Product Introduction

Types of Leather Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Leather

Clean and Accurate Cuts

Oscillating knife cutting machines deliver smooth, precise edges without fraying, tearing, or stretching the leather. This ensures components such as footwear uppers, upholstery panels, and fashion goods maintain consistent quality and professional finishes that meet demanding industry standards.

Cold-Cutting Technology

The process generates no heat, eliminating risks of burning, discoloration, or surface damage. This preserves the natural appearance, softness, and durability of leather, ensuring that both natural and synthetic materials retain their original properties after cutting.

Versatility Across Leather Types

From genuine hides and split leathers to synthetic materials like PU and PVC leather, oscillating knife cutting machines handle a wide variety of leather grades and thicknesses, making them suitable for multiple industries with diverse application requirements.

High Production Efficiency

With CNC automation and nesting software, these machines optimize material layouts, reduce setup time, and increase throughput. They are equally effective for prototypes or large-scale runs, helping manufacturers boost productivity while maintaining consistent, repeatable quality.

Reduced Material Waste

By producing precise, optimized cuts, oscillating knife machines minimize offcuts and scrap. Lower material waste means significant cost savings, improved sustainability, and a more efficient use of valuable leather resources in competitive manufacturing environments.

Consistency and Repeatability

Every cut is uniform, even in high-volume production runs. This repeatable precision eliminates costly rework, ensures reliable output, and helps manufacturers consistently meet strict quality standards required for footwear, automotive, furniture, and luxury leather products.

Compatible Leather Materials

- Full-Grain Leather

- Top-Grain Leather

- Corrected-Grain Leather

- Split Leather

- Genuine Leather

- Bonded Leather

- Nubuck Leather

- Suede Leather

- Aniline Leather

- Semi-Aniline Leather

- Pigmented Leather

- Embossed Leather

- Pull-Up Leather

- Patent Leather

- Vegetable-Tanned Leather

- Chrome-Tanned Leather

- Oil-Tanned Leather

- Aldehyde-Tanned Leather

- Synthetic PU Leather

- PVC Leather

- Eco Leather

- Faux Leather

- Microfiber Leather

- Reconstituted Leather

- Laminated Leather

- Metallic-Finish Leather

- Perforated Leather

- Coated Leather

- Printed Leather

- Exotic Leathers

- Ostrich Leather

- Goat Leather

- Sheep Leather

- Calfskin Leather

- Buffalo Leather

- Cowhide Leather

- Horsehide Leather

- Automotive Grade Leather

- Upholstery Leather

- Footwear Grade Leather

Application of Leather Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Ultrasonic Knife Cutting | Laser Cutting | Die Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | Ultrasonic vibrations with blade | Laser beam burns/cuts leather | Mechanical steel dies stamp out shapes |

| Cut Edge Quality | Clean, smooth, no burning | Smooth, sealed edges | Burnt, hardened, or discolored edges | Clean, but depends on die sharpness |

| Material Compatibility | Works with natural & synthetic leathers | Works on many leathers, may struggle with thick hides | Limited—thick hides burn, synthetics melt | Works on most leathers but thickness limited |

| Accuracy | High precision, ±0.1 mm | High precision | High, but heat distortion possible | Good, but limited to die accuracy |

| Cutting Speed | Fast, flexible for sheets & patterns | Fast, but slower on thicker materials | Fast, but risks heat damage | Very fast for mass production, slow setup |

| Design Complexity | Handles intricate patterns easily | Handles complex shapes | Handles complex shapes, risk of burning | Limited—requires new dies for each design |

| Material Waste | Minimal with nesting optimization | Minimal | Some waste from vaporization | Higher due to die clearances |

| Surface Finish | Natural leather finish preserved | Smooth finish | Burnt or charred edges | Clean, but risk of indentation |

| Heat Damage | None (cold cutting) | Minimal, localized | High—burning, melting, odor | None |

| Tool Wear | Low, blades easily replaced | Moderate, tips wear over time | None, but optics need care | High—dies dull quickly, frequent replacement |

| Noise Level | Low noise | Low to moderate | Low noise | Moderate to high (stamping noise) |

| Dust & Debris | Minimal | Minimal | Smoke and fumes | Leather scraps, dust |

| Energy Consumption | Moderate, efficient | Moderate | High | Low to moderate |

| Maintenance | Simple, low-maintenance | Requires ultrasonic unit upkeep | Optics cleaning, ventilation needed | Frequent die sharpening/replacement |

| Best Use Cases | Footwear, automotive, fashion, upholstery, luxury goods | Thin to medium leathers, precision applications | Engraving, decorative cuts, thin leather | High-volume, repeatable mass production runs |

