Introduction

Advantages of Laser Cutting Copper

High Precision and Accuracy

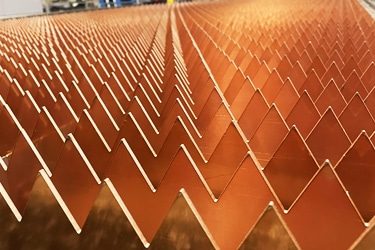

Laser cutting copper delivers excellent precision, allowing tight tolerances and fine details. This accuracy ensures consistent dimensions and repeatable results, which are critical for electrical components, connectors, and precision copper parts used in demanding applications.

Clean Edge Quality

The laser cutting process produces smooth, well-defined edges on copper with minimal burrs. This high edge quality often reduces or eliminates the need for secondary finishing, saving time and improving the appearance of finished components.

Minimal Heat-Affected Zone

Laser cutting concentrates heat in a small area, limiting thermal impact on surrounding material. This helps preserve copper's mechanical and conductive properties while reducing warping, especially when processing thin sheets or delicate designs.

Ability to Cut Complex Shapes

Laser cutting easily handles intricate geometries, small holes, and fine patterns in copper. This design flexibility supports custom parts, advanced electrical layouts, and rapid prototyping without the need for specialized tooling.

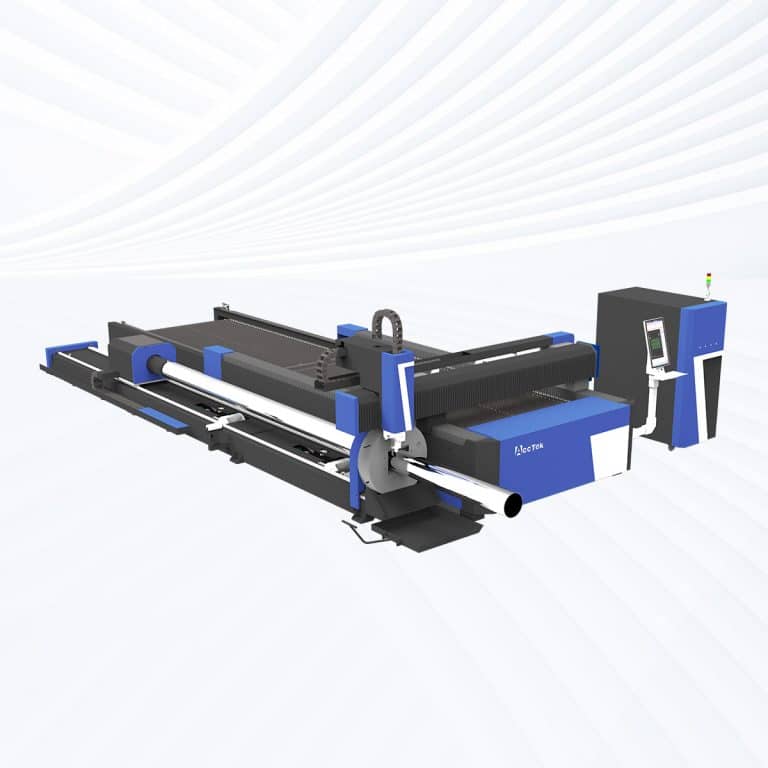

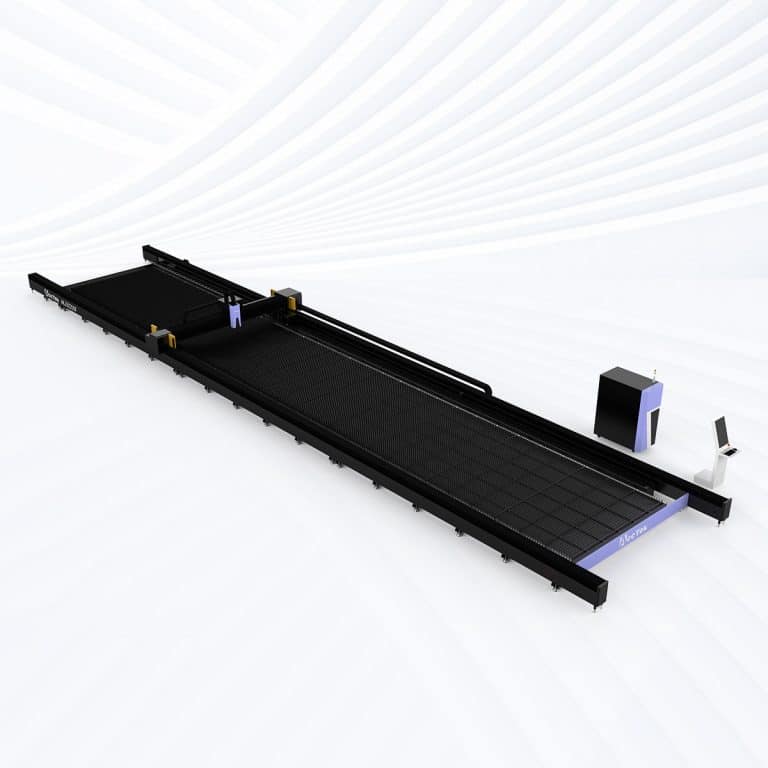

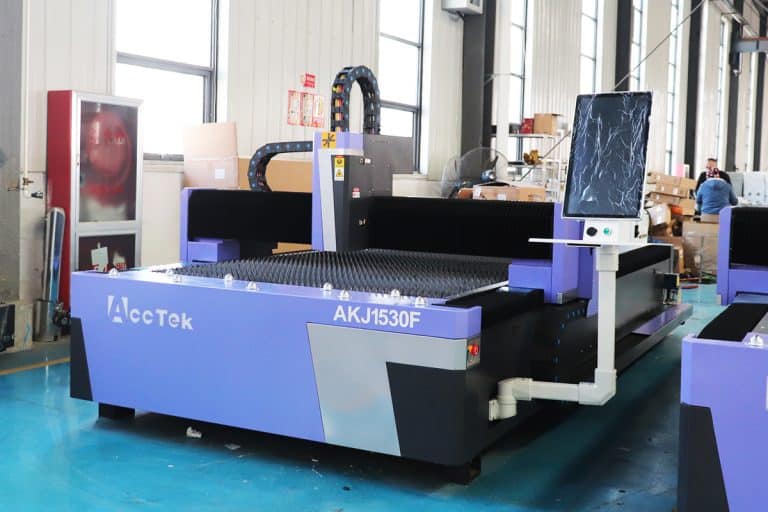

High Efficiency with Modern Fiber Lasers

Advanced fiber laser cutting systems with back-reflection protection make copper cutting faster and more stable. Optimized beam control improves cutting efficiency and reliability compared to traditional cutting methods.

