Introduction

Advantages of Laser Cutting Galvanized Steel

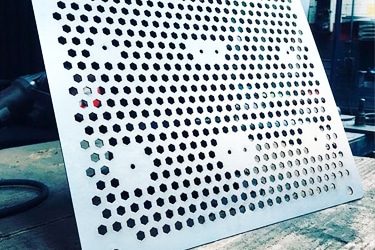

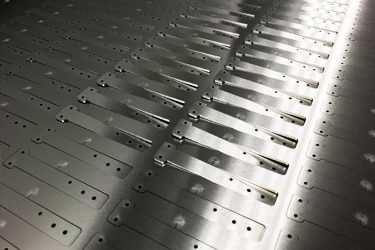

High Precision and Accuracy

Laser cutting provides exceptional precision, enabling tight tolerances and fine details. This high accuracy ensures that even complex shapes and intricate designs in galvanized steel are cut consistently, minimizing material waste and ensuring parts fit perfectly.

Clean, Smooth Edges

Laser cutting produces clean, burr-free edges with minimal oxidation, especially when using nitrogen as an assist gas. This reduces or eliminates the need for secondary finishing, saving time and labor costs while enhancing the part's overall appearance.

Minimal Heat-Affected Zone

Laser cutting minimizes the heat-affected zone, which is crucial when working with galvanized steel. This reduces the risk of compromising the material's structural integrity and the zinc coating, maintaining the steel's strength and corrosion resistance.

Fast Cutting Speeds

Laser cutting is a rapid process, especially when combined with high-powered fiber lasers and optimal assist gases. This speed allows for faster production cycles, improving overall efficiency and reducing lead times in both small and large-scale manufacturing runs.

Ability to Cut Complex Shapes

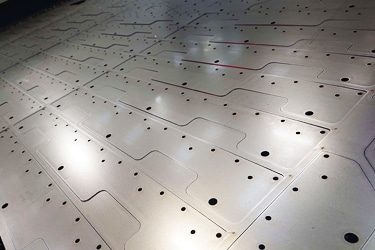

Laser cutting offers the flexibility to cut highly intricate geometries and complex shapes in galvanized steel. The technology allows for tight curves, holes, and fine details, making it ideal for industries requiring customized or precision parts.

Low Material Waste

The narrow kerf width of laser cutting helps to maximize material utilization, reducing scrap. Advanced nesting software can further optimize layouts, ensuring the most efficient use of galvanized steel sheets and minimizing waste, contributing to lower production costs.

Compatible Materials

- A36 Galvanized Steel

- A516 Grade 70 Galvanized Steel

- A572 Grade 50 Galvanized Steel

- A588 Galvanized Steel

- A1011 Galvanized Steel

- A1018 Galvanized Steel

- G60 Galvanized Steel

- G90 Galvanized Steel

- G100 Galvanized Steel

- G140 Galvanized Steel

- G165 Galvanized Steel

- Galvanized Steel Sheet

- Galvanized Steel Coil

- Galvanized Steel Plate

- Galvanized Steel Pipe

- Galvanized Steel Tube

- Galvanized Steel Fence Material

- Galvanized Steel Strip

- Galvanized Steel Wire

- DX51D Galvanized Steel

- DX52D Galvanized Steel

- DX53D Galvanized Steel

- Z100 Galvanized Steel

- Z120 Galvanized Steel

- Z180 Galvanized Steel

- Z275 Galvanized Steel

- Z350 Galvanized Steel

- GI (Galvanized Iron) Steel

- SGCC Galvanized Steel

- SGCD Galvanized Steel

- SPCC Galvanized Steel

- SPCE Galvanized Steel

- SS400 Galvanized Steel

- SS490 Galvanized Steel

- SS540 Galvanized Steel

- HRPO Galvanized Steel

- CRCA Galvanized Steel

- Aluzinc Coated Steel (Galvalume)

