Product Introduction

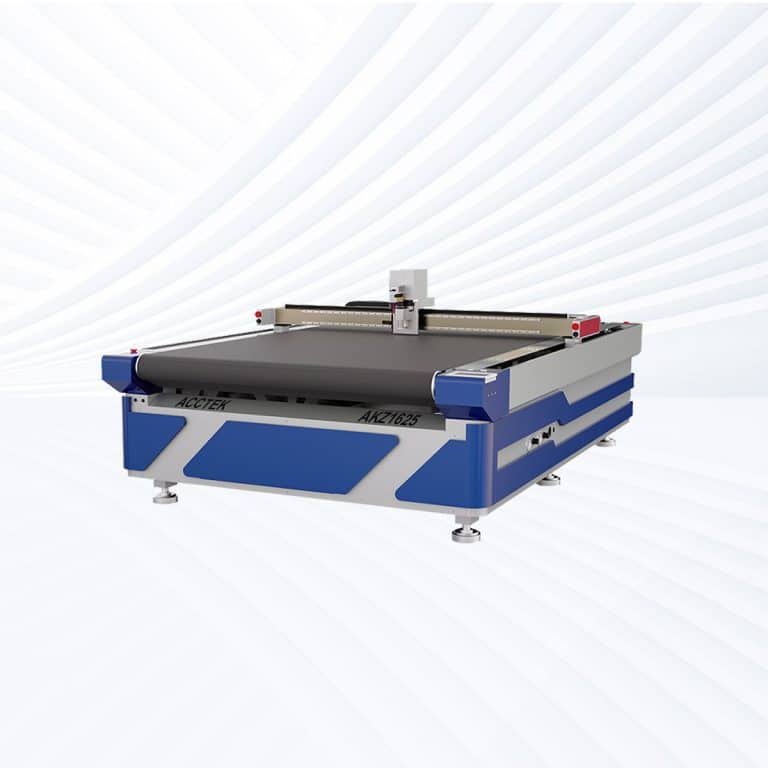

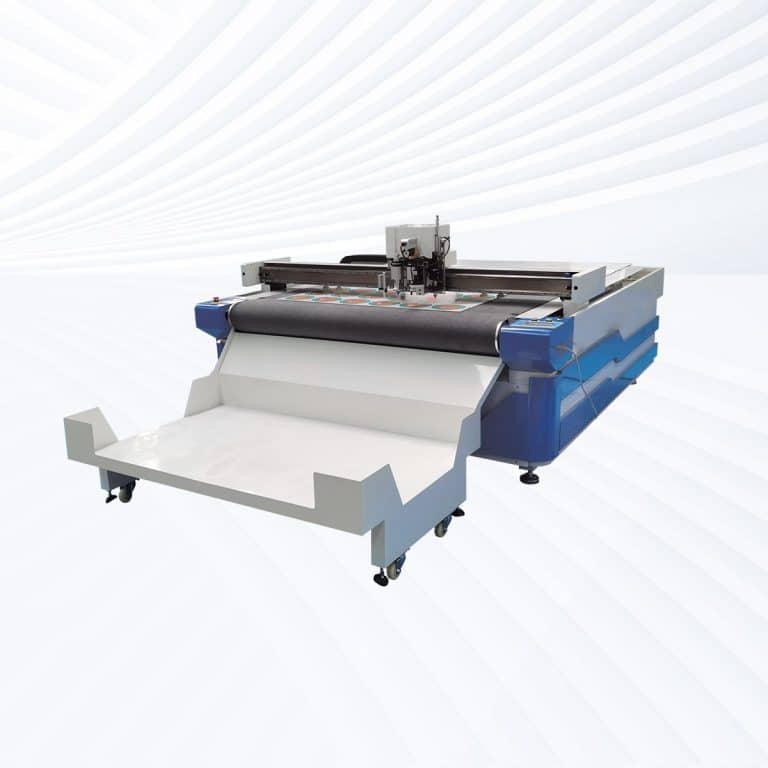

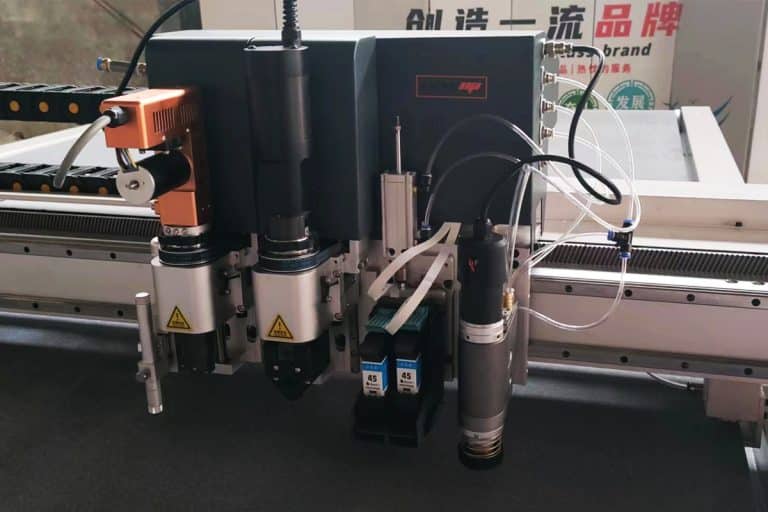

Types of Composite Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Composite

Clean and Accurate Cuts

Oscillating knife cutting machines deliver precise, smooth edges without fraying or delaminating composite layers. This ensures parts maintain structural integrity and exact dimensions, which is critical in industries like aerospace, automotive, and marine, where tolerances are tight.

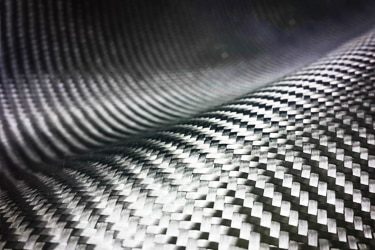

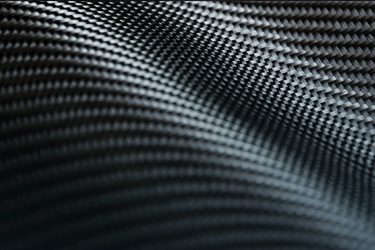

Cold-Cutting Technology

The process generates no heat, eliminating risks of burning, melting, or warping. This preserves the natural strength, texture, and performance of composites such as carbon fiber, fiberglass, and aramid, ensuring high-quality results in demanding applications.

Versatility Across Composite Types

From lightweight laminates to dense multi-layer panels, oscillating knife cutting machines handle diverse composites with ease. This versatility reduces the need for multiple cutting systems, giving manufacturers a flexible, all-in-one solution for varied projects.

High Production Efficiency

Equipped with CNC automation and nesting software, these machines optimize material usage, minimize setup times, and accelerate workflows. They support both small-batch prototyping and large-scale runs, improving productivity while maintaining consistent cutting precision.

Reduced Material Waste

Accurate cutting and intelligent nesting maximize material yield, significantly reducing scrap. For costly composites like carbon fiber, this translates into substantial savings and improved sustainability by minimizing waste in manufacturing processes.

Consistency and Repeatability

Each cut is uniform and reliable, even in high-volume production. This repeatable accuracy ensures composite parts meet strict quality standards, reduces rework, and guarantees dependable results across every batch, strengthening customer confidence in final products.

