Product Introduction

Types of Aluminum Laser Welding Machines

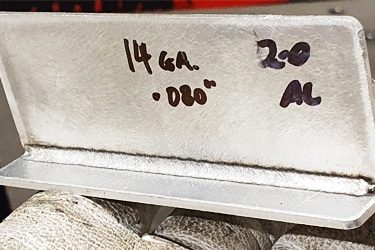

Welding Thickness Reference

| Laser Power | Welding Form | Thickness | Welding Speed | Defocus Amount | Protective Gas | Blowing Method | Flow | Welding Effect |

|---|---|---|---|---|---|---|---|---|

| 1000W | Butt Welding | 0.5mm | 70~80 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely |

| Butt Welding | 1mm | 50~60 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 1.5mm | 30~40 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 2mm | 20~30 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| 1500W | Butt Welding | 0.5mm | 80~90 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely |

| Butt Welding | 1mm | 70~80 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 1.5mm | 50~60 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 2mm | 30~40 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 3mm | 10~20 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| 2000W | Butt Welding | 0.5mm | 90~100 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely |

| Butt Welding | 1mm | 80~90 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 1.5mm | 70~80 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 2mm | 40~50 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 3mm | 20~30 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| 3000W | Butt Welding | 0.5mm | 100~110 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely |

| Butt Welding | 1mm | 90~100 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 1.5mm | 80~90 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 2mm | 70~80 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 3mm | 40~50 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 4mm | 20~30 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| 6000W | Butt Welding | 1mm | 110~120 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely |

| Butt Welding | 1.5mm | 100~110 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 2mm | 90~100 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 3mm | 80~90 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 4mm | 70~80 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 5mm | 40~50 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely | |

| Butt Welding | 6mm | 20~30 mm/s | -1~1 | Ar | Coaxial/Paraaxial | 5~10 L/min | Welded Completely |

Compatible Aluminum Grades

- 1050

- 1060

- 1070

- 1100

- 1145

- 1235

- 1350

- 2011

- 2014

- 2024

- 2219

- 3003

- 3004

- 3004

- 3105

- 5005

- 5050

- 5052

- 5056

- 5083

- 5086

- 5154

- 5182

- 5251

- 5454

- 5754

- 6010

- 6060

- 6061

- 6063

- 6106

- 6181

- 6201

- 6262

- 7005

- 7050

- 7072

- 7075

- 7475

- 8011

Application of Aluminum Laser Welding Machines

Customer Testimonials

Comparison VS Other Welding Technologies

| Comparison Item | Laser Welding | MIG Welding | TIG Welding | Stick Welding |

|---|---|---|---|---|

| Heat Input | Low (minimal distortion) | Moderate | Low to Moderate | High (risk of burn-through) |

| Weld Speed | Very High | High | Low | Moderate |

| Precision | Very High | Moderate | High | Low |

| Weld Cleanliness | Excellent (no spatter, minimal oxidation) | Fair (some spatter, oxidation) | Excellent | Poor (slag, rough) |

| Thin Material Capability | Excellent | Poor (burn-through likely) | Excellent | Poor |

| Filler Material Requirement | Often not required | Required | Often required | Required |

| Post-Weld Cleanup | Minimal | Moderate to High | Low | High |

| Porosity Control | Good with proper settings | Moderate (prone to porosity) | Good | Poor |

| Joint Appearance | Smooth, narrow, aesthetically clean | Acceptable | Excellent | Rough |

| Weld Strength | High (if properly configured) | High | High | Moderate |

| Automation Compatibility | Excellent (ideal for robotic systems) | Good | Moderate | Poor |

| Production Throughput | Very High | High | Low | Moderate |

| Operator Skill Requirement | Moderate (automated systems available) | Moderate | High | Low to Moderate |

| Initial Equipment Cost | High | Moderate | Moderate | Low |

| Operating Cost | Low (efficient, minimal consumables) | Moderate | High (slower, more gas use) | Low |

Why Choose Us

High Precision

Our machines deliver accurate, clean welds with minimal heat input, reducing distortion and ensuring strong, consistent joints across a wide range of materials and thicknesses.

Easy Operation

Designed with intuitive controls and user-friendly interfaces, our systems allow both experienced operators and new users to achieve professional results with minimal training.

Durable & Reliable

Built with high-quality components and strict quality standards, our welding machines provide stable performance, long service life, and low maintenance requirements.

