Introduction

Advantages of Laser Cutting Rubber

High Precision and Accuracy

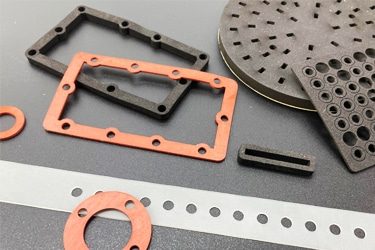

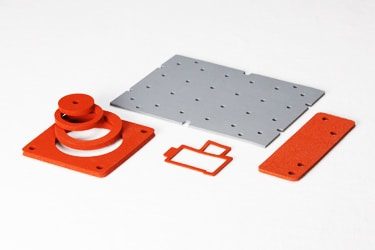

Laser cutting rubber delivers precise cuts and tight tolerances, allowing complex shapes and fine details to be produced consistently. This level of accuracy is ideal for gaskets, seals, and rubber components that require reliable dimensional control.

Non-Contact Cutting Process

Because laser cutting rubber is a non-contact process, the material is not compressed, stretched, or damaged during cutting. This helps preserve the natural elasticity and shape of rubber, especially for soft or thin materials.

Clean and Smooth Edges

Laser cutting rubber produces clean edges with minimal tearing or roughness. Properly adjusted settings reduce the need for secondary finishing, improving the appearance and performance of rubber parts used in sealing and insulation applications.

High Design Flexibility

Laser cutting rubber supports quick design changes through digital files without new tooling. Complex profiles, holes, and patterns can be easily produced, making it ideal for prototyping, customization, and short production runs.

Reduced Material Waste

The narrow kerf width of laser cutting rubber allows efficient nesting of parts. This maximizes material usage, reduces scrap, and lowers overall production costs, which is especially important when processing specialty rubber materials.

Fast Setup and Efficient Production

Laser cutting rubber requires minimal setup time and supports automated operation. High cutting speeds and repeatable results improve productivity and help manufacturers meet tight deadlines while maintaining consistent quality.

Compatible Materials

- Natural Rubber

- Silicone Rubber

- EPDM Rubber

- SBR

- Neoprene Rubber

- Nitrile Rubber

- Viton Rubber

- Buna-N Rubber

- Butyl Rubber

- Latex Rubber Sheets

- Foam Rubber

- Rubberized Cork

- Rubberized Fabric

- Conductive Rubber

- Anti-Static Rubber

- Laser-Engraving Rubber Sheets

- Stamp Rubber

- Rubber Gaskets

- Rubber Seals

- Rubber Mats

- Rubber Insulation Sheets

- High-Temperature Silicone Sheets

- Dense Rubber Sheets

- Soft Rubber Sheets

- Open-Cell Foam Rubber

- Closed-Cell Foam Rubber

- Colored Rubber Sheets

- Rubber with Textile Backing

- Weather Stripping Rubber

- Rubber Rollers

- Rubber Padding

- Rubber Tape

- Perforated Rubber Sheets

- Rubber Spacers

- Oil-Resistant Rubber

- UV-Resistant Rubber

- Fire-Retardant Silicone

- Recycled Rubber Sheets

- Rubber Floor Tiles

- Rubber Diaphragms

Laser Cutting Rubber VS Other Cutting Methods

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Rubber Materials | Highly suitable | Limited | Very suitable | Suitable |

| Cutting Precision | Very high | Medium | Medium | High |

| Edge Quality | Clean, smooth edges | Rough edges | Clean but uneven | Clean but wet |

| Material Deformation | None (non-contact) | High risk | Medium | None |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High | Moderate | High | Slow |

| Thickness Capability | Thin to medium rubber | Medium | Thin to medium | Thin to thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent | Good | Limited | Good |

