Introduction

Advantages of Laser Cutting Titanium

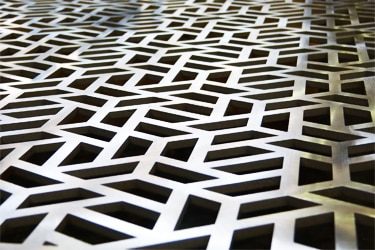

High Precision and Accuracy

Laser cutting offers exceptional precision, enabling the creation of intricate shapes and tight tolerances. This accuracy is especially important for titanium components used in industries such as aerospace and medical, where reliability and exact measurements are crucial.

Clean, Smooth Edges

The laser cutting process produces clean, smooth edges with minimal burrs or oxidation. This reduces the need for additional finishing, saving time and improving the aesthetic and functional quality of titanium parts used in high-performance applications.

Minimal Heat-Affected Zone

Laser cutting minimizes the heat-affected zone, preserving the material's mechanical properties. This is critical for titanium, which can be sensitive to heat distortion. By reducing HAZ, the cutting process maintains the strength, durability, and quality of the final product.

Fast Cutting Speed

Laser cutting is a rapid process, particularly with advanced fiber lasers. This efficiency helps reduce production times and improve throughput, especially when processing titanium components in high-volume production runs or custom orders with complex designs.

Ability to Cut Complex Shapes

Laser cutting allows for intricate and detailed geometries to be cut with ease. It can process fine features such as small holes, sharp corners, and complex curves, providing design flexibility and versatility for titanium parts used in demanding industries.

Reduced Material Waste

The narrow kerf produced by laser cutting minimizes material waste, optimizing material utilization. Additionally, advanced nesting software can maximize sheet layout, further reducing scrap and lowering overall production costs when working with titanium sheets.

Compatible Materials

- Ti-6Al-4V

- Ti-6Al-4V ELI

- Ti-3Al-2.5V

- Ti-6Al-2Sn-4Zr-6Mo

- Ti-5Al-2.5Sn

- Ti-2Al-1.5Mn

- Ti-6Al-7Nb

- Ti-6Al-4V-ELI

- Ti-4Al-3Mo-1V

- Ti-10V-2Fe-3Al

- Ti-15V-3Cr-3Sn-3Al

- Ti-5Al-2.5Fe

- Ti-8Al-1Mo-1V

- Ti-7Al-4Mo

- Ti-5Al-5V-5Mo-3Cr

- Ti-9Al-2Fe

- Ti-3Al-8V-6Cr-4Mo-4Zr

- Ti-6Al-4V-DF

- Ti-5Al-5V-5Mo-3Cr

- Ti-5Al-2.5Fe

- Ti-15Mo-3Al-3Nb

- Ti-6Al-4V Beta

- Ti-2Al-4Mn-2V

- Ti-4Al-4Mo

- Ti-5Al-4V

- Ti-6Al-7Nb-ELI

- Ti-6Al-2Sn-4Zr-6Mo

- Ti-6Al-4V Alpha Beta

- Ti-15Mo-3Al-3Nb

- Ti-7Al-2Mo

- Ti-8Al-1Mo

- Ti-5Al-3V-2Fe

- Ti-3Al-8V-6Cr-4Mo

- Ti-6Al-4V Plate

- Ti-6Al-4V Extrusion

- Ti-6Al-4V Forging

- Ti-9Al-2Fe

- Ti-10V-2Fe-3Al

- Ti-15Mo-2Al

- Ti-6Al-7Nb

Laser Cutting Titanium VS Other Cutting Methods

| Comparison Item | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Cutting Precision | Very high accuracy | Moderate to low | Very high accuracy | Low precision |

| Edge Quality | Smooth, clean, burr-free | Rough edges, dross | Smooth, but slightly matte | Rough, oxidized edges |

| Heat-Affected Zone (HAZ) | Minimal | Large | None (cold cutting) | Very large |

| Cutting Speed | Fast, especially on thinner materials | Moderate to fast | Slow | Very slow |

| Material Thickness Range | Thin to medium thickness | Medium to thick materials | Thin to very thick materials | Thick materials only |