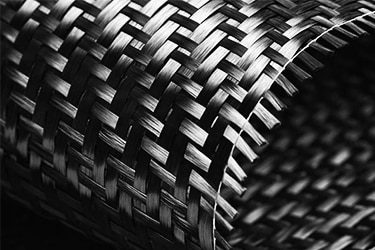

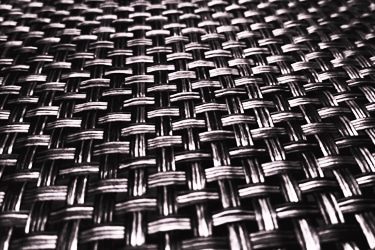

Compatible Composite Materials

- Carbon Fiber Reinforced Polymer

- Fiberglass Reinforced Plastic

- Aramid Fiber Composites

- Basalt Fiber Composites

- Hybrid Carbon/Kevlar Laminates

- Hybrid Carbon/Basalt Laminates

- Glass/Kevlar Hybrid Composites

- Honeycomb Core Panels

- Aluminum Honeycomb Composites

- Thermoplastic Composites

- Thermoset Composites

- Glass Fiber Reinforced Epoxy Laminates

- Carbon Fiber Prepreg Sheets

- Kevlar Prepreg Sheets

- Fiberglass Prepreg Sheets

- G10 Glass Epoxy Laminates

- FR4 Epoxy Glass Laminates

- Sheet Molding Compound

- Bulk Molding Compound

- Phenolic Resin Composites

- Vinyl Ester Composites

- Polyester Resin Composites

- Polyurethane-Based Composites

- Polypropylene-Based Composites

- High-Pressure Laminates

- Compact Laminates

- Architectural Composite Panels

- Marine-Grade Laminates

- Wind Energy Blade Composites

- Phenolic Resin Composites

- Structural Foam Core Composites

- PET Foam Core Composites

- PVC Foam Core Composites

- Balsa Wood Core Composites

- Recycled Fiber Composites

- Natural Fiber Reinforced Composites

- Biocomposites

- Conductive Carbon Composites

- Anti-Static Laminates

- Multi-Layer Technical Textile Composites

Application of Composite Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Wire Cutting | Waterjet Cutting | Die Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | Heated wire melts through material | High-pressure water jet (with/without abrasive) | Mechanical steel dies stamp out shapes |

| Cut Edge Quality | Clean, smooth, no fraying or delamination | Melted edges, risk of distortion | Clean, but edges may absorb moisture | Clean but limited by die sharpness |

| Material Compatibility | Wide range of composites: carbon, fiberglass, aramid, laminates | Limited to foams and soft composites | Works on thick composites, metals, and rigid boards | Works mainly with thin, flat composites |

| Accuracy | High precision, ±0.1 mm | Moderate, depends on wire thickness | Very high precision | Good, but limited by die accuracy |

| Cutting Speed | Fast for sheets and laminates | Slow for thick materials | Moderate; slower on thick laminates | Very fast for mass runs, but long setup |

| Design Complexity | Handles intricate patterns easily | Limited to simple shapes | Excellent for complex 2D shapes | Limited—new dies required for every design |

| Material Waste | Minimal with nesting software | High due to melted material | Minimal | Higher due to die clearances |

| Surface Finish | Natural finish preserved | Melted or hardened edges | Smooth finish but may require drying | Clean but flat edges only |

| Heat Damage | None (cold cutting) | High, melts material | None | None |

| Tool Wear | Low, blades easily replaced | Wires break frequently | Nozzle wear and pump upkeep | High—dies dull quickly |

| Noise Level | Low | Low | High (pump system) | Moderate (stamping noise) |

| Dust & Debris | Minimal | Some melted residue | Water slurry, abrasive disposal | Cardboard/fiber scrap |

| Energy Consumption | Moderate, efficient | Moderate | Very high | Low to moderate |

| Maintenance | Simple, low maintenance | Frequent wire replacement | Complex pump/nozzle care | Frequent die sharpening/replacement |

| Best Use Cases | Aerospace, automotive, marine, sports, construction composites | Foam and low-density composites | Thick, rigid composites, metals | High-volume, repeatable 2D parts |

Why Choose Us

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

Customizable Configurations for Any Industry

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Composite Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000 – $10,000): These models are suitable for small workshops, prototyping, and light production. They can handle basic composite sheets, textiles, or thin laminates, but may struggle with very thick or highly reinforced composite stacks. They typically feature smaller cutting beds and limited automation.

- Mid-Range Machines ($10,000 – $14,000): Mid-tier oscillating knife cutting machines are equipped for small-to-medium batch production. They offer stronger motors, more stable gantries, and higher cutting speeds. This price range often includes automatic tool-change systems, better dust extraction, and more advanced software integration for CAD/CAM.