- Galvanized Steel for Automotive Parts

- Galvanized Steel for Roofing

Laser Cutting Galvanized Steel VS Other Cutting Methods

| Comparison Item | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Cutting Precision | Very high accuracy | Moderate to low | Very high accuracy | Low precision |

| Edge Quality | Smooth, clean, burr-free | Rough edges, some dross | Smooth but slightly matte | Rough, oxidized edges |

| Heat-Affected Zone | Minimal | Large | None (cold cutting) | Very large |

| Cutting Speed | Fast, especially on thin plates | Moderate to fast | Slow | Slow |

| Material Thickness Range | Thin to medium thickness | Medium to thick materials | Thin to very thick materials | Thick materials only |

| Complexity of Cut | Excellent for intricate designs | Limited detail | Excellent for intricate cuts | Limited to straight lines |

| Kerf Width | Narrow | Wide | Moderate | Wide |

| Secondary Finishing | Minimal or none required | Often required | Rarely required | Always required |

| Suitability for Galvanized Steel | Excellent, minimal oxidation | Poor, oxidation likely | Excellent, no oxidation | Poor, oxidation and coating damage |

| Reflective Material Handling | Designed with reflection control | Poor for reflective materials | No reflection issues | Not applicable |

| Operating Cost | Moderate | Low | High | Low |

| Equipment Investment | Moderate to high | Low to moderate | High | Low |

| Automation Capability | Highly automated, CNC capable | CNC capable | CNC capable | Mostly manual |

| Environmental Impact | Low emissions, clean process | High fumes and noise | Water and abrasive waste | High smoke and gases |

| Cutting Quality Consistency | Excellent for repeatability | Inconsistent quality | Very consistent | Inconsistent |

Laser Cutting Capacity For Galvanized Steel

| Laser Power (kW) | Thickness (mm) | Cutting Speed (m/min) | Focus Position (mm) | Cutting Height (mm) | Gas | Nozzle (mm) | Pressure (bar) |

|---|---|---|---|---|---|---|---|

| 1KW | 1 | 4.8-7.2 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 2.4-3.6 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 1.2-1.8 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 0.8-1.2 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 0.6-0.9 | -2 | 0.6 | N2 | 2 | 14 | |

| 1.5KW | 1 | 6.5-10.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 3.2-4.9 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 1.6-2.4 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 1.1-1.6 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 0.8-1.2 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 0.6-1.0 | -2 | 0.6 | N2 | 2 | 14 | |

| 2KW | 1 | 8.2-12.2 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 4.1-6.1 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 2.0-3.1 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 1.4-2.0 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 1.0-1.5 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 0.8-1.2 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 0.5-0.8 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 0.4-0.6 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 0.3-0.4 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 3KW | 1 | 11.0-16.6 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 5.5-8.3 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 2.8-4.1 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 1.8-2.8 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 1.4-2.1 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 1.1-1.7 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 0.7-1.1 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 0.6-0.8 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 0.4-0.6 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 0.3-0.4 | -3 | 0.5 | N2 | 3 | 16 | |

| 4KW | 1 | 13.0-20.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 6.7-10.0 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 3.4-5.0 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 2.2-3.3 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 1.7-2.5 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 1.3-2.0 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 0.9-1.3 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 0.7-1.0 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 0.4-0.7 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 0.3-0.5 | -3 | 0.5 | N2 | 3 | 16 | |

| 16 | 0.2-0.4 | -3 | 0.5 | N2 | 3 | 16 | |

| 6KW | 1 | 17.3-26.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 8.6-13.0 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 4.3-6.5 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 2.9-4.3 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 2.2-3.2 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 1.7-2.6 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 1.2-1.7 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 0.9-1.3 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 0.6-0.9 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 0.4-0.6 | -3 | 0.5 | N2 | 3 | 16 | |

| 16 | 0.3-0.5 | -3 | 0.5 | N2 | 3 | 16 | |

| 18 | 0.25-0.4 | -4 | 0.5 | N2 | 3 | 16 | |

| 12KW | 1 | 26.0-39.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 13.0-19.5 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 6.5-9.7 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 4.3-6.5 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 3.2-4.9 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 2.6-3.9 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 1.7-2.6 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 1.3-2.0 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 0.9-1.3 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 0.6-1.0 | -3 | 0.5 | N2 | 3 | 16 | |