Reduced Material Waste

Narrow kerf widths and intelligent nesting software maximize material utilization. This reduces copper scrap, lowers production costs, and supports more efficient and sustainable manufacturing practices.

Compatible Materials

- C11000 Electrolytic Tough Pitch Copper

- C12000 Phosphorized Copper

- C14500 Deoxidized Copper

- C15000 High Purity Copper

- C17200 Beryllium Copper

- C17500 Copper Beryllium

- C18000 Copper Tungsten

- C18700 Copper Nickel

- C19400 Copper Chromium

- C19600 Copper Nickel Silica

- C21000 Commercial Bronze

- C22000 Yellow Brass

- C23000 Red Brass

- C26000 Cartridge Brass

- C27000 Brass

- C28000 Muntz Metal

- C31500 Leaded Brass

- C33000 Yellow Brass

- C34000 High-Leaded Brass

- C35000 Brass

- C36000 Free-Cutting Brass

- C36500 Lead-Free Brass

- C37700 Architectural Bronze

- C38000 High-Performance Brass

- C38500 Brass

- C39200 Special Brass

- C41500 Commercial Bronze

- C43000 Leaded Brass

- C46200 Naval Brass

- C47000 Lead-Free Brass

- C47500 Leaded Bronze

- C48500 Silicon Brass

- C49000 Silicon Bronze

- C52100 Phosphor Bronze

- C52400 Phosphor Bronze

- C54400 Silicon Bronze

- C57500 Tin Bronze

- C60800 Aluminum Bronze

- C62000 Nickel Bronze

- C65100 Tin-Copper Alloy

Laser Cutting Copper VS Other Cutting Methods

| Comparison Item | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Suitability for Copper | Excellent with fiber lasers | Poor, unstable arc | Excellent | Not suitable |

| Cutting Precision | Very high accuracy | Low to moderate | Very high accuracy | Very low |

