Introduction

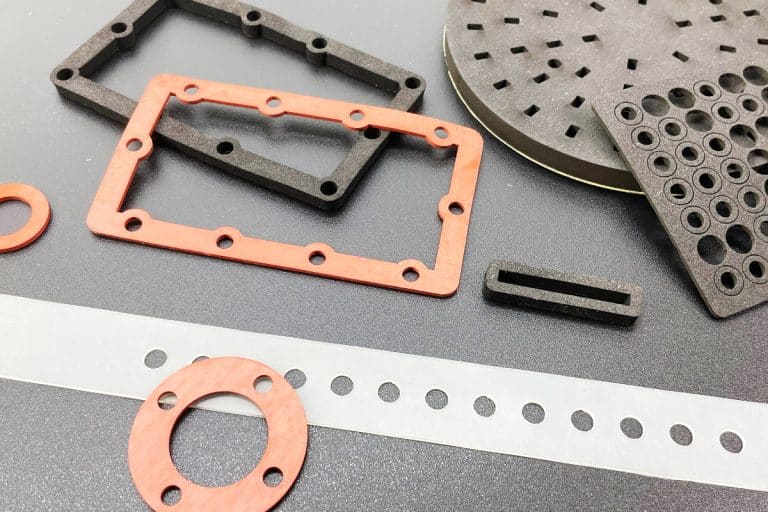

Materials Suitable for Laser Cutting

Key Advantages of Laser Cutting

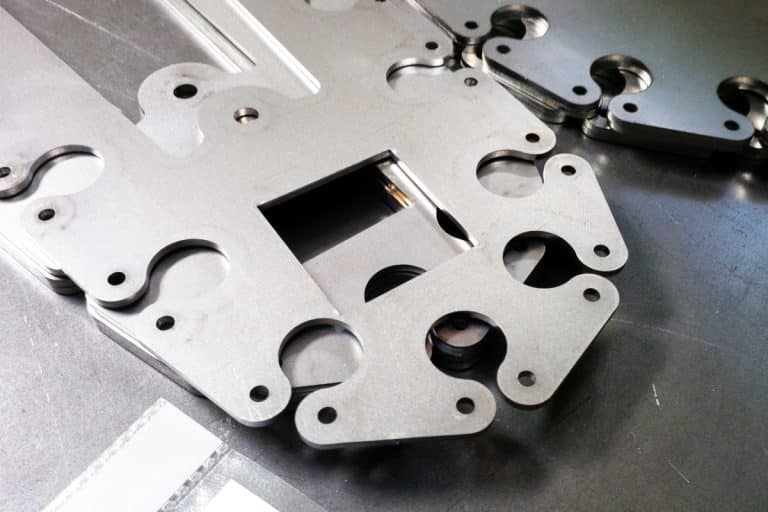

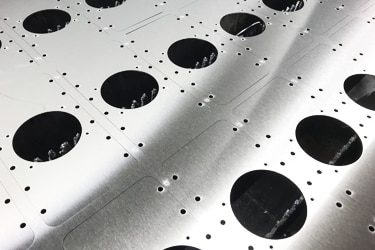

Exceptional Precision and Accuracy

Laser cutting delivers extremely precise cuts with tight tolerances, making it ideal for complex geometries and intricate designs. The focused laser beam ensures consistent accuracy across repeated cuts, even on thin or delicate materials.

Clean Cuts and High-Quality Edges

One major advantage of laser cutting is its ability to produce smooth, clean edges with minimal burrs. This often eliminates the need for secondary finishing processes, saving time, labor, and overall production costs.