| Detail & Complexity | Excellent for fine details | Limited detail | Excellent for intricate cuts | Very limited |

| Kerf Width | Narrow | Wide | Moderate | Wide |

| Secondary Finishing | Minimal or none required | Often required | Rarely required | Always required |

| Suitability for Titanium | Excellent, minimal oxidation | Poor, oxidation likely | Excellent, no oxidation | Poor, oxidation and coating damage |

| Reflective Material Handling | Designed with reflection control | Poor for reflective materials | No reflection issues | Not applicable |

| Operating Cost | Moderate | Low | High | Low |

| Equipment Investment | Moderate to high | Low to moderate | High | Low |

| Automation Capability | Highly automated, CNC capable | CNC capable | CNC capable | Mostly manual |

| Environmental Impact | Low emissions, clean process | High fumes and noise | Water and abrasive waste | High smoke and gases |

| Cutting Quality Consistency | Excellent for repeatability | Inconsistent quality | Very consistent | Inconsistent |

Laser Cutting Capacity For Titanium

| Laser Power (kW) | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| 1KW | 1 | 1.3-2.0 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 0.1-1.4 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 1.5KW | 1 | 1.4-2.1 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 1.0-1.5 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 0.8-1.2 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 2KW | 1 | 2.3-3.5 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 1.7-2.6 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 1.3-2.0 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 1.0-1.5 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 0.65-1.0 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 3KW | 1 | 3.0-4.6 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 2.3-3.5 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 1.7-2.6 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 1.3-2.0 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 0.9-1.3 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 0.6-0.9 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 4KW | 1 | 3.8-5.7 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 2.9-4.3 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 2.2-3.2 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 1.7-2.5 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 1.1-1.6 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 0.8-1.2 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 8 | 0.6-0.9 | -2.5 | 0.5 | N2 | 2.55 | 16 | |

| 6KW | 1 | 5.1-7.8 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 3.8-5.8 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 2.9-4.3 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 2.2-3.4 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 1.4-2.2 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 1.0-1.5 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 8 | 0.8-1.2 | -2.5 | 0.5 | N2 | 2.55 | 16 | |

| 10 | 0.6-1.0 | -3 | 0.5 | N2 | 2.55 | 16 | |

| 12 | 0.5-0.8 | -4 | 0.5 | N2 | 2.55 | 16 | |

| 14 | 0.4-0.6 | -4 | 0.5 | N2 | 3.05 | 16 | |

| 12KW | 1 | 5.8-8.6 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 4.3-6.5 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 3.4-5.0 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 2.2-3.2 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 1.5-2.3 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 1.2-1.8 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 8 | 1.0-1.4 | -2.5 | 0.5 | N2 | 2.55 | 16 | |

| 10 | 0.8-1.2 | -3 | 0.5 | N2 | 2.55 | 16 | |

| 12 | 0.6-0.9 | -4 | 0.5 | N2 | 2.55 | 16 | |

| 14 | 0.5-0.7 | -4 | 0.5 | N2 | 3.05 | 16 | |

| 16 | 0.3-0.5 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 18 | 0.2-0.3 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 20 | 0.15-0.25 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 20KW | 1 | 8.6-13.0 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 6.5-9.7 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 5.0-7.6 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 3.2-4.9 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 2.3-3.4 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 1.8-2.7 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 8 | 1.4-2.2 | -2.5 | 0.5 | N2 | 2.55 | 16 | |

| 10 | 1.2-1.7 | -3 | 0.5 | N2 | 2.55 | 16 | |

| 12 | 0.9-1.4 | -4 | 0.5 | N2 | 2.55 | 16 | |

| 14 | 0.7-1.1 | -4 | 0.5 | N2 | 3.05 | 16 | |

| 16 | 0.5-0.8 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 18 | 0.4-0.5 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 20 | 0.2-0.3 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 25 | 0.15-0.2 | -7 | 0.3 | N2 | 4.05 | 18 | |

