Introduction

Advantages of Laser Cutting Composite

High Precision and Accuracy

Laser cutting composite delivers exceptional precision, enabling tight tolerances and intricate geometries. The focused laser beam allows clean, consistent cuts, making it ideal for complex composite components where dimensional accuracy is critical to performance and assembly.

Non-Contact Cutting Process

Because laser cutting composite is a non-contact process, there is no physical force applied to the material. This eliminates tool wear, reduces the risk of delamination, and prevents mechanical stress or distortion often associated with traditional cutting methods.

Minimal Material Waste

Laser cutting composite produces a narrow kerf width and highly controlled cuts. This precision significantly reduces material waste, improves material utilization, and lowers overall production costs—especially important when working with expensive composite materials like carbon fiber.

Excellent Edge Quality

With properly optimized parameters, laser cutting composite yields smooth edges with minimal burrs or fraying. This reduces or eliminates the need for secondary finishing processes, saving time while improving the aesthetic and functional quality of the final part.

High Flexibility and Design Freedom

Laser cutting composite supports rapid design changes without the need for new tooling. Complex patterns, holes, and contours can be easily programmed, making the process ideal for prototyping, customization, and low-to-high volume production runs.

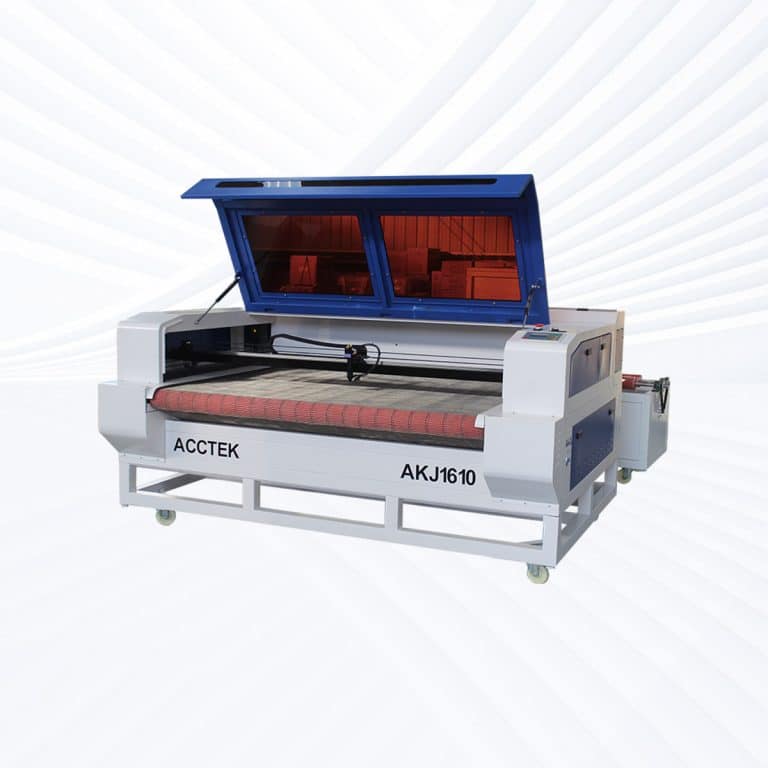

Efficient and Automatable Production

Laser cutting composite integrates seamlessly with CNC systems and automation. This enables high repeatability, faster cycle times, and consistent quality, making it well-suited for industries requiring scalable, efficient, and reliable composite manufacturing solutions.