Custom Options

We offer a variety of models and customizable features to match specific production needs, helping businesses improve workflow and adapt to changing manufacturing demands.

Related Resources

Laser Welding VS Arc Welding

This article explores the key differences between laser welding and arc welding, comparing their processes, advantages, limitations, and ideal applications across various industries.

What Welding Defects Can Occur In Laser Welding

This article helps to understand common laser welding defects, their causes, and effective prevention strategies to ensure consistent welding quality across different materials and applications.

Laser Welding Brass Guide

This article is a comprehensive guide to brass laser welding, covering welding techniques, parameters, challenges, equipment selection, and best practices for achieving precise, high-quality welds.

Autogenous VS Filler Laser Welding

This article explains the differences between autogenous and filler laser welding, detailing their principles, processes, parameters, and applications in industrial manufacturing.

Frequently Asked Questions

What Are The Optional Powers Of Aluminum Laser Welding Machines?

- 1000W Laser Welding Machines: This entry-level power setting is ideal for light-duty fabrication and precision welding tasks.

- Commonly used for enclosures, electronics, and small brackets

- Delivers clean, narrow seams with low heat input

- Requires good joint fit-up and clean surfaces for best results

- 1500W Laser Welding Machines: A balanced choice for many industrial applications requiring moderate weld strength and efficiency.

- Suitable for automotive panels, appliance housings, and architectural components

- Often paired with wobble welding heads for better weld formation

- Offers faster travel speeds and more consistent results than lower-power units

- 2000W Laser Welding Machines: Provides strong, stable performance for general-purpose aluminum welding.

- Frequently used in automated systems and high-throughput production lines

- Compatible with a wide range of aluminum alloys, including structural grades

- Capable of both pulsed and continuous welding modes

- 3000W Laser Welding Machines: Designed for more demanding fabrication needs, where deeper fusion and higher travel speeds are required.

- Common in industrial equipment manufacturing, transport systems, and large frames

- Works well with robotic systems for high-precision multi-axis welding

- Requires precise gas shielding and beam control

- 6000W Laser Welding Machines: High-power systems built for advanced, high-volume manufacturing environments.

- Used in aerospace, marine, and defense industries

- Supports complex weld paths and thicker assemblies

- Requires advanced optics, cooling systems, and operator expertise

How Thick Can Lasers Weld Aluminum?

- At 1000 watts, lasers can typically weld aluminum up to 2 mm thick. This range is ideal for thin sheet metal applications such as enclosures, brackets, and lightweight covers, where minimal heat input and precise control are important.

- With 1500W or 2000W, aluminum thickness up to 3 mm can be reliably welded. These power levels are commonly used in automotive bodywork, appliance panels, and general-purpose aluminum components that require moderate strength and clean seams.

- Increasing to 3000 watts allows for welding aluminum up to 4 mm thick. This power range is suitable for more demanding structural applications, such as transportation parts or medium-duty machine frames. At this level, maintaining beam focus and controlling the heat input become more critical to avoid porosity or burn-through.

- At the highest range, 6000-watt laser welding machines can handle aluminum sections up to 7 mm thick. These systems are typically used in industrial and aerospace settings where full penetration and structural integrity are essential. With the right shielding gas (often helium or helium-argon mixtures), tight joint tolerances, and clean surfaces, thick aluminum can be welded efficiently and with high mechanical strength.

How Does Laser Welding Handle Highly Reflective Aluminum Surfaces?

- Use of Fiber Lasers: Fiber lasers are more effective than CO2 lasers when welding reflective metals like aluminum.

- They emit at a shorter wavelength (around 1 µm), which is more readily absorbed by metal surfaces than the longer wavelength of CO2 lasers

- Better beam quality and focus allow higher energy density, improving penetration and weld consistency

- Less risk of back-reflection damaging internal optics

- Surface Preparation: Reducing surface reflectivity improves initial energy absorption.

- Mechanical abrasion, chemical cleaning, or anodizing can dull the surface to help the laser couple more efficiently

- Removing oxide layers and surface oils is essential to prevent porosity and improve weld quality

- Surface coatings (like blackening compounds) are sometimes used in automated systems

- Higher Power Density and Tight Focus: Laser systems handle reflection by delivering concentrated energy quickly.