| Edge Quality | Smooth, clean edges | Rough edges, dross | Smooth but matte edges | Rough, oxidized edges |

| Heat-Affected Zone | Minimal and controlled | Large | None (cold cutting) | Very large |

| Cutting Speed | Fast for thin sheets | Fast on thick metals | Slow to moderate | Very slow |

| Material Thickness Range | Thin to medium thickness | Medium to thick metals | Thin to very thick | Thick steel only |

| Detail & Complexity | Excellent for fine features | Limited detail | Excellent detail | Very limited |

| Kerf Width | Narrow kerf | Wide kerf | Moderate kerf | Wide kerf |

| Secondary Finishing | Rarely required | Often required | Rarely required | Always required |

| Reflective Material Handling | Designed with protection | Poor handling | No reflection issues | Not applicable |

| Operating Cost | Moderate | Low | High | Low |

| Equipment Investment | Moderate to high | Low to moderate | High | Low |

| Automation Capability | Highly automated CNC | CNC capable | CNC capable | Mostly manual |

| Environmental Impact | Low fumes, clean process | High fumes and noise | Water and abrasive waste | Heavy smoke and gases |

| Overall Copper Cutting Quality | Excellent balance of quality and speed | Poor for copper | High quality, slower | Not usable |

Laser Cutting Capacity For Copper

| Laser Power | Material Thickness (mm) | Cutting Speed (m/min) | Actual Laser Power (W) | Gas | Pressure (bar) | Nozzle Size (mm) | Focus Position (mm) | Cutting Height (mm) |