| 30KW | 1 | 10.1-15.9 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 7.9-11.9 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 6.2-9.2 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 4.0-6.0 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 2.8-4.2 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 2.2-3.3 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 8 | 1.8-2.6 | -2.5 | 0.5 | N2 | 2.55 | 16 | |

| 10 | 1.4-2.1 | -3 | 0.5 | N2 | 2.55 | 16 | |

| 12 | 1.1-1.7 | -4 | 0.5 | N2 | 2.55 | 16 | |

| 14 | 0.9-1.3 | -4 | 0.5 | N2 | 3.05 | 16 | |

| 16 | 0.6-0.9 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 18 | 0.4-0.6 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 20 | 0.26-0.4 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 25 | 0.18-0.26 | -7 | 0.3 | N2 | 4.05 | 18 | |

| 30 | 0.09-0.13 | -7 | 0.3 | N2 | 4.05 | 18 | |

| 40KW | 1 | 16.6-25.0 | 0 | 0.8 | N2 | 1.55 | 12 |

| 2 | 12.5-18.7 | -1 | 0.5 | N2 | 2.05 | 12 | |

| 3 | 9.4-14.0 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 4 | 7.3-11.0 | -1.5 | 0.5 | N2 | 2.05 | 14 | |

| 5 | 4.7-7.0 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 6 | 3.3-5.0 | -2 | 0.5 | N2 | 2.05 | 14 | |

| 8 | 2.6-3.9 | -2.5 | 0.5 | N2 | 2.55 | 16 | |

| 10 | 2.1-3.1 | -3 | 0.5 | N2 | 2.55 | 16 | |

| 12 | 1.7-2.5 | -4 | 0.5 | N2 | 2.55 | 16 | |

| 14 | 1.4-2.0 | -4 | 0.5 | N2 | 3.05 | 16 | |

| 16 | 1.0-1.6 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 18 | 0.7-1.1 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 20 | 0.5-0.8 | -5 | 0.5 | N2 | 3.05 | 16 | |

| 25 | 0.3-0.5 | -7 | 0.3 | N2 | 4.05 | 18 | |

| 30 | 0.2-0.3 | -7 | 0.3 | N2 | 4.05 | 18 | |

| 40 | 0.1-0.15 | -9 | 0.3 | N2 | 5.05 | 18 |

Applications of Laser Cutting Titanium

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

Does Laser Cutting Of Titanium Require Specialized Cutting Strategies?

- High Melting Point and Low Thermal Conductivity: Titanium has a high melting point (around 1,668℃ or 3,034℉), which means it requires more energy to melt compared to metals like steel or aluminum. Additionally, it has low thermal conductivity, which means the heat applied during the cutting process doesn’t dissipate quickly, causing the material to remain hot for longer. This requires careful control of laser power and cutting speed to avoid excess heat buildup, which can lead to warping, oxidation, or poor cut quality.

- Oxidation Concerns: Titanium is highly reactive to oxygen at elevated temperatures. When laser cutting titanium, especially in the presence of oxygen, the material can oxidize rapidly, resulting in poor edge quality and contamination of the cut. To prevent oxidation and maintain clean, high-quality cuts, inert assist gases such as nitrogen are often preferred over oxygen. Nitrogen helps create a controlled, oxygen-free environment around the cut, reducing the risk of oxidation and ensuring a smoother, cleaner edge.

- Thin vs. Thick Material Cutting: The cutting strategy for titanium varies significantly depending on the material thickness. For thin titanium sheets, laser cutting can be performed at relatively high speeds with lower laser power, whereas thicker titanium requires lower cutting speeds and higher laser power to ensure full penetration of the material. Special attention is needed when cutting thick titanium, as the heat from the laser can cause excessive thermal stress, leading to warping and surface imperfections.

- Assist Gas Selection: The choice of assist gas is crucial when laser cutting titanium. While oxygen is often used for cutting steel to enhance the cutting process, it is not suitable for titanium, as it leads to oxidation. Nitrogen, on the other hand, provides a non-reactive environment, preventing oxidation and ensuring that the cut edge remains clean and free of contamination. In some cases, a combination of gases, such as nitrogen and a small amount of oxygen, may be used to optimize cutting speed and quality for specific applications.

