Introduction

Advantages of Laser Cutting Stainless Steel

High Precision and Accuracy

Laser cutting offers exceptional precision, allowing for tight tolerances and intricate details when working with stainless steel. This high accuracy is essential for applications in industries like aerospace and medical devices, where component integrity is crucial.

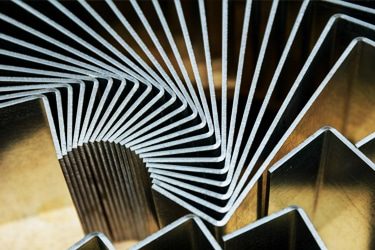

Clean, Smooth Edges

The laser cutting process creates smooth, burr-free edges with minimal oxidation. This reduces or eliminates the need for post-processing, saving time and labor while ensuring high-quality finishes for stainless steel parts used in visible or functional applications.

Minimal Heat-Affected Zone

Laser cutting generates a narrow heat-affected zone, which helps maintain the material's mechanical properties. This is particularly important for stainless steel, as excessive heat can weaken the material, leading to distortion or loss of strength.

Fast Cutting Speed

Laser cutting stainless steel is a fast process, particularly when working with thinner sheets. The high cutting speed reduces production time, increases throughput, and allows manufacturers to meet tight deadlines, making it ideal for high-volume production.

Ability to Cut Complex Shapes

Laser cutting allows for the creation of intricate shapes and fine details in stainless steel without the need for special tooling. This flexibility makes it an excellent choice for custom parts, complex designs, and prototypes.

Reduced Material Waste

With the narrow kerf width produced by laser cutting, material waste is minimized, improving efficiency and lowering production costs. Advanced nesting software can further optimize material usage, ensuring the best possible use of stainless steel sheets.

Compatible Materials

- 304 Stainless Steel

- 304L Stainless Steel

- 316 Stainless Steel

- 316L Stainless Steel

- 316Ti Stainless Steel

- 310 Stainless Steel

- 310S Stainless Steel

- 321 Stainless Steel

- 321H Stainless Steel

- 347 Stainless Steel

- 347H Stainless Steel

- 409 Stainless Steel

- 410 Stainless Steel

- 420 Stainless Steel

- 430 Stainless Steel

- 430F Stainless Steel

- 440C Stainless Steel

- 201 Stainless Steel

- 202 Stainless Steel

- 2205 Duplex Stainless Steel

- 2507 Super Duplex Stainless Steel

- 904L Stainless Steel

- 17-4 PH Stainless Steel

- 17-7 PH Stainless Steel

- 253MA Stainless Steel

- S32750 Super Duplex Stainless Steel

- S31803 Duplex Stainless Steel

- 15-5 PH Stainless Steel

- 17-12-2 Stainless Steel

- 14-8 Stainless Steel

- AISI 430 Stainless Steel

- AISI 904L Stainless Steel

- AISI 310S Stainless Steel

- Alloy 20 Stainless Steel

- Nitronic 50 Stainless Steel

- Nitronic 60 Stainless Steel

- 2205 Stainless Steel

- 254SMO Stainless Steel

- 904L Stainless Steel

- AM355 Stainless Steel

Laser Cutting Stainless Steel VS Other Cutting Methods

| Comparison Item | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Cutting Precision | Very high accuracy | Moderate to low | Very high accuracy | Low precision |

| Edge Quality | Smooth, clean, burr-free | Rough edges, dross | Smooth but slightly matte | Rough, oxidized edges |

| Heat-Affected Zone | Minimal | Large | None (cold cutting) | Very large |

| Cutting Speed | Fast, especially on thin sheets | Moderate | Slow | Very slow |

| Material Thickness Range | Thin to medium thickness | Medium to thick materials | Thin to very thick materials | Thick materials only |

| Detail & Complexity | Excellent for fine details | Limited detail | Excellent for intricate cuts | Very limited |

| Kerf Width | Narrow | Wide | Moderate | Wide |

| Secondary Finishing | Minimal or none required | Often required | Rarely required | Always required |

| Suitability for Stainless Steel | Excellent, minimal oxidation | Poor, oxidation likely | Excellent, no oxidation | Poor, oxidation and coating damage |

| Reflective Material Handling | Designed with reflection control | Poor for reflective materials | No reflection issues | Not applicable |

| Operating Cost | Moderate | Low | High | Low |

| Equipment Investment | Moderate to high | Low to moderate | High | Low |

| Automation Capability | Highly automated CNC | CNC capable | CNC capable | Mostly manual |

| Environmental Impact | Low emissions, clean process | High fumes and noise | Water and abrasive waste | High smoke and gases |

| Cutting Quality Consistency | Excellent for repeatability | Inconsistent quality | Very consistent | Inconsistent |