| 16 | 0.5-0.8 | -3 | 0.5 | N2 | 3 | 16 | |

| 18 | 0.4-0.6 | -4 | 0.5 | N2 | 3 | 16 | |

| 20 | 0.3-0.5 | -4 | 0.5 | N2 | 3 | 16 | |

| 25 | 0.2-0.3 | -4 | 0.5 | N2 | 3.5 | 16 | |

| 20KW | 1 | 38.0-57.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 19.2-28.8 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 9.6-14.4 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 6.4-9.6 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 4.8-7.2 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 3.8-5.8 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 2.6-3.8 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 1.9-2.9 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 1.3-1.9 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 1.0-1.4 | -3 | 0.5 | N2 | 3 | 16 | |

| 16 | 0.8-1.2 | -3 | 0.5 | N2 | 3 | 16 | |

| 18 | 0.6-1.0 | -4 | 0.5 | N2 | 3 | 16 | |

| 20 | 0.5-0.8 | -4 | 0.5 | N2 | 3 | 16 | |

| 25 | 0.3-0.5 | -4 | 0.5 | N2 | 3.5 | 16 | |

| 30 | 0.2-0.3 | -5 | 0.5 | N2 | 3.5 | 18 | |

| 30KW | 1 | 48.0-72.0 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 24.0-36.0 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 12.0-18.0 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 8.0-12.0 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 6.0-9.0 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 4.8-7.2 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 3.2-4.8 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 2.4-3.6 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 1.6-2.4 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 1.2-1.8 | -3 | 0.5 | N2 | 3 | 16 | |

| 16 | 1.0-1.4 | -3 | 0.5 | N2 | 3 | 16 | |

| 18 | 0.8-1.2 | -4 | 0.5 | N2 | 3 | 16 | |

| 20 | 0.6-1.0 | -4 | 0.5 | N2 | 3 | 16 | |

| 25 | 0.4-0.6 | -4 | 0.5 | N2 | 3.5 | 16 | |

| 30 | 0.3-0.4 | -5 | 0.5 | N2 | 3.5 | 18 | |

| 40 | 0.15-0.2 | -5 | 0.4 | N2 | 3.5 | 18 | |

| 40KW | 1 | 57.6-86.4 | 0 | 0.8 | N2 | 1.6 | 12 |

| 2 | 28.8-43.2 | -1 | 0.8 | N2 | 1.6 | 12 | |

| 3 | 14.4-21.6 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 4 | 9.6-14.4 | -1.5 | 0.6 | N2 | 2 | 14 | |

| 5 | 7.2-10.8 | -2 | 0.6 | N2 | 2 | 14 | |

| 6 | 5.8-8.6 | -2 | 0.6 | N2 | 2 | 14 | |

| 8 | 3.8-5.8 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 10 | 2.9-4.3 | -2.5 | 0.6 | N2 | 2.5 | 14 | |

| 12 | 1.9-2.9 | -3 | 0.5 | N2 | 2.5 | 14 | |

| 14 | 1.4-2.2 | -3 | 0.5 | N2 | 3 | 16 | |

| 16 | 1.1-1.7 | -3 | 0.5 | N2 | 3 | 16 | |

| 18 | 1.0-1.4 | -4 | 0.5 | N2 | 3 | 16 | |

| 20 | 0.8-1.2 | -4 | 0.5 | N2 | 3 | 16 | |

| 25 | 0.5-0.7 | -4 | 0.5 | N2 | 3.5 | 16 | |

| 30 | 0.3-0.5 | -5 | 0.5 | N2 | 3.5 | 18 | |

| 40 | 0.2-0.3 | -5 | 0.4 | N2 | 3.5 | 18 | |

| 50 | 0.1-0.2 | -5 | 0.4 | N2 | 4 | 18 |

Applications of Laser Cutting Galvanized Steel

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

How Does Zinc Evaporation Contaminate Laser Optics?

- Low Boiling Point and Rapid Vaporization: Zinc has a much lower boiling point than iron or copper. During laser cutting, the intense heat causes zinc to evaporate almost instantly before the base metal fully melts. This produces a dense zinc vapor cloud directly beneath the cutting head, increasing the likelihood that vapor will migrate upward toward optical components.

