Introduction

Advantages of Laser Cutting Plastic

High Precision and Accuracy

Laser cutting plastic delivers exceptional precision, allowing manufacturers to create complex shapes, fine details, and tight tolerances. The focused laser beam follows digital designs accurately, ensuring consistent dimensions and repeatable quality across production batches.

Non-Contact Cutting Process

Because laser cutting plastic is a non-contact method, there is no physical force applied to the material. This prevents cracking, warping, or surface damage, making it ideal for thin, brittle, or delicate plastic components.

Smooth and Clean Edges

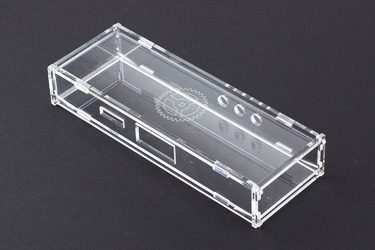

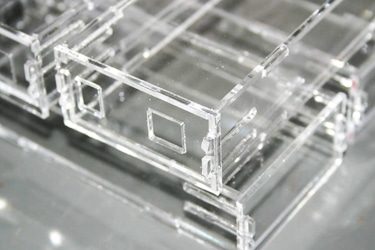

Laser cutting plastic produces clean, smooth edges, especially on materials like acrylic, often resulting in a polished finish. This reduces or eliminates the need for secondary finishing, saving time and improving overall part appearance.

High Design Flexibility

Laser cutting plastic allows quick changes to designs through digital files without the need for new tools. Intricate patterns, small holes, and customized shapes can be produced easily, supporting prototyping and short to medium production runs.

Reduced Material Waste

The narrow kerf width of laser cutting plastic enables efficient nesting of parts on a sheet. This maximizes material usage, minimizes scrap, and helps lower production costs, particularly when working with high-value plastic materials.

Fast Setup and Efficient Production

Laser cutting plastic requires minimal setup time and supports automated operation. High cutting speeds and repeatable results increase productivity, making it suitable for both rapid prototyping and large-scale manufacturing.

Compatible Materials

- Acrylic

- Cast Acrylic

- Extruded Acrylic

- Two-Tone Laminated Acrylic

- Polypropylene

- Polyethylene

- High-Density Polyethylene

- Low-Density Polyethylene

- Linear Low-Density Polyethylene

- Polystyrene

- ABS

- Delrin

- Nylon

- Polyurethane

- Polyester

- PETG

- Mylar

- Polyimide

- UHMW

- FR4

- Foam-Based Plastics

- PVC-Free Vinyl Films

- Melamine-Coated Plastics

- Styrene-Acrylonitrile

- Thermoplastic Elastomers

- Polybutylene Terephthalate

- Polyacrylic Blends

- Laminated Plastic Sheets

- Powder-Coated Plastic Surfaces

- Printable Plastic Film

- Glass-Filled Nylon

- Carbon-Filled Engineering Plastics

- Bakelite

- Polycarbonate

- Urethane Plastics

- Teflon

- Fluoropolymer Blends

- Polysulfone

- Engineering Plastics

- Specialty Laser-Mark Plastics

Laser Cutting Plastic VS Other Cutting Methods

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Plastic Materials | Highly suitable | Very suitable | Limited | Suitable |

| Cutting Precision | Very high | High | Medium | High |

| Edge Quality | Smooth, often polished | Good, may need finishing | Rough or compressed | Clean but wet |

| Material Deformation | None (non-contact) | Medium risk | High risk | None |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High for thin plastics | Moderate | High for soft plastics | Slow |

| Thickness Capability | Thin to medium plastics | Medium to thick | Thin sheets | Thin to very thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Surface Finish Consistency | Excellent | Good | Fair | Good |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent for complex shapes | Good | Limited | Good |

| Automation and Repeatability | Excellent | Excellent | Good | Good |

| Overall Efficiency for Plastic Processing | Excellent | Very good | Fair | Good |

Laser Cutting Capacity

| Power/Material | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plywood | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| MDF | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Solid Wood | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cork Sheet | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Bamboo Board | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Laminates | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Acrylic (PMMA) | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| ABS | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Delrin (POM) | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Composite | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| EVA Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Depron Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Gator Foam | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cardboard | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Stone | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

| Leather | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Textile | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Nylon | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Felt | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Rubber | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Ceramic | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

Applications of Laser Cutting Plastic

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

Why Do Different Plastics Absorb Laser Energy Differently?

