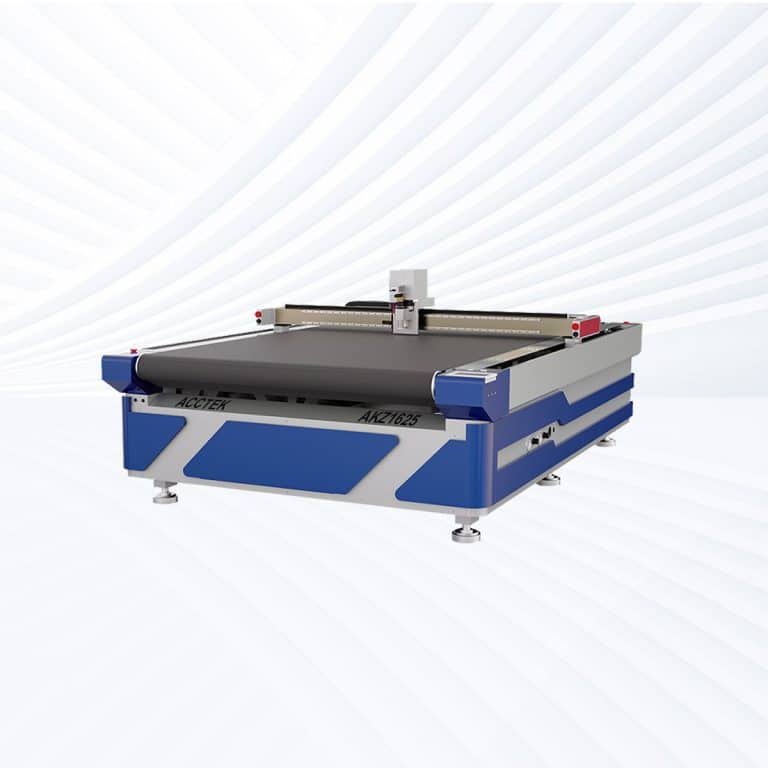

Product Introduction

Types of Film Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Film

Clean and Accurate Cuts

Oscillating knife cutting machines deliver sharp, smooth edges without fraying or distortion. Unlike thermal cutting, they avoid melting and burning, ensuring film products maintain their clarity, finish, and exact dimensions for professional, high-quality results across different applications.

Cold-Cutting Technology

The high-frequency blade cuts without generating heat, eliminating risks of shrinkage, warping, or surface damage. This makes the process safe for delicate and sensitive films, preserving material integrity and ensuring components meet performance requirements in demanding industries.

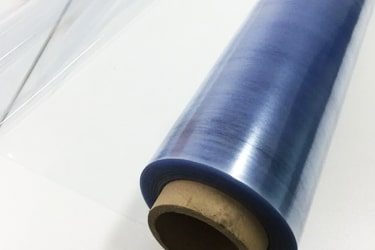

Compatibility with Diverse Films

From PET, PVC, and PP films to laminated and composite films, oscillating knife cutting machines handle a wide variety of materials. This versatility allows manufacturers to use one system for multiple product types, reducing equipment needs and costs.

High Production Efficiency

Equipped with CNC control and intelligent nesting software, these machines optimize layouts and minimize waste. Fast setup and automated cutting allow both small-batch prototypes and large-scale film production runs to be completed with high efficiency and consistent accuracy.

Reduced Material Waste

By delivering highly accurate cuts and optimizing film sheet usage, oscillating knife cutting minimizes offcuts and scrap. Manufacturers benefit from lower production costs and more sustainable operations, making the process environmentally friendly as well as economically efficient.

Consistency and Repeatability

Every cut is uniform and reliable, even in large production runs. This repeatable accuracy eliminates variations, reduces rework, and ensures film components meet strict quality standards—vital for industries like packaging, electronics, and automotive that require flawless performance.