|---|---|---|---|---|---|---|---|---|

| 6KW | 1 | 25-30 | 6000 | O2 | 14 | 2.0S | -0.5 | 1 |

| 2 | 15-18 | 6000 | O2 | 14 | 2.0S | -1 | 0.5 | |

| 3 | 8.0-10.0 | 6000 | O2 | 12 | 2.0S | -2 | 0.5 | |

| 4 | 5.0-6.0 | 6000 | O2 | 12 | 2.0S | -2 | 0.5 | |

| 5 | 3.0-4.0 | 6000 | O2 | 10 | 2.5S | -3 | 0.5 | |

| 12KW | 1 | 25-30 | 12000 | O2 | 5 | 2.0S | -0.5 | 1 |

| 2 | 20-25 | 12000 | O2 | 5 | 2.0S | -1 | 0.5 | |

| 3 | 16-18 | 12000 | O2 | 6 | 2.0S | -2 | 0.5 | |

| 4 | 10-12 | 12000 | O2 | 8 | 2.0S | -3 | 0.5 | |

| 5 | 6.0-8.0 | 12000 | O2 | 8 | 2.5S | -4.5 | 0.5 | |

| 6 | 4.0-5.0 | 12000 | O2 | 8 | 2.5S | -5 | 0.5 | |

| 8 | 2.0-2.5 | 12000 | O2 | 10 | 3.0S | -6 | 0.5 | |

| 20KW | 1 | 25-30 | 20000 | O2 | 5 | 2.0S | 0 | 1 |

| 2 | 25-30 | 20000 | O2 | 5 | 2.0S | 0 | 0.5 | |

| 3 | 20-25 | 20000 | O2 | 6 | 2.0S | 0 | 0.5 | |

| 4 | 16-18 | 20000 | O2 | 8 | 2.5S | -1 | 0.5 | |

| 5 | 10-12 | 20000 | O2 | 8 | 2.5S | -1 | 0.5 | |

| 6 | 8.0-10.0 | 20000 | O2 | 8 | 3.0S | -2 | 0.5 | |

| 8 | 4.0-6.0 | 20000 | O2 | 10 | 3.0S | -3 | 0.5 | |

| 10 | 2.0-3.5 | 20000 | O2 | 12 | 3.5S | -4 | 0.5 | |

| 30KW | 1 | 25-30 | 30000 | O2 | 5 | 2.0S | 0 | 1 |

| 2 | 25-30 | 30000 | O2 | 5 | 2.0S | 0 | 0.5 | |

| 3 | 20-25 | 30000 | O2 | 6 | 2.0S | 0 | 0.5 | |

| 4 | 18-20 | 30000 | O2 | 8 | 2.5S | -1 | 0.5 | |

| 5 | 15-18 | 30000 | O2 | 8 | 2.5S | -1 | 0.5 | |

| 6 | 10-15 | 30000 | O2 | 8 | 3.0S | -2 | 0.5 | |

| 8 | 6.0-10.0 | 30000 | O2 | 10 | 3.0S | -3 | 0.5 | |

| 10 | 2.0-3.5 | 30000 | O2 | 12 | 3.5S | -4 | 0.5 | |

| 12 | 2.0-2.5 | 30000 | O2 | 12 | 3.5S | -5 | 0.5 | |

| 40KW | 3 | 20-25 | 40000 | O2 | 6 | 2.0S | 0 | 0.5 |

| 4 | 18-20 | 40000 | O2 | 8 | 2.5S | -1 | 0.5 | |

| 5 | 15-18 | 40000 | O2 | 8 | 2.5S | -1 | 0.5 | |

| 6 | 10-15 | 40000 | O2 | 8 | 3.0S | -2 | 0.5 | |

| 8 | 6-10 | 40000 | O2 | 10 | 3.0S | -3 | 0.5 | |

| 10 | 2-3.5 | 40000 | O2 | 12 | 3.5S | -4 | 0.5 | |

| 12 | 2-2.5 | 40000 | O2 | 12 | 3.5S | -5 | 0.5 | |

| 14 | 1.5-2 | 40000 | O2 | 12 | 3.5S | -6 | 0.5 | |

| 16 | 1-1.5 | 40000 | O2 | 12 | 4.0S | -6 | 0.5 |

Applications of Laser Cutting Copper

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

How Does Copper's High Reflectivity Affect Laser Cutting?

- Reduced Laser Energy Absorption: Copper reflects a large percentage of incident laser energy, particularly at the near-infrared wavelengths used by most fiber lasers. As a result, only a small portion of the laser power is absorbed at the surface during initial contact. This makes it difficult to quickly reach the melting temperature, especially during piercing, and often requires higher laser power, slower speeds, or multiple passes to initiate cutting.

- Unstable Piercing and Cutting Start: Because of poor initial absorption, piercing copper can be inconsistent. The laser may struggle to form a stable melt pool, leading to sputtering, spatter, or failed pierce attempts. This instability increases cycle time and raises the risk of defects at the start of the cut.

- Back Reflection Risks to Equipment: High reflectivity increases the likelihood of back reflection, where laser energy bounces off the copper surface and travels back toward the cutting head or laser source. This reflected energy can damage sensitive optical components, fiber connections, and even the laser generator if protective measures such as isolators and sensors are not in place.

- Higher Thermal Load Requirements: To overcome reflectivity, operators often increase laser power or reduce cutting speed. This raises the thermal load on the cutting head, optics, and surrounding components. Sustained high-power operation accelerates wear on consumables such as lenses, protective windows, and nozzles.

- Edge Quality and Consistency Challenges: Inconsistent energy absorption can cause uneven melting along the cut path. This may result in rough edges, incomplete cuts, or excessive dross. Maintaining consistent cut quality requires very precise control of focus position, speed, and assist gas flow.

- Dependence on Advanced Laser Technology: Modern high-power fiber lasers, green lasers, or blue lasers are better suited for cutting copper because their wavelengths are absorbed more effectively. These systems reduce reflectivity-related issues but come at a higher equipment cost.

- Assist Gas Sensitivity: Efficient assist gas flow is critical when cutting copper. High-pressure nitrogen is commonly used to help eject molten material and stabilize the cut, but improper gas settings can quickly worsen cutting instability.

How Does Copper's Thermal Conductivity Hinder Laser Cutting?

- Rapid Heat Dissipation from the Cut Zone: Copper conducts heat faster than most industrial metals. When the laser beam strikes the surface, absorbed energy is quickly drawn away into the surrounding material. This prevents localized temperature buildup, making it harder for the laser to reach and maintain the melting point needed for a stable cut.

- Delayed and Unstable Piercing: Piercing is particularly challenging because the initial laser energy is dispersed before a melt pool can form. This often leads to longer pierce times, multiple pierce attempts, or incomplete penetration, increasing cycle time and reducing process reliability.

- Higher Power and Slower Speed Requirements: To overcome rapid heat loss, operators must increase laser power or reduce cutting speed. While this improves heat accumulation at the cut front, it also raises energy consumption, reduces throughput, and places greater thermal stress on the cutting head and optics.

