Introduction

Advantages of Laser Cutting Paper

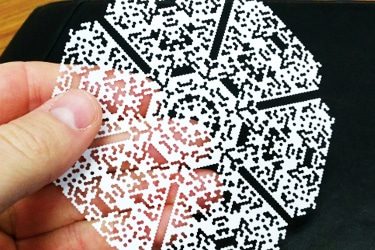

High Precision and Detail

Laser cutting paper enables extremely fine details, sharp corners, and intricate patterns that are difficult to achieve with traditional cutting methods. This precision is ideal for decorative designs, packaging prototypes, and detailed paper-based products.

Non-Contact Cutting Process

Because laser cutting paper does not involve physical contact, the paper is not stretched, torn, or bent during processing. This ensures smooth cuts and protects delicate or thin paper materials from mechanical damage.

Clean and Consistent Edges

Laser cutting paper produces clean, uniform edges with minimal burrs or fibers. With proper settings, the cut quality remains consistent across batches, reducing the need for manual finishing and improving the overall appearance of paper products.

High Design Flexibility

Laser cutting paper allows quick changes to designs using digital files. Complex shapes, patterns, and text can be easily modified without new tools, making it ideal for customization, prototyping, and short production runs.

Reduced Material Waste

The narrow kerf width of laser cutting paper enables efficient nesting of parts on a sheet. This maximizes material usage, minimizes scrap, and helps reduce overall production costs, especially for specialty or premium paper materials.

Fast Setup and Efficient Production

Laser cutting paper requires minimal setup time and supports automated operation. This improves production speed, ensures repeatable results, and helps manufacturers meet tight deadlines while maintaining consistent quality.

Compatible Materials

- Standard Printer Paper

- Cardstock

- Kraft Paper

- Construction Paper

- Copy Paper

- Recycled Paper

- Glossy Photo Paper

- Newspaper Print

- Coated Paper

- Watercolor Paper

- Handmade Paper

- Art Paper

- Vellum

- Parchment Paper

- Bristol Board

- Corrugated Cardboard

- Chipboard

- Matte Paper

- Metallic Paper

- Embossed Paper

- Textured Paper

- Bond Paper

- Label Paper

- Adhesive-Backed Paper

- Tissue Paper

- Crepe Paper

- Laminated Paper

- Thermal Paper

- Foil-Lined Paper

- Greeting Card Paper

- Invitation Paper

- Postcard Stock

- Wrapping Paper

- Tracing Paper

- Transparent Paper

- Engineering Plotter Paper

- Die-Cut Sticker Paper

- Book Cover Stock

- Calendar Paper

- Business Card Stock

Laser Cutting Paper VS Other Cutting Methods

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Paper Materials | Highly suitable | Poor | Very suitable | Poor |

| Cutting Precision | Very high | Medium | Medium | High |

| Edge Quality | Clean, sharp edges | Rough edges | Clean but uneven | Clean but wet |

| Material Deformation | None (non-contact) | High risk | Medium | None |

| Heat-Affected Zone (HAZ) | Small and controlled | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High | Moderate | High | Slow |

| Thickness Capability | Thin to medium paper | Medium materials | Thin to medium paper | Thin to thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent | Good | Limited | Good |

| Automation and Repeatability | Excellent | Good | Good | Good |

| Operating Cost | Moderate | Moderate | Low | High |

| Overall Efficiency for Paper Processing | Excellent | Fair | Good | Poor |

Laser Cutting Capacity

| Power/Material | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plywood | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| MDF | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Solid Wood | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cork Sheet | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Bamboo Board | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Laminates | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Acrylic (PMMA) | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| ABS | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Delrin (POM) | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Composite | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| EVA Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Depron Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Gator Foam | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cardboard | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Stone | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

| Leather | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Textile | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Nylon | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Felt | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Rubber | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Ceramic | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

Applications of Laser Cutting Paper

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

How Does Paper Density Variation Affect The Consistency Of Laser Cutting?

- Uneven Laser Energy Absorption: Denser paper contains more tightly packed cellulose fibers per unit area, allowing it to absorb more laser energy before fully cutting through. Lower-density paper, with more air gaps between fibers, absorbs energy more quickly and burns through faster. When a single laser setting is used across areas of varying density, some regions may cut cleanly while others may be undercut or overburned.