- Chemical Structure and Molecular Bonds: Plastics are made from different polymer chains with distinct chemical bonds. Some polymers, such as acrylic (PMMA), have molecular structures that strongly absorb the infrared wavelength produced by CO2 lasers. This absorption converts laser energy efficiently into heat, allowing clean melting and vaporization. Other plastics, like polyethylene or polypropylene, have molecular bonds that absorb less energy at the same wavelength, making them harder to cut and requiring higher power or slower speeds.

- Optical Properties and Transparency: A plastic’s transparency or opacity plays a major role in laser energy absorption. Transparent plastics may allow some laser energy to pass through or scatter within the material rather than being absorbed at the surface. Acrylic, although optically clear to visible light, absorbs infrared laser energy very well. In contrast, some clear or lightly colored plastics transmit or reflect more laser energy, reducing cutting efficiency.

- Thermal Properties: Different plastics have different melting points, thermal conductivity, and heat capacities. Plastics with low melting temperatures soften and melt quickly under laser exposure, absorbing energy efficiently but sometimes producing excessive melting or edge rounding. Plastics with higher melting points or greater thermal stability require more energy input before material removal begins, changing how effectively they absorb laser energy.

- Additives, Fillers, and Pigments: Commercial plastics often contain additives such as pigments, fillers, plasticizers, or flame retardants. These additives can significantly alter laser absorption. Dark pigments, for example, absorb laser energy more readily than light or reflective pigments. Fillers like glass fibers can scatter laser energy, reducing absorption and making cutting less uniform.

- Crystalline vs. Amorphous Structure: Amorphous plastics, such as acrylic, tend to absorb laser energy more uniformly and melt cleanly. Semi-crystalline plastics, like polyethylene and nylon, have ordered molecular regions that can reflect or redistribute energy, leading to uneven heating and less predictable cutting behavior.

- Decomposition Behavior: Some plastics vaporize cleanly when heated, while others decompose into gases, smoke, or molten residue. Plastics that decompose rather than vaporize may absorb energy but convert it inefficiently into cutting action, resulting in burning, charring, or excessive fume production.

- Surface Finish and Thickness: Surface texture and thickness also affect absorption. Rough or matte surfaces absorb more laser energy than smooth, glossy ones, while thicker materials require more absorbed energy to achieve full penetration.

Why Does Laser-Cut Plastic Melt?

- Thermoplastic Nature of Most Plastics: Common laser-cut plastics such as acrylic (PMMA), ABS, polyethylene, and Delrin are thermoplastics. These materials are designed to soften and melt when heated and then solidify again when cooled. When a laser beam strikes the plastic, it rapidly raises the local temperature above the material’s melting point, causing the plastic to liquefy instead of breaking or vaporizing cleanly.

- High Energy Density of the Laser Beam: Laser cutting focuses a large amount of energy into a very small spot. This intense, localized heat overwhelms the plastic’s ability to dissipate thermal energy. As a result, the material transitions into a molten state almost instantly, especially at slower cutting speeds or higher power settings.

- Limited Heat Dissipation: Plastics generally have low thermal conductivity, meaning heat does not spread quickly away from the cut zone. This causes heat to accumulate locally, further promoting melting. Instead of being carried away, the heat stays concentrated at the laser interaction point, deepening the molten region.

- Melting Occurs Before Vaporization: For many plastics, the temperature range between melting and vaporization is relatively wide. The laser energy often raises the temperature enough to melt the plastic but not enough to fully vaporize it. As a result, material removal happens through melting and flow rather than clean ablation, leaving molten edges behind.

- Molten Material Flow and Re-Solidification: Once melted, plastic can flow due to gravity, surface tension, or assist gas pressure. If this molten material is not completely expelled from the kerf, it cools and re-solidifies along the cut edge. This creates rounded edges, fused surfaces, or a glossy appearance typical of laser-cut plastic.

- Influence of Cutting Parameters: High power, slow cutting speeds, poor focus, or multiple passes increase heat input and exposure time, all of which intensify melting. Conversely, faster speeds and optimized power settings can reduce excessive melt but rarely eliminate it.

