Introduction

Advantages of Laser Cutting Brass

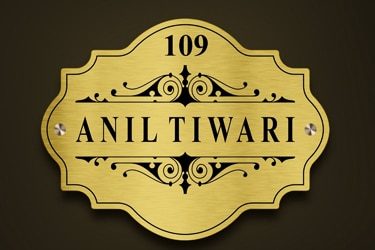

High Precision and Tight Tolerances

Laser cutting brass delivers excellent accuracy, allowing manufacturers to achieve tight tolerances and fine details. This precision ensures consistent dimensions and reliable repeatability, which is essential for electrical components and precision mechanical parts.

Clean and Smooth Edge Quality

The laser cutting process produces smooth, bright edges on brass with minimal burrs. This high edge quality often eliminates the need for secondary finishing, reducing labor time and improving the overall appearance of finished parts.

Minimal Heat-Affected Zone

Laser cutting concentrates heat in a small area, minimizing thermal impact on surrounding material. This helps preserve brass's mechanical properties and prevents warping, making it suitable for thin sheets and delicate designs.

Excellent Design Flexibility

Laser cutting easily handles complex geometries, small holes, and intricate patterns in brass. This flexibility supports custom designs, rapid prototyping, and quick design changes without the need for additional tooling or setup.

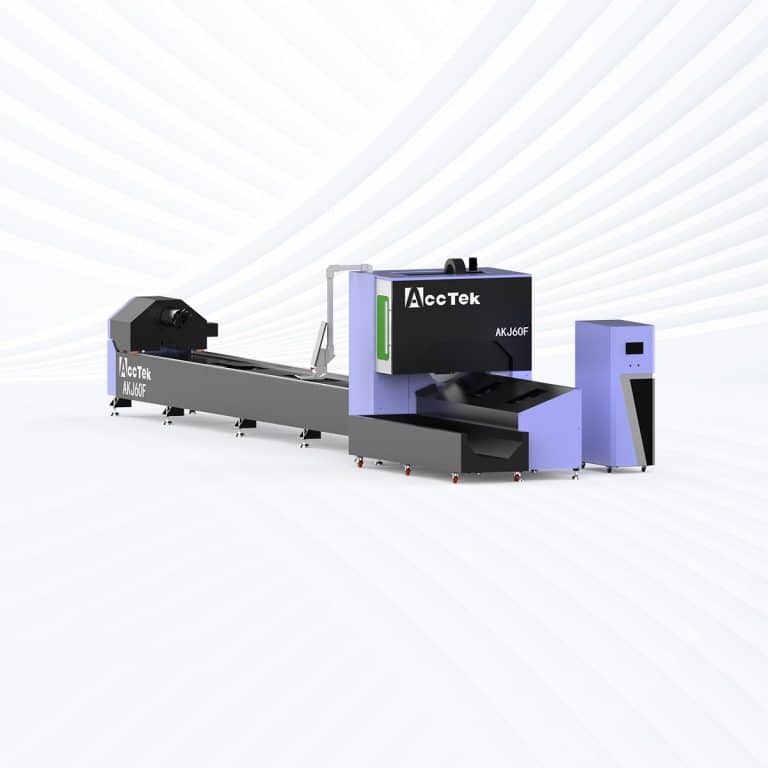

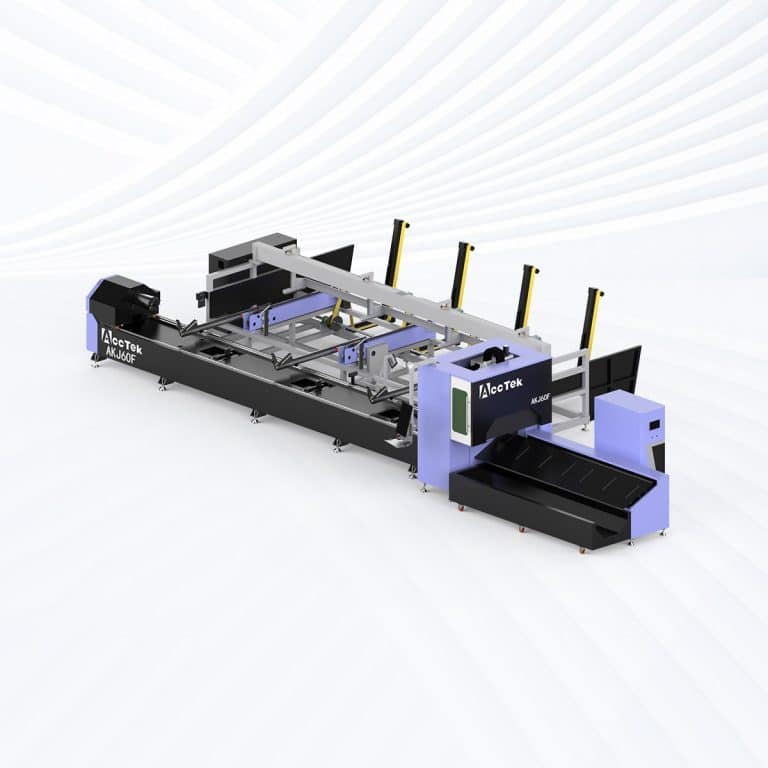

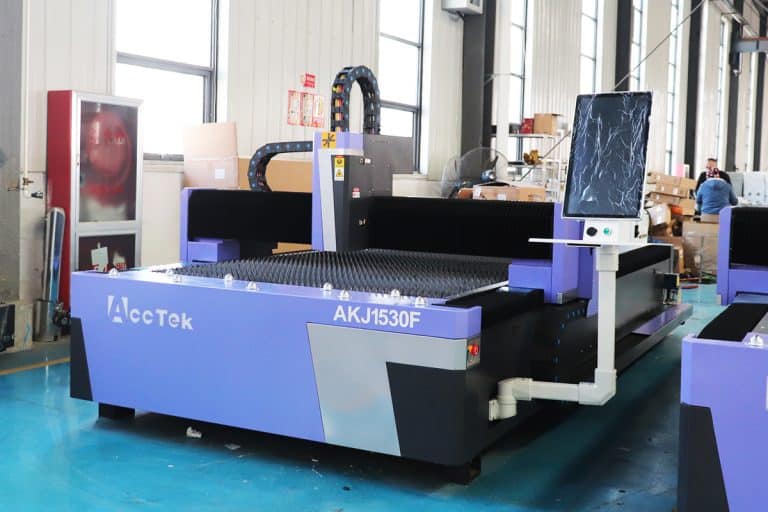

High Efficiency and Fast Processing