- Inconsistent Cut-Through and Incomplete Separation: Laser parameters are usually optimized for an average paper density. In higher-density regions, the laser may not deliver enough energy to fully sever fibers, resulting in incomplete cuts or areas that remain attached. Conversely, lower-density areas may burn excessively, creating widened kerfs or fragile edges.

- Variation in Edge Quality: Denser paper tends to produce darker, more charred edges because more material is exposed to heat before separation occurs. Lighter paper burns away faster, often leaving lighter-colored edges but with a higher risk of fraying or edge weakness. These differences lead to visible inconsistencies along the same cut path.

- Thermal Accumulation and Localized Burning: Paper is a poor thermal conductor, so heat remains localized at the cutting point. In dense regions, heat builds up longer before fibers separate, increasing charring and edge roughness. In low-density areas, rapid burn-through reduces heat exposure time, but can also cause excessive flare-ups or edge deformation.

- Influence of Fiber Distribution and Orientation: Density variations are often accompanied by uneven fiber distribution and orientation. Areas with randomly packed fibers may resist cutting differently than regions with more uniform alignment, causing irregular kerf widths and cut paths.

- Moisture Retention Differences: Denser paper may retain more moisture, which absorbs heat before combustion begins. This delays cutting and requires more energy, while drier, less dense areas ignite more quickly. These moisture-related differences further reduce cutting consistency.

- Fire and Stability Risks: Lower-density paper ignites more easily and can flare suddenly, while denser paper may smolder before fully cutting. This uneven burning behavior complicates consistent laser control and increases fire risk.

Why Is The Heat-Affected Zone So Large When Laser-Cutting Paper?

- Low Thermal Stability of Cellulose Fibers: Paper is composed mainly of cellulose, which begins to thermally degrade at relatively low temperatures. When exposed to a laser beam, cellulose does not melt; it decomposes and burns. This combustion-based material removal releases heat into surrounding fibers, extending thermal damage beyond the narrow laser kerf and increasing the HAZ.

- Poor Heat Dissipation: The paper has very low thermal conductivity, meaning it cannot efficiently transfer heat away from the cutting zone. As a result, heat accumulates locally and spreads laterally through neighboring fibers. This trapped heat causes adjacent areas to discolor, char, or weaken, expanding the heat-affected zone.

- Porous and Fibrous Structure: Paper’s porous network of fibers contains air pockets that support combustion. Once a region is heated by the laser, nearby fibers can continue burning or smoldering even after the laser has moved on. This sustained thermal activity enlarges the HAZ well beyond the point of direct laser contact.

- Rapid Ignition and Smoldering Behavior: Paper ignites easily, especially at laser cutting temperatures. In denser areas, fibers may smolder rather than burn away instantly, prolonging heat exposure. This smoldering effect spreads heat slowly outward, increasing the size of the HAZ and causing uneven edge discoloration.

- Extended Heat Exposure From Conservative Settings: To avoid excessive flare-ups or complete ignition, laser cutting paper is often done at lower power and slower speeds. While safer, these settings increase the time heat is applied to the material, allowing thermal energy to diffuse into surrounding areas and enlarge the HAZ.

- Influence of Moisture Content: Paper often contains residual moisture that absorbs heat before evaporating. Once moisture is driven off, temperatures rise rapidly, causing delayed but widespread burning. This sequence leads to a broader zone of thermal damage than the laser spot alone would suggest.

- Assist Air and Oxygen Effects: Air assist, while necessary for safety, introduces oxygen into the cutting area. This oxygen supports continued combustion at the cut edge, allowing heat to propagate further into the paper fibers and expand the HAZ.

Why Do The Edges Of Laser-Cut Paper Char?

- Combustion-Based Material Removal: Paper is made mainly of cellulose fibers, which are organic and highly flammable. When a laser beam strikes paper, temperatures rise rapidly above the ignition point of cellulose. Instead of being removed cleanly, the fibers combust or partially burn. This combustion leaves behind carbon-rich residues, which appear as darkened or charred edges.