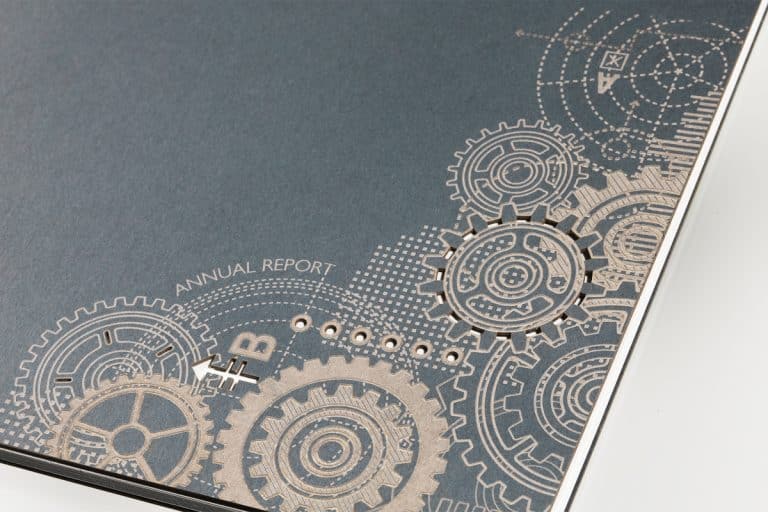

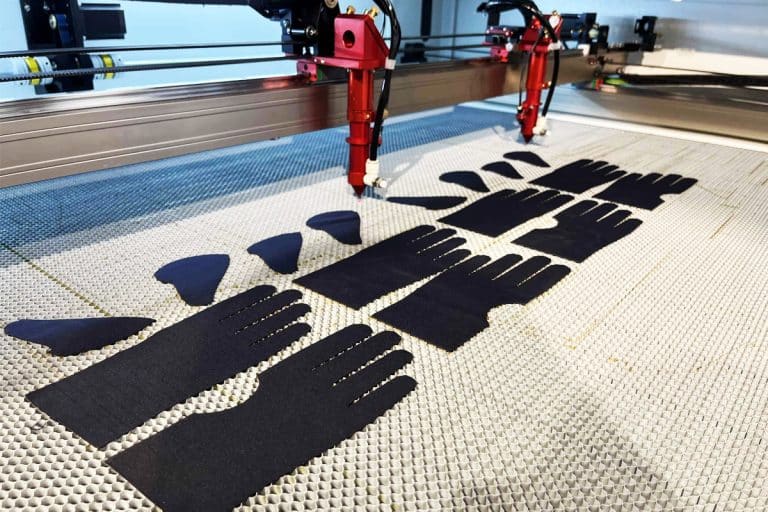

Versatility Across Materials

Laser cutting can process a wide variety of materials, including metals, plastics, wood, acrylic, textiles, and composites. This flexibility makes it suitable for many industries, from heavy manufacturing to creative and decorative applications.

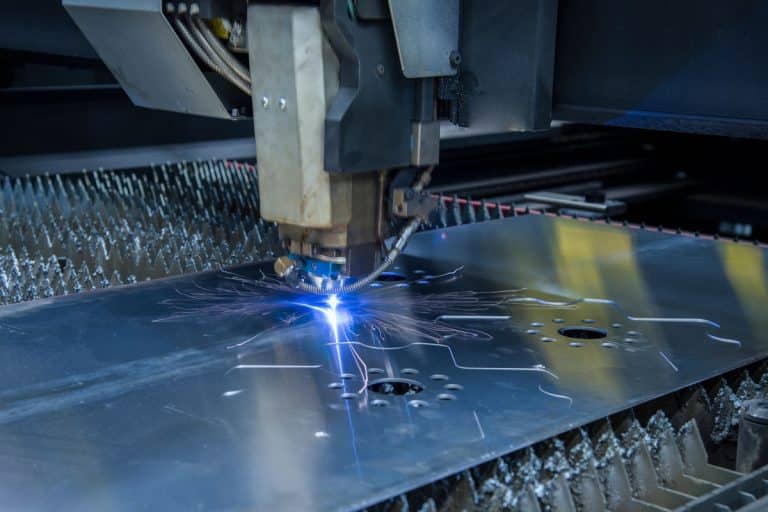

High Speed and Production Efficiency

Compared to traditional cutting methods, laser cutting is fast and highly efficient. Automated systems and CNC control allow rapid cutting cycles, improving productivity and enabling quick turnaround times for both prototypes and large batches.

