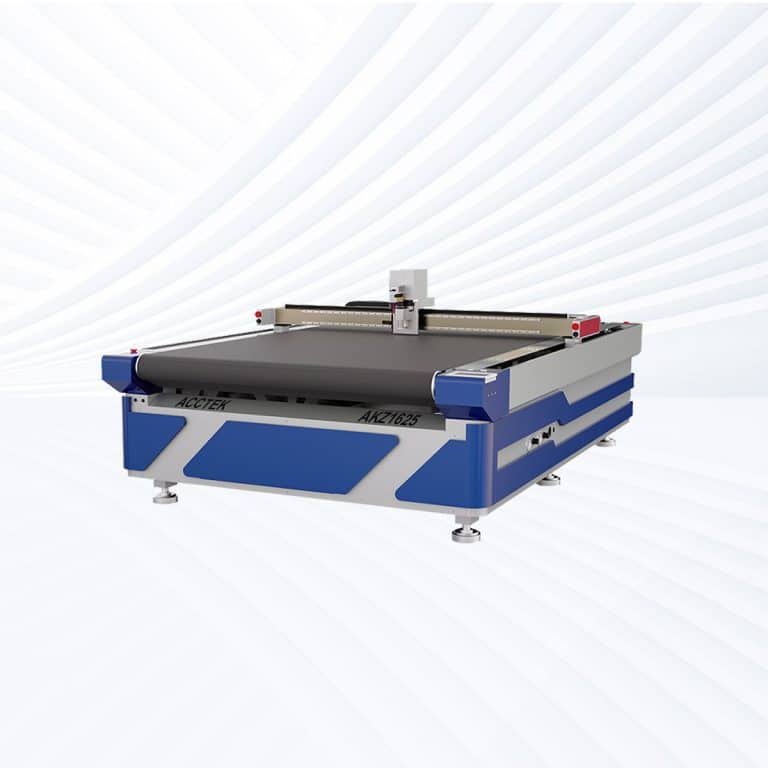

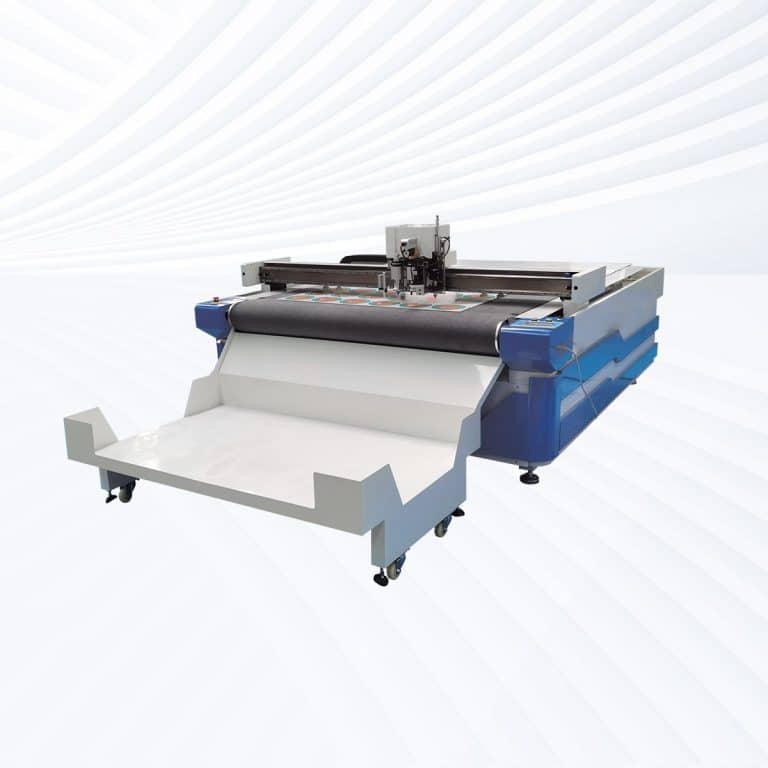

Product Introduction

Types of Foam Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Foam

Precise and Clean Cuts

Oscillating knife technology delivers highly accurate cuts with smooth, sealed edges. Unlike thermal cutting, it doesn’t melt or distort foam, ensuring components match design specifications perfectly. This precision reduces errors, saves material, and guarantees professional-quality results every time.