| Automation and Repeatability | Excellent | Good | Good | Good |

| Operating Cost | Moderate | Moderate | Low | High |

| Overall Efficiency for Rubber Processing | Excellent | Fair | Good | Good |

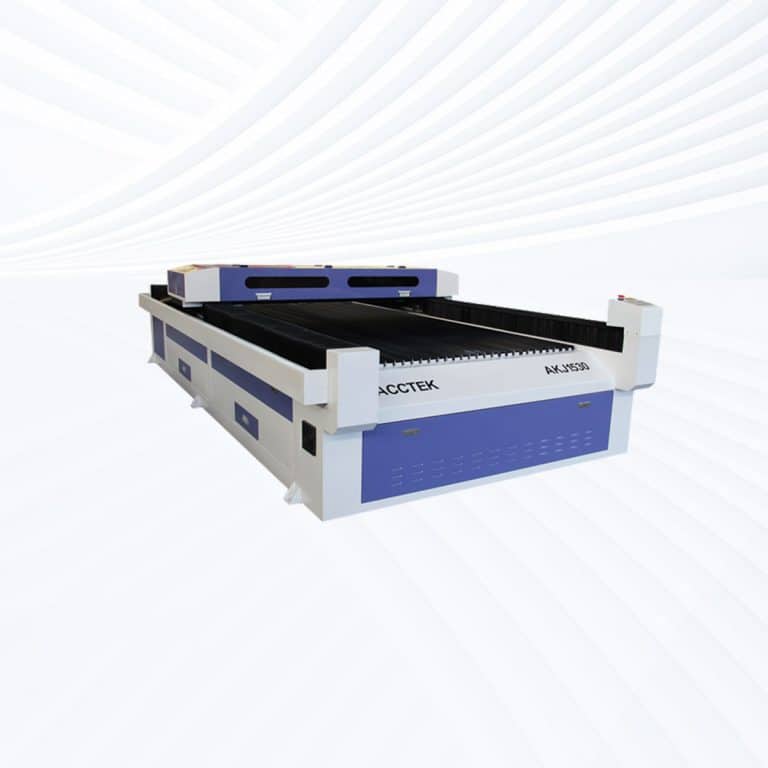

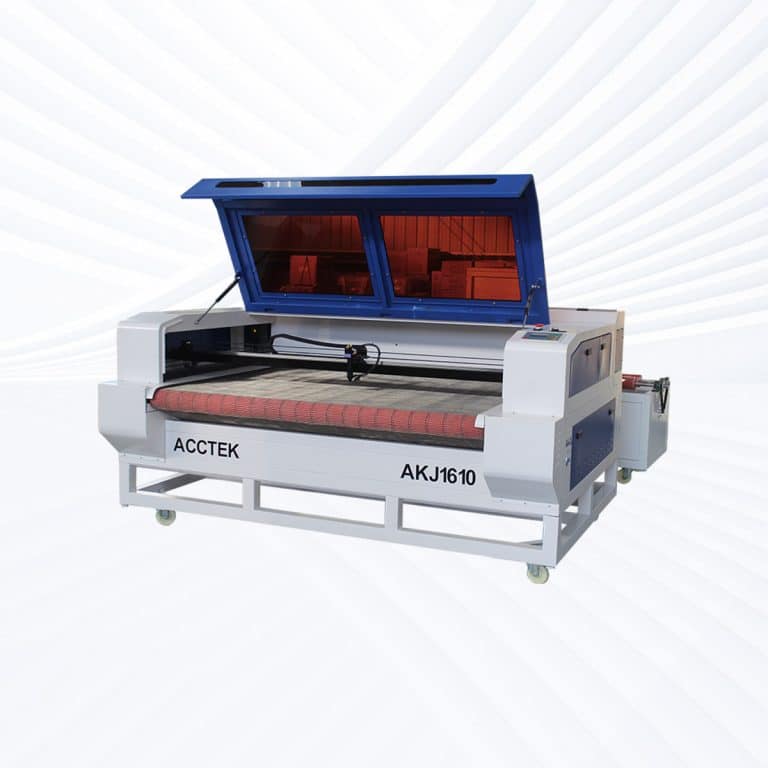

Laser Cutting Capacity

| Power/Material | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plywood | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| MDF | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Solid Wood | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cork Sheet | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Bamboo Board | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Laminates | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Acrylic (PMMA) | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| ABS | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Delrin (POM) | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Composite | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| EVA Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Depron Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Gator Foam | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cardboard | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Stone | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

| Leather | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Textile | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Nylon | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Felt | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Rubber | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Ceramic | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