Laser Cutting Capacity For Stainless Steel

| Laser Power | Material Thickness (mm) | Cutting Speed (m/min) | Actual Laser Power (W) | Gas | Pressure (bar) | Nozzle Size (mm) | Focus Position (mm) | Cutting Height (mm) |

|---|---|---|---|---|---|---|---|---|

| 1KW | 1 | 15-18 | 1000 | N2 | 10 | 2.0S | 0 | 0.8 |

| 2 | 4-4.5 | 1000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 1.5-2 | 1000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 4 | 1-1.3 | 1000 | N2 | 15 | 2.5S | -1.5 | 0.5 | |

| 1 | 18-20 | 1000 | Air | 10 | 2.0S | 0 | 0.8 | |

| 2 | 5-6 | 1000 | Air | 10 | 2.0S | 0 | 0.5 | |

| 3 | 2-2.5 | 1000 | Air | 10 | 2.0S | -1 | 0.5 | |

| 4 | 1.5-1.7 | 1000 | Air | 10 | 2.5S | -1.5 | 0.5 | |

| 1.5KW | 1 | 20 | 1500 | N2 | 10 | 1.5S | 0 | 0.8 |

| 2 | 7 | 1500 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 4.5 | 1500 | N2 | 12 | 2.5S | -1.5 | 0.5 | |

| 5 | 1.5 | 1500 | N2 | 14 | 3.0S | -2.5 | 0.5 | |

| 2KW | 1 | 28 | 2000 | N2 | 10 | 1.5S | 0 | 0.8 |

| 2 | 10 | 2000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 5 | 2000 | N2 | 12 | 2.0S | -1.5 | 0.5 | |

| 4 | 3 | 2000 | N2 | 14 | 2.5S | -2 | 0.5 | |

| 5 | 2 | 2000 | N2 | 14 | 3.0S | -2.5 | 0.5 | |

| 6 | 1.5 | 2000 | N2 | 14 | 3.0S | -3 | 0.5 | |

| 3KW | 1 | 28-35 | 3000 | N2 | 10 | 1.5S | 0 | 0.8 |

| 2 | 18-24 | 3000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 7-10 | 3000 | N2 | 12 | 2.5S | -0.5 | 0.5 | |

| 4 | 5-6.5 | 3000 | N2 | 14 | 2.5S | -1.5 | 0.5 | |

| 5 | 3-3.6 | 3000 | N2 | 14 | 3.0S | -2.5 | 0.5 | |

| 6 | 2-2.7 | 3000 | N2 | 14 | 3.0S | -3 | 0.5 | |

| 8 | 1-1.2 | 3000 | N2 | 16 | 3.5S | -4.5 | 0.5 | |

| 4KW | 1 | 30-40 | 4000 | N2 | 10 | 1.5S | 0 | 0.8 |

| 2 | 15-20 | 4000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 10-12 | 4000 | N2 | 12 | 2.0S | -1.5 | 0.5 | |

| 4 | 6-7 | 4000 | N2 | 12 | 2.5S | -2 | 0.5 | |

| 5 | 4-4.5 | 4000 | N2 | 14 | 2.5S | -2.5 | 0.5 | |

| 6 | 3-3.5 | 4000 | N2 | 14 | 3.0S | -3 | 0.5 | |

| 8 | 1.5-1.8 | 4000 | N2 | 14 | 3.0S | -4 | 0.5 | |

| 10 | 1-1.2 | 4000 | N2 | 16 | 4.0S | -5 | 0.5 | |

| 6KW | 1 | 40-50 | 6000 | N2 | 10 | 1.5S | 0 | 0.8 |

| 2 | 25-30 | 6000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 15-18 | 6000 | N2 | 12 | 2.5S | -1.5 | 0.5 | |

| 4 | 10-12 | 6000 | N2 | 14 | 2.5S | -2 | 0.5 | |

| 5 | 7-8 | 6000 | N2 | 14 | 3.0S | -2.5 | 0.5 | |

| 6 | 6-7 | 6000 | N2 | 15 | 3.0S | -3 | 0.5 | |

| 8 | 3.5-3.8 | 6000 | N2 | 15 | 3.0S | -4 | 0.5 | |

| 10 | 1.6-2 | 6000 | N2 | 15 | 3.5S | -6 | 0.5 | |

| 12 | 1-1.2 | 6000 | N2 | 16 | 3.5S | -7.5 | 0.5 | |

| 14 | 0.8-1 | 6000 | N2 | 16 | 4.0S | -9 | 0.5 | |

| 16 | 0.5-0.6 | 6000 | N2 | 18 | 4.0S | -10.5 | 0.5 | |

| 18 | 0.4-0.5 | 6000 | N2 | 20 | 5.0S | -11 | 0.3 | |

| 12KW | 1 | 50-60 | 12000 | N2 | 10 | 2.0S | 0 | 1 |

| 2 | 40-45 | 12000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 30-35 | 12000 | N2 | 13 | 2.0S | 0 | 0.5 | |