- Edge Quality and Taper: Titanium’s properties can lead to greater edge taper and surface roughness compared to other materials. Specialized strategies such as adjusting the laser beam focus, using the appropriate gas pressure, and modifying cutting speed are necessary to minimize taper and improve edge quality. These adjustments help ensure that the final cut is straight and precise with minimal heat-affected zones (HAZ).

- Material Distortion and Residual Stress: Titanium is known for its tendency to warp or distort when exposed to uneven heating. To mitigate this, specialized cutting strategies involve using lower laser powers, faster cutting speeds, and careful cooling techniques. This helps prevent excessive thermal stresses that can lead to warping or cracking, especially in precision applications.

Why Is Laser Cutting Titanium Prone To Oxidation?

- High Reactivity of Titanium: Titanium is known for its ability to react with oxygen at elevated temperatures, forming a layer of titanium oxide (TiO2) on its surface. This oxide layer can form quickly when titanium is heated by the laser beam during cutting. While titanium oxide provides some corrosion resistance, it can also negatively affect the cut’s appearance and quality, especially if the oxide layer becomes thick and uneven.

- Elevated Temperatures During Laser Cutting: Laser cutting involves applying a concentrated amount of energy to a small area of the material, rapidly heating it to extremely high temperatures. This intense heat causes the titanium surface to react with the oxygen in the air, leading to the formation of the titanium oxide layer. The higher the temperature and the longer the exposure, the greater the oxidation potential. Titanium’s melting point is also relatively high, so more heat is required to cut it, further increasing the likelihood of oxidation.

- Exposure to Atmospheric Oxygen: When cutting titanium, the material is exposed to atmospheric oxygen, which can easily react with the hot surface. Unlike some other metals that may form protective oxide layers under high heat, titanium forms a highly stable and thick oxide layer when it reacts with oxygen. This layer can compromise the aesthetic and functional quality of the cut, especially in applications requiring clean, smooth edges.

- Role of Assist Gases: The type of assist gas used during laser cutting plays a crucial role in preventing or promoting oxidation. Oxygen is often used as an assist gas in laser cutting because it can help enhance the cutting speed, especially for thicker materials. However, when cutting titanium, the presence of oxygen can exacerbate the oxidation process. To reduce oxidation, inert gases such as nitrogen are typically used to create a non-reactive environment, preventing the titanium from reacting with oxygen during the cutting process. If not managed properly, the use of oxygen can result in a poor-quality cut with thick oxide buildup.

- Inability to Evacuate Heat Quickly: Titanium has low thermal conductivity, meaning it does not dissipate heat as effectively as other metals. As a result, heat remains concentrated at the cutting zone for a longer period, increasing the time during which the material is exposed to the high temperature and oxygen, further promoting oxidation.

- Surface Contamination and Inconsistent Oxide Layers: Oxidation can also be inconsistent, depending on the cutting conditions. Areas where the laser cuts slowly or at a low power can have a thicker oxide layer, while faster cuts may result in minimal oxidation. Inconsistent oxide formation can lead to uneven surface quality and potentially affect the integrity of the material in applications where precision is critical.

Why Are Inert Gases Required For Laser Cutting Titanium?

- Prevention of Oxidation: Titanium reacts quickly with oxygen at high temperatures, forming titanium oxide (TiO2) on the surface. This oxide layer can degrade the cut quality, making the edges rough, discolored, or contaminated. Inert gases, such as nitrogen, help create a non-reactive environment during the cutting process, reducing the chance of oxidation. By preventing oxygen from interacting with the hot titanium surface, inert gases ensure cleaner, more precise cuts with minimal edge discoloration.

- Improved Cut Quality: When using inert gases, the cutting process can be controlled more precisely, leading to smoother edges and better surface finishes. The inert gases help stabilize the cutting zone, preventing the formation of unwanted oxide layers, which can cause uneven surfaces and weaken the material. This results in higher quality cuts with minimal post-processing required.