- Low Thermal Stability of Cellulose: Cellulose begins to thermally degrade at relatively low temperatures. Laser cutting easily exceeds this threshold, causing pyrolysis—a process where the material decomposes under heat before it can completely burn away. Pyrolysis produces char rather than clean separation, especially at the cut edges where heat exposure is greatest.

- Poor Heat Dissipation: The paper has very low thermal conductivity, so heat does not spread away from the laser interaction zone efficiently. As a result, heat accumulates at the cut edge and continues to affect nearby fibers. This prolonged exposure causes additional charring even after the laser has already cut through the material.

- Porous and Fibrous Structure: The fibrous structure of paper contains air pockets that support combustion. Once fibers near the cut ignite or smolder, adjacent fibers can continue to char due to residual heat and oxygen availability. This spreads thermal damage slightly beyond the laser’s kerf, darkening the edges.

- Smoldering After Laser Pass: In many cases, paper does not burn away instantly. Instead, fibers smolder briefly after the laser passes. This smoldering continues to generate heat locally, deepening the charred appearance along the edge.

- Effect of Cutting Speed and Power: Slower cutting speeds or higher laser power increase the time heat is applied to the paper. Longer exposure intensifies combustion and pyrolysis, resulting in darker and thicker char layers. Even small parameter changes can significantly affect edge appearance.

- Influence of Moisture and Additives: Variations in moisture content, fillers, or coatings in paper can alter how it burns. Drier areas tend to char more readily, while additives may decompose and contribute to discoloration at the edges.

- Role of Oxygen and Air Assist: Laser cutting is usually performed in air, providing ample oxygen to sustain burning. While air assist helps prevent flare-ups, it also supports oxidation, contributing to edge charring.

How Does The Paper Grain Orientation Affect The Laser Cutting Result?

- Directional Fiber Resistance to Cutting: When the laser cuts parallel to the paper grain, it follows the natural alignment of fibers. These fibers tend to separate and burn more uniformly, allowing cleaner cuts with smoother edges. When cutting perpendicular to the grain, the laser must sever many fiber ends rather than slide along them. This increases resistance to cutting, often resulting in rougher edges, incomplete separation, or localized tearing.

- Uneven Heat Absorption and Burn Rate: Fibers aligned with the grain can conduct heat slightly more efficiently along their length. As a result, heat spreads more evenly when cutting parallel to the grain, reducing localized overheating. Across the grain, heat is less evenly distributed, causing some fibers to overburn while others resist separation. This uneven heating increases edge charring and widens the heat-affected zone.

- Variation in Edge Charring: Cuts made across the grain tend to show darker, more irregular charring because fiber ends ignite and smolder more readily. Parallel-to-grain cuts often produce lighter, more consistent edge coloration since fibers burn more uniformly and are removed faster.

- Effect on Cut Consistency and Accuracy: Paper grain orientation can cause dimensional inconsistencies in laser-cut parts. Across-grain cuts may experience slight edge waviness or uneven kerf width due to irregular fiber breakage. Along-grain cuts typically yield more predictable kerf widths and smoother contours, especially on intricate designs.

- Influence on Smoldering and Fire Risk: When cutting across the grain, exposed fiber ends can smolder after the laser passes, increasing the risk of delayed burning. Along the grain, fibers are more likely to burn away cleanly, reducing lingering heat and smoldering behavior.

- Interaction With Cutting Speed and Power: Laser settings optimized for cutting along the grain may not perform well across the grain. Across-grain cuts often require slightly higher power or slower speeds to ensure full separation, which can increase charring if not carefully controlled.

- Impact on Fine Details and Small Features: Paper grain orientation is especially important for fine patterns and sharp corners. Across the grain, small features are more prone to distortion, edge roughness, or tearing due to uneven fiber breakage.

Why Does Laser Cutting Of Paper Produce Large Amounts Of Smoke?

- Thermal Decomposition of Cellulose: Paper is primarily made of cellulose, an organic polymer that breaks down at relatively low temperatures. When exposed to a laser beam, cellulose undergoes pyrolysis, releasing volatile gases and carbon-rich particles instead of disappearing cleanly. These decomposition products form dense smoke during cutting.

