Introduction

Advantages of Laser Cutting Textile

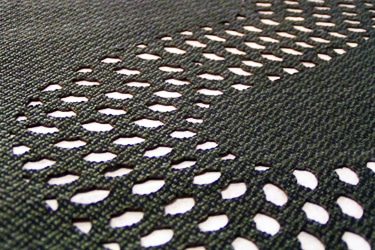

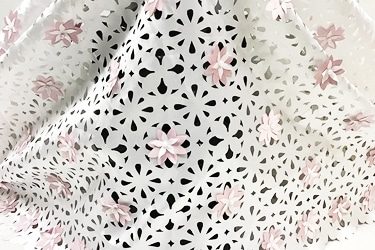

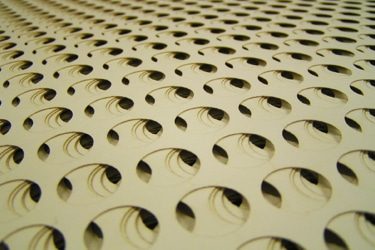

High Precision and Detail

Laser cutting textile provides exceptional accuracy, allowing intricate patterns, fine details, and complex shapes to be cut consistently. Digital control ensures repeatable results, making it ideal for detailed designs in fashion, upholstery, and technical textile applications.

Non-Contact Cutting Process

Because laser cutting textiles is a non-contact method, textiles are not stretched, pulled, or distorted during cutting. This helps maintain material shape and structure, especially for lightweight, elastic, or delicate textile materials.

Sealed and Clean Edges

Laser cutting textile can seal the edges of synthetic textiles as it cuts, reducing fraying and loose fibers. This improves the appearance and durability of textile parts and minimizes the need for additional edge finishing.

High Design Flexibility

Laser cutting textile supports quick design changes using digital files without new tools. Complex patterns, perforations, and custom shapes can be easily produced, making it ideal for prototyping, customization, and small-batch production.

Reduced Material Waste

The narrow kerf width and precise control of laser cutting textile allow efficient nesting of parts on textile rolls or sheets. This maximizes material usage, reduces scrap, and helps lower overall production costs.

Fast and Efficient Production

Laser cutting textile offers high cutting speeds and minimal setup time. Automated operation improves productivity, ensures consistent quality, and helps manufacturers meet tight delivery schedules while maintaining reliable results.

Compatible Materials

- Cotton

- Polyester

- Silk

- Wool

- Nylon

- Spandex

- Acrylic Fabric

- Denim

- Canvas

- Felt

- Fleece

- Lycra

- Microfiber

- Velvet

- Satin

- Tulle

- Lace

- Chiffon

- Organza

- Rayon

- Modal

- Hemp Fabric

- Bamboo Fabric

- Jersey Knit

- Suede

- Leather

- Faux Leather

- Neoprene

- PVC-Coated Fabric

- Mesh Fabric

- Upholstery Fabric

- Upholstery Vinyl

- Technical Textiles

- Softshell Fabric

- Nonwoven Fabric

- Aramid

- Carbon Fiber Fabric

- Filter Fabric

- Embroidered Textiles

- Reflective Textile Film

Laser Cutting Textile VS Other Cutting Methods

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Textiles | Highly suitable | Poor | Very suitable | Limited |

| Cutting Precision | Very high | Medium | Medium | High |

| Edge Quality | Clean, sealed (synthetics) | Rough edges | Clean but unsealed | Clean but wet |

| Material Deformation | None (non-contact) | High risk | Medium | None |

| Fraying Control | Excellent on synthetics | Poor | Medium | Poor |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High | Moderate | High | Slow |

| Thickness Capability | Thin to medium textiles | Limited | Thin textiles | Thin to thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent for complex patterns | Limited | Limited | Good |