Compatible Materials

- Fiberglass Reinforced Plastic

- Glass Fiber Reinforced Polymer

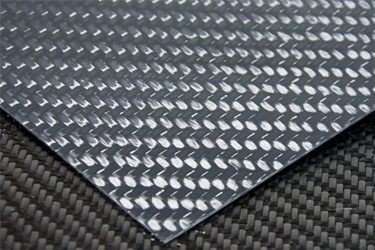

- Carbon Fiber Reinforced Polymer

- Epoxy Resin Composites

- Phenolic Resin Sheets

- Paper Phenolic Laminates

- Cotton Phenolic Laminates

- Fabric-Based Laminates

- Thermoplastic Composites

- Thermoset Composites

- Foam Core Composites

- Polymer Foam Composites

- Honeycomb Polymer Panels

- Polypropylene Composites

- Polyethylene Composites

- ABS/Polycarbonate Blends

- Wood-Plastic Composites

- Vinyl Ester Composites

- Resin-Impregnated Fabrics

- Composite Gasket Materials

- Silicone/Fiberglass Laminates Sheets

- Kevlar-Fabric Composites

- Nylon-Reinforced Composites

- Acrylic Composites Sheets

- PET-G Based Composites

- Teflon-Filled Composites

- PVC-Free Composites Panels

- Recycled Composites Board

- Reconstituted Composite Sheets

- Laminate Floor Composites

- Compressed Fiberboard

- Cardboard Composites

- Cork-Rubber Composites

- Textile-Laminated Composites

- Nonwoven Composite Sheets

- Insulation Board Composites

- Composite Foam board

- Industrial Paper Laminates

- FR-grade Composite Panels

- Phenolic Resin Boards

Laser Cutting Composite VS Other Cutting Methods

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Composite Materials | Highly suitable for many composites | Suitable but tool-dependent | Limited to soft composites | Excellent |

| Cutting Precision | Very high precision | High | Medium | High |

| Edge Quality | Clean, consistent edges | Good, may require finishing | Acceptable, may fray fibers | Very clean |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Mechanical Stress on Material | None (non-contact) | Moderate | Low | None |

| Risk of Delamination | Low with proper settings | Medium | Medium to high | Very low |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Cutting Speed | High for thin–medium materials | Moderate | High for soft materials | Moderate |

| Thickness Capability | Thin to medium composites | Medium to thick | Thin, flexible materials | Thin to very thick |

| Material Waste | Low | Medium | Medium | Higher due to kerf |

| Setup and Changeover Time | Very fast | Moderate | Fast | Longer |

| Automation and Repeatability | Excellent | Excellent | Good | Good |

| Operating Cost | Moderate | Moderate | Low | High |

| Overall Efficiency for Composite Production | Excellent | Good | Fair | Very good |

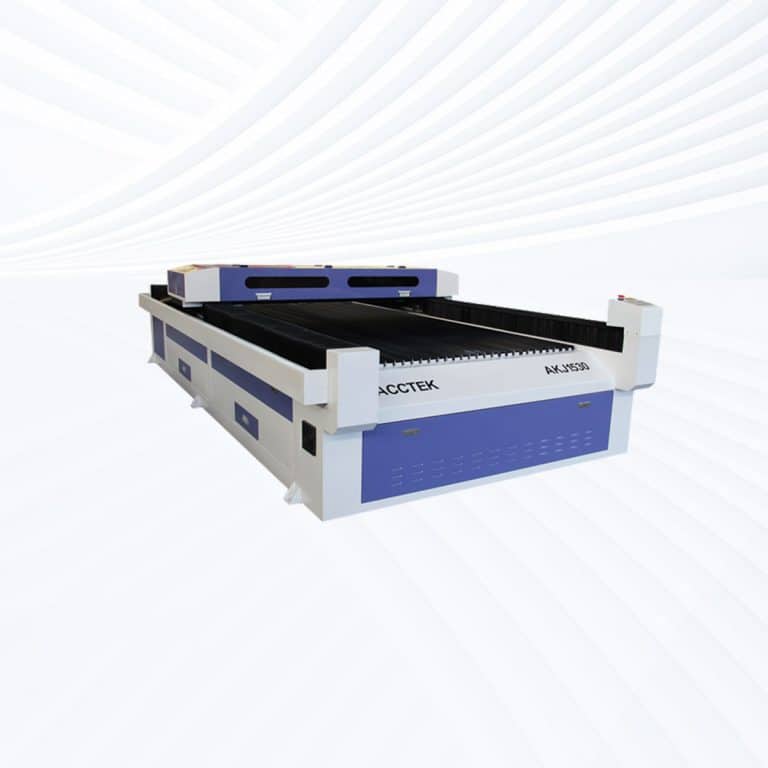

Laser Cutting Capacity

| Power/Material | 60W | 80W | 90W | 100W | 130W | 150W | 180W | 220W | 260W | 300W | 500W | 600W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Plywood | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| MDF | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Solid Wood | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cork Sheet | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Bamboo Board | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Laminates | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Acrylic (PMMA) | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| ABS | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Delrin (POM) | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Composite | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| EVA Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Depron Foam | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Gator Foam | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Cardboard | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Stone | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

