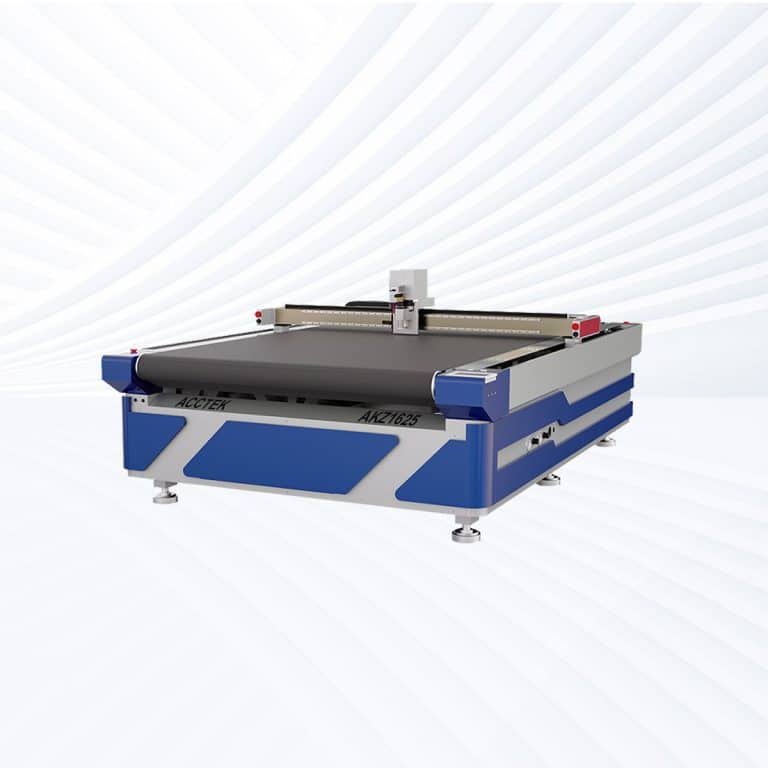

Product Introduction

Types of Cardboard Oscillating Knife Cutting Machines

Benefits of Oscillating Knife Cutting Cardboard

Clean and Accurate Cuts

Oscillating knife cutting delivers sharp, precise edges without crushing corrugated layers. This ensures packaging, inserts, and displays maintain their shape, strength, and professional appearance, giving businesses reliable quality and consistency across every production run.

Cold-Cutting Technology

Unlike thermal methods, the oscillating blade cuts without generating heat. This eliminates risks of burning, warping, or damaging cardboard surfaces, preserving the material’s integrity and making it suitable for sustainable, recyclable packaging applications.

Versatility Across Cardboard Types

From thin chipboard to multi-layer corrugated sheets, oscillating knife cutting machines handle diverse cardboard materials with ease. This versatility makes them ideal for packaging manufacturers, display producers, and custom box makers who require flexibility in their operations.

High Production Efficiency

With CNC control and advanced nesting software, these machines optimize layouts, reduce setup times, and process complex designs quickly. They enable seamless transitions between prototypes and high-volume production, improving workflow efficiency and reducing operational costs.

Reduced Material Waste

Precise cutting and intelligent nesting minimize offcuts and scrap. Manufacturers benefit from better material utilization, lower raw material expenses, and more sustainable production processes—critical advantages in today’s cost- and eco-conscious packaging industry.

Consistency and Repeatability

Every cut is uniform and reliable, even in large production runs. This repeatability ensures packaging and displays meet strict quality standards, reduces errors and rework, and strengthens brand reliability with consistent, high-quality cardboard products.

Compatible Cardboard Materials

- Single Wall Corrugated Board

- Double Wall Corrugated Board

- Triple Wall Corrugated Board

- Kraft Corrugated Cardboard

- White Corrugated Cardboard

- Recycled Corrugated Board

- Honeycomb Cardboard

- Chipboard

- Greyboard

- Duplex Board

- Triplex Board

- Solid Bleached Sulfate Board

- Solid Unbleached Sulfate Board

- Folding Boxboard

- Containerboard

- Linerboard

- Testliner Board

- Coated Recycled Board

- Wax-Coated Corrugated Board

- Water-Resistant Corrugated Board

- Heavy-Duty Industrial Corrugated Board

- Lightweight Microflute Corrugated Board

- E-Flute Corrugated Cardboard

- F-Flute Corrugated Cardboard

- B-Flute Corrugated Cardboard

- C-Flute Corrugated Cardboard

- BC Double Wall Corrugated Board

- EB Double Wall Corrugated Board

- Paperboard Packaging Board

- Bleached Kraft Board

- Unbleached Kraft Board

- Laminated Cardboard Sheets

- Poly-Coated Cardboard

- Foil-Lined Cardboard

- Printed Cardboard Sheets

- Colored Cardboard

- Display Board (POS/POP Board)