- Condensation on Cooler Optical Surfaces: As zinc vapor rises, it encounters cooler surfaces such as the protective window, focusing lens, or internal optics housing. When the vapor cools, it condenses into a thin metallic or oxide film on these surfaces. Even an extremely thin zinc layer is enough to interfere with laser transmission.

- Formation of Zinc Oxide Deposits: In the presence of oxygen, evaporated zinc rapidly oxidizes into zinc oxide. These fine oxide particles are easily carried by airflow and can settle on optics. Zinc oxide has high absorptivity at laser wavelengths, making it particularly damaging when deposited on lenses or protective glass.

- Energy Absorption and Localized Overheating: Once zinc or zinc oxide coats an optical surface, it begins absorbing part of the laser energy instead of transmitting it cleanly. This absorption causes localized heating on the lens or window. Over time, the heat damages anti-reflective coatings, leading to microcracks, and can permanently burn the optical surface.

- Progressive Contamination Cycle: As optics heat up due to contamination, they become even more effective at attracting additional vapor and particles. This creates a self-accelerating cycle: contamination increases absorption, absorption increases heat, and heat accelerates further deposition and damage.

- Impact on Beam Quality: Contaminated optics distort the laser beam, reducing focus precision and energy density at the cutting point. This leads to unstable cutting, increased spatter, and more zinc evaporation—further worsening optical contamination.

- Influence of Poor Airflow and Sealing: Inadequate protective airflow, worn seals, or misaligned nozzles allow zinc vapor easier access to the optical path. Without strong, clean shielding air, optics are far more vulnerable to contamination.

How Do Zinc Fumes Affect Operator Safety?

- Formation of Zinc Oxide Fumes: When zinc is exposed to the intense heat of laser cutting, it vaporizes rapidly due to its low boiling point. As the vapor cools and reacts with oxygen in the air, it forms zinc oxide fumes. These fumes appear as a fine white or bluish smoke and are easily inhaled if ventilation is inadequate.

- Metal Fume Fever: The most well-known health effect of zinc fume exposure is metal fume fever. This is an acute, flu-like condition that typically develops several hours after inhalation. Symptoms include fever, chills, muscle aches, headaches, nausea, fatigue, and chest discomfort. While symptoms usually subside within 24-48 hours, repeated exposure can reduce tolerance and worsen reactions over time.

- Respiratory System Irritation: Zinc oxide particles are extremely fine and can penetrate deep into the lungs. Short-term exposure may cause coughing, throat irritation, and shortness of breath. Prolonged or repeated exposure can lead to chronic respiratory irritation and increased susceptibility to lung infections.

- Reduced Operator Awareness and Performance: Symptoms such as fatigue, dizziness, and headaches can impair concentration and reaction time. In an industrial environment, this reduced alertness increases the risk of accidents, improper machine operation, and poor decision-making, indirectly affecting overall workplace safety.

- Potential Long-Term Health Concerns: While zinc itself does not typically accumulate in the body like some heavy metals, chronic exposure to zinc fumes may contribute to ongoing respiratory issues and reduced lung function. Combined exposure with other metal fumes can further increase health risks.

- Importance of Ventilation and Fume Extraction: Proper ventilation is the most effective way to protect operators. Localized fume extraction at the cutting zone prevents zinc fumes from dispersing into the workspace. High-efficiency filtration systems, including HEPA filters, help capture fine zinc oxide particles before they reach breathing zones.

- Personal Protective Measures: In environments where ventilation alone is insufficient, operators may require respiratory protection such as approved masks or respirators. Training and awareness are also essential so operators can recognize symptoms early and respond appropriately.

Why Does Laser Cutting Of Galvanized Steel Produce Excessive Spatter?

- Low Boiling Point of Zinc: Zinc has a much lower boiling point than steel. When the laser beam contacts galvanized steel, the zinc coating vaporizes almost instantly—often before the underlying steel fully melts. This rapid evaporation creates localized pressure beneath the molten steel surface, forcing molten metal to eject violently as spatter.

- Explosive Zinc Vapor Release: As zinc vapor forms, it expands rapidly. If this vapor becomes trapped beneath the molten steel layer, it escapes suddenly through the melt pool. This “boiling” effect disrupts the stability of the molten metal, causing droplets to be expelled upward and outward, increasing spatter intensity.