Versatility Across Foam Types

From soft, low-density packaging foam to rigid, high-density insulation, oscillating knife machines handle a wide range of materials with ease. This versatility eliminates the need for multiple cutting systems and gives manufacturers the flexibility to adapt quickly to changing projects.

Increased Production Efficiency

With automated CNC control and advanced nesting software, oscillating knife cutters streamline operations. They reduce setup time, optimize material use, and enable multi-layer cutting, making large production runs faster, more consistent, and significantly more cost-effective than traditional manual processes.

Consistency and Repeatability

Every cut remains uniform, no matter how many units are produced. The oscillating blade’s precision ensures repeatable accuracy for complex designs or high-volume jobs, helping businesses maintain quality standards while avoiding costly rework and inconsistencies across production batches.

Reduced Material Waste

By producing clean, accurate cuts and optimizing nesting layouts, these machines maximize material yield. Less scrap means lower costs, better sustainability, and more efficient use of foam sheets, helping companies cut expenses while minimizing environmental impact in manufacturing.

Non-Destructive Cutting Method

Oscillating blades cut without crushing, burning, or damaging the foam structure. This preserves the material’s integrity, cushioning performance, and appearance. The process ensures finished products meet functional requirements while keeping surfaces and edges intact, even on delicate or complex foam components.

Compatible Foam Materials

- Polyurethane Foam

- Polyethylene Foam

- Polypropylene Foam

- Expanded Polystyrene Foam

- Extruded Polystyrene Foam

- Cross-linked Polyethylene Foam

- Ethylene-Vinyl Acetate Foam

- Polyvinyl Chloride Foam

- Neoprene Foam

- Nitrile Rubber Foam

- Styrene-Butadiene Rubber Foam

- Silicone Foam

- Memory Foam

- Reticulated Foam

- Rebond Foam

- Acoustic Foam

- Open-Cell Foam

- Closed-Cell Foam

- Upholstery Foam

- High-Density Foam

- Low-Density Foam

- Spray Foam Sheets

- Polyisocyanurate Foam

- Rigid Urethane Foam

- Conductive Foam

- ESD Protective Foam

- Charcoal Foam

- Convoluted Foam

- Marine Foam

- Filter Foam

- Melamine Foam

- Latex Foam

- Graphite-Infused Foam

- Gel-Infused Foam

- Fire-Retardant Foam

- Insulation Foam Boards

- Cushion Foam Rolls

- Technical Foam Laminates

- Packaging Foam Inserts

- Specialty Composite Foams

Application of Foam Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Thermal Wire Cutting | CNC Routing | Laser Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | Heated wire melts through foam | Rotating spindle with cutting bit | High-powered laser beam burns material |

| Cut Edge Quality | Smooth, clean, no melting | Melts edges, may deform | Rough edges, possible fraying | Hard edges, possible burn marks |

| Material Compatibility | Works with wide range of foams (open/closed cell, rigid, soft) | Limited to soft/rigid polystyrene foams | Works on foams, plastics, woods | Limited foam use (risk of burning, toxic fumes) |

| Accuracy | High precision, ±0.1 mm possible | Moderate, depends on wire thickness | Good, but tool vibration can reduce accuracy | High, but heat can distort thin foams |

| Cutting Speed | Fast, especially for prototypes and production runs | Slow on complex shapes | Moderate to slow | Fast, but limited foam suitability |

| Design Complexity | Handles intricate patterns easily | Limited to simple 2D cuts | Can cut 3D contours, slower for fine details | Handles complex shapes but risky with foam |

| Material Waste | Minimal due to nesting software | More waste due to wire kerf | Moderate waste from tool paths | Some waste from vaporized material |

| Surface Finish | Clean, natural surface | Glossy, melted surface | Rough, requires finishing | Burned or charred finish |

| Heat Damage | None (cold cutting process) | High, material melts | Low, mainly mechanical stress | High, burns foam and releases fumes |

| Tool Wear | Low, blades are durable and replaceable | Low (wire replacement needed) | High (bits wear quickly on foam) | None (but optics require cleaning) |

| Noise Level | Low, quiet operation | Low noise | High noise from spindle | Low noise |

| Dust & Debris | Minimal, clean cutting | Little debris, some fumes | High dust, requires extraction | Hazardous fumes and smoke |

| Energy Consumption | Moderate, efficient operation | Low power requirements | High due to spindles | High due to laser power |

| Maintenance | Simple, low maintenance | Easy, occasional wire replacement | Frequent bit changes, lubrication | Requires optics alignment, ventilation |

| Best Use Cases | Versatile: packaging, furniture, automotive, insulation | Simple packaging blocks, insulation sheets | Structural foam parts, prototypes | Thin-sheet cutting, engraving, not ideal for foam |