- High-End Machines ($14,000 – $18,000): At the top of the range are industrial-grade composite oscillating knife cutting machines designed for aerospace, automotive, marine, and advanced manufacturing. These systems deliver high precision, consistent cutting across multiple layers, and often integrate conveyor systems for continuous feed. They also provide enhanced vibration control, dust management, and blade cooling features essential for composites.

What Is The Edge Quality Of Composites Cut With An Oscillating Knife?

- Fiberglass-Reinforced Plastics (FRP): Oscillating knives can cut fiberglass cleanly, producing relatively smooth edges with minimal fraying when the correct blade type and cutting pressure are applied. However, very thick laminates may show slight edge roughness, requiring secondary trimming or sanding.

- Carbon Fiber Composites: Carbon fiber sheets and prepregs cut with oscillating knives typically maintain high dimensional accuracy. Edges are generally clean, but some fiber pull-out or slight fuzzing can occur, particularly on thicker materials or multilayer stacks. Using sharp blades and optimized cutting speeds reduces this issue.

- Kevlar and Aramid Composites: These materials are notoriously difficult to cut because of their high toughness and fiber resilience. Oscillating knives often leave slightly fuzzy edges or frayed fibers if not managed correctly. Specialized blades and slower cutting speeds improve edge consistency, but finishing may still be required in high-precision applications.

- Hybrid Laminates (e.g., Carbon-Kevlar): Hybrid composites combine the challenges of both materials, which can lead to uneven edge quality. Oscillating knives can achieve serviceable results, but depending on thickness, edges may show alternating clean and frayed zones corresponding to different fiber types.

- Thermoplastic Composites: Oscillating knives handle thermoplastic composites better than thermosets, as these materials tend to cut with cleaner, more uniform edges. The finish is generally smooth, with less fiber breakout.

What Are The Disadvantages Of Using An Oscillating Knife To Cut Composite?

- Blade Wear and Maintenance: Composite materials, especially carbon fiber and fiberglass, are highly abrasive. They cause rapid blade dulling, which leads to increased tool replacement costs and frequent downtime for blade changes. Dull blades also reduce edge quality, leaving more fraying or uneven finishes.

- Fraying and Fiber Pull-Out: Aramid fibers, such as Kevlar, are particularly resistant to clean cutting and often result in frayed or fuzzy edges. Even with sharp blades, oscillating knives can struggle to maintain smooth edges in woven or hybrid laminates, requiring secondary finishing.

- Thickness Limitations: Oscillating knives perform best on thin to medium-thickness composite sheets. Very thick laminates or stacked composite layers may not cut cleanly, and attempts to do so can strain the machine or leave uneven edges.

- Slower Cutting Speeds: Compared to processes such as waterjet cutting or CNC milling, oscillating knives generally cut composites more slowly, particularly when higher accuracy is required. Cutting at high speeds can increase edge defects and reduce dimensional accuracy.

- Dust and Debris Generation: Unlike laser cutting, which vaporizes material, oscillating knives mechanically cut through composites, generating significant dust and fiber debris. Carbon and fiberglass dust can be hazardous if inhaled, so proper extraction systems and operator PPE are essential.

- Limited Capability with Complex Geometries: Oscillating knives are excellent for 2D profiles but may be less effective when cutting highly intricate, detailed, or multilayered shapes. For very fine features, edge quality may degrade, or the material may tear during cutting.

- Operator Skill Requirements: Achieving consistent results requires proper selection of blade type, oscillation frequency, and cutting speed. Inadequate setup can result in poor edge quality, excessive blade wear, or even material damage.

How To Buy Composite Oscillating Knife Cutting Machines?

- Assess Cutting Needs: Begin by defining the type and thickness of composite materials you plan to cut. Oscillating knives excel at thin to medium sheets, prepregs, and flexible laminates. If you need to process very thick or highly rigid composites, consider whether supplementary cutting methods like waterjet or CNC milling may also be required.