Modern fiber laser cutting systems cut brass quickly and consistently when properly configured. Faster cutting speeds and reduced setup times increase productivity and help shorten lead times for both small batches and large production runs.

Reduced Material Waste

Narrow kerf widths and advanced nesting software maximize material usage when cutting brass. This reduces scrap, lowers material costs, and supports more efficient and sustainable manufacturing processes.

Compatible Materials

- C11000 Copper

- C36000 Free-Cutting Brass

- C26000 Cartridge Brass

- C28000 Muntz Metal

- C23000 Half-Hard Yellow Brass

- C22000 Commercial Bronze

- C33000 Low-Leaded Brass

- C34000 High-Leaded Brass

- C37700 Architectural Brass

- C46400 Naval Brass

- C28000 Muntz Metal

- C5000 Brass

- C61000 Silicon Brass

- C23000 Leaded Brass

- C71500 Admiralty Brass

- C83600 Bearing Bronze

- C69300 Silicon Bronze

- C74200 Yellow Brass

- C75200 Nickel Brass

- C75900 Gunmetal Brass

- C76300 Phosphor Bronze Brass

- C77000 Architectural Bronze

- C79900 Brass

- C86300 Silicon Brass

- C89400 Tin Brass

- C22020 Brass

- C21000 Brass

- C23010 Brass

- C27000 Brass

- C26010 Brass

- C28010 Brass

- C28700 Brass

- C31800 Brass

- C32000 Brass

- C33010 Brass

- C35000 Brass

- C36010 Brass

- C36200 Brass

- C36400 Brass

- C46500 Brass

Laser Cutting Brass VS Other Cutting Methods

| Comparison Item | Laser Cutting | Plasma Cutting | Waterjet Cutting | Flame Cutting |