Compatible Film Materials

- Polyethylene Film

- High-Density Polyethylene Film

- Low-Density Polyethylene Film

- Linear Low-Density Polyethylene Film

- Polypropylene Film

- Biaxially Oriented Polypropylene Film

- Cast Polypropylene Film

- Polyvinyl Chloride Film

- Rigid PVC Film

- Flexible PVC Film

- Polyethylene Terephthalate Film

- Biaxially Oriented PET Film

- PETG Film

- Polycarbonate Film

- Acrylic Film

- Nylon Film

- Oriented Polyamide Film

- Ethylene-Vinyl Acetate Film

- Polyvinylidene Chloride Film

- Polyvinylidene Fluoride Film

- Polystyrene Film

- High Impact Polystyrene Film

- Cellophane Film

- Polylactic Acid Film

- Biodegradable Films

- Compostable Films

- Polyimide Film

- Fluoropolymer Films

- Metallized PET Film

- Metallized BOPP Film

- Transparent Barrier Films

- Multi-Layer Co-Extruded Films

- Shrink Films

- Stretch Films

- Laminated Films

- Protective Films

- Anti-Static Films

- Conductive Films

- Optical Films

- Specialty Coated Films

Application of Film Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Waterjet Cutting | Hot Knife Cutting | Laser Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | High-pressure water jet (with/without abrasive) | Electrically heated blade melts through film | High-powered laser beam burns through film |

| Cut Edge Quality | Clean, smooth, no melting | Clean, but may cause swelling/warping | Melted edges, sealed but uneven | Burnt, hardened, or discolored edges |

| Material Compatibility | Wide range of films (plastic, laminates, composites) | Works on films but risk of distortion | Limited to thermoplastic films | Limited—films often melt, shrink, or emit fumes |

| Accuracy | High precision, ±0.1 mm | Very high, but overkill for thin films | Moderate, edges may warp | High, but heat can distort thin films |

| Cutting Speed | Fast, ideal for thin sheets | Slow to moderate | Fast for simple cuts | Fast, but risky for delicate films |

| Design Complexity | Handles intricate shapes easily | Excellent for 2D profiles | Simple straight cuts | Handles complex shapes but may burn detail |

| Material Waste | Minimal due to nesting optimization | Minimal | Some waste from melted edges | Some waste from vaporization |

| Surface Finish | Smooth, natural finish | Clean but may need drying | Glossy but uneven melt lines | Burnt or charred edges |

| Heat Damage | None (cold cutting) | None | High, edges melt and deform | High, risk of melting or shrinking |

| Tool Wear | Low, blades easily replaced | Nozzle maintenance required | Moderate, heating element degrades | None, but optics need cleaning |

| Noise Level | Low noise | High noise from pumps | Low noise | Low noise |

| Dust & Debris | Minimal | Water slurry, disposal required | Minimal but melted residue | Hazardous smoke and fumes |

| Energy Consumption | Moderate, efficient | Very high | Moderate | High |

| Maintenance | Simple, low-maintenance | Complex, pump/nozzle care | Regular heating element replacement | Optics cleaning, ventilation system |

| Best Use Cases | Packaging films, laminates, specialty composites | Metals, thick composites, rigid plastics | Simple thermoplastic film sealing/cutting | Engraving thin plastics, not ideal for films |

Why Choose Us

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

Customizable Configurations for Any Industry

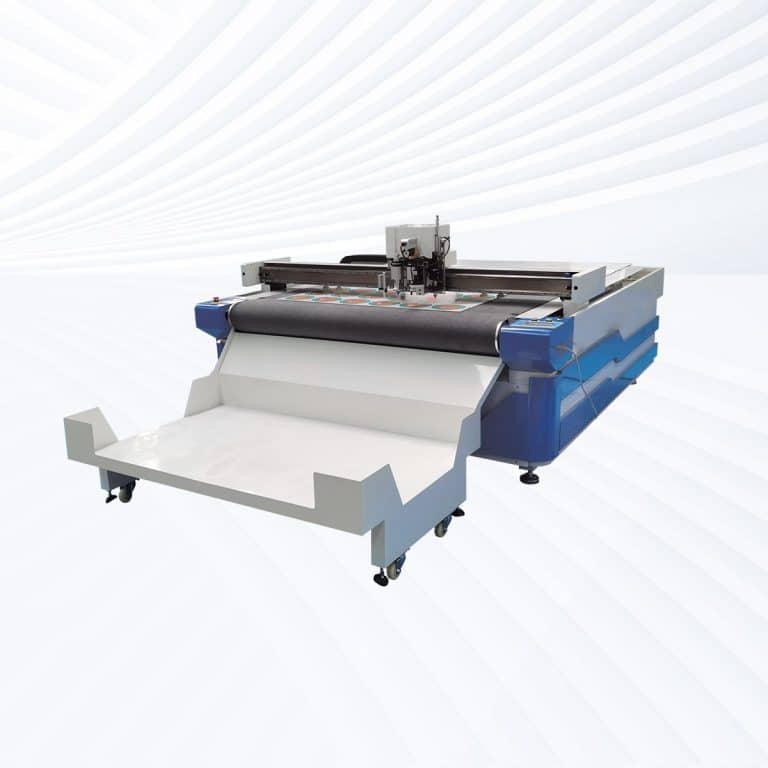

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

Does Oscillating Knife Cutting Cause Material Deformation

This article explores the potential for material deformation during oscillating knife cutting, examining factors such as cutting parameters, material properties, and industry-specific applications.