| 4 | 22-26 | 12000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 5 | 15-18 | 12000 | N2 | 15 | 2.5S | 0 | 0.5 | |

| 6 | 13-15 | 12000 | N2 | 8 | 3.5B | 0 | 0.5 | |

| 8 | 8-10 | 12000 | N2 | 7 | 5.0B | 0 | 0.5 | |

| 10 | 6.5-7.5 | 12000 | N2 | 5 | 5.0B | -1 | 0.5 | |

| 12 | 5-5.5 | 12000 | N2 | 6 | 6.0B | -4 | 0.5 | |

| 14 | 3-3.5 | 12000 | N2 | 6 | 7.0B | -6 | 0.3 | |

| 16 | 2-2.3 | 12000 | N2 | 6 | 7.0B | -8 | 0.3 | |

| 18 | 1.3-1.5 | 12000 | N2 | 6 | 7.0B | -9 | 0.5 | |

| 20 | 1.2-1.4 | 12000 | N2 | 6 | 7.0B | -11 | 0.3 | |

| 25 | 0.7-0.9 | 12000 | N2 | 6 | 7.0B | -13 | 0.3 | |

| 1 | 50-60 | 12000 | Air | 10 | 2.0S | 0 | 1 | |

| 2 | 40-45 | 12000 | Air | 10 | 2.5S | 0 | 0.5 | |

| 3 | 30-35 | 12000 | Air | 10 | 2.5S | 0 | 0.5 | |

| 4 | 22-28 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 5 | 16-19 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 6 | 14-17 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 8 | 9-11 | 12000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 10 | 7-8 | 12000 | Air | 10 | 3.5B | -1 | 0.5 | |

| 12 | 5.5-6 | 12000 | Air | 10 | 5.0B | -4 | 0.5 | |

| 14 | 3.5-4 | 12000 | Air | 10 | 5.0B | -6 | 0.5 | |

| 16 | 2.2-2.4 | 12000 | Air | 10 | 5.0B | -8 | 0.5 | |

| 18 | 1.3-1.6 | 12000 | Air | 10 | 5.0B | -9 | 0.5 | |

| 20 | 1.2-1.5 | 12000 | Air | 10 | 5.0B | -11 | 0.3 | |

| 25 | 0.7-1 | 12000 | Air | 10 | 5.0B | -13 | 0.3 | |

| 20KW | 1 | 50-60 | 12000 | N2 | 8 | 2.0S | 0 | 1 |

| 2 | 50-60 | 12000 | N2 | 8 | 2.0S | 0 | 0.5 | |

| 3 | 40-45 | 20000 | N2 | 8 | 2.5S | 0 | 0.5 | |

| 4 | 30-35 | 20000 | N2 | 8 | 2.5S | 0 | 0.5 | |

| 5 | 22-24 | 20000 | N2 | 8 | 3.0S | 0 | 0.5 | |

| 6 | 18-22 | 20000 | N2 | 8 | 3.5B | 0 | 0.5 | |

| 8 | 13-16 | 20000 | N2 | 8 | 5.0B | -1 | 0.5 | |

| 10 | 10-12 | 20000 | N2 | 8 | 5.0B | -1.5 | 0.3 | |

| 12 | 8-10 | 20000 | N2 | 8 | 6.0B | -2 | 0.5 | |

| 14 | 6-8 | 20000 | N2 | 8 | 6.0B | -4 | 0.3 | |

| 16 | 5-6 | 20000 | N2 | 8 | 6.0B | -5 | 0.3 | |

| 18 | 3.2-4 | 20000 | N2 | 8 | 6.0B | -6 | 0.3 | |

| 20 | 3-3.2 | 20000 | N2 | 12 | 6.0B | -7.5 | 0.3 | |

| 25 | 1.5-2 | 20000 | N2 | 12 | 7.0B | -12 | 0.3 | |

| 30 | 1-1.2 | 20000 | N2 | 12 | 7.0B | -16 | 0.3 | |

| 40 | 0.5-0.8 | 20000 | N2 | 16 | 7.0B | -16 | 0.3 | |

| 1 | 50-60 | 12000 | Air | 8 | 2.0S | 0 | 1 | |

| 2 | 50-60 | 12000 | Air | 8 | 2.5S | 0 | 0.5 | |

| 3 | 40-45 | 20000 | Air | 8 | 2.5S | 0 | 0.5 | |

| 4 | 30-35 | 20000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 5 | 22-24 | 20000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 6 | 18-22 | 20000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 8 | 13-16 | 20000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 10 | 11-13 | 20000 | Air | 10 | 3.5B | -1.5 | 0.3 | |