Why Choose Us

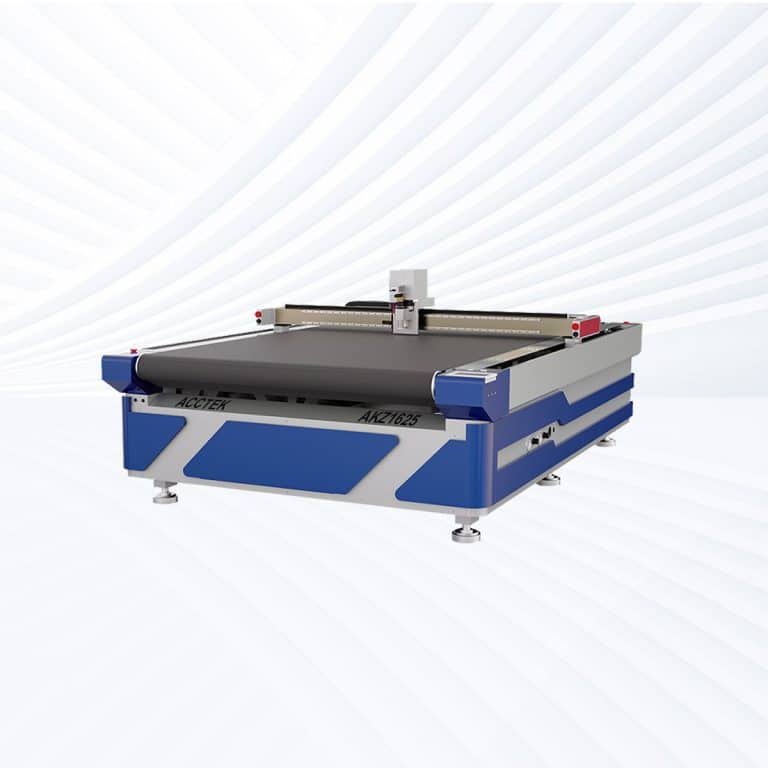

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

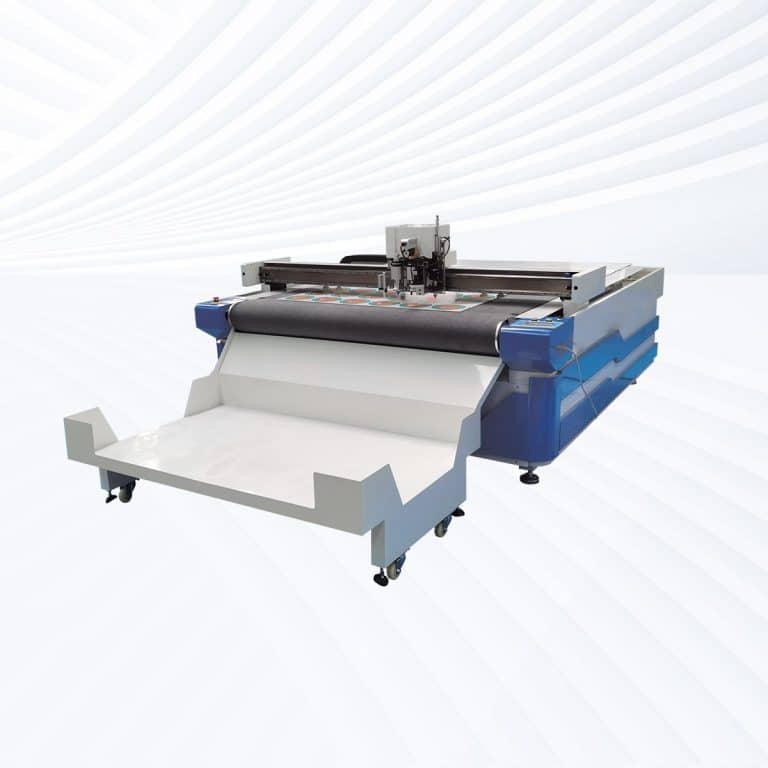

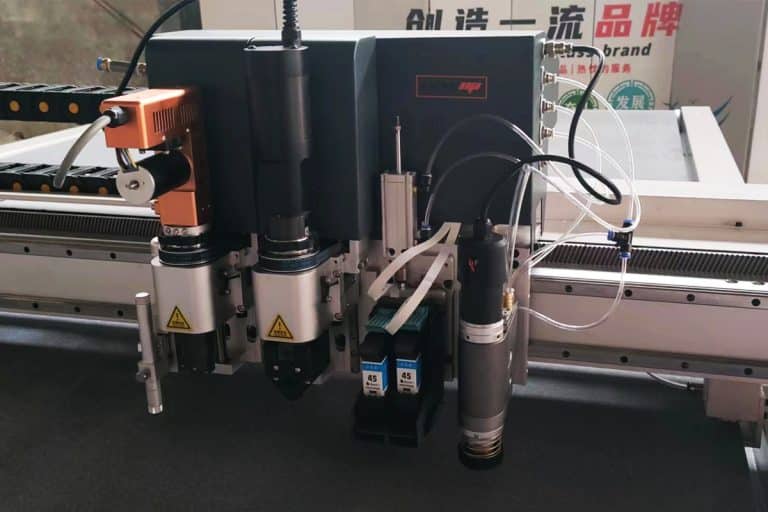

Customizable Configurations for Any Industry

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Leather Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000–$10,000): Compact cutting machines suited for small workshops, sampling, or light production. They handle natural leathers, suede, and synthetic leather alternatives effectively. These models usually have smaller cutting beds and fewer automation options, making them ideal for prototyping or limited runs.

- Mid-Range Machines ($10,000–$14,000): Built for medium-scale production, these machines provide larger work areas, stronger oscillating drives, and enhanced software compatibility. They can cut thicker hides, stack layers of leather, and integrate with CAD/CAM systems for pattern making and nesting. Upholstery workshops and footwear manufacturers often rely on machines in this range.

- High-End Machines ($14,000–$18,000): Industrial-grade systems designed for continuous, high-volume cutting. They feature conveyor-fed beds for roll or sheet processing, multi-tool heads (oscillating knives, punching tools, creasers), and advanced nesting software to minimize leather waste. These machines are commonly used in automotive interiors, large upholstery operations, and luxury leather goods manufacturing.

What Is the Edge Quality Of Leather Cut With An Oscillating Knife?

- Natural Hides (Full-Grain and Top-Grain Leather): Edges are sharp and smooth with no scorching or heat distortion. The natural texture and color of the leather are preserved, making oscillating knives ideal for footwear, upholstery, and luxury leather goods.