Why Choose Us

Industrial-Grade Precision and Stability

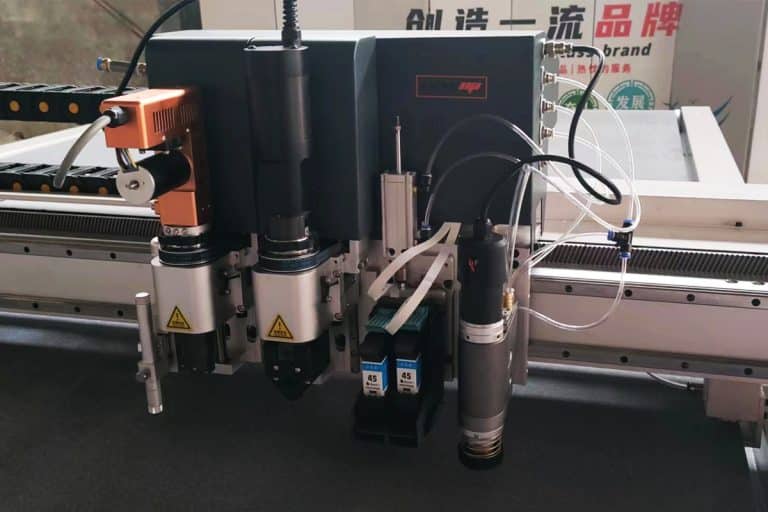

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

Customizable Configurations for Any Industry

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Foam Oscillating Knife Cutting Machines Cost?

- Entry-Level Models ($8,000–$10,000): These machines are compact and ideal for small workshops or light industrial use. They handle common foam types such as EVA, EPE, polyethylene, sponge, and acoustic foam. While affordable, they may have limitations in cutting thickness, speed, or advanced automation.

- Mid-Range Models ($10,000–$14,000): This category offers machines with larger cutting beds, stronger oscillating blades, and faster processing speeds. Many include user-friendly software, digital controls, and the ability to handle both straight and complex contour cuts. They are well-suited for medium-sized production facilities.

- High-End Models ($14,000–$18,000): Top-tier oscillating knife cutting machines are designed for heavy-duty industrial applications. They often include conveyor systems, multi-tool heads (oscillating knives, rotary blades, creasing wheels), and automated material feeding. These machines excel at high-volume production, intricate patterns, and consistent precision across thick or dense foams.

What Is The Edge Quality Of Foam Cut By An Oscillating Knife?

- Soft Foams (EVA, EPE, Sponge, Acoustic Foam): These materials cut very cleanly, with smooth edges and no melting or burn marks. Because the blade physically slices rather than burns, the foam retains its structure and flexibility. This makes oscillating knife cutting especially suitable for packaging inserts, protective padding, and custom cases.

- Medium-Density Foams (Polyethylene, PU Foam, Upholstery Foam): Edges remain sharp and well-defined, even on thicker sections. With proper oscillation speed and blade settings, the cuts are uniform and free of tearing. The precision helps maintain dimensional accuracy for applications in furniture, bedding, and automotive interiors.

- High-Density and Rigid Foams (XPS, Insulation Foam, Structural Foam): Edges are generally smooth but may show slight tool marks if the foam is extremely dense or abrasive. Adjusting cutting parameters, such as oscillation frequency and feed rate, reduces surface imperfections. These foams are often used in construction, aerospace, and prototyping.

- Thin and Flexible Foams (Foam Sheets, Gaskets, Laminated Foams): Oscillating knife excels at these, leaving crisp, fray-free edges even on delicate or layered materials. The absence of heat ensures adhesives and laminations aren’t compromised during cutting.

How Can I Purchase Foam Oscillating Knife Cutting Machines?

- Direct from Manufacturers: Many machine builders sell directly to customers through their own sales teams or official websites. Buying direct often gives you access to the latest models, customization options, and factory-level technical support. However, lead times may be longer, especially if the machine is built to order.