| 12 | 9-11 | 20000 | Air | 10 | 5.0B | -4 | 0.3 | |

| 14 | 7-9 | 20000 | Air | 10 | 5.0B | -6 | 0.3 | |

| 16 | 6-7 | 20000 | Air | 10 | 5.0B | -7 | 0.3 | |

| 18 | 3.5-4.5 | 20000 | Air | 10 | 5.0B | -8 | 0.3 | |

| 20 | 3.5-4.5 | 20000 | Air | 10 | 5.0B | -9 | 0.3 | |

| 25 | 1.8-2.5 | 20000 | Air | 10 | 5.0B | -13 | 0.3 | |

| 30 | 1.4-1.6 | 20000 | Air | 10 | 5.0B | -17 | 0.3 | |

| 40 | 0.5-0.8 | 20000 | Air | 16 | 7.0B | -16 | 0.3 | |

| 30KW | 1 | 50-60 | 12000 | N2 | 8 | 2.0S | 0 | 1 |

| 2 | 50-60 | 12000 | N2 | 8 | 2.0S | 0 | 0.5 | |

| 3 | 40-50 | 30000 | N2 | 8 | 2.5S | 0 | 0.5 | |

| 4 | 35-40 | 30000 | N2 | 8 | 2.5S | 0 | 0.5 | |

| 5 | 25-30 | 30000 | N2 | 8 | 3.0S | 0 | 0.5 | |

| 6 | 22-25 | 30000 | N2 | 8 | 3.5B | 0 | 0.5 | |

| 8 | 18-22 | 30000 | N2 | 8 | 5.0B | -1 | 0.5 | |

| 10 | 14-18 | 30000 | N2 | 8 | 5.0B | -1.5 | 0.3 | |

| 12 | 12-14 | 30000 | N2 | 8 | 6.0B | -2 | 0.5 | |

| 14 | 8-10 | 30000 | N2 | 8 | 6.0B | -4 | 0.3 | |

| 16 | 7.5-8.5 | 30000 | N2 | 8 | 6.0B | -5 | 0.3 | |

| 18 | 6-7 | 30000 | N2 | 8 | 6.0B | -6 | 0.3 | |

| 20 | 5-6 | 30000 | N2 | 12 | 6.0B | -7.5 | 0.3 | |

| 25 | 2-3 | 30000 | N2 | 12 | 7.0B | -12 | 0.3 | |

| 30 | 1.5-2 | 30000 | N2 | 12 | 7.0B | -16 | 0.3 | |

| 40 | 0.6-0.8 | 30000 | N2 | 16 | 7.0B | -16 | 0.3 | |

| 50 | 0.4-0.6 | 30000 | N2 | 16 | 8.0B | -18 | 0.3 | |

| 1 | 50-60 | 12000 | Air | 8 | 2.0S | 0 | 1 | |

| 2 | 50-60 | 12000 | Air | 8 | 2.5S | 0 | 0.5 | |

| 3 | 40-50 | 30000 | Air | 8 | 2.5S | 0 | 0.5 | |

| 4 | 35-40 | 30000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 5 | 25-30 | 30000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 6 | 22-25 | 30000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 8 | 18-22 | 30000 | Air | 10 | 3.5B | 0 | 0.5 | |