- Mounting Board

- Rigid Box Board

- Eco-Friendly Biodegradable Cardboard

Application of Cardboard Oscillating Knife Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Oscillating Knife Cutting | Die Cutting | Band Saw Cutting | Laser Cutting |

|---|---|---|---|---|

| Cutting Method | High-frequency oscillating blade | Steel dies stamp out shapes | Rotating saw blade slices board | Laser beam burns/vaporizes material |

| Cut Edge Quality | Smooth, clean edges, no crushing | Clean but limited by die wear | Rough, may crush corrugation | Burnt or discolored edges |

| Material Compatibility | Works with corrugated, chipboard, paperboard, specialty boards | Works with most cardboard types | Thick corrugated and rigid boards | Thin cardboard only, risk of burning |

| Accuracy | High precision, ±0.1 mm | Good, but limited to die precision | Moderate, less accurate | High, but heat distortion possible |

| Cutting Speed | Fast for prototypes and production | Very fast for mass production | Moderate to slow | Fast, but risky for cardboard |

| Design Complexity | Handles intricate patterns easily | Limited—requires a new die for each design | Simple straight or curved cuts | Handles detail, but burns fine features |

| Material Waste | Minimal with nesting software | Higher due to die clearance | High waste from wide kerf | Some waste from vaporization |

| Surface Finish | Clean and consistent | Clean but flat edges only | Rough, requires finishing | Burnt or charred finish |

| Heat Damage | None (cold cutting) | None | None | High—burns, odors, toxic fumes |

| Tool Wear | Low, blades easily replaced | High, dies wear and need sharpening | High, blades dull quickly | None, but optics need cleaning |

| Noise Level | Low noise | Moderate stamping noise | High noise | Low |

| Dust & Debris | Minimal | Cardboard scrap | High dust, requires extraction | Smoke and fumes |

| Energy Consumption | Moderate, efficient | Low to moderate | Moderate to high | High |

| Maintenance | Simple, low-maintenance | Frequent die sharpening/replacement | Frequent blade replacement | Optics cleaning and ventilation |

| Best Use Cases | Custom boxes, displays, short runs, prototypes, mass production | High-volume, repeat packaging runs | Heavy-duty corrugated sheets | Engraving or cutting thin cardboard |

Why Choose Us

Industrial-Grade Precision and Stability

Every AccTek Group's cutting machine is built with a reinforced frame, high-torque servo motors, and vibration-resistant drive systems for flawless cutting accuracy—even on long production runs.

Powerful Nesting Software Integration

Our machines come standard with BOKE Smart Nest software, giving you advanced automatic nesting tools to drastically reduce material waste and speed up job preparation.