- Enhanced Cutting Speed and Efficiency: Using an inert gas, especially nitrogen, can help increase cutting speed and improve the overall cutting efficiency. Nitrogen, when used as an assist gas, aids in removing the molten material from the kerf (the gap created by the cut), preventing it from re-solidifying on the surface. This increases the speed of cutting and improves the overall productivity of the laser cutting process.

- Reduced Risk of Material Contamination: Inert gases protect the titanium from contamination during the laser cutting process. When oxygen is used as an assist gas, it can introduce contaminants such as rust or scale, which could compromise the integrity of the cut. Inert gases prevent such contamination, ensuring that the titanium’s properties remain intact and that the final product meets quality standards.

- Heat Management: Titanium has low thermal conductivity, meaning heat does not dissipate quickly. As a result, the material tends to heat up rapidly, which can lead to warping or distortion. Inert gases help to stabilize the cutting area by preventing excessive oxidation, and they can also assist in dissipating heat more evenly. This helps in managing the heat distribution and minimizes the risk of unwanted thermal stresses or distortion.

Why Does Laser Cutting Titanium Produce Excessive Heat-Affected Zones?

- High Melting Point of Titanium: Titanium has a high melting point (around 1,668℃ or 3,034℉), meaning it requires a significant amount of heat to melt. When laser cutting, the heat required to melt the material is concentrated in a small area, causing a large thermal gradient. The rapid heating and cooling of titanium lead to the creation of a wider heat-affected zone, as the heat spreads from the cut zone to the surrounding material. This concentrated energy leads to changes in the microstructure of titanium, increasing the size of the HAZ.

- Low Thermal Conductivity of Titanium: Titanium has relatively low thermal conductivity, which means it does not efficiently dissipate heat across its surface. As a result, when the laser beam heats the material, the heat tends to remain localized around the cut area, causing the surrounding material to heat up significantly. The poor heat transfer away from the cutting area contributes to a wider HAZ, as the surrounding material is subjected to elevated temperatures for longer periods.

- Laser Beam Energy and Cutting Speed: The laser cutting process involves focusing a high-intensity beam onto a small area of the material, and the energy must be absorbed by the material to melt it. The speed at which the laser moves, combined with the power and focus of the beam, determines how much heat is applied in a given area. If the cutting speed is too slow or the laser power is too high, more heat is applied, leading to a wider HAZ. The slower the cutting speed, the more time the material has to heat, increasing the likelihood of a larger HAZ.

- Use of Assist Gases: The choice of assist gas used during laser cutting also plays a role in the HAZ formation. For example, oxygen is often used to enhance the cutting speed, but it can increase the heat input to the material. While gases like nitrogen or argon help prevent oxidation, they may not help with managing the heat buildup. The type of assist gas and the pressure applied can influence how heat spreads during the cutting process, potentially exacerbating the heat-affected zone.

- Material Thickness: The thickness of the titanium being cut is also a significant factor in determining the size of the heat-affected zone. Thicker materials require more energy to melt, which results in a larger amount of heat being generated. As the material thickness increases, the cutting process may need to be adjusted to minimize the heat input, but even with optimized settings, the heat buildup in the thicker material can cause a wider HAZ.

- Titanium’s Susceptibility to Thermal Stress: Titanium is more susceptible to thermal stress due to its relatively high coefficient of thermal expansion. This means that rapid temperature changes can cause the material to expand and contract, which can lead to distortion, cracking, or warping in the HAZ. As the material around the cut area cools, it may also undergo phase transformations that can alter the material properties, resulting in unwanted mechanical properties or compromised structural integrity in the heat-affected zone.

Why Does Laser Cutting Titanium Increase Maintenance Frequency?

- High Heat Generation: Titanium has a high melting point, and laser cutting requires significant heat to melt the material. This intense heat can put a strain on the laser cutting system, especially the optics, nozzles, and other heat-sensitive components. The repeated exposure to high temperatures during titanium cutting can cause these components to degrade faster, leading to more frequent maintenance needs.