| 10 | 14-18 | 30000 | Air | 10 | 3.5B | -1.5 | 0.3 | |

| 12 | 12-14 | 30000 | Air | 10 | 5.0B | -4 | 0.3 | |

| 14 | 10-12 | 30000 | Air | 10 | 5.0B | -6 | 0.3 | |

| 16 | 8-9 | 30000 | Air | 10 | 5.0B | -7 | 0.3 | |

| 18 | 6-7 | 30000 | Air | 10 | 5.0B | -8 | 0.3 | |

| 20 | 5-6 | 30000 | Air | 10 | 5.0B | -9 | 0.3 | |

| 25 | 2.5-3 | 30000 | Air | 10 | 5.0B | -13 | 0.3 | |

| 30 | 1.5-2 | 30000 | Air | 10 | 5.0B | -17 | 0.3 | |

| 40 | 0.8-1.2 | 30000 | Air | 16 | 7.0B | -16 | 0.3 | |

| 50 | 0.6-0.8 | 30000 | Air | 16 | 8.0B | -18 | 0.3 | |

| 40KW | 5 | 25-30 | 40000 | N2 | 8 | 3.0S | 0 | 0.3 |

| 6 | 22-25 | 40000 | N2 | 8 | 3.5B | 0 | 0.3 | |

| 8 | 20-23 | 40000 | N2 | 8 | 5.0B | -0.5 | 0.3 | |

| 10 | 16-21 | 40000 | N2 | 8 | 5.0B | -0.5 | 0.3 | |

| 12 | 12-14 | 40000 | N2 | 8 | 6.0B | -1 | 0.3 | |

| 14 | 10-12 | 40000 | N2 | 8 | 6.0B | -1 | 0.3 | |

| 16 | 9-11 | 40000 | N2 | 8 | 6.0B | -2 | 0.3 | |

| 18 | 8-9.5 | 40000 | N2 | 8 | 6.0B | -3 | 0.3 | |

| 20 | 7-8 | 40000 | N2 | 8 | 6.0B | -5 | 0.3 | |

| 25 | 4.5-5.5 | 40000 | N2 | 8 | 7.0B | -7 | 0.3 | |

| 30 | 3-4 | 40000 | N2 | 8 | 7.0B | -13 | 0.3 | |

| 40 | 1.5-2 | 40000 | N2 | 8 | 7.0B | -20 | 0.3 | |

| 50 | 0.5-0.8 | 40000 | N2 | 6 | 8.0B | -38 | 0.3 | |

| 60 | 0.4-0.6 | 40000 | N2 | 6 | 8.0B | -38 | 0.3 | |

| 70 | 0.2-0.3 | 40000 | N2 | 6 | 8.0B | -40 | 0.3 | |

| 5 | 30-34 | 40000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 6 | 25-30 | 40000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 8 | 22-25 | 40000 | Air | 8 | 3.5B | 0 | 0.5 | |

| 10 | 17-23 | 40000 | Air | 8 | 3.5B | -1.5 | 0.3 | |

| 12 | 13-16 | 40000 | Air | 8 | 5.0B | -4 | 0.3 | |

| 14 | 12-14 | 40000 | Air | 8 | 5.0B | -6 | 0.3 | |

| 16 | 9-11.5 | 40000 | Air | 8 | 5.0B | -7 | 0.3 | |

| 18 | 8-10 | 40000 | Air | 8 | 5.0B | -8 | 0.3 | |

| 20 | 7-8.5 | 40000 | Air | 8 | 5.0B | -9 | 0.3 | |

| 25 | 5-5.5 | 40000 | Air | 8 | 5.0B | -13 | 0.3 | |

| 30 | 3.5-4.5 | 40000 | Air | 8 | 5.0B | -15 | 0.3 | |

| 40 | 1.7-2.2 | 40000 | Air | 6 | 7.0B | -22 | 0.3 | |

| 50 | 0.7-1 | 40000 | Air | 6 | 8.0B | -38 | 0.3 | |

| 60 | 0.4-0.6 | 40000 | Air | 5 | 8.0B | -38 | 0.3 | |

| 70 | 0.3-0.4 | 40000 | Air | 5 | 8.0B | -44 | 0.3 |

Applications of Laser Cutting Stainless Steel

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

Why Are The Edges Of Laser Cutting Stainless Steel Rough?

- High Reflectivity of Stainless Steel: Stainless steel has a high reflectivity, particularly when using the standard CO2 laser wavelength (10.6 microns). This high reflectivity can cause less efficient absorption of the laser energy at the cutting surface. As a result, more energy is needed to effectively cut through the material. Inefficient energy absorption leads to uneven melting, which can cause rough edges as the laser struggles to maintain a consistent cut.

- Melting and Solidification Process: The laser melts the stainless steel, and the molten material is supposed to be blown away by the assisting gas (usually oxygen or nitrogen). If the gas pressure is insufficient or uneven, the molten material may not be fully expelled, causing it to cool and solidify along the cut edge. This results in the formation of dross, which appears as a rough, spiky residue along the cut edge.

- Assist Gas Effectiveness: Assist gas plays a crucial role in removing molten material from the kerf and preventing oxidation. Inadequate or inconsistent gas flow can leave more molten metal in the cut, contributing to roughness. For example, if nitrogen is used as an inert gas, it can result in clean edges, but if oxygen is used to increase cutting speed, it can cause oxidation and roughness due to the exothermic reactions, which further complicate achieving a smooth cut.

- Thermal Conductivity of Stainless Steel: Stainless steel has relatively low thermal conductivity compared to materials like aluminum. As a result, the heat generated during cutting does not dissipate quickly, leading to the surrounding material becoming overly heated. This can cause the cut edges to become brittle or develop microcracks, which add to the roughness.

- Laser Focus and Power Settings: Improper focus or power settings can contribute to rough edges. A misaligned focus point can cause uneven energy distribution, leading to inconsistent cutting and an uneven surface. Similarly, if the laser power is too high or too low, it can result in either excessive melting (causing a rough surface) or incomplete cutting, which leads to jagged edges.

- Cutting Speed and Thickness of Material: Slower cutting speeds are sometimes necessary to cut thicker stainless steel or ensure deeper penetration, but this extended exposure to heat can cause more molten metal to solidify along the cut, leading to rough edges. Additionally, thicker stainless steel requires higher power, which can exacerbate these issues.

Why Does Laser Cutting Stainless Steel Tend To Produce Excessive Slag?

- High Melting Point of Stainless Steel: Stainless steel has a higher melting point compared to other metals like mild steel. This requires more energy to melt the material, which increases the amount of molten material that is created during the cutting process. If this molten material is not effectively removed, it can cool and form slag on the cut edge. The higher the melting point, the more heat is required, and this results in more molten material that needs to be ejected from the kerf.