Minimal Material Waste

The narrow laser kerf and precise cutting path reduce excess material removal. This results in less scrap, better material utilization, and lower raw material costs, making laser cutting an environmentally and economically efficient option.

Non-Contact Process with Low Tool Wear

Because laser cutting is a non-contact process, there is no physical force applied to the material. This minimizes distortion, prevents tool wear, and ensures consistent performance over long production runs without frequent maintenance.

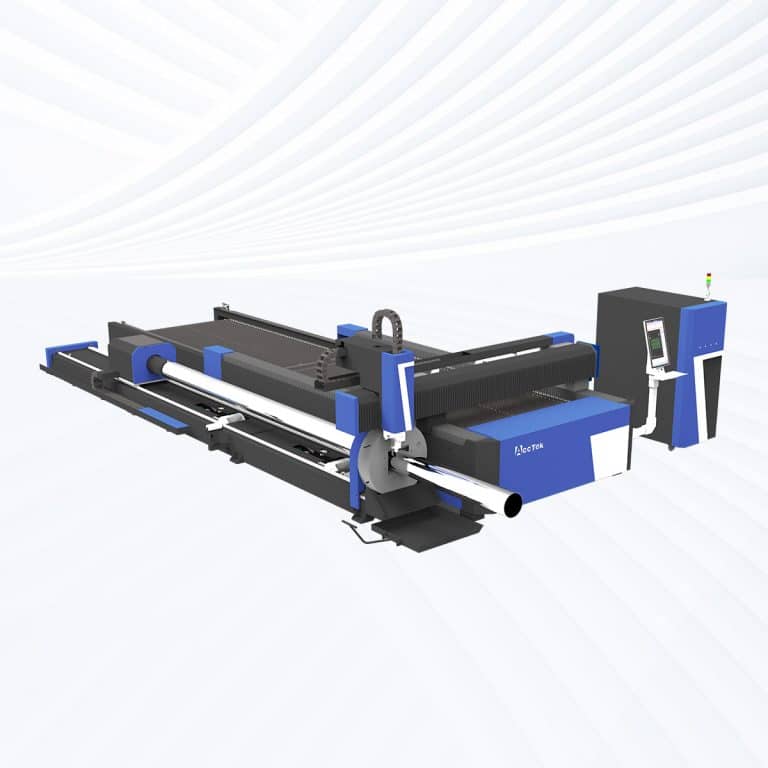

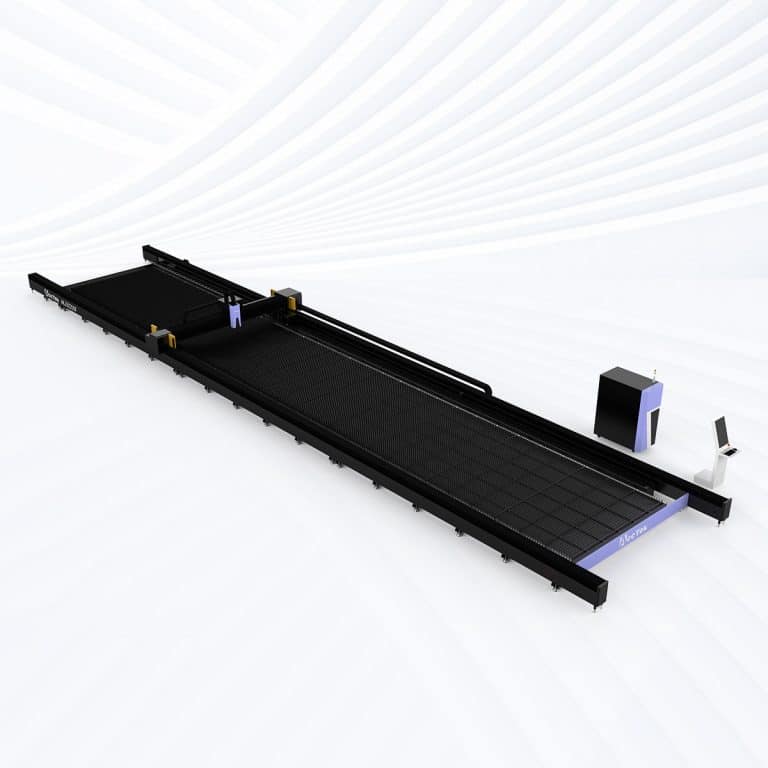

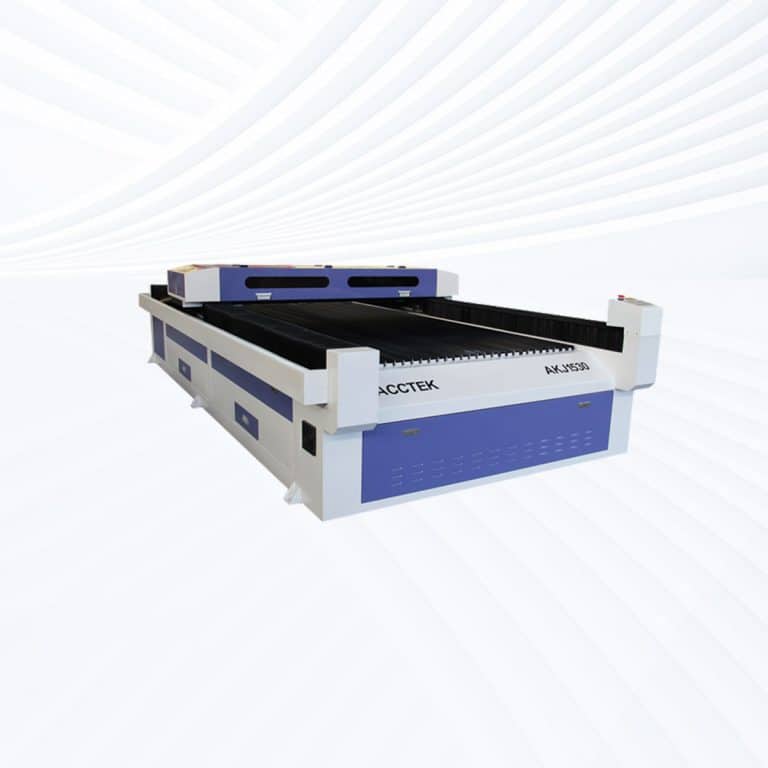

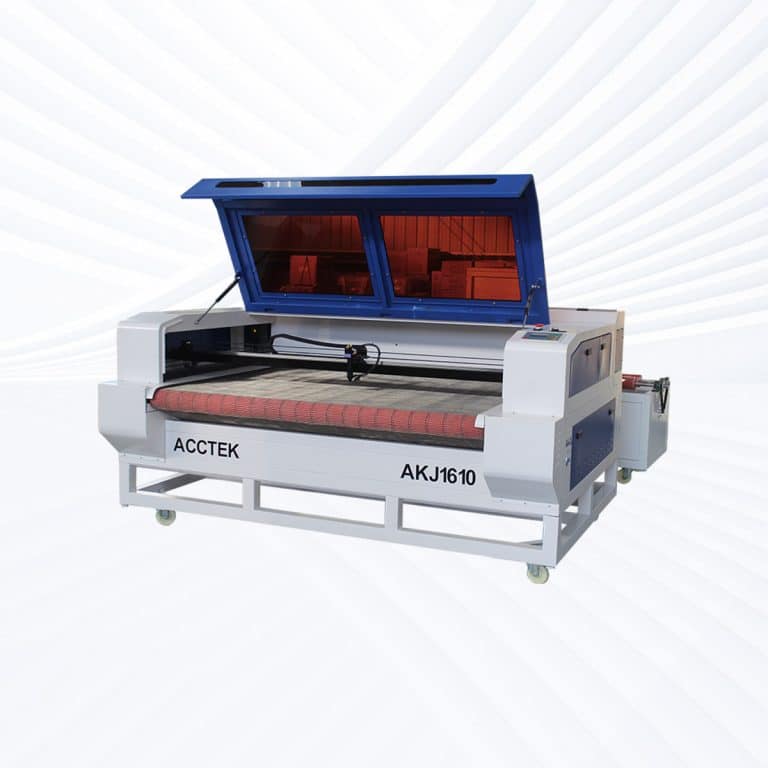

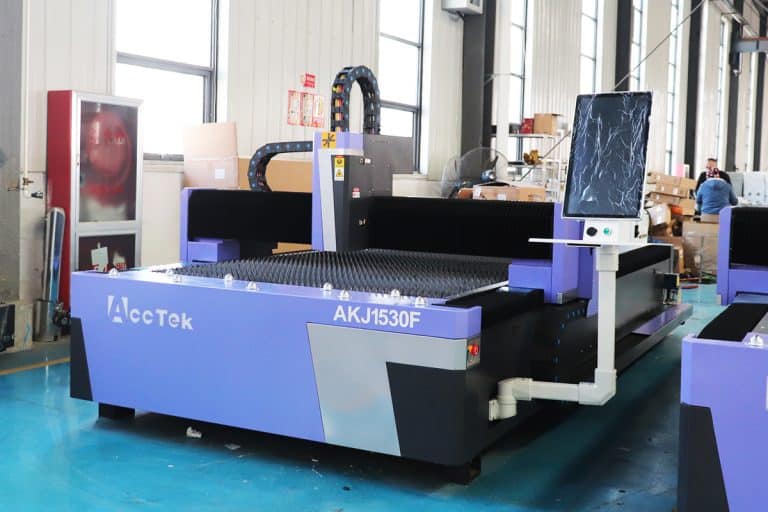

Laser Cutting Machines

Applications of Laser Cutting

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Understanding The Odors Associated With Laser Cutting

This article provides a comprehensive guide to laser cutting odors, explaining the causes of odors, material-specific odors, health risks, and practical strategies for effectively controlling odors and ensuring safer operation.

What Safety Measures Should Be Taken When Operating Laser Cutting Machines