- Using a tightly focused beam ensures that once melting begins, absorption increases rapidly

- High power density helps overcome the initial resistance to energy input from the reflective surface

- Pulse or wobble welding techniques can assist in stabilizing the arc and managing reflectivity

- Angle of Incidence Control: Altering the angle at which the beam hits the surface reduces the chance of harmful reflections.

- Tilting the laser slightly can redirect reflected energy away from sensitive optical components

- Especially important in robotic or automated systems where consistent angle control is possible

- Beam Oscillation (Wobble Welding): Oscillating the laser beam in a circular or figure-eight pattern spreads energy more evenly.

- Helps break through reflective surfaces more smoothly

- Reduces hot spots and allows better fusion between aluminum parts

- Often combined with fiber lasers for optimized weld quality

What Are The Advantages Of Laser Welding Aluminum?

- High Welding Speed: Laser welding operates at high travel speeds, especially when paired with fiber lasers.

- Greatly reduces production cycle times in automated or robotic systems

- Ideal for large-scale aluminum assembly in automotive and aerospace manufacturing

- Efficient for continuous or long seam welding applications

- Low Heat Input: The highly focused laser beam minimizes the heat-affected zone (HAZ), which is important for aluminum.

- Reduces distortion, warping, and material softening

- Preserves the mechanical properties and surface finish of heat-sensitive components

- Enables clean, fine welds on thin-gauge aluminum without burn-through

- Non-Contact Process: Since the laser doesn’t physically touch the material, mechanical stress is avoided.

- No tool wear or pressure applied to the workpiece

- Well-suited for delicate or precision-engineered parts

- Easier to integrate into automated production lines

- Narrow, Precise Welds: Laser beams produce narrow weld seams with minimal spatter.

- Requires less post-weld cleanup or grinding

- Enhances aesthetic quality and dimensional accuracy

- Allows welding in tight or complex joint configurations

- Excellent Repeatability: Laser welding systems are highly consistent when programmed correctly.

- Delivers uniform weld quality part after part

- Ideal for high-volume production with minimal variability

- Supports multi-axis robotic welding and vision-guided alignment

- Suitable for Dissimilar Metal Joining: Laser welding can join aluminum to other metals, such as copper or steel, with proper setup.

- Useful in EV battery packs, electronics, and aerospace applications

- May require tailored pulse control and filler materials for compatibility

- Reduces the need for fasteners or adhesive bonding

How Much Do Aluminum Laser Welding Machines Cost?

- Handheld aluminum laser welding machines are a more affordable and flexible option. These systems are typically used for manual fabrication, on-site repair, or custom part assembly. Entry-level models include basic 1000W setups suitable for light aluminum welding, while higher-end handheld units with 2000W–3000W power, wobble heads, and wire feeders support more demanding tasks. These machines are popular in small workshops and prototyping environments where mobility and ease of use are priorities.

- Automated aluminum laser welding machines are built for continuous, high-precision operations in industrial settings. These systems are integrated with CNC motion platforms, robotic arms, or multi-axis controls. Lower-priced models in this category offer basic automation and are well-suited for medium-volume production with consistent weld paths. Higher-end systems include advanced beam control, real-time monitoring, and seamless integration into existing production lines, making them ideal for applications in the automotive, aerospace, and electronics industries.

What Gas Is Used For Laser Welding Aluminum?

- Argon: Argon is the most commonly used shielding gas for laser welding aluminum.

- It is inert, readily available, and provides a stable welding environment

- Helps protect the weld pool from oxygen and nitrogen in the air

- Reduces the risk of porosity and prevents surface oxidation

- Works well in both pulsed and continuous-wave laser welding systems

- Often used alone in low- to mid-power applications and for thin aluminum sections

- Helium: Helium is sometimes used by itself or blended with argon to improve weld penetration.

- Offers higher thermal conductivity than argon, which promotes deeper keyhole formation

- Especially effective in high-speed or high-power aluminum welding setups

- Helps reduce reflectivity-related issues at the start of the weld

- More expensive than argon but often worth the cost for thick or high-reflectivity aluminum alloys

- Argon–Helium Mixtures: Gas mixtures offer the advantages of both elements and are commonly used for optimized weld quality.

- Typical ratios include 75% argon / 25% helium or 50/50, depending on material thickness and laser power

- Enhances arc stability and reduces the chance of pore formation

- Allows better control over heat input and bead shape in automated welding lines

- Gas Flow Control: Regardless of gas type, consistent shielding is critical.