- Increased Risk of Incomplete Cuts: If heat cannot be maintained consistently, sections of the cut may not fully separate. This results in uncut bridges, rough edges, or excessive dross. Inconsistent melting caused by heat loss is a common reason for quality issues when cutting copper.

- Larger Heat-Affected Zone (HAZ): Although copper spreads heat quickly, compensating with higher power can cause more surrounding material to warm up. This expands the heat-affected zone, potentially leading to discoloration, distortion, or changes in surface finish near the cut.

- Thermal Stress on Machine Components: Sustained high-power operation required to counter heat dissipation increases the thermal load on optics, nozzles, and protective windows. Over time, this accelerates wear and shortens maintenance intervals.

- Assist Gas Dependency: Efficient assistance of gas flow becomes critical when cutting copper. High-pressure nitrogen is often required to remove molten material quickly before it cools and re-solidifies due to heat loss. Poor gas performance further worsens the effects of high thermal conductivity.

- Narrow Process Window: Because heat is constantly being pulled away, copper cutting requires very precise control of power, speed, focus, and gas pressure. Small deviations can lead to sudden process instability.

How Does The Choice Of Assist Gas Affect Laser Cutting Of Copper?

- Nitrogen (N2): Nitrogen is the most commonly used and preferred assist gas for laser cutting copper. As an inert gas, it does not react chemically with molten copper. Its primary role is to blow molten material out of the kerf efficiently while preventing oxidation. Nitrogen produces clean, bright cut edges and stable cutting conditions, which are especially important for electrical and precision components. However, nitrogen cutting typically requires high gas pressure and higher operating costs.

- Oxygen (O2): Oxygen is rarely used for laser cutting copper because it reacts aggressively with molten copper. This oxidation creates rough edges, heavy dross, and dark discoloration. Unlike carbon steel, copper does not benefit from oxygen’s exothermic reaction in a controlled way. Instead, oxidation reduces cut quality and increases slag formation, making oxygen unsuitable for most copper applications.

- Compressed Air: Compressed air contains both nitrogen and oxygen. While it may be used for thin copper sheets in low-cost or non-critical applications, the oxygen content promotes surface oxidation and inconsistent edge quality. Air cutting also reduces process stability and increases the likelihood of dross, making it a compromise rather than a preferred solution.

- Gas Pressure and Flow Stability: Regardless of gas type, copper cutting requires high and stable gas pressure. Copper’s molten state cools and solidifies rapidly due to high thermal conductivity. Strong gas flow is essential to eject molten material before it reattaches to the cut edge. Insufficient pressure or turbulent flow quickly leads to incomplete cuts and excessive slag.

- Impact on Heat Control and Stability: Nitrogen does not add heat to the process, so all melting relies on laser energy alone. This makes precise control of power, speed, and focus essential. Proper gas flow helps stabilize the molten pool and compensate for copper’s tendency to dissipate heat rapidly.

- Nozzle and Optics Protection: Correct assist gas selection also protects machine components. Nitrogen reduces spatter and oxidation fumes, lowering the risk of nozzle contamination and lens damage. Oxygen or air increases fume generation and accelerates maintenance cycles.

Why Does Laser Cutting Of Copper Produce Stubborn Slag?

- High Thermal Conductivity: Copper conducts heat extremely efficiently, drawing energy away from the cutting zone almost as fast as it is absorbed. This rapid heat loss causes molten copper to cool and solidify very quickly. When molten material solidifies before it can be fully expelled by the assist gas, it adheres to the underside of the cut edge as stubborn slag.

- Low Laser Energy Absorption: Copper’s high reflectivity reduces the amount of laser energy absorbed at the surface, especially during initial cutting. Inconsistent absorption leads to unstable melting, where some areas melt fully while others only partially liquefy. This uneven melting increases the likelihood that molten copper will reattach instead of being cleanly removed.

- Highly Fluid Molten State: Once copper does melt, it becomes extremely fluid. Rather than breaking away cleanly, molten copper tends to flow along the kerf walls and underside of the material. As it cools rapidly, this flowing metal solidifies into smooth, strongly bonded slag that is difficult to remove.

- Assist Gas Limitations: Laser cutting copper relies heavily on high-pressure nitrogen to eject molten material. If gas pressure is insufficient, flow is turbulent, or nozzle alignment is slightly off, molten copper cannot be expelled effectively. Even small disruptions in gas flow allow molten material to linger long enough to solidify as slag.