- Oxidation and Residue Build-Up: Titanium reacts with oxygen at elevated temperatures, leading to the formation of an oxide layer. While this layer can be controlled with inert gases, the cutting process still generates some oxidation and residue. This buildup can affect the cutting efficiency and performance of the laser cutting system. The optics, lenses, and nozzles may become contaminated, requiring regular cleaning or replacement.

- Abrasive Particles and Debris: During laser cutting, small titanium particles and debris are produced as the material is melted and vaporized. These particles can accumulate in various parts of the laser cutting machine, such as the nozzle, lenses, and gas lines. Over time, this debris can hinder the cutting process and damage machine components, necessitating frequent cleaning and maintenance to ensure the equipment operates efficiently.

- Increased Wear on Nozzles and Lenses: The laser cutting process for titanium can be abrasive, especially when high-energy lasers are used to cut through thick or hard titanium alloys. This leads to rapid wear on nozzles, lenses, and other precision components. The need for regular calibration, alignment, and replacement of these parts significantly increases the maintenance frequency of laser cutting machines used for titanium.

- Thermal Stress and Material Properties: Titanium has a relatively low thermal conductivity, meaning heat from the laser stays concentrated in the cut area longer. This leads to thermal stresses that can cause warping, distortion, or even crack formation in the material. The excess heat and pressure on the machine’s cutting components can cause them to degrade more quickly, which leads to more frequent repairs or replacements.

- Assist Gas Requirements: Laser cutting titanium typically requires specialized assist gases, such as nitrogen or argon, to prevent oxidation and improve the cut quality. These gases can cause additional wear on the gas delivery system, increasing the likelihood of leaks or blockages. Regular maintenance of the gas lines and pressure systems is essential to ensure consistent cutting performance.

Why Does Laser Cutting Titanium Require Higher Gas Purity?

- Prevention of Oxidation and Contamination: Titanium is highly reactive, particularly at elevated temperatures, and can easily form an oxide layer when exposed to oxygen. The presence of impurities in the assist gas, such as oxygen, moisture, or other contaminants, increases the risk of oxidation during the cutting process. A higher purity gas, typically nitrogen or argon, helps create an inert environment around the cutting area, minimizing the interaction between oxygen and the titanium surface. This reduces oxidation, ensuring clean, high-quality cuts without discoloration or surface contamination.

- Improved Cut Quality: Titanium’s unique properties, such as its low thermal conductivity, make it difficult to cut with precision. The use of high-purity gases helps in maintaining a consistent cutting environment by stabilizing the molten metal at the cutting edge. Impure gases can lead to inconsistencies in the cutting process, producing rough edges, poor surface finishes, or an uneven cut. Higher purity gases ensure smoother, more precise cuts, which are essential for applications requiring tight tolerances and high-quality results.

- Prevention of Nitride Formation: Titanium alloys are particularly susceptible to forming titanium nitride (TiN) when exposed to nitrogen at high temperatures. Nitride formation can compromise the material’s mechanical properties and result in an undesirable surface finish. By using highly pure nitrogen or other inert gases during laser cutting, the risk of forming titanium nitride is significantly reduced, resulting in better surface integrity and fewer defects in the final product.

- Enhanced Laser Efficiency and Cutting Speed: Using a higher purity gas can also improve the efficiency of the laser cutting process. Impurities in the gas can cause irregularities in the laser beam or interfere with the heat dissipation during cutting. High-purity gases provide a more stable cutting environment, which can increase cutting speeds and reduce the energy required for the process. This contributes to better performance and a more efficient use of the laser cutting system.

- Protection of Machine Components: Impurities in the assist gas can also cause corrosion or damage to the laser cutting equipment itself. For example, oxygen or moisture in the gas stream can affect the optics, nozzles, and lenses, leading to accelerated wear and tear. Using high-purity gases minimizes the risk of such damage, helping to extend the lifespan of the machine components and reduce the frequency of maintenance.

Why Does Laser Cutting Titanium Require Strict Fume Management?

- Harmful Fumes and Toxic Gases: Titanium, when exposed to the high temperatures of a laser cutting process, can release a variety of harmful fumes, including titanium oxide (TiO2), nitrogen oxides (NOx), and other volatile compounds. These gases can be toxic if inhaled and may cause respiratory issues for operators and workers nearby. Managing these fumes is essential to maintain a safe working environment and to comply with health and safety regulations. Without proper ventilation or filtration, the accumulation of these gases could lead to significant health hazards.