- Material-Specific Behavior: Some plastics, like acrylic, melt and vaporize in a relatively controlled way, producing smooth, polished edges. Others, such as polyethylene or polypropylene, tend to melt excessively and smear, making clean cuts more difficult.

Why Does Laser-Cut Plastic Shrink?

- Thermal Expansion Followed by Rapid Cooling: When a laser beam cuts plastic, it rapidly heats the material in a narrow zone, causing the polymer chains to expand. Once the laser moves on, the heated area cools quickly. As the temperature drops, the material contracts. This rapid heat–cool cycle results in localized shrinkage, especially near the cut edges.

- Thermoplastic Molecular Behavior: Most laser-cut plastics are thermoplastics, meaning their molecular chains become mobile when heated. During laser cutting, these chains can relax or rearrange from their original manufactured state. When the plastic cools, the chains settle into a new, often more compact configuration, leading to permanent dimensional shrinkage.

- Residual Stress Release: Plastic sheets often contain internal stresses from extrusion, molding, or rolling during manufacturing. Laser cutting introduces heat that relieves these built-in stresses unevenly. As stresses are released, the material may contract or warp, causing shrinkage along the cut path or across the entire part.

- Localized Melting and Material Loss: Laser cutting removes material by melting and partial vaporization. As molten plastic flows away from the kerf or vaporizes, the remaining material pulls inward slightly to compensate for the lost volume. This inward movement contributes to edge shrinkage and dimensional changes.

- Low Thermal Conductivity of Plastics: Plastics do not conduct heat efficiently, so temperature gradients between the hot cut zone and the cooler surrounding material are steep. These gradients create uneven expansion and contraction forces, increasing the likelihood of shrinkage near laser-cut edges.

- Cooling Rate Effects: The speed at which plastic cools after laser exposure affects shrinkage severity. Rapid cooling can “freeze” the material before it fully relaxes, causing uneven contraction. Slower cooling allows more uniform relaxation but can still result in overall dimensional reduction.

- Material-Specific Shrinkage Tendencies: Different plastics shrink at different rates. Semi-crystalline plastics such as polyethylene or nylon tend to shrink more because their crystalline regions reorganize during cooling. Amorphous plastics like acrylic shrink less but can still experience noticeable dimensional changes near the cut edge.

- Influence of Cutting Parameters: Higher laser power, slower cutting speeds, and multiple passes increase heat input and exposure time, intensifying thermal effects and shrinkage. Poor focus can also widen the heated zone, increasing overall contraction.

Why Do Optical Components Easily Accumulate Dirt When Laser-Cutting Plastic?

- Generation of Sticky Plastic Vapors: When plastics are laser-cut, they do not simply vaporize cleanly. Instead, the intense heat causes melting and thermal decomposition of polymer chains. This process releases semi-molten vapors and aerosols that contain unburned hydrocarbons and plastic residues. As these vapors cool, they condense into sticky films that easily adhere to optical components.

- Fine Particulate and Smoke Production: Laser cutting plastics generates a mixture of smoke and microscopic solid particles. These particles remain airborne and are carried throughout the laser enclosure by airflow. Optical components, especially lenses and mirrors, act as natural collection points where these particles settle and accumulate over time.

- Electrostatic Attraction: Many plastics generate static charges during cutting due to friction, heat, and material separation. Optical components can become electrostatically charged as well, attracting airborne plastic particles and fumes. This electrostatic effect accelerates contamination, even when ventilation systems are functioning properly.

- Condensation on Cooler Optical Surfaces: Optical components are often cooler than the cutting zone. As hot plastic vapors rise and contact these cooler surfaces, they condense into thin films. Once deposited, these films are difficult to remove and can quickly build up with continued cutting.

- Incomplete Fume Extraction: Even well-designed exhaust systems cannot capture all fumes immediately at the source. Some plastic vapors escape localized extraction and circulate within the machine enclosure. Over time, repeated exposure leads to a gradual buildup of residue on optics, requiring frequent cleaning.

- Chemical Nature of Plastic Byproducts: Plastic fumes often contain oils, waxes, and partially decomposed polymers. These substances adhere strongly to coated optical surfaces and can bake onto lenses when exposed to reflected laser energy. This makes contamination more persistent than dust from materials like wood or paper.