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

Frequently Asked Questions

How Much Do Film Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000–$10,000): Compact systems with smaller cutting beds, suited for light-duty applications and workshops handling limited volumes of thin films. These machines cut efficiently but may lack advanced automation, making them better for prototyping or small production runs.

- Mid-Range Machines ($10,000–$14,000): These machines balance versatility and performance. With larger cutting areas, stronger oscillation mechanisms, and more advanced software, they handle a wider range of films, including laminated packaging materials and technical protective films. They often include CAD/CAM integration and nesting functions for better material utilization.

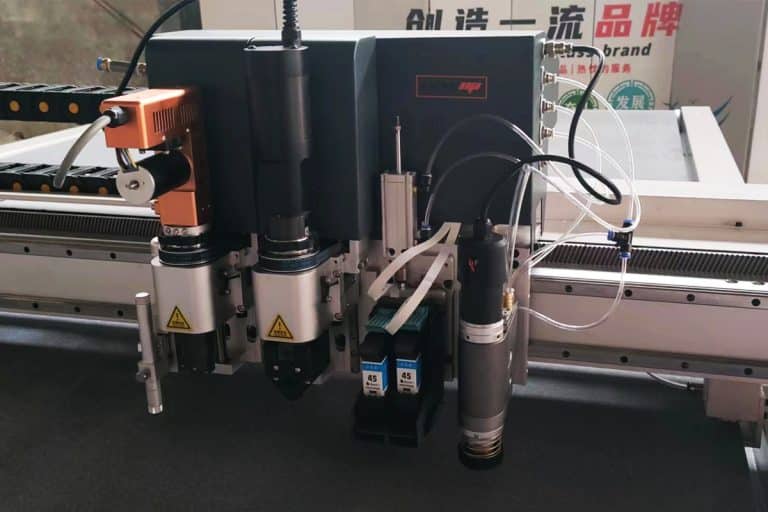

- High-End Machines ($14,000–$18,000): Industrial-grade models designed for high-volume cutting of films in packaging, printing, and electronics. They typically feature conveyor systems, automated feeding, multi-tool heads (oscillating knives, rotary blades, creasing wheels), and precision control systems. These machines excel at continuous production runs and complex pattern cutting.

How Fast Can An Oscillating Knife Cut Film?

- Thin Plastic Films (Polypropylene, Polyethylene, PET): Oscillating knives cut these very quickly, often at speeds of 1,000 to 1,500 mm/s (39–59 in/s). Since the material offers little resistance, operators can maximize throughput while maintaining smooth, accurate edges.

- Laminated Films (Packaging Films, Multi-Layer Sheets): Cutting speeds are slightly slower, usually around 800 to 1,200 mm/s (31–47 in/s). Multiple layers add resistance, and the adhesive layers in laminates may dull blades faster, requiring slightly slower feed rates to preserve cut quality.

- Technical and Specialty Films (Protective Films, Electronics Films, Optical Films): Speeds generally range between 600 and 1,000 mm/s (24–39 in/s). These films often require higher precision and cleaner edges, so cutting is performed at slightly reduced speeds to prevent material shifting or tearing.

- Very Thin or Delicate Films: For ultra-thin films, operators may slow the machine to 500–800 mm/s (20–31 in/s) to prevent wrinkling, misalignment, or static cling issues during cutting.

What Is The Edge Quality Of The Film Cut By The Oscillating Knife?

- Thin Plastic Films (Polypropylene, Polyethylene, PET): Edges are clean, sharp, and free of fraying. Since no heat is involved, there is no shrinkage, curling, or distortion of the thin sheet. This makes oscillating knives ideal for cutting flexible packaging and protective films.

- Laminated Films (Packaging Laminates, Multi-Layer Sheets): Edges remain neat and accurate, though adhesives in multi-layer films may leave minimal residue on blades over time. Regular blade cleaning ensures consistently smooth cuts without edge drag or tearing.

- Technical Films (Optical Films, Electronics Films, Protective Layers): High edge quality with tight tolerances. The absence of melting ensures that films with sensitive coatings or embedded layers remain intact and functional after cutting. Fine details and intricate patterns are well preserved.