Applications of Laser Cutting Rubber

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

How Does The Low Thermal Conductivity Of Rubber Affect Laser Cutting?

- Localized Heating and Melting: Rubber, being a poor conductor of heat, tends to retain the heat applied by the laser beam in a localized area. As the laser heats a small section of rubber to high temperatures, the heat does not spread efficiently throughout the material. This causes the area around the laser cut to become excessively hot, leading to uneven melting and sometimes excess material around the cut. In contrast, materials with higher thermal conductivity dissipate heat more evenly, allowing for cleaner and more consistent cuts.

- Inconsistent Cutting Quality: Because the heat remains concentrated in one spot, rubber can become soft and gummy in areas that are heated too much. This results in inconsistent cutting quality, where the edges of the cut may become deformed or jagged instead of clean and precise. As the laser moves along the rubber, the adjacent material may not cool quickly enough, leading to deformation or “dragging” at the cut line.

- Risk of Excessive Burning and Fumes: The concentrated heat in one area can also lead to burning or charring of the rubber. The material may not burn evenly, causing some sections to ignite or smolder while others remain unburned. Rubber is known to emit toxic fumes, including harmful gases such as nitrogen oxides and ozone, when burned or overheated. The difficulty in controlling heat spread further exacerbates the emission of these dangerous fumes, making proper ventilation essential when cutting rubber.

- Challenges in Controlling the Cut: The low thermal conductivity of rubber can make it difficult to control the cut depth, especially if the laser settings (speed and power) are not properly adjusted. Since the material doesn’t cool quickly or spread heat evenly, it may not solidify at the rate expected, leading to problems like excessive kerf width or rough, uneven edges.

- Increased Wear on Laser Components: The excess heat buildup in localized areas can also put extra strain on the laser components, particularly the lens. Overheating can cause the lens to become clouded or damaged more quickly due to the molten rubber residue, which can affect the laser’s efficiency and require more frequent maintenance.

Why Are The Edges Of Laser-Cut Rubber Rough?

- Low Thermal Conductivity: Rubber has low thermal conductivity, meaning it doesn’t spread heat efficiently. When the laser focuses on a small area, the heat stays concentrated in that spot, causing the rubber to melt unevenly. This results in inconsistent material flow, which can lead to rough or irregular edges. Unlike materials with higher thermal conductivity, which distribute heat more evenly and create a cleaner cut, rubber’s poor heat dissipation leads to melting that is more likely to result in deformation and roughness.

- Melting and Re-Solidification: As the laser cuts rubber, the intense heat causes the material to melt. Due to rubber’s elasticity and softness, the molten material often doesn’t hold a stable form and may flow irregularly. When it re-solidifies, it can form jagged, uneven edges. Additionally, the edges may remain sticky due to the melting process, making it harder for the material to solidify smoothly.

- Material Expansion and Shrinkage: The low thermal conductivity of rubber also causes it to expand rapidly when heated and shrink as it cools. This can result in warping and uneven edges. As rubber cools after being cut, the material may contract unevenly, leading to roughness along the cut edge. These thermal changes are more pronounced in rubber compared to materials like acrylic or wood, which may result in more consistent edge quality.

- Burning and Smoke Production: Rubber can burn or degrade when exposed to high temperatures for too long. If the laser settings are not optimized (too high of power or too slow a cutting speed), the rubber may char or burn along the edges. This not only affects the visual smoothness but also contributes to the roughness. In addition, the fumes produced during the burning process can cause soot or residue to build up along the edges, further increasing the roughness.