- Combustion in an Oxygen-Rich Environment: Laser cutting is typically performed in ambient air, where oxygen is readily available. The heated cellulose fibers partially combust as they decompose, producing smoke, soot, and other combustion byproducts. This incomplete combustion is a major source of visible smoke during laser cutting.

- High Surface Area of Paper Fibers: Paper has a fibrous and porous structure with a very high surface-area-to-volume ratio. When the laser interacts with the paper, many fibers are heated simultaneously. This widespread heating increases the volume of material undergoing decomposition at once, leading to higher smoke output.

- Poor Heat Dissipation: The paper has very low thermal conductivity, so heat remains localized at the cutting zone. This concentrated heat causes sustained decomposition and smoldering of fibers even after the laser passes. Smoldering fibers continue to emit smoke, increasing total smoke production.

- Smoldering and Delayed Burning: Unlike materials that burn away instantly, paper often smolders briefly. This smoldering releases smoke over a longer period rather than in a single burst, making smoke generation appear more excessive during cutting.

- Influence of Cutting Parameters: To prevent flare-ups or uncontrolled ignition, paper is often cut at lower power or slower speeds. These conservative settings increase the time fibers are exposed to heat, encouraging prolonged pyrolysis and greater smoke generation.

- Role of Additives and Coatings: Paper frequently contains fillers, sizing agents, inks, or coatings. When heated, these additives decompose and volatilize, contributing additional smoke and sometimes strong odors.

- Air Assist Effects: Air assist helps prevent open flames but can spread smoke throughout the cutting area. While it improves safety, it can make smoke more visible and widespread if extraction is insufficient.

Why Does The Auxiliary Air Supply During Laser Cutting Of Paper Exacerbate Combustion?

- Increased Oxygen Availability at the Cut Zone: Paper is composed mainly of cellulose, which burns readily in the presence of oxygen. Auxiliary air delivers a continuous stream of oxygen directly to the laser-paper interaction zone. When the laser heats the paper above its ignition temperature, the added oxygen accelerates oxidation reactions, causing fibers to burn more vigorously instead of simply decomposing or separating.

- Promotion of Sustained Combustion: Without air assist, laser cutting may cause brief pyrolysis or localized charring. However, the introduction of airflow sustains combustion by feeding oxygen to smoldering fibers. This can transform momentary heating into continuous burning along the cut path, increasing flame intensity and duration.

- Acceleration of Smoldering Fibers: Paper often smolders rather than burns away instantly. Auxiliary air can convert smoldering into an open flame by increasing oxygen diffusion into the porous fiber network. As a result, fibers that might otherwise self-extinguish can reignite or continue burning after the laser has moved on.

- Enhanced Flame Spread Through Porous Structure: Paper’s fibrous, porous structure allows air to penetrate deeply between fibers. The auxiliary air stream can push oxygen into internal layers, enabling combustion to spread beyond the immediate kerf. This increases the likelihood of edge charring, widening of the heat-affected zone, and uncontrolled flame propagation.

- Increased Heat Release and Feedback Effects: Combustion releases additional heat beyond that supplied by the laser. When auxiliary air intensifies burning, this extra heat feeds back into adjacent fibers, raising their temperature and making them more likely to ignite. This feedback loop amplifies overall combustion severity.

- Disruption of Thermal Balance: Air assist is often used to cool materials and remove smoke, but with paper, the cooling effect is outweighed by the combustion-enhancing effect of oxygen. The net result is more heat generation from burning than heat removal from airflow.

- Influence of Air Pressure and Direction: High air pressure or poorly directed airflow can worsen the problem by aggressively feeding flames or spreading embers along the cut. This can cause sudden flare-ups and uneven burning, especially on thin paper.

- Safety Trade-Off: While auxiliary air helps prevent debris accumulation and improves visibility, it must be carefully controlled. Excessive airflow increases fire risk rather than reducing it when cutting paper.

Why Does Laser Cutting Of Paper Pose Fire Hazards?