| Leather | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Textile | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Nylon | Engrave Only | Limited Cut | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Felt | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Rubber | Limited Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut | Cut |

| Ceramic | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only | Engrave Only |

Applications of Laser Cutting Composite

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

How Does Fiber Orientation In Composite Materials Affect Laser Cutting Quality?

- Directional Heat Absorption and Cutting Consistency: Laser cutting relies on localized heating to ablate or vaporize material. Fibers aligned parallel to the cutting direction tend to conduct heat along their length, allowing more uniform energy distribution. This often results in smoother edges and more consistent kerf widths. In contrast, fibers oriented perpendicular or at steep angles to the cut can disrupt heat flow, leading to uneven material removal and rougher edges.

- Fiber Pull-Out and Edge Integrity: When the laser beam intersects fibers at unfavorable angles, especially perpendicular orientations, incomplete fiber severing may occur. This can cause fiber pull-out, fraying, or protruding strands along the cut edge. Such defects are more pronounced in composites with long or continuous fibers and can compromise both aesthetics and structural integrity.

- Thermal Damage and Heat-Affected Zone (HAZ): Fiber orientation also influences the size and severity of the heat-affected zone. Fibers that efficiently conduct heat can spread thermal energy into surrounding areas, increasing the risk of matrix degradation, resin charring, or delamination. Poorly oriented fibers may trap heat locally, causing excessive burning or microcracking near the cut.

- Variation Between Fiber Types: Carbon fibers, with high thermal conductivity, amplify orientation effects more than glass fibers, which conduct heat less efficiently. As a result, carbon fiber composites are especially sensitive to cutting direction, requiring tighter control of laser power, speed, and focus.

- Process Optimization Considerations: To mitigate orientation-related issues, manufacturers often adjust cutting parameters or plan cut paths that align favorably with dominant fiber directions. Multiple passes at lower power, optimized assist gas flow, or alternative cutting technologies may also be used for complex layups.

Why Is The Heat-Affected Zone Large After Laser Cutting Of Composite Materials?

- Low Thermal Stability of the Polymer Matrix: Most composite materials use thermoset or thermoplastic resins as the matrix, which have relatively low thermal degradation temperatures compared to metals. During laser cutting, the intense, localized heat easily exceeds the resin’s decomposition temperature. Instead of melting cleanly, the matrix can char, burn, or vaporize, allowing heat to spread into surrounding regions and enlarging the HAZ.

- Mismatch in Thermal Properties: Fibers and matrix materials have very different thermal conductivities and heat capacities. For example, carbon fibers conduct heat efficiently along their length, while polymer resins act as thermal insulators. This mismatch causes uneven heat dissipation, leading to heat accumulation in certain regions and extending thermal damage beyond the intended cut path.

- Laser-Material Interaction Mechanism: Laser cutting of composites is primarily a thermal ablation process rather than a clean melting-and-ejection mechanism. The laser must supply enough energy to decompose the matrix and sever the fibers. This prolonged energy input increases the duration of heat exposure, allowing heat to diffuse into adjacent material layers and enlarging the HAZ.

- Delamination and Internal Heat Trapping: Composites are layered structures, and laser-induced heating can cause interlaminar separation. Once delamination begins, trapped heat and gases cannot escape efficiently, further increasing local temperatures and worsening thermal damage around the cut edge.

- Gas and Smoke Shielding Effects: As the matrix decomposes, it produces smoke, vapors, and charred residue. These byproducts can partially absorb or scatter the laser beam, reducing cutting efficiency. To compensate, higher power or slower cutting speeds are often used, which unintentionally increases heat input and expands the HAZ.