| Automation and Repeatability | Excellent | Good | Good | Good |

| Overall Efficiency for Textile Processing | Excellent | Poor | Good | Fair |

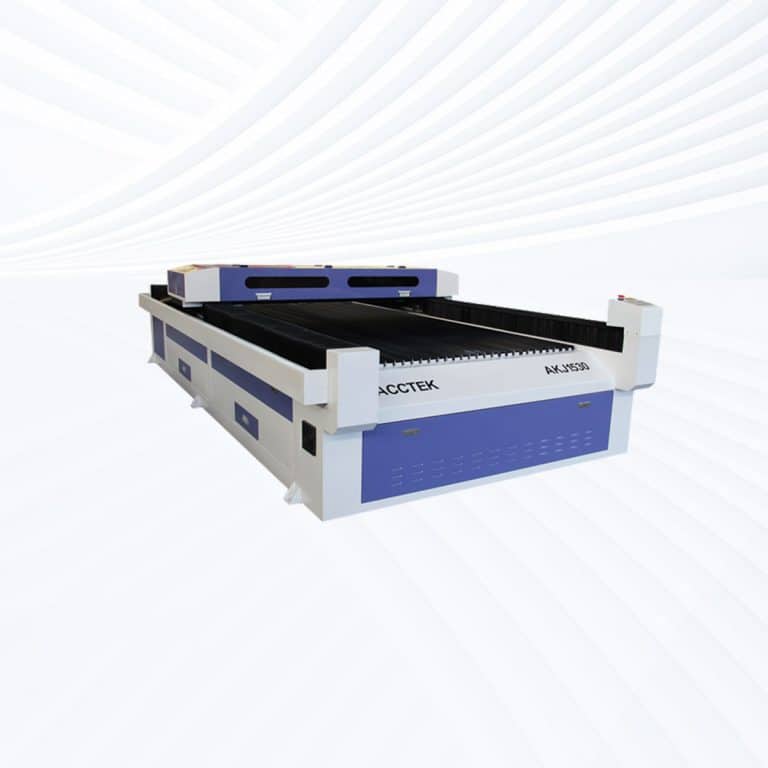

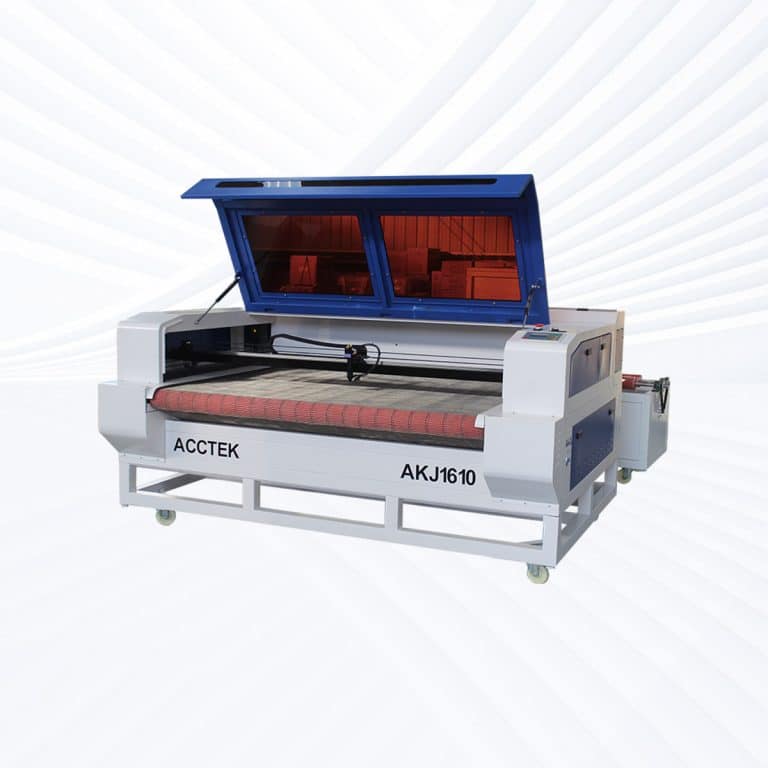

Laser Cutting Capacity

| Power/Material | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plywood | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| MDF | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Solid Wood | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cork Sheet | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Bamboo Board | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Laminates | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Acrylic (PMMA) | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| ABS | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Delrin (POM) | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Composite | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| EVA Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Depron Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Gator Foam | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cardboard | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Stone | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

| Leather | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Textile | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Nylon | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Felt | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Rubber | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Ceramic | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

Applications of Laser Cutting Textile

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

Why Can Laser Energy Penetrate Loosely Woven Textiles?

- Light Transmission Through Loosely Woven Textiles: Loosely woven textiles have more gaps between the individual fibers compared to tightly woven textiles. These gaps create larger spaces for the laser beam to pass through, allowing more energy to penetrate the material. When the laser hits these areas, the energy is absorbed by the fibers, causing localized heating and vaporization of the material. The reduced density in these areas means the laser can more easily affect the material without encountering significant resistance.

- Reduced Reflection and Scattering: Textiles with looser weaves have less compactness, which results in less reflection and scattering of the laser beam. When the material is dense or tightly woven, the laser energy may scatter or reflect off the fibers, reducing the amount of energy absorbed by the textile. In contrast, loosely woven textiles allow more of the laser energy to reach the fibers, facilitating the cutting process.