- Ineffective Assist Gas Flow: Assist gases, typically nitrogen or oxygen, are used to expel molten material from the cutting zone. When the assist gas pressure is insufficient or inconsistent, molten metal is not efficiently removed from the kerf, causing it to cool and solidify as slag. Oxygen, used for faster cutting, can also promote oxidation, which results in oxidized slag that is harder to remove. If the gas flow is not optimized or the pressure is too low, the molten metal will be left behind, contributing to excess slag.

- Viscous Molten Metal: The molten metal created when cutting stainless steel is more viscous than that of other metals, like aluminum. This higher viscosity means the molten material does not flow as easily, and the assist gas may have difficulty expelling it completely from the kerf. As a result, more molten material is left behind, leading to slag formation on the cut edges.

- Slow Cutting Speeds: To ensure a smooth and precise cut, stainless steel often needs to be cut at slower speeds, particularly for thicker gauges. Slower cutting speeds mean the laser dwells longer on the material, generating more molten metal, which increases the chance of slag formation. If the assist gas cannot keep up with the removal of this molten material, slag is more likely to form.

- Thermal Conductivity of Stainless Steel: Stainless steel has relatively low thermal conductivity, meaning the heat generated by the laser cutting process is not efficiently transferred away from the cutting area. This results in a larger heat-affected zone, where the molten material can cool and solidify, leading to slag on the edges.

- Edge Quality and Cooling Rates: The rapid cooling rate of the molten material contributes to the solidification of slag along the cut edge. If cooling is uneven, areas of the cut can solidify before they are properly ejected, causing slag to adhere to the edges of the material.

Why Is There So Much Spatter During Laser Cutting Stainless Steel?

- High Reflectivity of Stainless Steel: Stainless steel has a high reflectivity, particularly with CO2 lasers. This means that not all of the laser energy is absorbed by the material; some of it is reflected away. This leads to less efficient cutting, especially at lower power levels, which in turn creates more molten material. When the laser energy is not efficiently absorbed, more heat accumulates in the material, causing more material to be ejected as spatter.

- Viscous and Dense Molten Metal: When stainless steel melts, it forms a molten pool that is denser and more viscous compared to other materials, such as aluminum. The high viscosity of the molten metal makes it more likely to remain in the kerf rather than being easily expelled by the assist gas. This can result in the molten material being ejected unevenly, creating spatter that splashes out from the kerf.

- Ineffective Assist Gas Flow: The role of assist gas is to blow molten metal away from the kerf to prevent it from re-solidifying on the cut edge and to maintain a clean cut. However, if the assist gas pressure is too low or not properly directed, the molten metal may not be effectively removed. This leads to an increase in spatter, as the molten droplets remain suspended in the air or adhere to the cutting edge, rather than being blown away from the kerf.

- Thermal Expansion and Material Behavior: Stainless steel has a relatively low thermal conductivity compared to other metals like copper or aluminum. This means that heat does not dissipate quickly, causing a larger heat-affected zone. The longer the material remains molten, the greater the likelihood of spatter formation, as the material tends to flow unevenly and clings to surfaces around the cut.

- Slow Cutting Speeds and Thick Materials: When cutting thicker stainless steel, the laser beam needs to dwell longer on the material to ensure complete penetration. This increased dwell time generates more heat, which raises the likelihood of excessive molten material and spatter. Additionally, slower cutting speeds provide more time for molten metal to cool and solidify, increasing the chances of spatter formation.

- Assist Gas Selection (Oxygen vs. Nitrogen): The choice of assist gas can also affect the amount of spatter. Oxygen can cause an exothermic reaction, which accelerates the cutting process by adding heat, but also leads to oxidation and more spatter. In contrast, nitrogen helps reduce oxidation but does not add extra heat, potentially resulting in slower cutting speeds and more molten material that may lead to spatter.

Why Does Edge Hardening Occur During Laser Cutting Stainless Steel?

- High Heat Input and Rapid Cooling: Laser cutting generates extreme heat at the focal point, which melts the stainless steel in the cut zone. As the laser moves, the material rapidly cools, often faster than it would in other cutting processes. This rapid cooling leads to the formation of martensitic microstructures near the cut edge. Martensite is a hard, brittle phase that forms when austenitic stainless steel is cooled too quickly, and it significantly increases the hardness of the material at the edge.

- Thermal Gradient and Heat-Affected Zone (HAZ): Stainless steel experiences a steep thermal gradient during laser cutting. The area directly exposed to the laser beam is intensely heated, while the surrounding material cools more slowly. The rapid heating and cooling create a heat-affected zone (HAZ) at the edge, where the microstructure of the stainless steel changes. The rapid cooling near the surface can lead to the formation of hardened phases like martensite, which can make the edge harder than the rest of the material.