- Limited Cooling Efficiency: Unlike metals, composites do not readily conduct heat away from the cutting zone. The lack of efficient heat dissipation means that even brief laser exposure can result in a relatively wide region of thermal degradation.

Why Does Laser Cutting Of Laminated Composite Materials Cause Material Delamination?

- Thermal Degradation of the Bonding Matrix: The primary cause of delamination is the thermal breakdown of the resin or adhesive that bonds the laminate layers. During laser cutting, temperatures at the cut zone rise rapidly and frequently exceed the glass transition or decomposition temperature of the matrix. Once the bonding material softens, chars, or vaporizes, its ability to hold adjacent layers together is significantly reduced, allowing plies to separate.

- Differential Thermal Expansion: Fibers, resins, and adhesives in laminated composites have different coefficients of thermal expansion. When exposed to the rapid heating of a laser beam, each layer expands at a different rate. This mismatch generates high interlaminar stresses at the interfaces. If these stresses exceed the weakened bond strength of the heated matrix, delamination occurs either during cutting or shortly after the material cools.

- Internal Gas Pressure Build-Up: Laser-induced decomposition of the polymer matrix produces gases and vapors. In laminated composites, these gases can become trapped between layers, especially when cutting through multiple plies at once. The resulting internal pressure acts like a wedge, forcing layers apart and promoting delamination along the laminate interfaces.

- Poor Heat Dissipation Through Thickness: Composites generally have low thermal conductivity in the thickness direction. Heat introduced at the surface cannot be efficiently conducted away, causing temperature gradients across the laminate. These gradients intensify thermal stresses between layers, further increasing the likelihood of interlaminar separation.

- Non-Uniform Energy Absorption: Different plies may have varying fiber orientations or material compositions, leading to uneven laser energy absorption. Some layers may overheat while others remain relatively cool, creating localized weakening of interlayer bonds and initiating delamination at those hotspots.

- Mechanical Effects of Material Removal: As the laser removes material, rapid matrix vaporization and fiber severing can generate micro-shocks and localized recoil forces. Although small, these mechanical disturbances act directly at the laminate interfaces, contributing to layer separation when combined with thermal damage.

Why Does Laser Cutting Of Composite Materials Cause Oxidation?

- High Localized Temperatures at the Cut Zone: Laser cutting generates intense, concentrated heat that can raise surface temperatures to several hundred or even thousands of degrees Celsius within milliseconds. At these elevated temperatures, many materials in composites become chemically reactive. When exposed to oxygen in the air, this thermal energy accelerates oxidation reactions on freshly exposed surfaces.

- Exposure of Fresh Reactive Surfaces: As the laser removes material, it continuously exposes new fiber and matrix surfaces. These freshly cut surfaces are highly reactive because they lack protective coatings or oxide layers. Immediate contact with atmospheric oxygen leads to rapid oxidation, particularly along the cut edges.

- Oxidation of Reinforcing Fibers: Certain fibers used in composites, such as carbon fibers, are especially prone to oxidation at high temperatures. While carbon fibers are thermally stable in inert environments, they oxidize readily in air when heated during laser cutting. This results in fiber thinning, surface pitting, or weakened edges due to material loss from oxidative burning.

- Thermal Degradation of the Polymer Matrix: The polymer matrix surrounding the fibers also contributes to oxidation effects. Under laser heating, the matrix can decompose, char, or burn. These reactions are oxidative in nature when oxygen is present, producing visible discoloration, embrittlement, and a roughened cut surface. The byproducts of matrix oxidation can further promote oxidative damage to nearby fibers.

- Prolonged Heat Exposure and Slow Cutting Speeds: To fully sever fibers and decompose the matrix, laser cutting of composites often requires slower cutting speeds or higher energy input than homogeneous materials. This extended exposure time allows more oxygen to diffuse into the hot zone, increasing the extent of oxidation along the edges and within the heat-affected zone.

