- Safety Footwear: Steel-toe or reinforced shoes help protect against injury from handling heavy rubber sheets, rolls, or machine components.

- Hearing and Ergonomic Aids: In facilities with prolonged cutting operations, anti-fatigue floor mats and vibration-dampening gloves (for handling materials, not during blade operation) may also improve operator comfort and reduce strain.

- Key Safety Advantage Over Lasers: Oscillating knives do not generate toxic fumes, sparks, or fire risks, so operators do not need specialized fume extraction PPE. Standard industrial protective equipment is sufficient when combined with safe operating procedures.

What Are The Environmental Requirements For Using Plastic Oscillating Knife Cutting Machines?

- Stable Power Supply: The precision motors that drive blade oscillation and positioning require steady electrical input. A stable power supply, supported by surge protection or an uninterruptible power supply (UPS), prevents voltage fluctuations that could disrupt accuracy or damage sensitive electronics.

- Clean and Dust-Controlled Workspace: Cutting plastics does not produce smoke, but some rigid or composite plastics may shed fine particles or shavings. Keeping the workspace clean prevents debris from interfering with the cutting bed, motors, and guide rails. Vacuum extraction systems or periodic cleaning routines help maintain accuracy.

- Ventilation: Unlike lasers, which require heavy-duty fume extraction, oscillating knife cutting machines only need general ventilation. This prevents light dust or odors from lingering when cutting certain plastics (such as ABS or composites). Standard workshop airflow is usually sufficient.

- Temperature and Humidity Control: Plastics are sensitive to environmental conditions. Excessive heat may soften some plastics, while extreme cold can make them brittle. Humidity can also affect laminates or adhesives. Optimal conditions are usually 18–26℃ (65–79℉) with moderate humidity, ensuring both machine stability and material consistency.

- Floor Space and Layout: Machines should be installed on a level, vibration-free surface. Larger models with conveyor-fed systems require adequate space for material loading and unloading. Clear floor layouts reduce handling risks and improve workflow efficiency.

- Noise Management: Oscillating knives generate vibration and moderate noise levels, especially at high speeds on dense plastics. Facilities may require noise barriers or operator PPE (ear protection) if used continuously in shared work environments.

- Safety Features and Operator Protection: The machine area should remain uncluttered to reduce operator risk. Safety guards, emergency stops, and blade shields must always be functional. Operators should also have easy access to PPE such as safety glasses and protective clothing.

- Professional Servicing Environment: For long-term performance, the workspace must allow access for technicians to conduct inspections, calibration, lubrication, and part replacements during routine maintenance schedules.

What Training Is Required To Operate Plastic Oscillating Knife Cutting Machines?

- Basic Machine Operation: Operators must learn how to start, stop, and calibrate the machine. Training includes loading plastic sheets or films, securing materials to the cutting bed, setting the cutting depth, and adjusting the oscillation speed. Understanding machine controls is essential for consistent performance.

- Software and Digital File Preparation: Since these machines rely on CAD/CAM integration, training covers importing design files, creating cutting paths, and applying nesting strategies to maximize plastic sheet usage. Proper file preparation ensures clean cuts and reduces waste.

- Blade Selection, Handling, and Maintenance: Plastics vary in hardness and thickness, so operators must know which blade types to use for rigid sheets (like ABS or HDPE) versus thin films (like PET or PP). Training includes how to safely replace blades, align them correctly, and monitor wear to prevent poor edge quality.

- Material Knowledge: Different plastics react differently under oscillating knives. Training teaches operators how to adjust machine settings for soft plastics, rigid sheets, or laminates to prevent cracking, edge roughness, or incomplete cuts.

- Safety Protocols: Although oscillating knives don’t produce toxic fumes like lasers, training emphasizes safe practices around moving blades. Operators are instructed on using blade guards, emergency stop functions, and proper PPE, including safety glasses and hearing protection.

- Troubleshooting and Quality Control: Operators learn to recognize and correct problems such as material slippage, incomplete cuts, or jagged edges. Training also includes calibration procedures and routine machine checks to ensure accuracy.

- Manufacturer and Ongoing Training: Most suppliers provide initial training at installation. Additional courses or refreshers may be available for advanced features such as automated feeding, multi-tool systems, or updated software.