Customizable Configurations for Any Industry

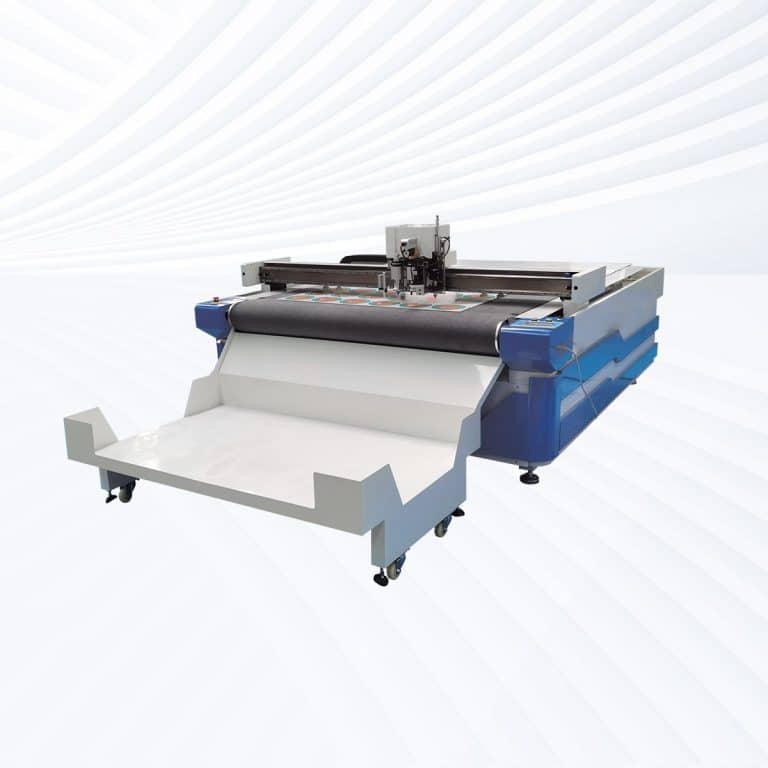

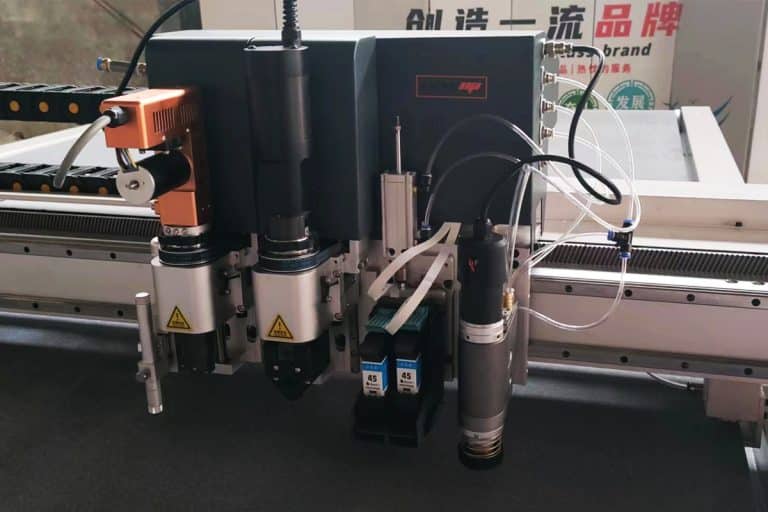

From leatherwork to automotive insulation, we offer modular options including multi-tool heads, conveyor systems, and material feeders to suit your exact production needs.

Responsive Technical Support and Training

Our experienced support team offers fast remote diagnostics, hands-on training, and ongoing guidance to keep your equipment running at peak performance.

Related Resources

What Defects Can Occur In Oscillating Knife Cutting

This article explores the common defects that can occur in oscillating knife cutting, including causes, effects, and practical solutions to improve cutting quality and efficiency in various industries.

What Are the Risks of Using Oscillating Knife Cutting Machines

This article explores the potential risks of using oscillating knife cutting machines, including mechanical, electrical, ergonomic, and operational hazards, and how to manage them safely.

What Safety Measures Should Be Taken When Operating Oscillating Knife Cutting Machines

Discover essential safety measures for operating oscillating knife cutting machines, covering setup, PPE, maintenance, and controls to protect workers and equipment.

What Are The Applications of Oscillating Knife Cutting Machines

Explore the diverse applications of oscillating knife cutting machines, their capabilities, industries served, and key factors for selecting the right solution.

Frequently Asked Questions

How Much Do Cardboard Oscillating Knife Cutting Machines Cost?

- Entry-Level Machines ($8,000–$10,000): Smaller models with limited cutting bed sizes. Suitable for small businesses, prototyping, or short-run packaging work. They handle corrugated cardboard, chipboard, and carton board with good precision but may lack advanced automation.

- Mid-Range Machines ($10,000–$14,000): These machines balance affordability with capability. They typically offer larger cutting beds, higher oscillation speeds, and better software integration for CAD/CAM and nesting. Suitable for packaging workshops, signage companies, and short-to-medium production runs.

- High-End Machines ($14,000–$18,000): Industrial-grade cutting machines designed for continuous, high-volume cardboard processing. They often include conveyor systems, automatic feeding, multi-tool heads (oscillating knife, creasing wheel, V-cut), and advanced control software. These systems are widely used in large-scale packaging, point-of-purchase displays, and custom corrugated products.

What Is The Edge Quality Of Cardboard Cut With An Oscillating Knife?