- Limited Use of Protective Atmospheres: Unlike some metal laser-cutting processes that use inert assist gases, composite laser cutting is frequently performed in ambient air. Without shielding gases such as nitrogen or argon, there is little to prevent oxygen from interacting with hot material surfaces, making oxidation unavoidable.

Why Is Optimizing Cutting Parameters For Laser-Cut Composite Materials More Complex?

- Multiple Material Constituents With Different Behaviors: Composite materials consist of fibers (such as carbon or glass) embedded in a resin matrix. Fibers typically require high energy to sever, while the polymer matrix degrades at much lower temperatures. Increasing laser power to cut fibers efficiently can easily overheat the matrix, causing charring, oxidation, or excessive heat-affected zones. Balancing these competing requirements complicates parameter optimization.

- Anisotropic Thermal and Optical Properties: The thermal conductivity and laser absorption of composites vary with fiber orientation. Heat may be conducted efficiently along fibers but poorly across layers, leading to uneven temperature distribution. As a result, parameters that work well for one cutting direction may produce poor edges, delamination, or fiber pull-out when the cutting path changes direction.

- Sensitivity to Heat-Affected Damage: Composite materials are highly sensitive to thermal damage such as matrix decomposition, delamination, and oxidation. Small changes in cutting speed, focus position, or pulse duration can significantly alter the size of the heat-affected zone. This narrow processing window makes fine-tuning parameters more demanding than for materials that tolerate higher heat input.

- Layered and Variable Structures: Many composites are laminated or have varying fiber layups and thicknesses within the same component. Each layer may absorb laser energy differently, requiring adjustments in power or speed to maintain cut-through consistency. Optimizing parameters for one laminate configuration may not be suitable for another, even within the same material family.

- Interaction With Assist Gases and Byproducts: The decomposition of the polymer matrix generates smoke, gases, and char that can interfere with laser energy delivery. Assist gas pressure and type influence how effectively these byproducts are removed. Improper gas settings can reduce cutting efficiency, forcing parameter changes that further complicate optimization.

- Trade-Offs Between Quality Metrics: Improving one quality aspect, such as cutting speed or fiber severing, often worsens another, such as edge smoothness or delamination. Parameter optimization, therefore, becomes a multi-objective problem rather than a straightforward adjustment.

Why Are Assist Gases Required For Laser Cutting Of Composite Materials?

- Efficient Removal of Molten and Decomposed Material: During laser cutting, the polymer matrix in composites does not melt cleanly; it decomposes, vaporizes, and forms char and molten residue. Assist gases provide a high-velocity flow that blows these byproducts out of the kerf. Without this removal mechanism, debris can re-solidify on the cut edge, leading to poor surface finish, increased kerf width, and incomplete cutting.

- Reduction of Heat Accumulation: Composite materials generally have low thermal conductivity, meaning heat is not easily dissipated away from the cutting zone. Assist gases help carry away heat from the interaction area, reducing localized temperature build-up. This cooling effect limits the size of the heat-affected zone and minimizes thermal damage such as matrix burning, fiber degradation, and delamination.

- Control of Oxidation and Burning: Many composites are cut in ambient air, where oxygen promotes oxidation of fibers and burning of the polymer matrix. Using assist gases such as nitrogen can displace oxygen around the cut zone, significantly reducing oxidation, edge discoloration, and fiber weakening. Even compressed air, when properly directed, helps moderate uncontrolled combustion by stabilizing the cutting environment.

- Improved Laser Energy Coupling: Smoke, vapors, and char produced during cutting can absorb or scatter the laser beam, reducing the amount of energy reaching the material surface. Assist gases clear the optical path by removing these byproducts in real time, ensuring consistent laser-material interaction and more stable cutting conditions.

- Prevention of Re-Deposition and Kerf Blockage: Without assist gases, decomposed resin and severed fiber fragments can accumulate in the kerf, partially blocking the laser beam and requiring higher power or slower cutting speeds. Gas flow keeps the kerf open, allowing the laser to penetrate through the full thickness of the composite more effectively.