|---|---|---|---|---|

| Suitability for Brass | Excellent, widely used | Poor, unstable arc | Excellent | Not suitable |

| Cutting Precision | Very high precision | Low to moderate | Very high precision | Very low precision |

| Edge Quality | Smooth, bright edges | Rough edges, dross | Smooth, matte edges | Rough, oxidized edges |

| Heat-Affected Zone | Minimal | Large | None (cold cutting) | Very large |

| Cutting Speed | Fast for thin sheets | Fast on thick metals | Slow to moderate | Slow |

| Material Thickness Range | Thin to medium thickness | Medium to thick metals | Thin to very thick | Thick steel only |

| Detail & Complexity | Excellent for fine details | Limited detail | Excellent detail | Very limited |

| Kerf Width | Narrow kerf | Wide kerf | Moderate kerf | Wide kerf |

| Secondary Finishing | Rarely required | Often required | Rarely required | Always required |

| Reflective Material Handling | Designed with protection | Not suitable | No reflection issues | Not applicable |

| Operating Cost | Moderate | Low | High | Low |

| Equipment Investment | Moderate to high | Low to moderate | High | Low |

| Automation Capability | Highly automated CNC | CNC capable | CNC capable | Mostly manual |

| Environmental Impact | Low fumes, clean process | High fumes and noise | Water and abrasive waste | Heavy smoke and gases |

| Overall Brass Cutting Quality | Excellent balance of speed and quality | Poor quality for brass | High quality, slower | Not usable |

Laser Cutting Capacity For Brass

| Laser Power | Material Thickness (mm) | Cutting Speed (m/min) | Actual Laser Power (W) | Gas | Pressure (bar) | Nozzle Size (mm) | Focus Position (mm) | Cutting Height (mm) |

|---|---|---|---|---|---|---|---|---|

| 1KW | 1 | 9 | 1000 | N2 | 12 | 2.0S | 0 | 0.5 |

| 2 | 2 | 1000 | N2 | 14 | 2.0S | -1 | 0.5 | |

| 1.5KW | 1 | 15 | 1500 | N2 | 12 | 1.5S | 0 | 0.5 |

| 2 | 5 | 1500 | N2 | 14 | 2.0S | -1 | 0.5 | |

| 3 | 1.8 | 1500 | N2 | 14 | 2.5S | -1.5 | 0.5 | |

| 2KW | 1 | 18 | 2000 | N2 | 12 | 1.5S | 0 | 0.8 |

| 2 | 8 | 2000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 3 | 2000 | N2 | 14 | 2.5S | -1.5 | 0.5 | |

| 4 | 1.3 | 2000 | N2 | 16 | 3.0S | -2 | 0.5 | |

| 3KW | 1 | 20-28 | 3000 | N2 | 12 | 1.5S | 0 | 0.8 |

| 2 | 10-15 | 3000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 5-6 | 3000 | N2 | 14 | 2.5S | -1 | 0.5 | |

| 4 | 2.5-3 | 3000 | N2 | 14 | 3.0S | -2 | 0.5 | |

| 5 | 1.8-2.2 | 3000 | N2 | 14 | 3.0S | -2.5 | 0.5 | |

| 4KW | 1 | 25-28 | 4000 | N2 | 12 | 1.5S | 0 | 0.6 |

| 2 | 12-15 | 4000 | N2 | 12 | 1.5S | -1 | 0.6 | |

| 3 | 7-8 | 4000 | N2 | 14 | 2.0S | -1 | 0.6 | |

| 4 | 4-5 | 4000 | N2 | 14 | 2.5S | -2 | 0.5 | |

| 5 | 2.5-3 | 4000 | N2 | 14 | 3.0S | -2 | 0.5 | |

| 6 | 2-2.5 | 4000 | N2 | 16 | 3.0S | -2.5 | 0.5 | |

| 6KW | 1 | 30-40 | 6000 | N2 | 12 | 1.5S | 0 | 1 |

| 2 | 18-20 | 6000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 12-14 | 6000 | N2 | 14 | 2.5S | -1 | 0.5 | |