- Evaluate Machine Specifications: Look for models with high cutting accuracy, adjustable oscillation frequencies, and compatible blade systems for handling abrasive fibers. Features such as automatic tool changing, vacuum hold-down tables, and CNC integration can greatly improve efficiency in production environments.

- Blade Options and Wear Management: Since composites cause rapid blade wear, choose a system that supports a wide range of replaceable blade types, including carbide-reinforced options. Machines with quick-change blade systems minimize downtime during maintenance.

- Dust Control and Extraction: Cutting composites generates hazardous dust and fiber debris, particularly from carbon and fiberglass. Prioritize machines that include or support advanced dust collection and filtration systems to protect both operators and the equipment.

- Software and Automation: Ensure the machine integrates with CAD/CAM software for precise part nesting and optimization of material usage. Automated features such as camera-based registration, barcode scanning, and workflow tracking can be highly valuable in composite-heavy industries like aerospace, automotive, and sporting goods.

- Supplier Selection: Purchase only from trusted manufacturers or distributors with proven expertise in composite cutting. Evaluate their track record, customer support availability, and ability to provide spare parts and consumables. Since composites are demanding, reliable technical service is essential to minimize downtime.

- Budget and ROI Considerations: Composite oscillating knife cutting machines typically cost $8,000 to $18,000, depending on cutting area, automation features, and material handling capabilities. When comparing options, consider not only the upfront cost but also ongoing expenses such as blades, filters, and service contracts.

What Problems Can Be Encountered When Cutting Composite With An Oscillating Knife?

- Blade Wear and Breakage: Composites are extremely abrasive, especially carbon and glass fibers. Oscillating knife blades can dull very quickly, leading to frequent replacements and increased operating costs. In severe cases, blades may chip or break under stress.

- Fraying and Fiber Pull-Out: When cutting woven composites or laminates, fibers can fray or pull out along the cut edge. This not only compromises the precision and aesthetic of the cut but may also weaken the integrity of the material.

- Heat and Delamination Risks: Although oscillating knives produce far less heat than laser or rotary tools, excessive friction or improper cutting parameters can still cause localized heating. This may soften resin systems, cause delamination between layers, or distort the cut edge.

- Dust and Particle Generation: Cutting composites produces fine, hazardous dust (carbon and glass fibers), which can be harmful to both operators and equipment. Without effective dust extraction, particles may contaminate the work area, reduce visibility, and damage machine components.

- Limited Cutting Thickness: Oscillating knives are best suited for thin to moderately thick composite sheets or prepregs. Cutting very thick laminates may result in incomplete cuts, uneven edges, or excessive tool strain, making alternative cutting methods (e.g., waterjet or milling) more effective.

- Material Handling Challenges: Composites are stiff and brittle, which makes them prone to cracking or splintering if not properly supported during cutting. Inadequate clamping or vacuum hold-down may lead to material shifting, reducing cut accuracy.

- Operator and Machine Strain: Because composites are harder to process than foams or textiles, the machine’s motor, bearings, and knife assembly are placed under higher loads. Without proper maintenance, this can shorten service life and increase downtime.

What Is The Service Life Of Composite Oscillating Knife Cutting Machines?

- Average Service Life: Composite oscillating knife cutting machines typically deliver 8 to 12 years of reliable operation in industrial environments. With consistent maintenance, controlled dust extraction, and proper handling, service life can extend to 15 years or more. Machines used in high-intensity, multi-shift operations may fall on the shorter end of this range due to the abrasive nature of composites.

- Factors That Influence Service Life:

- Machine Build Quality: High-end machines with rigid frames, sealed electronics, and precision linear guides are designed to withstand the stresses of composite cutting. Lower-cost models may experience alignment issues or accelerated wear.

- Material Abrasiveness: Cutting composites creates fine, abrasive dust that can damage bearings, guide rails, and vacuum systems over time. Effective dust-extraction systems are critical to extending service life.

- Workload Intensity: Machines running occasional production for thin laminates experience less wear than those in continuous production, cutting dense carbon fiber boards.