- Low Ignition Temperature of Paper: Paper is primarily made of cellulose fibers, which ignite at relatively low temperatures. The focused laser beam easily exceeds this ignition threshold in milliseconds. Even brief exposure can cause paper to catch fire rather than simply separate cleanly, especially at slow cutting speeds or high power settings.

- Combustion-Based Cutting Mechanism: Laser cutting paper relies on burning and thermal decomposition instead of melting. This means that open flames or glowing embers are a natural byproduct of the process. Once ignition begins, combustion can continue independently of the laser, increasing fire risk.

- Porous, Fibrous Structure: The paper’s porous structure allows oxygen to flow easily between fibers, supporting combustion. Once a fiber ignites, flames or smoldering can spread rapidly along the grain or through layers of stacked paper. This internal oxygen access makes fires difficult to predict and control.

- Poor Heat Dissipation and Smoldering: The paper has very low thermal conductivity, so heat remains localized at the cutting zone. After the laser passes, fibers can continue to smolder, releasing heat and potentially reigniting nearby material. Smoldering fires may not be immediately visible, creating delayed ignition hazards.

- Influence of Air Assist and Ventilation: Air assist is often used to clear smoke and prevent flare-ups, but it also introduces oxygen directly to the cutting zone. This additional oxygen can intensify combustion, causing small flare-ups to grow quickly into sustained flames.

- Accumulation of Combustible Debris: Paper cutting generates char, ash, and fine dust, which can accumulate on the cutting bed or surrounding areas. These residues are highly combustible and can ignite suddenly when exposed to heat or laser reflections.

- High Cutting Speeds and Thin Material: Thin paper heats up almost instantly under laser exposure. Small errors in focus, speed, or power can cause rapid ignition before the operator has time to react.

- Delayed Fire Risk After Cutting: Even after cutting stops, residual heat and smoldering fibers can ignite minutes later. This delayed ignition is especially dangerous if the machine is left unattended.

Why Does Laser Cutting Of Paper Increase The Frequency Of Maintenance?

- Heavy Smoke and Soot Contamination: Paper is composed of cellulose fibers that burn and decompose when cut by a laser. This process produces dense smoke and carbon-rich soot that spreads throughout the cutting chamber. Soot easily deposits on lenses, mirrors, and protective windows, reducing laser power transmission and beam focus. As contamination builds up, frequent cleaning or replacement of optical components becomes necessary to maintain cutting accuracy.

- Rapid Lens and Mirror Degradation: Laser optics are highly sensitive to airborne particulates. Paper smoke contains sticky tar-like residues that adhere to optical surfaces and can burn into coatings under laser exposure. Even small amounts of residue can cause hot spots on lenses, increasing the risk of cracking or permanent damage and requiring more frequent inspection and replacement.

- Accumulation of Ash and Paper Debris: Laser cutting paper produces fine ash, charred fibers, and dust that accumulate on the cutting bed, rails, honeycomb tables, and motion components. This debris can interfere with part positioning, airflow, and machine movement, requiring frequent cleaning to prevent mechanical issues and cutting inconsistencies.

- Increased Load on Ventilation and Filtration Systems: Paper cutting places a heavy burden on exhaust fans, ducts, and filtration units. Filters clog rapidly due to high particulate output, reducing airflow efficiency. Frequent filter replacement and duct cleaning are required to maintain proper smoke extraction and prevent heat buildup inside the machine.

- Fire Residue and Burn Marks: Small flare-ups or smoldering fibers can leave burn marks, melted residues, or debris on machine surfaces. These residues not only require cleanup but also pose ongoing fire risks if allowed to accumulate.

- Higher Risk of Corrosion and Component Wear: Paper smoke can contain acidic byproducts, especially from coated or treated papers. These compounds can accelerate corrosion of metal components, fasteners, and electrical contacts, increasing long-term maintenance demands.

- Frequent Alignment and Calibration Needs: Contaminated optics and mechanical components can gradually affect beam alignment and cutting precision. As a result, recalibration and alignment checks are needed more often than when cutting cleaner materials like acrylic.

- Safety-Driven Maintenance: Because paper cutting has a higher fire risk, machines must be inspected more frequently for debris buildup, airflow obstructions, and heat-damaged components to ensure safe operation.