- Corrugated Cardboard: When cutting corrugated sheets, oscillating knives produce smooth, accurate edges with minimal crushing of the fluted interior. Proper blade sharpness and oscillation settings are critical—dull blades or excessive pressure may flatten the flutes, reducing structural integrity.

- Chipboard and Carton Board: Dense boards like chipboard and carton stock cut with straight, clean edges free from fraying. For thicker grades, the machine may require slower speeds to prevent slight tearing or roughness along the edge.

- Multi-Layer and Laminated Cardboard: For laminated boards or coated surfaces, oscillating knives achieve consistent edge quality without charring or delamination. However, improper blade selection can lead to slight peeling at the laminate edges.

- Fine Paperboard: On thinner materials, oscillating knives maintain sharp, precise cuts suitable for packaging prototypes and detailed patterns. Since there is no heat, delicate materials do not warp or discolor.

What Is The Precision Of Cardboard Oscillating Knife Cutting Machines?

- Single-Ply Cardboard and Paperboard: When cutting thin carton board, chipboard, or single-ply sheets, oscillating knives achieve exceptionally clean and precise results. The absence of heat ensures that edges do not warp or shrink, keeping measurements true to the design.

- Corrugated Cardboard: For corrugated materials, precision depends on flute size and thickness. High-quality oscillating knife cutting systems maintain tight tolerances without crushing the flutes, provided the vacuum hold-down system secures the sheet properly.

- Laminated or Coated Cardboard: Machines handle laminated and coated boards with consistent accuracy, though slight variations may occur if the blade is not matched to the surface finish. Proper tool selection minimizes edge fraying or delamination.

- Large Format Cutting: Even on oversized sheets for packaging or displays, oscillating knives maintain alignment and dimensional accuracy. Advanced models with camera-based registration can compensate for material shifts, ensuring designs are cut exactly to CAD specifications.

What Are The Disadvantages Of Cardboard Oscillating Knife Cutting Machines?

- Blade Wear and Maintenance: Cardboard, especially corrugated and coated varieties, can dull blades quickly. Frequent blade replacement is required to maintain clean edges. Dull blades cause tearing, fraying, and reduced accuracy. This adds to ongoing maintenance costs.

- Cutting Speed on Thick or Multi-Layer Boards: While oscillating knives cut efficiently, thick or double-wall corrugated cardboard slows down cutting speed. Multiple passes may be required to achieve clean edges, reducing throughput compared to high-powered lasers or die-cutting systems.

- Material Shifting Issues: For large sheets, stable vacuum suction is critical. Insufficient hold-down can cause material movement, leading to misaligned cuts. Extra care must be taken in securing oversized cardboard sheets during operation.

- Limited Tool Life with Abrasive Boards: Recycled and rough-surfaced boards contain fibers that act as abrasives. These wear down blades faster than virgin or smooth boards, increasing consumable usage.

- Noise and Vibration: High-speed oscillating knives generate mechanical vibration and noise. In larger machines running continuously, operators may require hearing protection, and vibration can contribute to long-term wear on machine components.

- Complex Designs vs. Die-Cutting: While oscillating knives are flexible and suitable for custom, small-batch runs, they are slower for mass production of identical designs compared to traditional die-cutting, which can stamp out high volumes more efficiently.

- Initial Investment Cost: Though not as expensive as large industrial lasers, oscillating knife cutting machines still require a significant upfront cost ($8,000–$18,000). Additional costs for software, training, and blade replacements must also be factored in.

How Should I Choose Cardboard Oscillating Knife Cutting Machines?

- Cutting Bed Size: Larger beds allow you to process full sheets of corrugated or chipboard without trimming. For packaging and display applications, a bigger working area improves efficiency by reducing repositioning. Smaller beds are fine for prototyping or short runs.

- Material Compatibility: Different machines handle single-ply, corrugated, chipboard, and laminated cardboard with varying effectiveness. If you work primarily with double-wall or coated boards, look for a machine with stronger motors and higher oscillation frequencies.

- Tool Options:

- Advanced machines support multiple tool heads, such as:

- Oscillating knife for clean cutting.

- Creasing wheels for folding lines in packaging.

- V-cut tools for display board assembly.

- Software Integration: CAD/CAM compatibility and nesting software are important for packaging and custom display work. Systems with camera-based registration can correct alignment automatically, which is valuable for printed or pre-marked boards.