- Suede and Nubuck: Soft, fibrous leathers cut cleanly without crushing or fraying. Edges maintain their soft texture, though regular blade maintenance is important to prevent drag marks on delicate surfaces.

- Synthetic Leathers (PU, PVC, Vegan Alternatives): Oscillating knives cut synthetics with smooth edges free from melting or hardening. Unlike lasers, which can release harmful fumes from PVC or polyurethane coatings, mechanical cutting avoids this problem while delivering crisp, precise edges.

- Thick or Multi-Layer Leather: Dense hides and stacked layers are cut evenly with the right blade and oscillation settings. Edges remain consistent across thicknesses, although blade wear is faster compared to cutting thin or soft leathers.

- Coated or Treated Leathers (Embossed, Laminated, or Finished Surfaces): Edges remain uniform without damaging surface coatings or embossing. Oscillating knives maintain decorative finishes intact, which is crucial in luxury applications.

How Can I Purchase Leather Oscillating Knife Cutting Machines?

- Authorized Dealers and Distributors: Most manufacturers sell through regional distributors who provide demonstrations, quotations, and installation services. Buying from an authorized dealer ensures access to genuine machines, spare parts, and warranty coverage.

- Direct from Manufacturers: Some global brands allow direct purchases from their websites or sales teams. This option may offer lower prices and customized solutions, but often requires handling shipping, import duties, and setup independently unless local support is available.