- Impact of Optical Contamination: Once dirt accumulates, optical performance degrades. Contaminated lenses absorb more laser energy, creating localized hot spots that can damage coatings, crack optics, or distort the laser beam. This not only reduces cutting quality but also shortens the lifespan of expensive optical components.

- Frequency of Exposure: Plastics are often cut at slower speeds or higher power settings, increasing fume generation per cut. This extended exposure time further accelerates contamination of optics.

Why Do The Edges Of Laser-Cut Plastic Change Color?

- Thermal Decomposition and Chemical Changes: When a laser cuts plastic, the temperature at the cut edge rises rapidly. Many plastics do not simply melt; they partially decompose. This thermal decomposition breaks polymer chains and creates new chemical compounds, some of which are darker or more opaque than the original material. These altered compounds remain at the edge, causing yellowing, browning, or darkening.

- Oxidation at High Temperatures: Laser cutting is typically performed in ambient air, allowing oxygen to interact with hot plastic surfaces. At elevated temperatures, oxidation reactions occur readily. Oxidized polymer surfaces often appear discolored, especially in clear or light-colored plastics. This is a common reason why transparent plastics develop yellow or amber edges after cutting.

- Localized Overheating and Charring: If laser power is high or cutting speed is slow, excessive heat input can cause localized overheating. In such cases, the plastic may char slightly rather than melt cleanly. This charring produces darker edges, ranging from light brown to black, depending on the severity of thermal damage.

- Re-Solidification of Molten Material: Molten plastic often flows and then re-solidifies along the cut edge. As it cools, the material can trap microbubbles, degraded polymer fragments, or condensed vapors. These features scatter light differently than the bulk material, making the edge appear cloudy, frosted, or discolored, even if the chemistry has not changed dramatically.

- Influence of Additives and Pigments: Plastics commonly contain pigments, dyes, stabilizers, or fillers. Laser heating can alter these additives chemically or physically. Some pigments darken when overheated, while others break down and leave residues that change the edge color. This is why different colored plastics respond differently to the same laser settings.

- Material-Specific Responses: Amorphous plastics like acrylic often produce clear, polished edges but can still yellow slightly if overheated. Semi-crystalline plastics such as polyethylene or polypropylene are more prone to whitening, graying, or uneven discoloration due to structural changes during melting and cooling.

- Effect of Cutting Parameters: Higher power, slower speed, poor focus, or multiple passes increase heat exposure and deepen color changes. Optimized settings reduce discoloration but rarely eliminate it.

Why Is The Kerf Width Inconsistent When Laser-Cutting Plastic?

- Material Properties and Composition: Different plastics have varying chemical compositions, thermal conductivities, and melting points. For example, acrylic (PMMA) may behave differently from polyethylene or ABS when exposed to laser heat. These differences affect how the plastic melts, flows, or vaporizes during cutting. As a result, some areas may absorb more laser energy and expand, leading to a wider kerf, while others may remain more compact, resulting in a narrower kerf.

- Uneven Heat Distribution: Laser cutting involves focused, intense heat that is applied to a specific area of the plastic. However, because plastics generally have low thermal conductivity, heat does not spread evenly across the material. Areas closer to the laser’s focal point will experience more heat and undergo more melting, while areas farther away may not receive enough energy to melt uniformly. This can cause inconsistencies in kerf width, especially if the laser speed or power settings are not optimized for the material.

- Cutting Speed and Laser Power: The laser cutting speed and power settings significantly influence kerf width. If the laser moves too quickly, the material may not melt sufficiently, leading to a narrow and inconsistent kerf. Conversely, slower speeds and higher power settings can cause the material to overheat and melt too much, resulting in a wider kerf. The variation in heat input during the cutting process, especially when speeds and power settings are not carefully controlled, can lead to uneven kerf widths.

- Laser Focus and Spot Size: The focus of the laser beam is crucial for achieving a consistent cut. A laser that is out of focus or has an inconsistent focal spot will result in uneven heating across the cut, leading to variations in the kerf width. A smaller, sharper focus can produce a more precise cut with a narrow, uniform kerf, while a broader focus may produce a wider and more inconsistent kerf.