- Authorized Distributors and Dealers: Distributors typically carry multiple brands and can recommend machines that match your production requirements and budget. They also provide demonstrations, installation services, and training. Buying from a dealer often ensures faster delivery and more localized customer support.

- Online Marketplaces and Industrial Platforms: Websites like Alibaba, Made-in-China, and ThomasNet list a wide range of oscillating knife cutting machines at different price points. While this offers convenience and competitive pricing, buyers must carefully vet suppliers, check certifications, and confirm after-sales service availability before purchasing.

- Trade Shows and Industry Exhibitions: Events such as packaging, manufacturing, or textile expos often showcase oscillating knife cutting technology. Attending allows you to see machines in action, compare models side by side, and negotiate directly with manufacturers or distributors.

- Secondhand Equipment Dealers: For smaller budgets, refurbished or pre-owned machines can be purchased through equipment resellers. While cost savings can be significant, buyers should verify the machine’s condition, remaining lifespan, and whether spare parts and service support are still available.

How Accurate Are Foam Oscillating Knife Cutting Machines?

- Thin and Flexible Foams (Sheets, Gaskets, Laminated Foams): Oscillating knife cutting machines deliver extremely high accuracy when processing thin or layered foams. The cuts are crisp and consistent, with tolerances typically within fractions of a millimeter. This makes them suitable for producing gaskets, seals, or laminated foam products where edge precision is critical.

- Medium-Density Foams (Polyurethane, Upholstery Foam, Packaging Inserts): Accuracy remains strong, with consistent edge quality across varying thicknesses. The machines can follow complex contours, logos, or patterns with minimal deviation. Software-driven nesting also helps ensure precise material utilization and uniform part shapes.

- High-Density and Structural Foams (XPS, Insulation, Rigid Polyethylene): These foams can be more challenging due to their stiffness, but oscillating knife systems maintain reliable accuracy when properly configured. Slower feed rates and optimized oscillation settings prevent edge drag or tool deflection, allowing for tight tolerances even in thicker materials.

- Complex Geometries and Intricate Patterns: One of the strengths of oscillating knife cutting is its ability to reproduce fine details. CAD/CAM integration ensures that digital designs are cut with near-exact replication, making these machines a strong choice for prototyping, custom inserts, or branding elements.

- Large-Format Cutting: For oversized foam sheets or bulk cutting, accuracy is maintained across the entire bed size. High-end machines with conveyor systems and servo-driven positioning can hold tolerances over long runs, ensuring consistent results even at scale.

What Are The Disadvantages Of Using An Oscillating Knife To Cut Foam?

- Blade Wear and Replacement: Because oscillating knives rely on physical contact, the blades dull over time, especially when cutting dense or abrasive foams. Frequent blade replacement is necessary to maintain clean edges, which adds to operating costs and downtime.

- Cutting Speed on Dense or Thick Foams: While oscillating knives handle soft and medium-density foams well, very thick or rigid foams require slower cutting speeds. Pushing the machine too fast may cause tool deflection, rough edges, or uneven cuts. This makes them less efficient than waterjet systems for extremely dense materials.

- Limited Suitability for Certain Materials: Oscillating knives are optimized for foams, fabrics, and other soft materials. They are not designed for metals, glass, or very hard composites. Companies that work with mixed materials may need additional cutting systems to cover all their needs.

- Noise and Vibration: The rapid oscillation of the blade generates noticeable vibration and noise during operation. While not hazardous with proper machine housing and safety measures, it can contribute to operator fatigue in long production runs.

- Maintenance Requirements: Regular blade changes, lubrication, and machine calibration are necessary to maintain precision. Unlike non-contact cutting methods (like lasers), the mechanical nature of oscillating knives means wear-and-tear is inevitable.

- Initial Investment Cost: High-quality oscillating knife cutting machines are more expensive than manual cutting tools and entry-level alternatives. Businesses must weigh the purchase price against production volume and long-term efficiency gains.

Is It Safe To Cut Foam With An Oscillating Knife?

- Soft and Flexible Foams (EVA, EPE, Sponge, Acoustic Foam): Safe to cut with no risk of melting or combustion. The blade slices cleanly, and because no heat is generated, workers are not exposed to smoke or harmful emissions.