| 4 | 8-9 | 6000 | N2 | 14 | 3.0S | -1.5 | 0.5 | |

| 5 | 5-5.5 | 6000 | N2 | 14 | 3.0S | -2 | 0.5 | |

| 6 | 3.2-3.8 | 6000 | N2 | 16 | 3.0S | -2.5 | 0.5 | |

| 8 | 1.5-1.8 | 6000 | N2 | 16 | 3.5S | -3 | 0.5 | |

| 10 | 0.8-1 | 6000 | N2 | 16 | 3.5S | -3 | 0.5 | |

| 12KW | 1 | 35-45 | 12000 | N2 | 12 | 2.0S | 0 | 1 |

| 2 | 30-35 | 12000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 3 | 18-22 | 12000 | N2 | 12 | 2.0S | -1 | 0.5 | |

| 4 | 15-18 | 12000 | N2 | 12 | 2.0S | -2 | 0.5 | |

| 5 | 12-15 | 12000 | N2 | 14 | 2.5S | -3 | 0.5 | |

| 6 | 8-10 | 12000 | N2 | 14 | 2.5S | -3 | 0.5 | |

| 8 | 5-7 | 12000 | N2 | 14 | 2.5S | -4 | 0.5 | |

| 10 | 4-5 | 12000 | N2 | 14 | 5.0B | -5 | 0.5 | |

| 12 | 1.8-2 | 12000 | N2 | 14 | 5.0B | -5 | 0.5 | |

| 14 | 1.2-1.4 | 12000 | N2 | 16 | 5.0B | -8 | 0.5 | |

| 20KW | 1 | 40-45 | 20000 | N2 | 12 | 2.0S | 0 | 1 |

| 2 | 35-40 | 20000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 28-30 | 20000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 4 | 19-22 | 20000 | N2 | 12 | 2.5S | 0 | 0.5 | |

| 5 | 18-19 | 20000 | N2 | 14 | 2.5S | 0 | 0.5 | |

| 6 | 12-15 | 20000 | N2 | 14 | 3.0S | 0 | 0.5 | |

| 8 | 8-10 | 20000 | N2 | 14 | 3.0S | 0 | 0.5 | |

| 10 | 7-8 | 20000 | N2 | 14 | 5.0B | -1 | 0.3 | |

| 12 | 2.5-3.5 | 20000 | N2 | 14 | 5.0B | -2 | 0.3 | |

| 14 | 2-2.5 | 20000 | N2 | 16 | 5.0B | -3 | 0.3 | |

| 16 | 1.5-2 | 20000 | N2 | 18 | 5.0B | -3 | 0.3 | |

| 18 | 1.2-1.5 | 20000 | N2 | 18 | 5.0B | -4 | 0.3 | |

| 30KW | 1 | 40-45 | 30000 | N2 | 12 | 2.0S | 0 | 1 |

| 2 | 35-40 | 30000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 3 | 28-30 | 30000 | N2 | 12 | 2.0S | 0 | 0.5 | |