- Unstable Melt Pool Formation: A stable melt pool is essential for clean laser cutting. Zinc vapor interferes with this stability by continuously disturbing the molten steel. The melt pool becomes turbulent, leading to irregular material ejection and excessive spatter around the cut zone.

- Increased Interaction with Assist Gas: When oxygen or air is used as the assist gas, zinc vapor reacts readily with oxygen, forming zinc oxide fumes. These reactions add turbulence to the cutting zone and can intensify spatter. Even with nitrogen, rapid vapor expansion can overpower the gas flow, reducing control over molten material ejection.

- Back Pressure and Poor Material Ejection: Zinc vapor escaping from the kerf can partially block downward material flow. This back pressure forces molten steel upward toward the nozzle and cutting head, increasing spatter and contamination of nearby components.

- Coating Thickness Variations: Inconsistent zinc coating thickness across the sheet leads to uneven vaporization. Areas with thicker zinc layers generate more vapor, causing sudden bursts of spatter and inconsistent cut behavior along the cutting path.

- Cutting Parameter Sensitivity: Galvanized steel requires more precise parameter control than bare carbon steel. Cutting too slowly increases zinc vapor buildup, while cutting too fast prevents stable steel melting. Both conditions worsen spatter formation.

- Impact on Machine Components: Excessive spatter not only affects cut quality but also accelerates nozzle fouling, lens contamination, and maintenance frequency.

Why Does Laser Cutting Of Galvanized Steel Produce Rougher Cut Edges?

- Rapid Zinc Vaporization: Zinc melts and vaporizes at much lower temperatures than steel. When the laser beam strikes galvanized steel, the zinc coating vaporizes almost instantly, often before the underlying steel reaches a stable molten state. This rapid vaporization disrupts the cutting process, preventing smooth and continuous melting of the steel and resulting in uneven edge formation.

- Melt Pool Instability: A smooth cut edge depends on a stable molten pool. Zinc vapor escaping from beneath the molten steel creates turbulence in the melt pool. This turbulence causes irregular material flow and inconsistent melt ejection, leading to jagged or rough edge surfaces rather than clean, uniform cuts.

- Interference with Assist Gas Flow: Assist gas is intended to blow molten material cleanly out of the kerf. Zinc vapor expansion can counteract or disturb this gas flow, reducing its effectiveness. When molten steel is not expelled evenly, it re-solidifies along the cut edge, increasing surface roughness and dross formation.

- Formation of Zinc Oxide Residues: As zinc vapor reacts with oxygen, it forms zinc oxide particles. These particles can deposit along the cut edge and within the kerf, further degrading edge smoothness. Zinc oxide buildup also changes how heat is distributed along the cut, contributing to uneven melting.

- Back Pressure and Molten Metal Reattachment: Zinc vapor trapped in the kerf creates back pressure that pushes molten steel upward or sideways instead of allowing it to flow downward smoothly. This causes molten metal to cling to the cut edge before solidifying, resulting in rough, irregular surfaces.

- Coating Thickness Variations: Galvanized steel often has uneven zinc coating thickness. Areas with thicker zinc layers produce more vapor, creating sudden changes in cutting behavior along the same cut path. These fluctuations lead to inconsistent edge quality and visible roughness.

- Parameter Sensitivity: Galvanized steel requires tighter control of cutting speed, power, and focus. Cutting too slowly allows excessive zinc vapor buildup, while cutting too quickly prevents full steel melting. Both scenarios worsen edge roughness if not carefully managed.

- Impact on Post-Processing: Rougher edges may require additional grinding or finishing, increasing production time and cost.

Why Does Laser Cutting Of Galvanized Steel Increase Maintenance Frequency?

- Zinc Vapor and Oxide Contamination: Zinc has a low boiling point and vaporizes rapidly during laser cutting. The resulting zinc vapor oxidizes into fine zinc oxide particles that circulate within the cutting enclosure. These particles readily deposit on protective windows, focusing lenses, and sensor surfaces. Even thin zinc oxide layers absorb laser energy, increasing lens temperature and accelerating optical degradation, which shortens cleaning and replacement cycles.