This article teaches the basic safety measures for operating a laser cutting machine, including hazard awareness, engineering controls, PPE, fire prevention, ventilation, training, and emergency response drills.

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Frequently Asked Questions

Why Can't Lasers Completely Cut Materials?

- Material Absorption Limitations: Laser cutting relies on a material’s ability to absorb laser energy and convert it into heat. Some materials reflect or transmit a large portion of the laser beam instead of absorbing it. For example, highly reflective metals or transparent materials at certain wavelengths prevent sufficient energy absorption, meaning the laser cannot generate enough heat to fully penetrate the material thickness.

- Insufficient Energy Density: Every material requires a minimum energy density to melt, burn, or vaporize completely. If the laser power is too low, the cutting speed is too high, or the focal point is misaligned, the energy delivered may be insufficient to cut through the entire thickness. This often results in partial cuts, uncut fibers, or tabs holding the part in place.

- Thermal Dissipation and Heat Loss: Some materials dissipate heat faster than the laser can concentrate it. Materials with high thermal conductivity spread heat away from the cutting zone, reducing the temperature needed for full penetration. As a result, the laser may only engrave or partially cut instead of producing a clean through-cut.

- Material Thickness Constraints: Laser cutting is highly sensitive to thickness. As material thickness increases, the laser beam loses focus and energy intensity as it travels deeper into the cut. This widening of the kerf and loss of power at the bottom of the material can prevent complete separation, especially with low-power machines or dense materials.

- Chemical and Physical Changes During Cutting: Some materials melt, char, or re-solidify rather than vaporize cleanly. Plastics, rubber, and fabrics may melt and fuse back together behind the laser path, giving the appearance of an incomplete cut. Similarly, layered or composite materials may react differently across layers, preventing uniform penetration.

- Assist Gas and Process Limitations: Incomplete cutting can also occur if assist gas flow is insufficient or poorly selected. Assist gases help remove molten material and debris from the kerf. Without proper gas pressure or flow, melted material can remain in the cut path, blocking full penetration.