- Too little gas allows oxygen to contaminate the weld pool

- Excessive gas flow can create turbulence and lead to porosity

- Shielding gas nozzles should be properly aligned and kept clean for even coverage

How To Deal With The Heat-Affected Zone And Deformation Of Laser-Welded Aluminum?

- Optimize Heat Input: Excessive heat can enlarge the HAZ and increase the chance of deformation.

- Use the lowest laser power necessary to achieve full penetration

- Increase welding speed to reduce the time heat stays concentrated in one spot

- Consider pulsed or wobble welding modes to distribute energy more evenly

- Use Proper Fixturing: Clamping and fixtures help hold the material in place during welding.

- Secure the aluminum parts tightly to prevent movement as they expand and contract

- Use thermal sinks or backing plates to draw heat away from critical areas

- Fixtures should be heat-resistant and allow for slight expansion to reduce stress buildup

- Apply Preheating Selectively: In some cases, preheating the material can reduce thermal shock.

- Helps control thermal gradients and minimizes cracking in the HAZ

- Should be applied carefully—excess preheat can increase warping instead of preventing it

- Typically used for thicker aluminum parts or highly restrained joints

- Design for Symmetry and Balance: Joint design has a direct impact on heat concentration and part distortion.

- Use symmetrical weld paths to balance shrinkage forces

- Stagger welds or alternate sides during multi-pass welding to prevent heat buildup on one side

- Avoid over-welding—oversized beads add unnecessary heat and increase stress

- Post-Weld Cooling and Stress Relief: Proper cooling can reduce internal stress and prevent part distortion.

- Allow parts to cool slowly and evenly; avoid forced cooling unless uniform

- For critical components, consider post-weld heat treatment to normalize internal structure

- In some applications, mechanical straightening or reshaping may be required after welding

- Material and Alloy Selection: Some aluminum alloys handle heat better than others.

- 5xxx and 6xxx series generally offer better weldability and lower risk of deformation

- Alloys with high silicon content tend to resist cracking and shrinkage more effectively

- Avoid high-strength or heat-treated alloys if post-weld deformation is a concern

How To Reduce The Thermal Crack Sensitivity of Laser-Welded Aluminum?

- Choose the Right Aluminum Alloy: Not all aluminum alloys weld equally well. Some are far more crack-prone than others.

- 5xxx and 6xxx series alloys (e.g., 5052, 6061) generally show lower thermal crack sensitivity compared to high-strength 2xxx or 7xxx series alloys.

- Avoid alloys with high copper or zinc content, which are particularly susceptible to cracking.

- Select filler wire compatible with the base material, often with higher silicon content to reduce brittleness.

- Use Proper Filler Material: The filler wire composition plays a critical role in crack resistance.

- ER4047 (12% Si) and ER4045 (10% Si) filler wires are often used to reduce hot cracking due to their lower solidification temperature and increased fluidity.

- Higher silicon reduces the freezing range of the weld pool, minimizing crack formation during solidification.

- Control Heat Input and Cooling Rate: Thermal cracking is often a result of excessive shrinkage stresses from rapid temperature changes.

- Use the lowest effective laser power and faster travel speeds to keep heat input controlled.

- Avoid preheating unless necessary. It may reduce cracking in some thick-section or highly restrained joints, but can also increase heat-affected zone (HAZ) width if not managed properly.

- Maintain a stable, shallow weld pool to reduce shrinkage stress buildup.

- Joint Design and Fit-Up: Poor joint geometry or excessive gaps can increase cracking risk.

- Use a tight, consistent joint fit-up to avoid stress concentrations.

- Favor joint types like lap joints or butt joints with proper edge prep over configurations that introduce uneven thermal stress.

- Minimize restraint during welding to allow the material to expand and contract more freely.

- Optimize Shielding Gas: Shielding gas protects the molten pool from oxidation and contamination.

- Argon is the standard shielding gas for aluminum, providing excellent arc stability.

- Helium or argon-helium mixtures may improve penetration and fluidity but can also increase heat input, so they should be used with caution.

- Post-Weld Treatments and Stress Relief: After welding, the joint remains vulnerable to residual stress and microcracks.

- Post-weld heat treatment can be used in critical applications to relieve residual stresses.

- In some cases, mechanical straightening or surface grinding helps eliminate visible surface defects and stress concentrations that could propagate cracks.