- Thermal Effects and Material Shrinkage: Plastics are subject to thermal expansion and shrinkage during the cutting process. As the plastic melts, it may contract after cooling, causing slight shifts in the width of the cut. Additionally, if the laser settings are too aggressive, the heat can cause uneven shrinkage, leading to a wider or irregular kerf in certain areas.

Why Does Laser-Cutting Plastic Produce Toxic Fumes?

- Thermal Decomposition of Plastics: Plastics, particularly synthetic ones like PVC, ABS, or polyethylene, are made of long polymer chains that decompose when exposed to the high heat of a laser. The heat breaks the chemical bonds in the material, releasing volatile organic compounds (VOCs), gases, and potentially toxic byproducts. These compounds may include carbon monoxide, acrolein, formaldehyde, hydrochloric acid (particularly when cutting PVC), and other harmful gases that are hazardous to human health when inhaled.

- Chemical Additives and Fillers: Many plastics contain additives, stabilizers, plasticizers, flame retardants, and pigments that are incorporated during the manufacturing process to modify properties like flexibility, color, and durability. When these plastics are laser-cut, the additives can also decompose, releasing additional toxic fumes. For example, some flame-retardant chemicals release halogenated compounds, which are toxic and can produce acidic fumes.

- Incomplete Combustion and Smoke Generation: Unlike metals or glass, plastics do not vaporize cleanly when heated by the laser; instead, they burn, melt, and smolder, producing smoke. This smoke can contain a mix of particulate matter, gases, and vapors that can irritate the eyes, nose, and respiratory system. Even plastics that are labeled as “safe” may release particles or gases that, if inhaled, can cause long-term health problems.

- Material-Specific Toxicity: The toxicity of the fumes depends largely on the type of plastic. For instance:

- PVC (Polyvinyl Chloride) releases chlorine gas, which is highly toxic and can cause respiratory issues.

- Acrylic (PMMA) produces fumes that can irritate the eyes and respiratory system, but are generally less toxic than those from PVC.

- ABS (Acrylonitrile Butadiene Styrene) releases styrene and other VOCs, which can be harmful with prolonged exposure.

- Need for Proper Ventilation: To mitigate these hazards, laser cutting of plastics should always be conducted in a well-ventilated area, ideally with a fume extraction system that captures and filters out the harmful emissions. Without proper ventilation, these toxic fumes can accumulate and pose serious health risks to operators and others in the vicinity.

Why Is Personal Protective Equipment Needed For Laser-Cutting Plastic?

- Toxic Fume Inhalation: Laser cutting plastic materials, especially those like PVC, ABS, and acrylic, generates fumes that can contain dangerous chemicals such as hydrochloric acid, formaldehyde, styrene, and acrolein. These substances can be harmful if inhaled and may cause irritation to the eyes, throat, and respiratory system. Prolonged exposure can lead to more severe health effects, including respiratory issues and long-term damage to the lungs. PPE, such as a proper respirator, is essential to protect against inhalation of these toxic fumes.

- Heat Exposure: The laser cutting process produces intense localized heat, which can cause burns or heat-related injuries if not handled properly. Protective gloves and appropriate clothing are necessary to shield operators from accidental contact with hot surfaces or molten plastic that may splatter during the cutting process.

- Particulate Matter and Smoke: The cutting of plastic generates smoke and fine particulates that can irritate the eyes, nose, and respiratory system. These particles can also linger in the air, increasing the risk of exposure. Safety goggles or face shields protect the eyes from particulate matter and other debris, while respirators help prevent inhalation of these harmful particles.

- Flame and Fire Hazards: Plastics are combustible, and laser cutting creates a significant fire risk if not carefully monitored. In the event of flare-ups or small fires, protective clothing, including flame-resistant apparel, can prevent burns or injuries. A fire extinguisher should always be available when cutting plastics to handle any accidental ignitions.

- Eye Protection from Laser Exposure: CO2 lasers emit high-intensity light, which can be hazardous to the eyes. Without proper eye protection, exposure to the laser light can cause serious eye injuries. Laser safety goggles are designed to protect against both direct and reflected laser light, ensuring safe operation.

- Preventing Long-Term Health Issues: Repeated exposure to laser-cutting fumes and chemicals over time can lead to chronic health issues, such as respiratory problems or even cancer. PPE, including respirators with appropriate filters, helps minimize this risk, offering long-term protection for operators.