- Inconsistent Cutting Speed or Laser Focus: The roughness of the edges can also result from improper laser settings. If the laser is cutting too slowly, more heat will be applied to the rubber, leading to excessive melting and rough edges. Additionally, if the laser focus is not optimal, the cut will be less precise, further contributing to unevenness along the edges.

Why Is The Heat-Affected Zone Large After Laser Cutting Rubber?

- Low Thermal Conductivity of Rubber: Rubber has low thermal conductivity, meaning that heat from the laser does not dissipate quickly. As the laser heats the material, the surrounding areas also absorb some of the heat, causing a larger area to be affected by the elevated temperature. Unlike materials with higher thermal conductivity (such as metals), which can spread heat more efficiently, rubber retains heat in the local area, expanding the HAZ.

- Slow Heat Dissipation: When laser cutting rubber, the material tends to absorb heat and retain it, which prevents rapid cooling in the affected region. This prolonged exposure to heat not only affects the immediate cut area but can also cause surrounding areas to soften, melt, or degrade. The lack of rapid cooling causes the HAZ to extend beyond the immediate cut path, making it larger than would be seen in materials with better heat dissipation characteristics.

- Thermal Expansion and Contraction: As the laser cuts through rubber, the material expands locally due to heat. Once the laser moves away, the rubber cools and contracts. This thermal cycle can cause a larger HAZ as the material continues to soften and warp in areas near the cut. In addition, as the rubber cools, it may shrink or deform, contributing to the broader heat-affected zone.

- Material Decomposition: Rubber can undergo thermal decomposition when exposed to high temperatures. The laser’s heat can break down the rubber’s chemical bonds, especially in areas that are excessively heated. This decomposition can lead to charring, discoloration, or further melting in the surrounding areas, which increases the size of the heat-affected zone.

- Burning and Smoke Production: When rubber is heated to high temperatures by the laser, it can start to burn or emit fumes. The surrounding rubber may degrade, creating an expanded HAZ where the material is affected by both heat and chemical breakdown. The production of smoke can also affect nearby areas, causing further localized damage and increasing the size of the HAZ.

Why Does Laser Cutting Rubber Release Fumes?

- Thermal Decomposition of Rubber: Rubber contains a variety of chemical compounds, including additives like plasticizers, stabilizers, and curing agents. When exposed to the heat of the laser, these compounds break down. The thermal decomposition of rubber produces a range of volatile organic compounds (VOCs), including carbon monoxide, carbon dioxide, acrolein, and other potentially toxic gases. The exact composition of the fumes depends on the type of rubber being cut, as different formulations can release different chemicals.

- Additives and Fillers in Rubber: Many types of rubber, such as synthetic rubber or rubber compounds used in industrial applications, contain fillers, pigments, and other chemical additives. These additives can also break down during laser cutting, releasing additional fumes. Some rubber compounds, particularly those with chlorine content, can emit chlorine gas, which is highly toxic and poses significant health risks. These harmful fumes are often produced when cutting materials like PVC or rubber with flame retardants.

- Incomplete Combustion: Rubber does not vaporize cleanly under laser heat; instead, it melts and sometimes burns. When this happens, incomplete combustion occurs, generating additional smoke, soot, and particulate matter. This can create a larger volume of fumes and smoke than what is produced by materials that vaporize cleanly, like acrylic.

- Fume Concentration: Due to the rubber’s low thermal conductivity, heat does not dissipate evenly, causing some areas to become much hotter than others. This localized heating increases the likelihood of excessive burning and fume production around the cut edges. Inadequate fume extraction systems can cause these fumes to build up in the workspace, increasing exposure to harmful substances.

- Health and Safety Risks: The fumes produced during laser cutting rubber can irritate the eyes, skin, and respiratory system. Prolonged exposure can lead to more severe health issues, such as chronic respiratory problems. For these reasons, it is essential to have proper ventilation, air extraction, and PPE (personal protective equipment) when laser cutting rubber.