- Laser Beam Power and Speed: The power and speed of the laser also influence the amount of heat introduced into the material. Higher power settings and slower cutting speeds result in more heat being concentrated in the cut area, which exacerbates the hardening effect. Slower cutting speeds give the material more time to melt and then cool rapidly, increasing the potential for martensite formation and a harder edge.

- Material Composition and Alloying Elements: The chemical composition of the stainless steel also plays a role in edge hardening. Stainless steels with higher carbon content or specific alloying elements, such as chromium and molybdenum, are more prone to forming martensitic structures during rapid cooling. These materials can experience more significant hardening at the cut edge.

- Assist Gas Effect: The type of assist gas used can influence the cooling rate and, consequently, the hardening of the edge. Oxygen, for example, can promote oxidation and result in higher temperatures at the cut, leading to more significant changes in the microstructure of the material. In contrast, nitrogen helps to avoid oxidation but can still contribute to rapid cooling, resulting in hardening, albeit with less oxidation.

Why Does Laser Cutting Stainless Steel Require Higher Gas Purity?

- Oxidation Prevention: One of the primary roles of the assist gas in laser cutting stainless steel is to prevent oxidation of the material. Stainless steel tends to form an oxide layer when exposed to high temperatures during cutting, which can compromise the quality of the cut and the material’s corrosion resistance. Higher purity gases, such as nitrogen or oxygen, are necessary to maintain a clean cutting environment. Impurities in the gas, like moisture, hydrocarbons, or oxygen contaminants, can lead to incomplete or uneven protection, resulting in unwanted oxidation and poor edge quality.

- Cleaner Cuts: Higher purity gases ensure that the laser cutting process remains clean and free of contaminants that could cause imperfections in the cut. Contaminated gases can introduce particles or chemicals that interfere with the molten metal removal process, leading to rougher edges, excessive slag, or dross formation. Purity ensures that the gas efficiently evacuates molten material from the kerf and maintains a smooth, clean cut, which is particularly important in applications requiring high precision.

- Better Control of the Cutting Process: Stainless steel, especially thicker gauges, requires precise heat management during laser cutting. Higher purity gases, such as nitrogen, help in achieving a consistent and stable laser cutting process. Impurities in the assist gas can cause fluctuations in the cutting parameters, leading to inconsistencies in the laser’s energy output and the removal of molten material. This inconsistency can cause variations in cut quality, such as uneven edges, excessive taper, or an increase in heat-affected zones (HAZ).

- Reduced Maintenance Needs: When gases are not pure, they can introduce contaminants that damage the laser optics and nozzles, leading to the need for more frequent maintenance. High-purity gases reduce the risk of such contamination, allowing for longer maintenance intervals and consistent cutting performance. Cleaner gases reduce the accumulation of debris or residues inside the cutting head, ensuring optimal focus and nozzle performance.

- Improved Gas Reactivity: For certain types of laser cutting, such as oxygen-assisted cutting, the gas’s reactivity can be critical. Oxygen promotes exothermic reactions that help speed up the cutting process, especially for thicker materials. However, the purity of the oxygen must be high to ensure consistent reaction rates and minimize impurities that might interfere with the chemical reaction, which could otherwise result in excessive heat, oxidation, or surface defects.

Why Does Laser Cutting Stainless Steel Increase Fume Extraction Requirements?

- Formation of Hazardous Fumes and Gases: When stainless steel is cut by a laser, the intense heat vaporizes not just the steel, but also any surface coatings, oils, or contaminants present on the material. This vaporization results in the release of various harmful gases and fumes, including metal oxides (primarily chromium and nickel), as well as volatile organic compounds (VOCs) from any lubricants or surface treatments. These fumes can be hazardous to human health, making effective fume extraction essential to maintain a safe working environment.

- Oxidation of the Material: Laser cutting of stainless steel, particularly when oxygen is used as the assist gas, induces oxidation reactions. This leads to the formation of metal oxides like iron oxide (rust) and chromium oxide. The oxides and particulate matter generated during these reactions become airborne and need to be captured by fume extraction systems to prevent contamination of the surrounding area and avoid inhalation by operators.

- Increased Temperature and Material Vaporization: Stainless steel’s high melting point means that more heat is required to cut through it, leading to greater vaporization of material. The higher the temperature, the more vapor and particulate matter are generated, which leads to a higher volume of fumes. These fumes can include hazardous substances, depending on the alloy’s composition, making efficient extraction even more important.

- Larger Amount of Material Cut: In industrial applications, laser cutting is often used for larger sheets or thicker gauges of stainless steel. Cutting larger volumes of material generates more vapor and particulate matter, further increasing the demands on the fume extraction system. As the cutting process continues, the buildup of smoke and gases in the work area can lead to a decline in air quality, posing health risks for operators if not properly vented.

- Effect of Assist Gases: The choice of assist gas can influence the volume and composition of fumes. For example, using oxygen as an assist gas accelerates the cutting process but also results in more aggressive oxidation, which generates more fumes. In contrast, using nitrogen reduces oxidation, but it can still generate fumes from the high heat and molten material. Regardless of the assist gas, capturing these fumes is necessary to avoid respiratory issues or contamination of the work environment.