- Thermal Penetration and Vaporization: Laser cutting works by focusing high-intensity light onto a small area, which generates enough heat to melt or vaporize the material. In loosely woven textiles, the lack of dense material structure means the energy can penetrate deeply into the textile without significant interference. The laser energy heats the fibers in the textile, causing them to melt or vaporize at the point of contact, creating a clean cut.

- Effect of Fiber Composition: The type of material that the textile is made of also influences how well the laser can penetrate. For example, natural fibers like cotton or wool absorb laser energy more effectively than synthetic fibers. This makes them easier to cut, especially when the textile is loosely woven, as the fibers can quickly absorb heat and vaporize.

- Uniformity of Cut: In loosely woven textiles, the laser beam’s ability to penetrate helps to achieve a more uniform cut. Tightly woven or denser textiles might create more resistance and uneven heating, leading to less precise cuts. The flexibility and relatively low resistance of loosely woven textiles allow the laser to cut through with minimal distortion, making them easier to work with.

Why Does Laser-Cut Textile Melt?

- High Heat Generation: A CO2 laser operates by emitting a concentrated beam of infrared light. When the laser hits the textile, the energy is absorbed by the material, causing the temperature at the point of contact to rise rapidly. Textiles, especially synthetic materials such as polyester, nylon, and acrylic, have a relatively low melting point, meaning they begin to melt when exposed to the high heat of the laser. This heat also causes the surrounding fibers to soften, leading to the melted appearance at the edges of the cut.

- Material Composition: Different textiles respond to laser cutting differently depending on their composition. Natural fibers, such as cotton, tend to burn more than melt, whereas synthetic fibers like polyester or nylon melt when exposed to the laser’s heat. These synthetic fibers are made from plastic polymers that, when heated by the laser, turn into a molten state before solidifying again once the laser moves away. This results in melting around the edges of the cut. Textiles with higher synthetic content are more prone to melting compared to those made from purely natural fibers.

- Laser Settings: The intensity and speed of the laser also play a significant role in whether a textile will melt. If the laser’s power is too high or the cutting speed is too slow, the heat exposure can be prolonged, causing more material to melt and resulting in uneven edges. Conversely, if the settings are optimized for the material being cut, the laser can cut through the textile cleanly with minimal melting. Improper settings can lead to undesirable outcomes, like excessive melting, charring, or frayed edges.

- Textile Thickness and Density: Thicker or denser textiles absorb more heat, which increases the likelihood of melting. Thin textiles may not have enough material to absorb enough energy for melting, but thicker, denser textiles, especially synthetic ones, accumulate more heat, resulting in the melting of fibers along the cut line.

- Lack of Cooling Mechanism: Unlike other materials that may have cooling systems or air assist to minimize heat buildup, textile cutting often lacks the necessary cooling, leading to localized melting. Some textiles may also trap heat due to their porous structure, which exacerbates the melting effect.

Why Is The Heat-Affected Zone Of Laser-Cut Textile Wide?

- Thermal Conduction in Textiles: Textiles, especially natural and synthetic fibers, have relatively low thermal conductivity, meaning heat spreads across the material more slowly but stays localized. When a CO2 laser cuts through the textile, the energy is absorbed at the cut site, raising the temperature in the immediate area. Due to the low thermal conductivity, the heat can spread out from the cut and affect a wider portion of the textile. This leads to a larger heat-affected zone around the laser’s focal point, as the heat doesn’t dissipate quickly enough to be contained to a smaller area.

- Longer Exposure Time: Unlike materials like metal, which conduct heat away from the cutting point quickly, textile tends to absorb and hold heat longer, especially if they’re made from synthetic materials. This prolonged exposure time causes the heat to penetrate more deeply into the fibers and the surrounding area, expanding the width of the heat-affected zone. In the case of dense textiles or multi-layer materials, this effect can be even more pronounced.

- Textile Composition: Different textiles respond to heat differently, which can affect the size of the heat-affected zone. Synthetic fibers, such as polyester and nylon, have lower melting points compared to natural fibers like cotton. These synthetic materials tend to melt and deform at the laser’s focal point, causing the surrounding area to experience high temperatures for a longer duration. On the other hand, natural fibers might char or burn instead of melting, but they still experience heat diffusion, leading to a wider HAZ.

- Laser Power and Cutting Speed: The settings on the laser cutting machine also influence the size of the heat-affected zone. A higher laser power or slower cutting speed increases the amount of heat generated at the cut site, leading to a wider HAZ. If the laser energy is not properly controlled, the excess heat can cause unwanted changes to the textile, including warping, excessive melting, or even discoloration in the surrounding material.