| 4 | 20-25 | 30000 | N2 | 12 | 2.5S | 0 | 0.5 | |

| 5 | 18-20 | 30000 | N2 | 14 | 2.5S | 0 | 0.5 | |

| 6 | 15-18 | 30000 | N2 | 14 | 3.0S | 0 | 0.5 | |

| 8 | 10-15 | 30000 | N2 | 14 | 3.0S | 0 | 0.5 | |

| 10 | 8-10 | 30000 | N2 | 14 | 5.0B | -1 | 0.3 | |

| 12 | 5-8 | 30000 | N2 | 14 | 5.0B | -2 | 0.3 | |

| 14 | 3-5 | 30000 | N2 | 16 | 5.0B | -3 | 0.3 | |

| 16 | 1.5-2 | 30000 | N2 | 18 | 5.0B | -3 | 0.3 | |

| 18 | 1.2-1.5 | 30000 | N2 | 18 | 5.0B | -4 | 0.3 | |

| 40KW | 5 | 25-30 | 40000 | N2 | 14 | 2.5S | 0 | 0.5 |

| 6 | 20-25 | 40000 | N2 | 14 | 3.0S | 0 | 0.5 | |

| 8 | 18-22 | 40000 | N2 | 14 | 3.0S | 0 | 0.5 | |

| 10 | 10-14 | 40000 | N2 | 14 | 5.0B | -1 | 0.3 | |

| 12 | 8-11 | 40000 | N2 | 14 | 5.0B | -2 | 0.3 | |

| 14 | 6-8 | 40000 | N2 | 16 | 5.0B | -3 | 0.3 | |

| 16 | 5-7 | 40000 | N2 | 18 | 5.0B | -3 | 0.3 | |

| 18 | 4-5 | 40000 | N2 | 18 | 5.0B | -4 | 0.3 | |

| 20 | 3-4 | 40000 | N2 | 18 | 6.0B | -5 | 0.3 | |

| 25 | 2.5-3 | 40000 | N2 | 18 | 6.0B | -7 | 0.3 |

Applications of Laser Cutting Brass

Customer Testimonials

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

Why Does Brass Reflect Laser Light So Strongly?

- High Free-Electron Density: Brass is an alloy primarily composed of copper and zinc, both of which are excellent electrical conductors. Metals with high electrical conductivity also have a high density of free electrons on their surface. When laser light strikes brass, these free electrons oscillate and re-emit much of the incoming energy rather than allowing it to be absorbed. This electron-driven response is the primary reason for brass’s strong reflectivity.

- Laser Wavelength Interaction: Most industrial lasers operate at specific wavelengths, such as fiber lasers around 1 µm. Brass reflects a large percentage of light at these wavelengths, especially when the surface is smooth or polished. Because absorption is low at the initial contact point, it takes more energy to initiate melting, increasing reflection during the early stages of laser processing.

- Smooth and Polished Surface Characteristics: Brass often has a smooth, bright surface finish, which further enhances reflectivity. Smooth surfaces reflect light more uniformly than rough or oxidized ones. In laser cutting, this mirror-like behavior causes more laser energy to bounce away from the material rather than penetrate it.

- High Thermal Conductivity: Brass conducts heat efficiently, quickly spreading absorbed energy away from the interaction zone. This rapid heat dissipation prevents localized temperature buildup, making it harder for the laser to overcome reflectivity and start a stable melt pool. As a result, reflection remains high until sufficient energy is applied.

- Oxide Layer Behavior: Unlike steel, brass does not form a thick, dark oxide layer that would increase laser absorption. Its thin, light-colored oxide layer reflects rather than absorbs laser energy, maintaining high reflectivity throughout processing.

- Impact on Laser Cutting Machines: Strong reflection increases the risk of back reflection, where laser energy returns toward the cutting head and laser source. This can damage optics and fiber connections if protective systems are not in place, making specialized equipment essential for processing brass safely.

What Fumes Are Produced When Laser Cutting Brass?

- Zinc Oxide Fumes: Zinc has a relatively low boiling point compared to copper, so it vaporizes quickly during laser cutting. When zinc vapor reacts with oxygen in the air, it forms zinc oxide fumes, which appear as a fine white or bluish smoke. Inhaling zinc oxide can cause metal fume fever, a short-term illness with flu-like symptoms such as fever, chills, nausea, and fatigue. While typically temporary, repeated exposure without proper ventilation poses health risks.

- Copper Oxide Particles: Copper does not vaporize as easily as zinc, but it can still oxidize under laser heat. This produces copper oxide particles that become airborne as fine dust. Prolonged exposure to copper oxide fumes may irritate the respiratory tract and, over time, contribute to more serious lung issues if not properly filtered.

- Metallic Vapors and Fine Particulates: In addition to oxides, laser cutting brass generates microscopic metallic particles from the rapid melting and ejection of material. These ultrafine particulates can remain suspended in the air for extended periods, increasing the risk of inhalation. Their small size allows them to penetrate deep into the lungs, making effective extraction systems essential.