- Machine and Setup Factors: Dirty optics, worn lenses, misalignment, or unstable material positioning can reduce effective laser power at the cutting point. Even minor setup issues can prevent the laser from delivering consistent energy through the entire cut.

Why Does The Laser Cutting Head Overheat?

- High Thermal Load from Continuous Operation: During laser cutting, a significant amount of energy passes through the cutting head in the form of concentrated laser radiation. Prolonged cutting at high power levels generates continuous heat within lenses, mirrors, and nozzles. If the machine runs for long periods without adequate pauses, the accumulated heat may exceed the cutting head’s ability to dissipate it, leading to overheating.

- Contaminated Optical Components: Smoke, fumes, resin vapors, and fine particles generated while cutting materials such as wood, plastics, rubber, fabrics, and foam can deposit on protective windows and focusing lenses. These contaminants absorb part of the laser energy instead of allowing it to pass cleanly. Absorbed energy converts directly into heat, rapidly increasing the temperature of the cutting head and potentially damaging optical coatings.

- Inadequate Cooling or Airflow: Laser cutting heads rely on cooling systems—such as air assist, water cooling, or heat sinks—to regulate temperature. Blocked air lines, malfunctioning cooling fans, insufficient water flow, or incorrect coolant temperature can drastically reduce heat removal. Without proper cooling, even normal operating power levels can cause the cutting head to overheat.

- Improper Focus and Alignment: When the laser beam is misaligned or improperly focused, energy does not concentrate efficiently at the cutting point. Instead, part of the beam may strike internal surfaces of the nozzle or lens housing. This stray energy generates unnecessary heat inside the cutting head, increasing thermal stress and accelerating overheating.

- Excessive Reflected Energy: Certain materials—especially reflective or uneven surfaces—can reflect laser energy toward the cutting head. This back-reflection adds extra heat to optical components that are not designed to absorb laser energy, contributing to rapid temperature rise and potential failure.

- Worn or Damaged Components: Aging lenses, cracked protective windows, damaged nozzles, or degraded seals can disrupt airflow and heat transfer. These defects prevent proper thermal regulation and allow heat to accumulate faster than designed.

- Incorrect Process Parameters: Using laser power settings that are too high for the material, combined with slow cutting speeds, increases thermal exposure time. This not only heats the material but also raises the temperature of the cutting head itself.

Why Is The Laser Output Power Unstable?

- Power Supply and Electrical Instability: One of the most common causes of unstable laser output is inconsistent electrical input. CO2 laser cutting systems rely on high-voltage power supplies to excite the laser gas. Voltage fluctuations, poor grounding, worn cables, or failing power supply components can cause irregular excitation, leading to pulsing or drifting output power. Inadequate electrical regulation directly translates into unstable laser energy.

- Thermal Effects in the Laser Tube: Laser output is highly sensitive to temperature. If the laser tube or resonator overheats due to insufficient cooling, output power can fluctuate. Cooling systems that are clogged, improperly set, or experiencing pump or chiller failures allow temperature variations that alter gas pressure and energy conversion efficiency inside the tube, reducing stability.

- Gas Degradation or Aging of the Laser Tube: CO2 lasers depend on a precise gas mixture. Over time, gas composition degrades due to chemical reactions, contamination, or leakage. As the gas ages, ionization becomes less uniform, causing inconsistent laser generation. This is especially common in older or heavily used laser tubes nearing the end of their service life.

- Optical Contamination and Alignment Issues: Dirty or damaged mirrors and lenses absorb part of the laser energy instead of transmitting it efficiently. Smoke, resin vapors, and dust from cutting materials such as wood, plastics, rubber, and fabrics can coat optics. This contamination causes uneven energy transmission, resulting in fluctuating output power at the cutting head. Misaligned optics further amplify this instability by scattering energy unpredictably.

- Control System and Modulation Errors: Modern laser cutters use electronic controllers to regulate output power through pulse-width modulation or analog control signals. Faulty control boards, loose signal connections, or software errors can cause inconsistent power commands, making the laser output appear unstable even if the laser source itself is functioning correctly.