Why Does Laser Cutting Rubber Cause Serious Health Hazards?

- Release of Toxic Gases and Fumes: Rubber, especially synthetic types, contains various chemical compounds such as plasticizers, stabilizers, and fillers. When exposed to the intense heat of the laser, these compounds break down, releasing volatile organic compounds (VOCs), including acrolein, carbon monoxide, and formaldehyde. Some types of rubber, such as those containing chlorine (like PVC-based rubbers), release chlorine gas when heated. Chlorine gas is particularly hazardous as it can cause respiratory distress, irritation, and long-term damage to the lungs. Prolonged exposure to these toxic gases can lead to chronic respiratory issues, lung damage, and even cancer.

- Inhalation of Particulate Matter and Smoke: Laser cutting rubber also produces smoke and fine particulates that can become airborne and easily inhaled. These particles, along with other byproducts like soot, are harmful to the respiratory system and can irritate the eyes, throat, and lungs. Exposure to fine particulate matter has been linked to respiratory diseases, including asthma, bronchitis, and other chronic pulmonary conditions.

- Incomplete Combustion: Rubber does not vaporize cleanly when heated by the laser, often undergoing incomplete combustion, which results in additional byproducts, including more toxic fumes and smoke. This incomplete burning process can lead to a more significant release of harmful substances, increasing the overall risk of exposure to dangerous chemicals.

- Long-Term Health Effects: Repeated exposure to the fumes and gases generated during laser cutting of rubber can have cumulative effects on health. Over time, these substances can lead to more severe conditions such as chronic lung diseases, neurological damage, and an increased risk of cancer. Individuals working in environments where rubber is regularly cut without adequate ventilation and protective equipment are at greater risk of these long-term health issues.

- Importance of Safety Measures: Given the serious health risks, proper safety measures, including effective ventilation systems, fume extraction, and the use of personal protective equipment (PPE) such as respirators and protective eyewear, are essential when laser cutting rubber. These measures help mitigate the harmful effects of the toxic fumes and particulates generated during the process.

Why Is PPE Required For The Laser Cutting Of Rubber?

- Exposure to Toxic Fumes: When rubber is laser cut, it undergoes thermal decomposition, which releases volatile organic compounds (VOCs) such as acrolein, carbon monoxide, formaldehyde, and, in the case of certain rubber types, chlorine gas. These substances can irritate the respiratory system, eyes, and skin. Inhaling these toxic fumes can lead to short-term health issues, such as coughing, wheezing, and eye irritation, as well as long-term conditions like asthma, bronchitis, and even cancer with prolonged exposure. PPE, particularly respiratory protection like masks or respirators, helps to filter out these harmful fumes and prevents inhalation.

- Particulate Matter and Smoke: Laser cutting rubber also generates smoke and fine particulate matter that can linger in the air. These particles, when inhaled, can cause respiratory problems and irritate the eyes. Proper PPE, including safety goggles or face shields, helps protect workers from these particles, reducing the risk of eye injuries and respiratory distress.

- Burn and Heat Protection: Laser cutting involves intense heat that can cause rubber to burn or melt. This can lead to hot splashes of molten material, posing a burn risk. Protective gloves, heat-resistant clothing, and face shields are essential to prevent direct contact with hot surfaces and molten rubber, reducing the risk of burns or other heat-related injuries.

- Fire Hazards: Rubber is a combustible material, and laser cutting increases the risk of accidental ignition, particularly if the heat is not controlled properly. Fire-resistant clothing and equipment are needed to minimize the risk of fire-related injuries, especially in environments where flammable materials are present.

- Long-Term Health Effects: Repeated exposure to the toxic fumes and particulates generated during laser cutting can have cumulative effects on health, leading to chronic respiratory problems, damage to the lungs, and other severe health conditions. PPE is necessary not only to protect against immediate hazards but also to minimize long-term health risks associated with repeated exposure to harmful substances.