- Ozone Formation: High-energy laser beams can interact with surrounding air to produce small amounts of ozone. While ozone levels are usually low, poor ventilation can allow concentrations to build up, leading to throat irritation, coughing, or breathing discomfort.

- Contaminant-Related Fumes: Surface coatings, oils, or residues on brass sheets can burn during cutting, producing additional fumes such as hydrocarbons or unpleasant odors. These byproducts further degrade air quality and may pose secondary health concerns.

- Importance of Fume Extraction and Filtration: Because brass cutting fumes can be hazardous, proper fume extraction systems are critical. High-efficiency filters, sealed cutting enclosures, and regular system maintenance help capture zinc oxide, copper particles, and other airborne contaminants before they reach operators.

How Should Ventilation Be Handled When Laser Cutting Brass?

- Source Capture at the Cutting Area: Ventilation should begin with capturing fumes as close to the cutting zone as possible. Most modern laser cutting machines are equipped with integrated exhaust ports beneath the cutting table or near the cutting head. These systems pull fumes downward and away from the operator before they can disperse into the surrounding air, significantly reducing exposure.

- High-Efficiency Filtration Systems: Because brass cutting produces zinc oxide fumes and fine metal particulates, standard ventilation is not sufficient. Filtration systems should include multi-stage filters, such as pre-filters for larger particles and HEPA filters for ultrafine metal dust. Activated carbon filters are also recommended to absorb gaseous byproducts and odors.

- Adequate Airflow and System Sizing: Ventilation systems must be properly sized to match the laser’s power and cutting volume. Insufficient airflow allows fumes to escape the enclosure, while excessive airflow can disrupt the cutting process. Manufacturers typically specify required air volume and pressure, which should be followed closely to ensure effective extraction.

- Sealed Cutting Enclosures: Using a fully enclosed laser cutting system helps contain fumes and ensures they are directed into the extraction system. Sealed enclosures also improve workplace safety by preventing accidental exposure to laser radiation and airborne contaminants.

- Regular Maintenance and Filter Replacement: Ventilation performance degrades over time if filters become clogged with metal dust. Regular inspection, cleaning, and timely filter replacement are essential to maintain consistent airflow and filtration efficiency. Neglected systems can lead to reduced fume capture and increased health risks.

- Compliance with Safety Regulations: Ventilation systems should meet local occupational safety and environmental regulations regarding airborne metal exposure. In some facilities, air quality monitoring may be required to verify that zinc oxide and copper particle levels remain within permissible limits.

- Supplementary Room Ventilation: While local extraction is critical, general room ventilation helps prevent residual fumes from accumulating. Fresh air intake and controlled exhaust improve overall air quality and worker comfort.

What Nozzle Problems Might Occur When Laser Cutting Brass?

- Molten Metal Adhesion and Spatter Buildup: Brass produces highly fluid molten metal during cutting. If cutting parameters are not optimized, molten droplets can splash upward and adhere to the nozzle tip. Over time, this buildup partially blocks the nozzle opening, disrupting gas flow and causing unstable cutting, increased dross, or incomplete cuts.

- Nozzle Orifice Damage: High reflectivity in brass can cause back-reflected laser energy to heat the nozzle. Prolonged exposure may deform or erode the nozzle orifice, especially on copper nozzles. A damaged or misshapen orifice leads to uneven gas distribution, which directly impacts cut-edge quality.

- Gas Flow Disturbances: Even minor nozzle contamination can alter the laminar flow of assist gas. Turbulent or off-center gas flow reduces the ability to expel molten brass from the kerf. This often results in increased slag, excessive sparks, and rough edges, particularly on thicker brass sheets.

- Nozzle Misalignment: Brass cutting requires precise nozzle centering relative to the laser beam. Any misalignment caused by thermal expansion, collision with warped material, or improper installation can lead to uneven heating and inconsistent cutting. Misalignment also increases the risk of molten metal striking the nozzle.

- Accelerated Nozzle Wear: Because brass cutting often requires higher gas pressure and tighter process control, nozzles wear faster than when cutting less reflective materials. Frequent thermal cycling and exposure to hot metal particles shorten nozzle lifespan and increase consumable costs.