- Enhanced Process Stability and Repeatability: Assist gases help create a more predictable cutting process by controlling byproduct removal, heat input, and chemical reactions. This stability is essential when cutting composites with varying fiber orientations or layered structures.

Why Does Laser Cutting Of Composite Materials Produce Harmful Fumes?

- Thermal Decomposition of Polymer Matrices: Most composite matrices are made from thermoset or thermoplastic polymers such as epoxy, polyester, or phenolic resins. During laser cutting, temperatures rapidly exceed the decomposition point of these polymers. Instead of melting, the matrix breaks down into smaller chemical compounds, releasing volatile organic compounds (VOCs), toxic gases, and fine particulate matter. These byproducts are a major source of harmful fumes.

- Formation of Toxic Gases and Irritants: Depending on the resin chemistry, laser-induced degradation can produce substances such as carbon monoxide, formaldehyde, benzene derivatives, and acidic gases. These fumes are hazardous when inhaled and can cause respiratory irritation, headaches, or more serious health effects with prolonged exposure. Additives, fillers, and flame retardants in composite materials further increase the complexity and toxicity of emitted fumes.

- Oxidation and Combustion Reactions: Laser cutting is often performed in ambient air, allowing oxygen to interact with hot material surfaces. This promotes oxidation and partial combustion of the polymer matrix, generating smoke, soot, and additional toxic byproducts. These reactions intensify fume production compared to processes carried out in inert environments.

- Fiber-Related Emissions: While fibers such as carbon or glass do not vaporize easily, laser cutting can damage their surfaces and release fine airborne particles. Carbon fiber oxidation can produce carbon-rich particulates, while fractured glass fibers may become respirable dust. These particles pose inhalation risks and can irritate the skin, eyes, and lungs.

- High Energy Density and Rapid Heating Rates: The concentrated energy of a laser causes extremely rapid heating and cooling cycles. This sudden thermal shock prevents controlled breakdown of materials and instead leads to violent decomposition, increasing the volume and toxicity of fumes generated in a short time.

- Accumulation Without Adequate Extraction: If fume extraction and ventilation systems are insufficient, harmful gases and particulates can accumulate around the cutting area. This not only poses health risks but can also interfere with laser performance by absorbing or scattering the beam.

Why Do The Edges Of Composite Materials Become Brittle After Laser Cutting?

- Thermal Degradation of the Polymer Matrix: The polymer matrix in composite materials has limited resistance to high temperatures. During laser cutting, the matrix near the cut edge is exposed to temperatures well above its glass transition and decomposition limits. This causes molecular chain scission, charring, or cross-link breakdown, resulting in a hardened, carbonized layer that is much more brittle than the original material.

- Loss of Matrix Toughness and Ductility: As the resin degrades, it loses its ability to absorb energy and deform plastically. The heat-damaged matrix becomes stiff and fragile, reducing its capacity to hold fibers together effectively. This weakened fiber–matrix interface contributes to brittle behavior along the cut edge.

- Fiber Damage and Oxidation: Reinforcing fibers can also be affected by laser-induced heat. Carbon fibers, for example, may oxidize at elevated temperatures, leading to surface erosion and reduced strength. Glass fibers can develop microcracks due to thermal shock. Damaged fibers are less able to bridge cracks, which increases edge brittleness.

- Rapid Heating and Cooling Cycles: Laser cutting involves extremely fast heating followed by rapid cooling. These thermal cycles induce residual stresses at the cut edge. Tensile stresses, in particular, promote crack initiation and propagation in the heat-affected zone, making the edge more prone to brittle fracture under even small mechanical loads.

- Formation of a Heat-Affected Zone (HAZ): The heat-affected zone surrounding the cut experiences altered material properties compared to the bulk composite. Within this zone, the matrix may be partially decomposed, fibers may be weakened, and interlaminar bonding can be reduced. The cumulative effect of these changes is a stiff, fragile edge region.

- Microstructural Defects and Porosity: Laser-induced vaporization of the matrix can create microvoids and porosity near the cut edge. These defects act as stress concentrators, further reducing toughness and increasing the likelihood of brittle failure.