- Online Marketplaces and Industrial Equipment Platforms: Websites such as Alibaba, Made-in-China, or ThomasNet list multiple suppliers of oscillating knife cutting machines. While prices are competitive, buyers must carefully verify supplier credibility, product specifications, and after-sales support before committing.

- Trade Shows and Industry Expositions: Events like leather goods fairs, textile technology shows, and manufacturing expos are excellent opportunities to see machines in action, compare models, and negotiate directly with suppliers. Live demonstrations allow you to evaluate cut quality on your own materials.

What Problems May Occur When Cutting Leather With An Oscillating Knife?

- Material Variability in Natural Hides: Leather is an organic material with irregular thickness, density, and grain. Variations across a single hide can cause inconsistent cuts—edges may appear rougher in denser sections or softer in thinner areas. Careful calibration and blade selection help manage these inconsistencies.

- Blade Wear and Frequent Replacement: Cutting thick or abrasive leathers, such as full-grain or embossed hides, wears blades quickly. A dull blade can drag instead of slicing, leading to frayed or uneven edges. Frequent blade changes are necessary to maintain precision.

- Edge Fraying or Roughness on Soft Leathers: Suede, nubuck, and other fibrous leathers may produce slightly fuzzy or frayed edges if cut with improper blade settings or at high speeds. Slowing the cutting speed and using sharper blades improves results.

- Shifting or Slipping During Cutting: If hides are not held firmly with vacuum suction or clamps, they may shift during processing. This can cause misaligned cuts or pattern distortion, especially on larger hides used in upholstery or automotive applications.

- Difficulty with Coated or Laminated Leathers: Leathers treated with protective coatings, laminates, or embossing can create extra resistance for the blade. This may result in blade drag marks, minor delamination, or inconsistent edges unless the machine is properly calibrated.

- Static and Dust Accumulation: Synthetic leathers, especially PVC or PU-based materials, may generate static electricity during cutting, attracting dust or small particles. This can interfere with clean cutting lines and requires anti-static control measures.

- Noise and Vibration: High-speed oscillating knives generate mechanical vibration and noise, which may contribute to operator fatigue in long production runs. Hearing protection and vibration-dampening systems may be necessary.

- Waste Management Challenges: Since leather is a premium material, even small cutting errors can be costly. Without optimized nesting software, material waste may increase, affecting profitability.

Are Leather Oscillating Knife Cutting Machines Safe?

- Blade Safety: The primary hazard comes from the sharp, fast-moving oscillating blade. Direct contact can cause cuts, so safety guards, restricted access zones, and operator training are essential. Operators should never handle leather near the moving blade, and cut-resistant gloves should only be used when changing or cleaning blades, not during active operation.

- No Heat or Fume Risks: Unlike CO2 lasers, oscillating knives do not generate high temperatures, flames, or smoke. This eliminates the risk of fire and harmful fumes when cutting natural or synthetic leathers, making them safer for indoor workshops with limited ventilation.

- Noise and Vibration: These machines produce mechanical noise and vibration, particularly at high oscillation frequencies. While not inherently dangerous, prolonged exposure can contribute to operator fatigue or hearing damage. Ear protection may be recommended in large-scale facilities.

- Material Handling Safety: Leather hides can be heavy, creating ergonomic risks when loading and unloading large sheets. Machines with conveyor systems and automated feeding help reduce strain on operators.

- Electrical and Static Safety: Industrial models require a stable power supply and proper grounding. While natural leathers pose little risk, synthetic leathers may generate static electricity, which can cause minor shocks or attract dust. Anti-static controls can improve safety and efficiency.

- Maintenance and Blade Replacement: Most accidents occur during maintenance rather than cutting. Blades should always be changed with the power off, and manufacturers typically provide safety fixtures or tools to make replacements safer.

What Is The Service Life Of Leather Oscillating Knife Cutting Machines?

- Blade Lifespan vs. Machine Lifespan: It is important to distinguish between blade life and overall machine life. Blades wear quickly when cutting thick, dense, or abrasive leathers and may need replacement after hours or days of production. In contrast, the main machine frame, motors, and control systems are designed for years of continuous operation.