- Cutting Speed Sensitivity: Cutting too fast prevents full melting, while cutting too slowly creates excessive molten material. Both conditions increase slag formation. Because copper has a very narrow process window, minor deviations in speed can significantly worsen slag buildup.

- Thickness Effects: Thicker copper plates produce larger volumes of molten material, which are harder to remove before cooling occurs. As thickness increases, the likelihood of stubborn slag rises sharply unless laser power and gas pressure are carefully increased and balanced.

- Oxidation and Surface Reactions: If oxygen or air is present, copper oxides may form during cutting. These oxides can increase slag adhesion, making deposits harder and more resistant to mechanical removal.

Why Are Burrs More Likely To Form When Laser Cutting Copper?

- High Reflectivity Reduces Effective Melting: Copper reflects a large percentage of laser energy, particularly at standard fiber laser wavelengths. This reduces the amount of energy absorbed at the cutting front, making it harder to maintain a stable and uniform melt pool. When melting is inconsistent, molten copper is not fully separated from the base material and tends to remain attached as burrs.

- Extremely High Thermal Conductivity: Copper conducts heat away from the cutting zone faster than most industrial metals. This rapid heat dissipation causes molten copper to cool and solidify quickly. If the molten material cools before being completely expelled by the assist gas, it reattaches to the edge and forms burrs, especially on the underside of the cut.

- Highly Fluid Molten Behavior: Once copper melts, it becomes extremely fluid. Instead of breaking away cleanly, molten copper often flows along the kerf walls and edges. As it cools rapidly, this flowing metal solidifies into thin ridges or droplets, which appear as burrs along the cut edge.

- Assist Gas Ejection Challenges: Laser cutting copper relies heavily on high-pressure nitrogen to blow molten material out of the kerf. Any reduction in gas pressure, nozzle misalignment, or turbulence in gas flow reduces ejection efficiency. Even small disturbances allow molten copper to linger and re-solidify, increasing burr formation.

- Narrow Process Window: Copper has a very narrow range of acceptable cutting parameters. Cutting too fast results in incomplete melting, while cutting too slowly produces excessive molten material. Both conditions increase the likelihood that molten copper will adhere to the cut edge rather than being removed cleanly.

- Thickness Sensitivity: As copper thickness increases, more molten material is generated. The larger volume of molten copper is harder to expel before cooling occurs, making burrs more common on thicker sheets and plates.

- Surface Oxidation Effects: If oxygen or air is present, copper oxides may form during cutting. These oxides increase surface roughness and adhesion, making molten material more likely to stick to the cut edge and solidify as burrs.

Why Is It Difficult To Form Stable Kerfs When Laser Cutting Copper?

- High Reflectivity Limits Energy Coupling: Copper reflects a very high percentage of incident laser energy, particularly at the near-infrared wavelengths used by most fiber lasers. This reflection reduces effective energy coupling at the cutting front, making it difficult to sustain a uniform melt pool. As a result, the kerf may intermittently narrow, widen, or collapse as energy absorption fluctuates along the cut path.

- Extremely High Thermal Conductivity: Copper rapidly conducts heat away from the cutting zone. Even when energy is absorbed, it is quickly dispersed into the surrounding material instead of remaining concentrated at the kerf. This constant heat loss destabilizes the molten zone, making it difficult to maintain consistent kerf width and depth throughout the cut.

- Unstable Melt Pool Formation: A stable kerf requires a continuous molten front. In copper, uneven heating causes the melt pool to form and collapse repeatedly. These fluctuations interrupt material removal, leading to wavering kerf geometry, incomplete separation, or sudden cut interruptions.

- Highly Fluid Molten Behavior: Once copper melts, it becomes extremely fluid. Instead of flowing cleanly downward, molten copper tends to spread along the kerf walls. As it cools rapidly, this flowing metal can partially re-solidify inside the kerf, narrowing it and disrupting gas flow, which further destabilizes the cut.

- Assist Gas Sensitivity: Copper cutting relies heavily on high-pressure nitrogen to remove molten material. Any minor variation in gas pressure, nozzle alignment, or flow symmetry can significantly affect kerf stability. Insufficient or turbulent gas flow allows molten copper to linger and reattach, causing kerf irregularities.