- Fine Particulate Matter (PM): Laser cutting titanium also produces fine particulate matter, including small titanium droplets and oxide particles, that can be harmful if inhaled or if they contaminate the workspace. These particles can affect the quality of the cut and cause equipment malfunction if they accumulate on sensitive components, like the laser optics and sensors. Proper fume extraction systems, such as high-efficiency particulate air (HEPA) filters, are necessary to remove these particles from the air, preventing contamination of both the workspace and the laser cutting machine.

- Equipment Protection and Longevity: Fumes generated during laser cutting can not only pose a health risk but also contribute to the wear and tear of laser cutting equipment. Oxidation, corrosion, and residue buildup from the fumes can clog filters, nozzles, and cooling systems, leading to inefficient operation and increased maintenance requirements. Strict fume management helps to protect the laser cutting machine from damage, extends its lifespan, and reduces the frequency of costly repairs and downtime.

- Ensuring Cut Quality: The presence of fumes and particulates in the cutting zone can also affect the quality of the laser cut. As these materials interfere with the laser beam or block the gas flow, they can lead to irregular cuts, rough edges, or even incomplete cuts. By effectively managing the fumes, the cutting process becomes cleaner and more efficient, ensuring higher precision and superior cut quality.

- Regulatory Compliance: In many regions, strict regulations govern the emission of hazardous fumes and particulates from industrial operations. These regulations require businesses to implement effective fume extraction and filtration systems to reduce the environmental impact of their operations. Compliance with these standards not only protects workers but also avoids potential fines or legal action for exceeding allowable emission limits.

Why Is The Edge Color Inconsistent When Laser Cutting Titanium?

- Heat-Affected Zone (HAZ) and Oxidation: Titanium is highly reactive to heat, and laser cutting involves extremely high temperatures that can cause the material to oxidize. The varying levels of heat applied during the cutting process can lead to different amounts of oxidation along the edge, resulting in color inconsistency. The heat-affected zone (HAZ), where the material is exposed to intense laser energy, will often exhibit more pronounced oxidation, causing colors like blue or purple to form. Inconsistent cooling and gas flow around the cutting area can amplify these effects, causing patches of differing colors along the cut.

- Assist Gas Type and Pressure: The type of assist gas used during laser cutting also plays a significant role in determining the edge color. Inert gases like nitrogen are commonly used for titanium cutting to prevent oxidation, while oxygen may be used to assist in the cutting process, especially when higher cutting speeds are needed. The use of oxygen can result in more noticeable oxidation, leading to darker edge colors. Variations in assist gas pressure and flow rates can cause inconsistent gas coverage, further contributing to uneven oxidation and edge color.

- Laser Power and Speed Settings: Laser cutting parameters such as power, speed, and focus have a direct impact on the heat distribution and cooling rate during the cut. If the laser power is too high or the cutting speed too slow, the titanium may overheat and produce excessive oxidation, resulting in a darker or more colorful edge. Conversely, too low a laser power or too fast a cutting speed may not produce enough heat to cut cleanly, leading to incomplete cuts and inconsistent coloring along the edges.

- Material Quality and Surface Condition: Titanium’s surface condition before cutting also affects the final edge color. Variations in surface cleanliness, such as oil, dirt, or residual coatings, can interfere with the laser’s ability to cut consistently, leading to areas of uneven oxidation and color. The quality of the titanium material, such as the presence of impurities or alloying elements, can also influence how the material reacts to heat and oxygen, further contributing to inconsistent edge coloration.

- Post-Cutting Processes: Sometimes, the color inconsistency can also be influenced by post-cutting processes. If the titanium is exposed to different environmental conditions (such as humidity or exposure to chemicals) after cutting, it may undergo further oxidation, causing the edge color to change. Additionally, using cleaning agents or methods to remove residue may alter the appearance of the edge, introducing further color variation.