- Specialty and Ultra-Thin Films: Even delicate films cut cleanly, though at slower speeds to prevent wrinkling or static-related issues. Edges are crisp, with no burn marks or polished heat edges. Static control systems may be required for ultra-thin materials to maintain edge consistency.

What Are The Disadvantages Of Using Film Oscillating Knife Cutting Machines?

- Blade Wear and Frequent Replacement: Cutting films, especially laminated or adhesive-backed types, dull blades quickly. Adhesive residues can also stick to the blade, requiring frequent cleaning or replacement to maintain smooth edges and accuracy.

- Material Handling Challenges: Thin films can wrinkle, shift, or stick due to static electricity, which affects cut precision. Without proper hold-down systems such as vacuum beds or anti-static devices, films may move during cutting, leading to inconsistent results.

- Limited Suitability for Ultra-Thick or Rigid Materials: Oscillating knives are optimized for thin and flexible materials. They are not designed for thick or rigid plastic sheets, meaning companies working with both films and heavier plastics may need additional cutting systems.

- Speed Limitations on Delicate Films: While oscillating knives can cut films at high speeds, very thin or delicate materials often require slower cutting to prevent tearing or misalignment. This can reduce throughput in high-volume production.

- Noise and Vibration: The rapid oscillation of the knife generates mechanical vibration and noise. While less disruptive than some heavy industrial machines, operators in continuous-use environments may require hearing protection.

- Maintenance Requirements: Regular cleaning, lubrication, and calibration are necessary to keep the machine in top condition. Neglecting maintenance increases blade wear and reduces precision, especially when cutting laminated films with adhesives.

- Initial Investment Cost: Although less expensive than high-power laser systems, film oscillating knife cutting machines still require a significant investment—typically $8,000 to $18,000—which may be high for small-scale users compared to manual cutting solutions.

What Problems Can Be Encountered When Using Film Oscillating Knife Cutting Machines?

- Material Shifting and Wrinkling: Films are lightweight and can move on the cutting bed during operation. Without proper hold-down methods such as vacuum suction or static-control devices, materials may wrinkle or slip, leading to uneven edges and misaligned cuts.

- Static Electricity Issues: Thin plastic films, particularly PET and polypropylene, generate static charges during cutting. This can cause sheets to cling together, misfeed, or attract dust, compromising cut quality and machine cleanliness. Anti-static devices or grounding systems are often required.

- Blade Wear and Adhesive Buildup: Laminated and adhesive-backed films quickly dull blades and leave sticky residues. This reduces edge quality and may cause tearing unless blades are cleaned and replaced frequently.

- Edge Fraying or Tearing: Very thin or delicate films can tear if cutting speeds are too high or blades are not sharp enough. Proper speed control, blade selection, and consistent maintenance are necessary to avoid damaged edges.

- Accuracy Loss in Multi-Layer Films: Cutting multi-layer or reinforced films can stress the blade, leading to slight deviations in cut paths. Without regular calibration, precision may be reduced in detailed or intricate designs.

- Dust or Particle Accumulation: While films don’t produce fumes, laminated and coated types may shed fine particles. If not cleaned regularly, this buildup can interfere with machine movement and reduce cutting accuracy.

- Noise and Vibration: High-frequency blade oscillation creates vibration and noise, especially in continuous production. Without sound management or operator hearing protection, this may lead to fatigue over time.

- Software and Nesting Inefficiencies: For industries like packaging or printing, where material efficiency is critical, improper nesting setup or file preparation can result in wasted film and reduced productivity.

How Should Film Oscillating Knife Cutting Machines Be Maintained?

- Blade Care and Replacement: Films, especially laminates and adhesive-backed sheets, cause rapid blade wear and residue buildup. Operators should inspect blades frequently, clean adhesive buildup with safe solvents, and replace dull blades promptly. Sharp, properly aligned blades prevent edge tearing and ensure smooth cuts.

- Cleaning the Cutting Bed and Hold-Down System: Thin films are prone to shifting during cutting. Vacuum beds, clamps, or static-control systems must be kept clean to maintain proper hold-down. Regular cleaning of the bed prevents slippage, wrinkles, or misalignment during high-speed cutting.

- Lubrication of Moving Components: Like all oscillating knife cutting machines, bearings, guide rails, and oscillation drives require periodic lubrication. Using manufacturer-approved lubricants prevents overheating, reduces friction, and extends the lifespan of mechanical parts.

- Calibration and Software Updates: Accurate film cutting requires regular calibration of blade depth, alignment, and machine axes. Software updates should also be applied to improve nesting, anti-static control features, and cutting path efficiency, reducing material waste.