- Increased Spatter and Nozzle Fouling: The rapid expansion of zinc vapor destabilizes the molten steel, producing excessive spatter. Molten metal droplets and zinc residues adhere to nozzle tips more frequently than when cutting bare steel. This disrupts assist gas flow and beam symmetry, requiring frequent nozzle cleaning or replacement to maintain cut quality.

- Higher Load on Fume Extraction Systems: Galvanized steel cutting generates heavier and finer particulate loads than standard carbon steel. Zinc oxide fumes clog filters more quickly, reducing airflow efficiency. As a result, filter replacement intervals are shorter, and ductwork and extraction units require more frequent cleaning to prevent contamination from spreading to sensitive machine components.

- Accelerated Wear of Protective Components: Protective windows, seals, and air-knife systems are exposed to higher chemical and thermal stress when zinc is present. Zinc compounds can adhere to seals and degrade their effectiveness, allowing contaminants to reach internal optics. This accelerates wear and increases preventive maintenance demands.

- Thermal Stress on Optics and Sensors: Zinc-related instability often forces operators to adjust parameters, such as slowing cutting speed or increasing power. These changes raise thermal load around the cutting head, contributing to faster aging of optical coatings, focus sensors, and electronic components.

- Cutting Table and Slat Buildup: Molten zinc and steel droplets accumulate on cutting slats and trays. This buildup hardens quickly and is more difficult to remove than steel slag alone, requiring more frequent table cleaning to maintain flatness, part quality, and fire safety.

- Process Instability Drives Preventive Checks: Because galvanized steel cutting is less stable, operators must perform more frequent inspections to catch early signs of contamination or wear before they cause cut failures or machine damage.

Why Does Laser Cutting Of Galvanized Steel Lead To Excessive Slag Formation?

- Low Boiling Point of Zinc: Zinc melts and vaporizes at much lower temperatures than steel. When the laser beam contacts galvanized steel, the zinc coating vaporizes rapidly—often before the underlying steel reaches a stable molten state. This premature vaporization interferes with smooth steel melting and disrupts the downward flow of molten material, increasing slag formation.

- Zinc Vapor Trapping and Back Pressure: As zinc vapor forms, it expands quickly within the kerf. If the vapor cannot escape efficiently, it creates back pressure beneath the molten steel. This pressure forces molten steel sideways or upward instead of allowing it to flow cleanly downward, causing molten material to cling to the bottom edge and solidify as slag.

- Melt Pool Instability: A stable melt pool is essential for clean slag-free cutting. Zinc vapor continuously disturbs the molten steel, creating turbulence and uneven melting. This instability prevents consistent material ejection, allowing partially melted steel to reattach to the cut edge.

- Interference with Assist Gas Effectiveness: Assist gas is designed to blow molten material out of the kerf. Zinc vapor expansion counteracts this gas flow, reducing its ability to remove molten steel efficiently. When assist gas cannot maintain control over melt ejection, excess molten material accumulates and forms slag.

- Formation of Zinc Oxides: As zinc vapor reacts with oxygen, it forms zinc oxide particles. These oxides can mix with molten steel, increasing viscosity and adhesion. The resulting mixture cools and solidifies more readily on the cut edge, producing thicker and more stubborn slag deposits.

- Coating Thickness Variations: Galvanized steel often has uneven zinc coating thickness. Areas with thicker zinc layers generate more vapor, causing sudden changes in melt behavior along the cut. These fluctuations increase the likelihood of inconsistent slag formation along the same cut path.

- Parameter Sensitivity: Cutting galvanized steel requires tighter parameter control than bare steel. Cutting too slowly increases zinc vapor buildup, while cutting too fast prevents complete steel melting. Both conditions make it harder for molten material to be expelled cleanly, worsening slag accumulation.

- Impact on Productivity: Excessive slag often requires secondary grinding or cleaning, adding time and cost to production.

Why Does Laser Cutting Of Galvanized Steel Cause Edge Chipping?