- Laser Beam Interaction with the Material: The way the laser beam interacts with the textile is another contributing factor. CO2 lasers operate by emitting infrared light, which is absorbed by the textile, converting it into heat. In loose, porous textiles, the laser beam can penetrate more deeply, affecting a larger area. This can further increase the HAZ, particularly in delicate materials that can’t dissipate heat effectively.

Why Does Laser-Cut Textile Reduce Tear Strength?

- Thermal Damage to Fibers: The CO2 laser generates intense heat at the point of contact with the textile. This heat causes the fibers to melt, burn, or warp, depending on the material composition. For synthetic textiles like polyester or nylon, the laser’s heat can cause the fibers to soften and lose their strength. Even for natural textiles like cotton, the laser can scorch the fibers, which reduces their load-bearing capacity. The affected fibers in the cut zone are more susceptible to breakage under stress, leading to a decrease in tear strength.

- Loss of Material Integrity: When a laser cuts through a textile, it essentially severs the fibers. While this cut is clean and precise, it disrupts the continuity of the material. Textiles rely on the alignment of their fibers to distribute stress and force evenly across the surface. Laser cutting creates a weak point along the cut, and because the fibers are no longer intact at that location, the textile is more likely to tear or rupture under load. This reduction in fiber integrity significantly weakens the material’s overall tear strength.

- Thermal Expansion and Shrinkage: Laser cutting involves a rapid thermal process that causes local expansion of the textile around the cut. As the material cools, it may shrink or contract, altering the structure of the fibers around the cut. This shrinkage further weakens the textile, as the fibers are now under additional stress in a region that has been thermally affected. The combination of thermal expansion and contraction can make the textile more prone to tearing, especially in areas with significant heat exposure.

- Edge Behavior and Fraying: Laser cutting often results in a smooth edge, but for certain textiles, especially those with loosely woven or knit structures, the edges may become more prone to fraying after the heat treatment. When fibers become loose or dislodged due to melting or shrinkage, they compromise the textile’s ability to resist tearing. These weakened edges contribute to the overall reduction in tear strength.

Why Are The Edges Of Laser-Cut Textile Rough?

- Thermal Effects on the Textile: Laser cutting generates intense heat, which causes the textile fibers to melt at the point of contact. For synthetic textiles like polyester or nylon, this can result in a slight deformation or “melting” of the fibers at the cut edges. While the laser is effective at creating a clean cut, the heat can cause some fibers to shrink, become uneven, or fray, leading to roughness at the edges. This is especially true for textiles that don’t have a tightly woven structure, as the edges are more prone to pulling apart or being unevenly affected by the heat.

- Fiber Behavior and Fraying: Textile is made of fibers, which can unravel or fray when exposed to heat or friction. When the laser interacts with the textile, the surrounding fibers that aren’t directly cut may be loosened or damaged, causing them to fray. This results in uneven or rough edges. Natural fibers like cotton are particularly prone to fraying when exposed to the heat of the laser, as the material may not have the same heat resistance as synthetic fibers.

- Laser Settings and Speed: The settings of the laser cutting machine, such as the speed, power, and focal point, can influence the edge quality. If the laser power is too high or the cutting speed is too slow, excessive heat may be applied to the textile, increasing the likelihood of rough, burned, or melted edges. A slower cutting speed can lead to a more pronounced heat-affected zone, which can make the edges more irregular and rough. Additionally, improper calibration or alignment of the laser can result in uneven cuts, further contributing to rough edges.

- Textile Composition and Thickness: The composition and thickness of the textile also play a significant role in edge quality. Thicker textiles or those made from more complex blends of fibers may absorb more heat, leading to more pronounced thermal damage at the edges. Similarly, loosely woven textiles are more susceptible to irregular melting, which can cause roughness or distortion along the cut lines.

Why Does Laser-Cut Textile Release Toxic Gases?

- Composition of Synthetic textiles: Many textiles are made from synthetic fibers such as polyester, nylon, and acrylic. These fibers are derived from petrochemicals and, when subjected to the intense heat of a CO2 laser, can break down and release harmful fumes. For example, polyester can release volatile organic compounds (VOCs) like styrene, acetaldehyde, and formaldehyde, while acrylic fibers may emit hazardous gases such as hydrogen cyanide. These gases are toxic and pose serious health risks if inhaled.

- Chemical Treatments on Textiles: Textiles often undergo chemical treatments during manufacturing, such as dyes, finishes, and flame retardants. These treatments can interact with the laser heat and release noxious gases when the textiles are cut. For example, certain dyes or chemical finishes used to enhance textile performance (like water repellency or anti-wrinkle treatments) can break down under the laser’s heat, releasing volatile chemicals, including formaldehyde and other potentially carcinogenic substances.