- Light-to-Medium Use (Workshops & Small-Scale Production): Machines in smaller workshops, where production is limited to a few hours a day, often exceed 12 years of service. Reduced strain on motors and fewer blade replacements extend operating life.

- Industrial Use (High-Volume Production): In factories producing footwear, automotive interiors, or upholstery at scale, machines are run continuously. Under these conditions, typical service life is closer to 8–10 years, with more frequent part replacements (belts, bearings, and oscillating motors).

How Should I Maintain Leather Oscillating Knife Cutting Machines?

- Daily Cleaning: Leather cutting produces dust, fibers, and small fragments that can accumulate on the cutting bed and moving parts. Operators should clean the machine at the end of each shift, removing debris from the cutting area, vacuum system, and tool heads to prevent clogging and misalignment.

- Blade Care and Replacement: Blades are the most frequently replaced consumables. Cutting thick hides, oily leathers, or coated materials dulls them faster. Dull blades cause dragging, fraying, or rough edges. Inspect blades daily and replace them promptly to maintain edge quality. Always power off the machine before changing blades.

- Lubrication of Moving Parts: Guide rails, bearings, and oscillating mechanisms should be lubricated regularly to reduce friction and prevent wear. Using manufacturer-recommended lubricants helps avoid contamination and ensures smooth blade oscillation.

- Vacuum and Hold-Down System Checks: Vacuum systems are essential to keep hides flat during cutting. Clogged filters or weak suction can cause material shifting and misaligned cuts. Inspect vacuum pumps, seals, and filters weekly, and clean or replace as needed.

- Software Calibration: Pattern accuracy depends on proper machine calibration. Regularly check alignment, blade oscillation settings, and software-to-machine communication. Updates to CAD/CAM or nesting software should be installed promptly for optimal performance.

- Monthly and Annual Inspections:

- Monthly: Inspect belts, drive systems, and sensors for wear. Tighten loose components to prevent vibration or miscuts.

- Annual: Schedule a full service inspection, including motor performance checks, electrical system evaluation, and replacement of worn belts or bearings.

- Environment Maintenance: Leather fibers and dust can accumulate in the workshop. Keeping the environment clean, with stable humidity (to prevent static in synthetic leathers) and proper ventilation, reduces strain on the machine.

- Operator Training: Well-trained operators extend machine life by handling hides properly, running accurate nesting programs, and identifying early signs of blade wear or system errors.

What Are The Environmental Requirements For Using Leather Oscillating Knife Cutting Machines?

- Workspace Cleanliness: Leather cutting generates dust, fibers, and small scraps. A clean workspace prevents these particles from interfering with the vacuum hold-down system, clogging filters, or wearing down moving parts. Regular cleaning of both the machine and the workshop floor is essential to avoid buildup.

- Ventilation and Air Quality: Unlike CO2 lasers, oscillating knives do not create harmful fumes from burning materials. However, cutting synthetic leathers such as PU or PVC can release low levels of particulates or odors when friction heats the blade. Proper workshop ventilation ensures fresh air circulation and helps keep dust levels manageable.

- Humidity and Temperature Control: Leather is sensitive to moisture and temperature changes, which can cause warping, stretching, or shrinkage. Maintaining stable humidity (ideally 40–60%) and moderate temperature prevents dimensional changes in hides and ensures consistent cutting results.

- Static Control (for Synthetic Leathers): When cutting PU or PVC-based leathers, static buildup can attract dust and fibers to the material surface, affecting cut quality. Anti-static devices or humidifiers may be necessary in dry climates to minimize this issue.

- Noise and Vibration Management: High-speed oscillation generates mechanical vibration and moderate noise. Machines should be placed on a stable floor with vibration-dampening pads, and operators may require hearing protection in larger production environments.

- Power Supply Requirements: Industrial oscillating knife cutting machines require a stable electrical supply and grounding to prevent sudden shutdowns or electrical surges. Installing surge protection safeguards sensitive electronics.

- Space and Workflow Layout: Large hides are cumbersome to handle. Adequate floor space is needed around the cutting machine for loading and unloading leather safely. Conveyor-fed models benefit from extended clearance for material flow.

- Fire Safety Considerations: While there is no flame risk from the cutting process, leather scraps and dust are flammable. Workshops should maintain proper waste collection and have fire extinguishers accessible as a precaution.