- Reflected Energy and Material Interaction: Certain materials reflect laser energy into the system. This back-reflection can interfere with the laser cavity, momentarily destabilizing the output. Repeated reflections may also damage optical components, worsening instability over time.

- Mechanical Vibrations and Environmental Factors: Vibrations from nearby machinery, unstable machine frames, or poor mounting can slightly shift optical alignment during operation. Environmental factors such as dust, humidity, and temperature changes also influence laser performance.

Why Does Taper Appear At The Laser-Cut Edge?

- Laser Beam Divergence and Focus Geometry: A laser beam is focused to a small spot at a specific focal point, but it naturally diverges before and after that point. The highest energy density occurs at the focus, typically near the material’s top surface. As the beam travels deeper into the material, it spreads out and loses intensity. This reduced energy at the lower portion of the cut removes less material, causing the bottom of the cut to be narrower than the top and creating taper.

- Energy Loss with Depth: As the laser penetrates deeper, part of its energy is absorbed by the material, part is lost to heat conduction, and part is blocked by molten or vaporized material. This progressive energy loss reduces cutting efficiency at greater depths. Thicker materials amplify this effect, making the taper more pronounced.

- Material-Specific Thermal Behavior: Different materials respond to heat differently. Plastics, wood, rubber, and fabrics may melt, char, or re-solidify during cutting. Molten material can cling to the cut walls or partially reattach near the bottom of the kerf, restricting material removal and increasing taper. Materials with low thermal conductivity retain heat near the top, further widening the upper kerf compared to the lower section.

- Assist Gas Flow Limitations: Assist gases help eject molten material from the kerf. However, gas pressure and flow effectiveness decrease with depth, especially in narrow cuts. Insufficient gas removal at the bottom allows molten material to accumulate, narrowing the lower cut and contributing to taper.

- Improper Focus Position: If the laser is focused too high above the material surface, the beam diverges excessively as it travels downward, increasing taper. Conversely, focusing too deeply may cause excessive burning at the top while still limiting energy at the bottom. Accurate focus placement is critical to minimizing taper.

- Cutting Speed and Power Imbalance: High cutting speeds or insufficient laser power reduce the amount of energy delivered to deeper regions of the cut. This causes incomplete material removal at the bottom, increasing taper. Slower speeds or higher power improve penetration but may increase thermal damage if not balanced correctly.

- Optical Alignment and Beam Quality: Misaligned optics or degraded beam quality can cause uneven energy distribution across the cut depth. This unevenness leads to asymmetric or exaggerated taper along the cut edge.

Why Does The Laser-Cut Edge Discolor?

- Thermal Degradation and Burning: Laser cutting works by melting, vaporizing, or burning material. In organic materials such as wood, paper, leather, and natural fabrics, the heat causes carbonization or charring. This thermal degradation darkens the cut edge, often producing brown or black discoloration. The longer the material is exposed to heat—due to slow cutting speeds or high power—the more pronounced the discoloration becomes.

- Oxidation Reactions: At high temperatures, materials react with oxygen in the surrounding air. This oxidation alters the chemical structure of the material surface. In plastics and rubber, oxidation can change the molecular bonds, resulting in yellowing, browning, or whitening along the cut edge. Even metals and coated materials can show heat-tinting effects due to surface oxidation, although fiber lasers are typically better suited for metals.

- Melting and Re-Solidification Effects: Many plastics, synthetic fabrics, rubber, and foam melt during laser cutting. When the molten material cools and re-solidifies, it may trap gases, impurities, or degraded polymers, causing color changes along the edge. This is especially common in acrylic, ABS, polyethylene, and synthetic textiles, where the cut edge may appear cloudy, darkened, or glossy with a different color tone than the base material.