Why Is Selecting The Right Gas Important For Laser Cutting Rubber?

- Control of Fume Production: Different gases play specific roles in managing the fumes produced when laser cutting rubber. Common assist gases like oxygen, nitrogen, and air help manage the reaction between the laser and the material. Oxygen, for example, may increase the combustion of rubber, producing more heat and potentially leading to more intense fume generation. In contrast, using nitrogen or air as an assist gas helps reduce the burning of the rubber and the production of harmful, toxic fumes like carbon monoxide, acrolein, and formaldehyde. Using the right gas can help control these fumes and minimize the release of noxious substances, ensuring a safer work environment.

- Quality of the Cut: The assist gas also plays a role in the quality of the cut. For rubber, using air as an assist gas can help prevent excessive melting and charring along the cut edges. When the appropriate gas is chosen, it can improve the precision of the cut, leading to smoother edges and reducing roughness that can be common in rubber cuts. The right gas helps the laser work more efficiently, enhancing the overall performance of the machine.

- Prevention of Excessive Burning: The laser cutting of rubber generates intense heat, and without the proper assist gas, this heat can cause the rubber to burn excessively. Using nitrogen as an assist gas, for example, helps cool the cutting area and prevents the rubber from igniting or producing excessive heat, which can lead to dangerous conditions, including the risk of fire.

- Minimizing Toxic Emissions: Rubber materials, especially those with chlorine content (such as PVC-based rubbers), can release highly toxic chlorine gas when heated by the laser. The correct choice of gas can help minimize the formation of harmful byproducts. Nitrogen or air can help suppress some of the chemical reactions that lead to chlorine or other hazardous emissions, making the cutting process safer for operators and the environment.

- Long-Term Equipment Protection: Choosing the right assist gas can also help protect the laser cutting machine from damage. For example, using nitrogen can reduce the buildup of residues from burned rubber, which can accumulate on the lens or other components. This reduces the need for frequent cleaning and maintenance, extending the life of the equipment.

Why Does Rubber Shrink After Laser Cutting?

- Thermal Expansion and Contraction: When rubber is exposed to the intense heat of the laser beam, the material initially expands due to the rapid thermal energy. Rubber, being a thermoplastic material, is highly sensitive to temperature changes. The heat from the laser causes the polymer chains in the rubber to loosen, leading to expansion in the immediate area around the cut. However, once the laser moves away and the material starts to cool, the rubber contracts. This contraction happens because the heat is no longer localized in the cut area, and the rubber solidifies and returns to a smaller volume than its heated state, resulting in shrinkage.

- Loss of Elasticity: Rubber’s elasticity is reduced by the heat generated during laser cutting. The laser’s heat weakens the molecular bonds within the rubber, causing the material to lose some of its flexibility and elasticity in the cut area. This reduced elasticity results in shrinkage as the rubber cools and returns to a less flexible state. The loss of elasticity is more pronounced in thicker rubber materials and can lead to visible shrinkage around the edges of the cut.

- Decomposition of Additives: Rubber often contains various additives such as plasticizers, stabilizers, and fillers to modify its properties. During laser cutting, the heat can cause some of these additives to break down, further contributing to the shrinkage. For instance, if plasticizers are lost due to the high temperatures, the rubber becomes stiffer and shrinks in size.

- Chemical Reactions in the Cutting Area: In some cases, the rubber may undergo chemical changes when exposed to intense heat. For example, some types of rubber, particularly those with chlorine-based additives, can release gases during the cutting process. These gases can contribute to the shrinking of the material as the chemical structure of the rubber is altered by the heat.

- Uneven Cooling: The cooling process after laser cutting is not instantaneous and can vary in speed across the rubber material. Areas near the cut may cool faster than the rest of the material, leading to uneven shrinkage. This uneven cooling can further distort the shape of the rubber, contributing to the shrinkage effect.