- Clogging from Oxides and Fumes: Zinc oxide fumes and fine metallic particles generated during brass cutting can accumulate around the nozzle tip and internal gas passages. This gradual clogging reduces gas efficiency and can go unnoticed until cut quality deteriorates significantly.

- Increased Risk of Nozzle Collisions: Brass sheets may distort slightly under heat, increasing the chance of the nozzle contacting the material surface. Such collisions can damage the nozzle, affect focus height sensing, and lead to unplanned downtime.

Does The Thermal Conductivity Of Brass Affect Laser Cutting?

- Rapid Heat Dissipation: Brass quickly transfers heat away from the laser interaction zone. When the laser beam strikes the surface, a large portion of the absorbed energy spreads into the surrounding material instead of remaining localized at the cut front. This makes it more difficult to raise the temperature to the melting point, especially during initial pierce, and often requires higher laser power or slower cutting speeds.

- Delayed and Unstable Piercing: Due to rapid heat conduction, piercing brass can be inconsistent. Heat disperses before a stable melt pool forms, leading to longer pierce times or incomplete penetration. This instability can increase spatter, nozzle contamination, and the risk of back reflection to sensitive optical components.

- Wider Heat-Affected Zone (HAZ): Although brass spreads heat quickly, excessive energy input to overcome this effect can expand the heat-affected zone. A wider HAZ may cause slight edge rounding, surface discoloration, or dimensional distortion, particularly on thin sheets or intricate geometries.

- Reduced Cutting Efficiency: Because thermal conductivity continuously draws heat away from the cut, the laser must work harder to maintain a clean kerf. This reduces overall cutting efficiency compared to materials with lower heat conductivity, such as carbon steel. Productivity may decrease, especially when processing thicker brass sections.

- Increased Risk to Laser Optics: The combination of high thermal conductivity and strong reflectivity means that insufficient energy absorption can result in higher reflected energy. This increases the risk of back reflection, which can damage the cutting head or fiber laser source if protective measures are not in place.

- Assist Gas Dependence: Efficient assist gas flow becomes more critical when cutting brass. Proper gas pressure and nozzle alignment help remove molten material quickly, minimizing heat buildup and compensating for rapid heat dissipation. Poor gas performance exacerbates cutting instability caused by thermal conductivity.

- Impact on Parameter Sensitivity: Laser cutting brass requires narrow process windows. Small deviations in power, speed, focus, or gas pressure can lead to inconsistent cuts because heat is constantly being pulled away from the cutting zone.

Does Laser Cutting Of Brass Require Slower Cutting Speeds?

- High Reflectivity Reduces Energy Absorption: Brass reflects a large portion of the incident laser energy, particularly at common fiber laser wavelengths. Because less energy is absorbed at the cut front, moving the laser too quickly does not allow sufficient heat buildup to fully melt the material. Slower cutting speeds increase the interaction time between the laser beam and the brass, improving energy absorption and melt formation.

- High Thermal Conductivity Draws Heat Away: Brass rapidly conducts heat away from the cutting zone. At higher cutting speeds, this heat dissipation prevents the formation of a stable melt pool. Reducing speed allows more energy to accumulate locally, compensating for thermal losses and enabling consistent material separation.

- Piercing and Cut Stability: Slower speeds are especially important during piercing, where insufficient heat can lead to failed or erratic pierce attempts. Inadequate piercing often causes excessive spatter, nozzle contamination, and unstable cutting conditions. A reduced speed helps establish a clean pierce and smoother transition into continuous cutting.

- Edge Quality and Dross Control: Higher speeds tend to produce incomplete cuts, rough edges, and increased dross on brass. Slower cutting allows molten material to be more effectively expelled by assist gas, improving edge smoothness and reducing post-processing requirements.

- Machine Safety and Optics Protection: Operating at overly high speeds increases the risk of back reflection because the laser energy is not efficiently absorbed. Slower speeds help maintain a stable cutting front, reducing reflected energy that could damage optics, the cutting head, or the laser source.