- Narrow Process Window: Copper has a very tight tolerance for cutting parameters. Small deviations in power, speed, focus position, or stand-off distance can quickly destabilize the kerf. Cutting too fast results in insufficient melting, while cutting too slowly creates excessive molten material that interferes with kerf formation.

- Piercing Challenges: Kerf instability often begins at piercing. Difficulty establishing a clean initial hole leads to irregular melt behavior at the start of the cut, which can propagate instability along the entire kerf path.

Why Does Laser Cutting Of Copper Increase Maintenance Frequency?

- High Reflectivity and Back Reflection Risk: Copper reflects a large portion of laser energy, especially at standard fiber laser wavelengths. Reflected energy can travel back toward the cutting head and optics, increasing thermal load on lenses, protective windows, and fiber connections. Even with protective systems in place, repeated exposure accelerates coating degradation and increases the need for frequent inspection and replacement.

- Elevated Thermal Load on Optics: To overcome poor energy absorption and rapid heat dissipation, copper cutting often requires higher laser power or slower speeds. This sustained high-power operation increases heat buildup around the cutting head. Optics exposed to higher temperatures experience faster aging, leading to more frequent cleaning and shorter service life.

- Molten Spatter and Vapor Contamination: Copper produces highly fluid molten material that can splash upward during unstable cutting. Fine copper vapor and spatter can settle on nozzles, protective glass, and lenses. Even small amounts of contamination absorb laser energy and cause localized overheating, making regular cleaning essential to prevent damage.

- Nozzle Wear and Blockage: High-pressure nitrogen is typically required to cut copper effectively. The combination of strong gas flow and molten copper spatter leads to faster nozzle erosion and more frequent blockages. Nozzles must be inspected and replaced more often to maintain stable gas flow and consistent cut quality.

- Increased Demand for Fume Extraction Systems: Copper cutting generates fine metallic particles that load filters quickly. These particles can bypass weak filtration systems and contaminate internal machine components. As a result, filter replacement, duct cleaning, and extractor maintenance cycles are shorter.

- Tighter Parameter Sensitivity and Process Instability: Copper has a very narrow process window. Small deviations in focus, alignment, or gas pressure can cause unstable cutting, increasing spatter and contamination. This instability indirectly raises maintenance needs by accelerating wear on consumables and sensors.

- Higher Risk of Component Stress and Failure: Frequent high-power operation and thermal cycling place stress on seals, sensors, and electronic components near the cutting head. Over time, this leads to earlier failures and more frequent preventive maintenance checks.

Why Does Laser Cutting Of Copper Require Specialized Parameter Calibration?

- High Reflectivity Demands Precise Energy Control: Copper reflects a large portion of laser energy, particularly at near-infrared wavelengths. This means only a small fraction of the laser power is absorbed at the cutting front. Specialized calibration is needed to balance power and focus so that sufficient energy is delivered without causing excessive back reflection that could damage optics.

- Extremely High Thermal Conductivity: Copper rapidly conducts heat away from the cutting zone. As a result, energy that does get absorbed is quickly dissipated, making the melt pool highly unstable. Cutting parameters must be carefully adjusted to maintain consistent heat concentration at the kerf, often requiring slower speeds or higher power levels than standard materials.

- Narrow Process Window: Copper has a very limited range of acceptable cutting settings. Small deviations in speed, focus position, stand-off distance, or gas pressure can quickly destabilize the cut. Specialized calibration helps define this narrow window and ensures repeatability across different thicknesses and part geometries.

- Assist Gas Sensitivity: High-pressure nitrogen is typically required to eject molten copper efficiently. Gas pressure, nozzle diameter, and alignment must be precisely matched to the cutting conditions. Inadequate calibration can result in turbulent gas flow, poor melt ejection, and increased slag or burr formation.

- Piercing Parameter Complexity: Piercing copper is especially difficult due to poor initial energy absorption. Separate, carefully tuned piercing parameters are often required to establish a stable starting hole without excessive spatter or reflection. Incorrect piercing settings can compromise the entire cut path.

- Optics and Nozzle Protection Considerations: Improper parameter calibration increases spatter, back reflection, and thermal stress on optics and nozzles. Fine-tuned settings reduce these risks by stabilizing the melt pool and minimizing upward ejection of molten material.

- Thickness and Alloy Variability: Different copper thicknesses and alloy compositions respond differently to laser energy. Specialized calibration ensures consistent results across variations in material properties, preventing unexpected quality issues.