- Blade Wear: Composites dull blades quickly, requiring frequent replacements. Operating with dull blades increases strain on motors and cutting heads, reducing longevity.

- Maintenance Practices: Preventive care—such as lubrication, inspection of seals, regular cleaning of dust extraction systems, and calibration of cutting heads—directly extends service life.

What Training Is Required To Operate Composite Oscillating Knife Cutting Machines?

- Machine Operation Training: Operators must learn the fundamentals of machine setup, calibration, and operation. This includes understanding cutting head functions, adjusting oscillation speeds, and using vacuum tables or clamping systems to secure composite sheets. Training also covers software integration, such as importing CAD/CAM files, nesting patterns, and optimizing toolpaths for efficiency.

- Material Handling and Safety: Unlike softer materials, composites generate hazardous dust and sharp fiber fragments. Training emphasizes proper handling of raw sheets, dust management practices, and the correct use of extraction systems. Operators must also be familiar with the risks of inhaling carbon fiber or glass fiber particles and the importance of maintaining clean work zones.

- Blade Management: Cutting composites dulls blades quickly, so training includes blade selection (different geometries for thin laminates vs. thick boards), monitoring wear, and safe replacement techniques. Properly maintaining sharp blades ensures clean cuts, reduces machine strain, and prevents costly downtime.

- Maintenance and Troubleshooting: Operators should be trained in routine maintenance, such as cleaning dust filters, lubricating moving components, and checking alignment. They must also know how to identify early signs of wear, such as inconsistent cut quality or increased vibration, and how to troubleshoot minor issues before they become major failures.

- Software and Programming Skills: Modern composite oscillating knife cutting machines often rely on advanced control software. Training includes file preparation, nesting optimization, cut-order prioritization, and parameter adjustments to maximize yield while minimizing tool wear and material waste.

- Health and Safety Protocols: Since composites release airborne dust that can irritate the lungs and skin, operators are trained to use appropriate PPE (respirators, gloves, and protective eyewear). They must also understand fire safety procedures, as composite dust is highly combustible if not properly managed.

How Should Composite Oscillating Knife Cutting Machines Be Maintained?

- Blade Care and Replacement: Oscillating knives used for composites dull faster than when cutting softer materials like foam or textiles. Regular inspection of blade sharpness is essential to ensure clean edges and prevent fiber fraying. Operators should follow a replacement schedule, keeping spare blades available to minimize downtime. Proper blade installation and alignment reduce vibration and extend machine life.

- Dust and Debris Management: Cutting composites produces hazardous dust particles, especially with carbon and glass fiber sheets. Machines should be equipped with effective dust extraction and filtration systems, which require routine cleaning and filter replacement. Keeping the work area free of debris prevents buildup that could affect cutting precision and protects operator health.

- Lubrication and Moving Parts: Linear guides, bearings, and drive systems must be regularly lubricated to prevent wear from fine composite particles. Operators should follow the manufacturer’s lubrication schedule and use only recommended lubricants to avoid contamination. This helps maintain smooth motion and accuracy during cutting.

- Software and Calibration: Precision cutting relies on proper calibration of cutting heads, vacuum tables, and motion control systems. Regular calibration checks ensure that cut paths align with programmed toolpaths. Software should also be updated when manufacturers release patches or improvements, as these may enhance cutting efficiency or address known issues.

- Vacuum Table and Material Hold-Down: The vacuum system that secures composite sheets must be kept clean and free of blockages. Dust can clog holes or channels, reducing suction power. Periodic cleaning ensures materials remain firmly in place during cutting, preventing slippage that could compromise cut quality.

- Routine Inspections: Daily checks should include verifying oscillation frequency, examining the cutting head for wear, and inspecting belts and motors for tension and alignment. Any unusual vibration, noise, or drop in cut quality should be addressed immediately to prevent long-term damage.

- Health and Safety Considerations: Since composite dust is harmful, maintaining extraction systems is as much about operator safety as it is about machine care. Maintenance protocols should include inspection of dust containment and ensuring operators use proper PPE when performing cleaning tasks.