- Dependence on Laser Power and Thickness: While higher-powered lasers can cut brass faster than lower-powered systems, speeds are still typically slower than those used for steel of similar thickness. Thicker brass plates further amplify the need for reduced cutting speed to maintain cut integrity.

- Balancing Speed and Productivity: Although slower speeds reduce throughput, they often prevent costly downtime caused by poor cut quality or equipment damage. Optimized speed settings ensure consistent results and longer component life.

Why Are Burrs More Likely To Form When Laser Cutting Brass?

- High Reflectivity Reduces Effective Heating: Brass reflects a large portion of the laser energy, especially at common fiber laser wavelengths. This reflection reduces the amount of energy absorbed at the cutting front, leading to inconsistent or incomplete melting. When molten brass is not fully formed or evenly distributed, it tends to re-solidify along the edge, creating burrs.

- High Thermal Conductivity: Brass rapidly conducts heat away from the laser interaction zone. This makes it difficult to maintain a stable melt pool, particularly at higher cutting speeds. As heat dissipates into the surrounding material, molten brass cools and solidifies too quickly, preventing clean ejection from the kerf and encouraging burr buildup.

- Low Melting Point and High Molten Fluidity: Once brass melts, it becomes very fluid. Instead of being cleanly expelled downward by assist gas, molten brass can flow along the cut edge. As it cools, this flowing metal solidifies into thin ridges or droplets, which appear as burrs on the underside or along the cut surface.

- Assist Gas Limitations: Efficient assist gas flow is essential for removing molten brass. If gas pressure is too low, the nozzle is misaligned, or gas flow becomes turbulent, molten material cannot be fully cleared. This allows excess metal to cling to the cut edge and form burrs, especially on thicker sections.

- Cutting Speed and Focus Sensitivity: Brass requires narrow parameter windows. Cutting too fast leads to incomplete melting, while cutting too slowly causes excessive molten material. Incorrect focus position reduces energy density at the cut front, further increasing the likelihood of uneven melting and burr formation.

- Material Thickness and Alloy Variations: Thicker brass plates generate more molten material, increasing the chance that some will reattach before being expelled. Different brass alloys also melt and solidify at slightly different rates, affecting burr tendency.

Why Does Laser Cutting Of Brass Produce More Slag?

- High Reflectivity Limits Energy Absorption: Brass reflects a significant portion of incoming laser energy, especially at fiber laser wavelengths. This reduced absorption makes it harder to maintain a stable and continuous melt pool. When melting is inconsistent, portions of molten brass are not cleanly separated and instead solidify at the bottom of the cut as slag.

- High Thermal Conductivity Draws Heat Away: Brass conducts heat away from the cutting zone very quickly. This rapid heat dissipation cools the molten material before it can be fully blown out by the assist gas. As the molten brass loses temperature, it becomes more viscous and adheres to the underside of the part, forming stubborn slag deposits.

- Low Melting Point and High Molten Fluidity: Once brass reaches its melting point, it becomes highly fluid. This molten metal can spread along the kerf walls rather than being expelled downward. As it cools, the flowing metal re-solidifies and attaches to the cut edge, increasing slag formation.

- Assist Gas Flow Challenges: Effective assist gas flow is critical for removing molten brass. Insufficient gas pressure, improper nozzle alignment, or turbulent gas flow reduces the force needed to eject molten material. As a result, excess molten brass accumulates and solidifies as slag, particularly on thicker plates.

- Cutting Speed Sensitivity: Cutting too fast prevents complete melting, while cutting too slowly creates excessive molten material. Both conditions make it harder for assist gas to remove all molten brass efficiently, increasing the likelihood of slag buildup.

- Material Thickness and Alloy Composition: Thicker brass sections naturally produce more molten material, increasing the chances of incomplete ejection. Additionally, different brass alloys have varying zinc content, which affects melting behavior and slag tendency.

- Nozzle and Focus Condition: Worn nozzles, contaminated optics, or incorrect focus position reduce cutting efficiency and gas effectiveness. These issues contribute to unstable melting and poor molten metal removal, further increasing slag formation.