- Regulatory Compliance: Due to the health hazards posed by fumes, regulations around air quality and worker safety require adequate fume extraction during laser cutting. Compliance with local safety standards and regulations mandates the installation of effective fume extraction systems that can capture and filter out harmful particles and gases.

Why Does Laser Cutting Stainless Steel Generate Excessive Thermal Stress?

- High Heat Input and Temperature Gradients: Laser cutting involves the rapid application of intense heat to a small area of stainless steel, causing it to melt. The localized heating creates a significant temperature gradient between the cut zone and the surrounding material. As the laser moves, the material rapidly cools, leading to uneven thermal expansion and contraction across the material. This rapid heating and cooling induce internal stresses, which can result in thermal stress within the material, potentially causing warping, distortion, or cracking.

- Low Thermal Conductivity of Stainless Steel: Stainless steel has relatively low thermal conductivity compared to metals like aluminum or copper. This means that the heat generated during the laser cutting process does not dissipate quickly, concentrating more heat in the area surrounding the cut. As a result, the surrounding material remains hot for longer periods, which increases the thermal gradient and contributes to the build-up of thermal stress. The slower heat dissipation makes the material more prone to warping or bending as the material tries to compensate for the rapid temperature changes.

- Rapid Cooling and Shrinkage: Once the laser moves away from the cutting area, the molten material cools rapidly, especially when the assist gas (typically nitrogen or oxygen) is used to blow away the molten material. The rapid cooling of the molten steel causes it to shrink quickly. This shrinkage can create uneven stresses in the material, leading to deformation or distortion along the cut edges. The faster the cooling rate, the higher the potential for thermal stresses to develop.

- Material Properties and Alloy Composition: The specific alloy composition of stainless steel also plays a role in how it reacts to thermal stress. Stainless steel contains elements such as chromium, nickel, and molybdenum, which contribute to the material’s strength and resistance to corrosion but also make it more prone to thermal stress under laser cutting conditions. The differing expansion rates of these alloying elements during heating and cooling can exacerbate thermal stress.

- Cutting Speed and Laser Power: The laser cutting parameters, such as cutting speed and laser power, also affect thermal stress. Slower cutting speeds and higher laser power result in more prolonged exposure to heat, causing more significant thermal gradients and increasing the potential for thermal stress. Faster cutting speeds may reduce the heat-affected zone, but they can also lead to an incomplete cut or other quality issues if not properly optimized.

Why Does Laser Cutting Stainless Steel Increase The Risk Of Back Reflection?

- High Reflectivity of Stainless Steel: Stainless steel, especially when using a CO2 laser, has a high reflectivity at the laser’s wavelength. This means a significant portion of the laser beam is reflected off the surface rather than being absorbed into the material. The greater the reflectivity of the material, the higher the likelihood of back reflection. This issue is more pronounced with highly polished stainless steel surfaces, which are more reflective compared to duller or coated surfaces.

- Laser Beam Interaction with the Material: The laser cutting process involves focusing a high-intensity laser beam onto the stainless steel to melt and vaporize the material. As the laser cuts through the material, the reflected energy can bounce back towards the cutting head or laser source, especially if the beam strikes a highly reflective surface at an angle. This back-reflected energy can damage the optical components, such as the lens or mirrors, which are critical for guiding and focusing the laser beam.

- Cutting Angle and Surface Conditions: The angle at which the laser beam strikes the stainless steel surface can affect the amount of reflection. If the laser is cutting at an oblique angle or if the surface is not properly prepared, such as being overly polished or contaminated, it can increase the chances of back reflection. Additionally, rough or uneven surfaces can cause the laser beam to scatter, contributing to unpredictable reflection patterns.

- Use of Assist Gases: Assist gases, such as oxygen or nitrogen, are used to help expel molten material from the kerf during the cutting process. In some cases, these gases can interact with the molten material, causing more intense reflections. For instance, using oxygen as an assist gas can increase the likelihood of oxidation, leading to additional surface irregularities that may result in higher reflectivity and more back-reflected energy.

- Potential Damage to Laser Cutting Equipment: When back reflection occurs, it can potentially cause damage to the laser source or optics. Over time, this can degrade the performance of the laser cutting system, resulting in higher maintenance costs and more frequent repairs. In extreme cases, the damage from back reflection can result in the need to replace key components, such as lenses or mirrors, which are expensive and essential for proper laser operation.

- Control of Laser Parameters: Proper control of laser parameters, including beam focus, power settings, and cutting speed, is crucial to minimizing back reflection. If these parameters are not optimized, excessive energy may be reflected, increasing the risk of damage to the laser cutting system. Fine-tuning these settings can help ensure that the laser beam is absorbed more effectively by the stainless steel and minimize unwanted reflections.