- Dust, Static, and Particle Management: While films don’t produce fumes, laminated or coated varieties may shed fine particles. Regular cleaning prevents buildup inside housings and motors. Static-control devices should be maintained to reduce film clinging and improve accuracy.

- Inspection of Electrical and Safety Systems: Emergency stops, blade guards, and sensors should be tested regularly. Wiring and connectors must be inspected for wear or damage to prevent interruptions in high-volume cutting environments.

- Professional Servicing: Scheduled servicing by manufacturer-trained technicians is recommended, particularly for industrial-grade systems. Professionals can identify wear in oscillation drives, check motor alignment, and replace worn conveyor components before breakdowns occur.

What Is The Lifespan Of Film Oscillating Knife Cutting Machines?

- Average Machine Lifespan: With proper care, film oscillating knife cutting machines typically last 8 to 12 years in standard production environments. In lighter-use facilities, they may exceed this range, while in heavy-duty, continuous-use operations, service life may be closer to 7–9 years without major refurbishments.

- Blade Lifespan vs. Machine Lifespan: Blades are consumables and wear out far more quickly than the machine itself. Thin films are generally easy on blades, but laminated, adhesive-backed, or multi-layer films accelerate wear. Blade service life ranges from several days to several weeks, depending on material type, cutting speed, and maintenance routines.

- Impact of Film Type on Longevity:

- Thin, single-layer films (PE, PP, PET): Minimal stress on blades and mechanical systems, extending machine life.

- Laminated and adhesive-backed films: Increase blade wear and may leave residues on cutting tools, requiring more frequent maintenance.

- Specialty or coated films: May generate fine dust or static buildup, putting additional strain on cleaning and static-control systems.

- Maintenance Influence: Routine maintenance is the single most important factor in extending service life. Regular blade replacement, cleaning of adhesive buildup, lubrication of moving parts, and calibration of the cutting head significantly reduce wear on motors and oscillation systems. Neglecting these steps can shorten lifespan by several years.

- Component Lifespan Breakdown:

- Oscillating motors and drives: Typically last 8–10 years with proper lubrication and balanced workloads.

- Electronics and software controls: Remain reliable for 8–12 years, though software updates may be needed.

- Cutting beds and vacuum hold-down systems: May require replacement or refurbishment every 3–5 years in high-volume use.

- Manufacturer Support and Upgradability: Machines backed by reputable manufacturers often last longer due to available spare parts, software updates, and upgrade options. Some high-end machines can be retrofitted with advanced heads, conveyor systems, or updated software, extending their functional lifespan.

What Training Is Required To Operate Film Oscillating Knife Cutting Machines?

- Basic Machine Operation: Operators must be trained to power up, calibrate, and safely operate the machine. This includes loading and securing thin films, setting the cutting depth, and adjusting oscillation frequency. Training also covers the use of vacuum beds, clamps, or anti-static systems that prevent films from shifting during cutting.

- Software and Digital File Preparation: Like other oscillating knife cutting systems, film cutters rely heavily on CAD/CAM software. Training includes importing digital files, generating cut paths, and using nesting strategies to minimize waste. Operators also learn how to scale and align graphics for applications like packaging, signage, or electronic films.

- Blade Selection, Handling, and Maintenance: Different films—such as polypropylene, PET, laminates, or coated optical films—require specific blade types. Training emphasizes safe blade changes, proper alignment, and monitoring blade wear to maintain smooth, accurate edges. Cleaning procedures are also important for removing adhesive buildup from laminated films.

- Material Knowledge: Films can be highly variable in thickness, rigidity, and static charge. Training ensures operators know how to adjust feed rates, oscillation speed, and hold-down methods to prevent wrinkling, misalignment, or tearing. Special instruction may also be required for handling anti-static or coated films.

- Safety Protocols: Even though oscillating knives avoid the fumes and fire risks of lasers, operator safety remains critical. Training covers proper use of blade guards, emergency stop systems, and PPE such as safety glasses, dust masks, and hearing protection. Operators are also taught how to avoid direct contact with blades during cutting and replacement.

- Troubleshooting and Quality Control: Operators are trained to identify issues such as incomplete cuts, film wrinkling, static cling, or adhesive buildup on blades. Instruction includes how to correct errors by adjusting speed, pressure, or calibration, as well as how to maintain consistent cut accuracy across long production runs.

- Manufacturer and Ongoing Training: Most suppliers provide initial on-site training when machines are installed. Advanced or refresher courses are often available for features such as conveyor feeding, multi-tool heads, or upgraded CAD/CAM systems.