- Medium-Density Foams (Polyurethane, Upholstery Foam, Packaging Foams): Safe when standard operating practices are followed. Blades remain cool during cutting, preventing off-gassing or surface burns. Proper guarding should still be in place to protect operators from contact with the oscillating blade.

- High-Density and Rigid Foams (XPS, Insulation Boards, Structural Foams): Also safe, though cutting speed should be controlled to maintain accuracy and prevent excessive vibration. Dust particles may be generated, so localized extraction or protective masks are recommended during extended production runs.

- Foams with Laminates or Adhesives: Generally safe, but adhesives or films may produce light debris or dust. Unlike lasers, oscillating knives won’t vaporize adhesives, so operators avoid toxic fumes. Routine blade inspection is advised since laminated foams can dull blades more quickly.

What Training Is Required To Operate Foam Oscillating Knife Cutting Machines?

- Basic Machine Operation: Operators are trained to start, stop, and calibrate the machine. This includes loading foam sheets or rolls, securing materials on the cutting bed, and adjusting cutting parameters such as oscillation frequency, cutting depth, and feed rate.

- Software and Digital File Preparation: Most machines integrate with CAD/CAM systems. Training covers how to import digital design files, set up cutting paths, apply nesting functions to optimize material usage, and troubleshoot software-related errors. Proper file preparation ensures accuracy and reduces material waste.

- Blade Handling and Maintenance: Since oscillating knives rely on sharp blades for clean cuts, operators learn how to safely replace, align, and maintain cutting tools. Training also covers routine inspections to identify blade wear, prevent tool breakage, and maintain consistent edge quality.

- Material Knowledge: Different foams require different cutting settings. Training helps operators recognize how to adjust parameters for soft, medium, and high-density foams, as well as laminated or adhesive-backed materials. This ensures both safety and cut quality across various applications.

- Safety Protocols: Operators must be trained on safety guards, emergency stop functions, and personal protective equipment (PPE). While oscillating knives are safer than heat-based cutters, training emphasizes how to avoid accidental contact with moving blades and manage foam dust during extended production runs.

- Troubleshooting and Quality Control: Training includes diagnosing common problems such as frayed edges, incomplete cuts, or misalignment. Operators learn to fine-tune settings, recalibrate cutting heads, and check for software-to-hardware synchronization issues.

- Ongoing Learning and Manufacturer Support: Many suppliers provide on-site or virtual training sessions during installation. Operators may also receive refresher courses or advanced training as new software updates, automation features, or machine upgrades are introduced.

How Should I Maintain Foam Oscillating Knife Cutting Machines?

- Blade Care and Replacement: Blades are the most critical consumables. They dull with use, especially when cutting dense or laminated foams. Operators should routinely inspect blade edges, replace worn blades promptly, and ensure proper alignment. A sharp, correctly seated blade prevents frayed edges and improves accuracy.

- Cleaning the Cutting Bed: Foam dust and debris can build up on the cutting surface. Regular cleaning keeps the bed flat and prevents material slippage. For conveyor-based systems, periodic inspection of belts and rollers ensures smooth feeding and reduces wear.

- Lubrication of Moving Parts: Oscillating knives rely on fast-moving mechanical components. Proper lubrication of bearings, guide rails, and oscillation mechanisms reduces friction, prevents overheating, and minimizes long-term wear. Always use manufacturer-recommended lubricants.

- Software and Calibration Checks: Maintaining cutting accuracy requires regular calibration of the machine’s axes and cutting depth. Operators should also keep software updated to access the latest features, improve nesting efficiency, and ensure compatibility with CAD/CAM files.

- Dust and Particle Management: While oscillating knives don’t generate fumes like lasers, cutting certain rigid foams can produce dust particles. Machines should be kept clean with vacuum extraction systems or scheduled wipe-downs to prevent buildup inside mechanical housings.

- Electrical and Safety Systems: Routine inspection of wiring, sensors, and emergency stop switches ensures the machine operates safely. Faulty connections or worn cables should be addressed immediately to prevent operational hazards.

- Periodic Professional Servicing: Manufacturers or certified technicians often recommend scheduled servicing at set intervals. These inspections catch early signs of wear in motors, oscillation drives, and electronic controls that operators might miss during daily maintenance.