- Automation Features: Industrial models may include conveyor beds, automatic feeding, and scrap collection. These features improve throughput and reduce manual labor, making them ideal for high-volume production environments.

- Precision and Repeatability: Check for machine specifications on tolerance. High-quality cutting machines maintain ±0.1–0.3 mm accuracy, which is critical for detailed packaging prototypes and branding work.

- Blade and Consumable Costs: Cardboard, especially recycled and coated types, wears down blades quickly. Evaluate the availability and cost of replacement blades and whether the machine supports different blade types for versatility.

- Support and Service: Choose a supplier with strong after-sales support, including training, spare parts availability, and technical assistance. A cheaper machine without reliable service may cost more in downtime over time.

- Budget Considerations: Machines range from $8,000 to $18,000, with entry-level models suitable for small businesses and high-end automated systems designed for large packaging operations. Factor in not just the upfront cost but also software, blades, and maintenance.

What Training Is Required To Operate Cardboard Oscillating Knife Cutting Machines?

- Machine Setup and Operation: Operators must learn how to correctly load cardboard sheets, adjust vacuum suction or clamping systems, and select the right cutting parameters. Training includes setting blade oscillation frequency, cutting depth, and feed rate based on whether the material is corrugated, chipboard, or laminated cardboard.

- Tool Handling and Blade Maintenance: Since cardboard dulls blades relatively quickly, operators need to know how to change blades safely, select the correct blade type for the material, and inspect for wear. Proper handling reduces downtime and ensures clean, accurate edges.

- Software and CAD/CAM Integration: Most oscillating knife cutting machines work with CAD/CAM software for design input and nesting optimization. Training typically covers importing design files, adjusting tool paths, and using registration systems to align pre-printed or pre-marked sheets.

- Safety Training: Operators should be trained to follow standard PPE guidelines, including cut-resistant gloves, safety glasses, and hearing protection in high-speed operations. They must also learn safe startup/shutdown procedures and how to avoid hazards from moving blades and vacuum systems.

- Quality Control and Troubleshooting: Training covers monitoring cut quality, recognizing signs of blade dullness or misalignment, and troubleshooting common issues like edge fraying, crushing of corrugated flutes, or material shifting.

- Routine Maintenance: Operators are instructed in daily cleaning, lubrication, and calibration checks. They also learn to monitor consumables and ensure the machine stays in peak condition for accuracy and efficiency.

What PPE Is Required When Cutting Cardboard With An Oscillating Knife?

- Eye Protection: Operators should wear safety glasses or goggles to shield against small cardboard fibers, dust, or debris created during cutting. While the process is generally low-risk compared to laser cutting, airborne particles can still irritate.

- Hand Protection: Because oscillating knives use very sharp blades, cut-resistant gloves are recommended when changing or handling blades. Gloves should not be worn near moving parts during operation to avoid entanglement, but are essential during blade replacement and maintenance.

- Hearing Protection: High-speed oscillating knives generate mechanical vibration and noise, especially in industrial settings where multiple machines may run simultaneously. Operators in these environments should use earplugs or earmuffs to prevent long-term hearing damage.

- Respiratory Protection (Optional): Cutting large volumes of cardboard can release fine dust. In facilities with poor ventilation, dust masks or respirators may be necessary to protect against respiratory irritation. Machines with built-in dust extraction reduce this need.

- Protective Clothing: Operators should wear fitted work clothing that does not hang loose, preventing accidental contact with moving parts. Aprons or long sleeves can also reduce minor abrasions from handling cardboard sheets.

- Foot Protection: Safety shoes with non-slip soles are recommended in production areas to prevent accidents while handling large cardboard sheets or stacks.

What Is The Service Life Of Cardboard Oscillating Knife Cutting Machines?

- Average Service Life: Well-built oscillating knife cutting machines typically last 8 to 12 years in regular production environments. Entry-level models may last closer to 5–7 years, while heavy-duty industrial models can exceed 15 years with consistent upkeep.

- Blade Life vs. Machine Life: It’s important to distinguish between consumables and the machine itself. Blades wear quickly when cutting dense or coated cardboard and may need replacing daily or weekly, depending on use. The machine structure, motors, and drive systems last far longer but require routine inspection.

- Manufacturer Support: Machines backed by strong after-sales service and available spare parts are easier to keep in operation for over a decade. Lack of support can shorten usable life even if the hardware remains sound.