- Uneven Zinc Vaporization Creates Local Stress: Zinc has a much lower boiling point than steel, so it vaporizes almost instantly when exposed to the laser. This rapid vaporization does not occur uniformly along the cut. Localized bursts of zinc vapor create sudden pressure changes and uneven forces at the cut edge, weakening edge integrity and making small sections more likely to chip away.

- Melt Pool Instability and Interrupted Cutting: A stable melt pool is essential for smooth material separation. Zinc vapor continuously disturbs the molten steel, causing fluctuations in melt flow. These interruptions can result in partial melting along the edge, leaving brittle, weak areas that break off easily as chipping.

- Thermal Shock at the Cut Edge: Laser cutting introduces rapid heating followed by rapid cooling. In galvanized steel, the zinc layer heats and vaporizes faster than the steel beneath it. This mismatch in thermal response creates localized thermal shock at the edge, promoting microfractures. These microfractures can later propagate into visible edge chips.

- Formation of Brittle Zinc Oxides: As zinc vapor reacts with oxygen, it forms zinc oxide. Zinc oxide can deposit along the cut edge and mix with molten steel. This contamination creates a brittle surface layer that lacks the ductility of pure steel. Brittle edge material is far more prone to chipping during cooling, handling, or downstream processing.

- Back Pressure and Irregular Material Separation: Zinc vapor trapped in the kerf creates back pressure that interferes with smooth downward material flow. Instead of a clean separation, steel may tear unevenly at the bottom of the cut. These torn areas form weak points where small edge fragments can detach.

- Sensitivity to Cutting Parameters: Galvanized steel has a narrower process window than uncoated steel. Cutting too fast can leave partially fused material, while cutting too slowly increases zinc vapor buildup. Both conditions increase the likelihood of incomplete edge formation and subsequent chipping.

- Mechanical Stress After Cutting: Edges weakened by zinc-related thermal and chemical effects are more susceptible to chipping during part removal, stacking, or bending. What begins as micro-damage during cutting can become visible edge chipping during handling.

Why Does Laser Cutting Of Galvanized Steel Require More Frequent Nozzle Replacements?

- Zinc Vapor and Spatter Adhesion: Zinc has a low boiling point and vaporizes rapidly during laser cutting. As the zinc coating evaporates, it produces dense zinc vapor and molten droplets that are expelled upward and outward from the kerf. These particles readily adhere to the nozzle tip, especially around the orifice, where temperatures are lower. Once zinc residue accumulates, it disrupts gas flow and increases nozzle wear, often making cleaning ineffective and requiring replacement.

- Formation of Hard Zinc Oxide Deposits: When zinc vapor reacts with oxygen, it forms zinc oxide. These oxide particles can fuse to the nozzle surface and harden under repeated heat exposure. Zinc oxide deposits are more difficult to remove than steel spatter and can permanently alter the nozzle opening, degrading cutting performance and necessitating frequent replacement.

- Unstable Melt Ejection and Increased Back Spatter: Zinc vapor expansion creates instability in the molten steel, increasing the likelihood of upward spatter. This back spatter impacts the nozzle directly, accelerating physical erosion and surface damage. Repeated exposure gradually enlarges or distorts the nozzle orifice, reducing gas flow precision.

- Disrupted Assist Gas Flow: A clean, symmetrical gas stream is essential for effective cutting. Zinc buildup partially blocks or reshapes the nozzle opening, causing turbulent or uneven gas flow. Poor gas flow further increases spatter and contamination, creating a self-reinforcing cycle that rapidly degrades nozzle condition.

- Higher Thermal Stress at the Nozzle Tip: Galvanized steel cutting often requires parameter adjustments, such as slower speeds or increased power, to compensate for zinc-related instability. These changes raise localized temperatures around the nozzle, accelerating thermal fatigue and material degradation at the nozzle tip.

- Increased Nozzle-to-Material Interaction: Zinc vapor pressure can push molten material closer to the nozzle than in standard steel cutting. This reduces the effective stand-off distance and increases the likelihood of direct contact between spatter and the nozzle, further shortening its lifespan.

- Limitations of Cleaning and Reuse: While steel spatter can sometimes be cleaned from nozzles, zinc and zinc oxide deposits often bond more strongly. Repeated cleaning risks damaging the nozzle geometry, making replacement the safer and more consistent option.