- Heat-Induced Decomposition: The laser cutting process involves high temperatures that cause textiles to melt, vaporize, and decompose. During this decomposition, not only do the fibers themselves break down, but the chemicals used in manufacturing (such as stabilizers, plasticizers, and other additives) also break down into gases. The decomposition of synthetic fibers, in particular, leads to the release of toxic fumes. The high temperature can cause polymers in the textiles to degrade, further exacerbating the release of toxic fumes.

- Incomplete Combustion and Soot Formation: If the laser cutting process is not optimized for the material, incomplete combustion can occur. This results in the production of smoke and particulate matter that can contain harmful compounds. For example, burning synthetic textiles can produce soot, which may contain carbon particles and other toxic substances that can be harmful if inhaled.

- Material Blends: Many textiles are blends of natural and synthetic fibers, such as cotton-polyester blends. In these cases, the natural fibers like cotton, when burned, may release carbon monoxide and other gases, while the synthetic fibers release their own set of toxic fumes. This combination increases the complexity of the gases released during the laser cutting process.

Why Is Personal Protective Equipment Needed For Laser-Cut Textile?

- Fume and Smoke Exposure: When textiles, especially synthetic textiles like polyester, acrylic, or vinyl, are cut with CO2 lasers, they can release hazardous fumes and gases. These fumes may include toxic compounds such as formaldehyde, acrolein, and volatile organic compounds (VOCs), which can be harmful when inhaled. Wearing a respirator or face mask helps to filter out harmful particulates and gases, reducing the risk of respiratory issues.

- Eye Protection: The intense light and infrared radiation produced by CO2 lasers can cause severe damage to the eyes if exposed directly. Laser light is invisible, making it difficult to detect, and can cause serious injuries if not properly controlled. Special laser safety glasses or goggles are essential to protect the eyes from both the laser beam and the intense light emitted during the cutting process.

- Skin Protection: The laser beam can also pose a risk of burns if it makes contact with the skin, either through accidental exposure to reflected beams or from the material being cut. Materials like synthetic textiles may catch fire or smolder, leading to additional burn hazards. Gloves and flame-resistant clothing are recommended to protect the skin from heat, sparks, and possible flames.

- Fire Risk: Cutting textiles, particularly flammable materials such as cotton, polyester, or felt, can present a significant fire hazard. Sparks or heat buildup may ignite the material, and this risk is exacerbated when working with flammable textiles or improperly controlled machines. Fire-resistant gloves and clothing, along with proper ventilation and fire safety protocols, are critical to mitigate this danger.

- Noise Exposure: Although not always significant, laser cutting can generate noise that could contribute to hearing damage with prolonged exposure. Ear protection may be necessary in high-noise environments to prevent hearing loss.

Why Does Laser-Cut Textile Pose Fire Hazards?

- Flammability of Textile Materials: Many textiles, particularly natural fibers like cotton and synthetic fabrics such as polyester, are highly flammable. When exposed to the intense heat from a CO2 laser, these materials can ignite quickly. The laser beam, which is concentrated and intense, provides enough heat to cause flammable materials to catch fire, especially if the laser settings are not properly adjusted for the type of textile being cut.

- Heat Build-up: The laser cutting process involves focusing a concentrated beam of light onto the textile, which generates significant heat. The heat is absorbed by the textile, and if it is not quickly dissipated, it can cause localized areas to ignite. Textiles with low heat resistance or those that are thicker may absorb more heat and ignite more easily, especially if the laser is cutting too slowly or with excessive power.

- Presence of Synthetic Fibers: Many textiles contain synthetic fibers like nylon, polyester, or acrylic, which are particularly prone to ignition under high heat. When these fibers are exposed to the laser, they can melt and catch fire, producing toxic fumes and increasing the fire risk. Synthetic materials can also release harmful gases when burned, such as formaldehyde, which can exacerbate the danger.

- Lack of Supervision and Ventilation: The fire risk is heightened if the laser cutting process is not closely monitored. Textiles are often highly flammable and may ignite quickly if left unattended. Additionally, without proper air assist or ventilation, the heat and smoke generated during the cutting process can accumulate, raising the likelihood of a fire. Air assist systems help by cooling the cutting area and removing the heat and smoke, which significantly reduces fire risks.

- Accumulation of Flammable Debris: As the laser cuts through the textile, small fibers, dust, and other debris are produced. These particles can accumulate in and around the cutting area, creating additional fire hazards. If the debris is not cleared away, it can catch fire from the laser’s heat, causing a flare-up.