- Heat-Affected Zone (HAZ): Discoloration often extends beyond the actual cut line into the heat-affected zone. Heat conducted into the surrounding material alters pigments, dyes, or additives. Dyed fabrics, painted surfaces, laminated boards, and coated plastics are particularly sensitive, as pigments can break down or chemically transform under laser heat, resulting in uneven or unexpected color changes.

- Smoke and Residue Deposition: During cutting, smoke, soot, and vaporized material are generated. If ventilation or air assist is insufficient, these byproducts can settle back onto the cut edge. This residue can stain the surface, causing dark or uneven discoloration that is not purely thermal but contamination-related.

- Assist Gas and Airflow Influence: Air assist helps blow molten material and smoke away from the cut. Poor airflow allows heat buildup and residue accumulation, worsening discoloration. In some cases, oxygen-rich air increases burning, while inert gases can reduce discoloration but are not always practical for non-metal cutting.

- Improper Cutting Parameters: Excessive laser power, slow cutting speed, incorrect focus, or multiple passes increase heat input. This amplifies burning, oxidation, and melting effects, leading to more severe discoloration.

Why Does Laser Cutting Produce Excessive Smoke?

- Thermal Decomposition of Materials: Laser cutting works by melting, burning, or vaporizing material using a high-energy laser beam. Most non-metal materials—such as wood, paper, plastics, rubber, foam, leather, and fabrics—do not simply melt cleanly. Instead, they undergo thermal decomposition. This process breaks complex molecular structures into smaller particles, gases, and carbon-based residues, which become visible smoke.

- Combustion and Charring Effects: Organic materials like wood, paper, cardboard, leather, and natural fabrics contain carbon-based compounds. When exposed to laser heat, these materials partially burn or char. Incomplete combustion produces soot, carbon particles, and volatile gases that rise as thick smoke. Higher laser power or slower cutting speeds intensify combustion, increasing smoke output.

- Melting and Vaporization of Polymers: Plastics, rubber, and foams tend to melt and vaporize rather than burn cleanly. As polymers break down, they release fumes composed of vaporized plastic, additives, and fillers. When these vapors cool, they condense into fine particles suspended in the air, appearing as dense smoke. Materials like ABS, polyethylene, EVA foam, and rubber are especially prone to heavy smoke generation.

- Additives, Binders, and Coatings: Many materials contain adhesives, resins, dyes, coatings, and fillers. For example, plywood and MDF include glue resins, while fabrics may contain dyes and finishes. These substances often decompose at lower temperatures than the base material, producing additional smoke even when cutting conditions seem correct.

- Insufficient Ventilation or Air Assist: Smoke becomes excessive when fume extraction or air assist is inadequate. Without strong airflow to remove vaporized material immediately, smoke accumulates in the cutting area. Poor ventilation also allows smoke to recirculate, making it appear denser and lingering longer.

- Improper Laser Parameters: Using excessive laser power, slow cutting speeds, or poor focus increases heat input beyond what is necessary to cut the material. This excess heat causes more burning, melting, and decomposition, dramatically increasing smoke production.

- Material Thickness and Density: Thicker and denser materials require more energy to cut. The increased energy input leads to greater thermal breakdown and, consequently, more smoke. Multi-layer or composite materials amplify this effect because different layers decompose differently.

Why Does Laser Cutting Produce Slag?

- Incomplete Ejection of Molten Material: During laser cutting, the laser beam melts the material while assist gas (such as air, nitrogen, or oxygen) is used to blow the molten material out of the kerf. If the gas pressure, flow rate, or direction is insufficient, molten material is not fully removed. Instead, it cools and solidifies along the cut edge or bottom surface, forming slag.

- Insufficient Laser Energy at Depth: As the laser penetrates deeper into the material, its energy density decreases due to beam divergence and absorption losses. When the energy is not high enough to keep the material fully molten through the entire thickness, partial melting occurs near the bottom of the cut. This semi-molten material is more likely to stick and solidify as slag.

- Improper Cutting Parameters: Slag formation is strongly influenced by laser power, cutting speed, and focus position. Low power or excessively high cutting speed may fail to maintain a fully molten kerf, while overly slow speeds can cause excessive melting that overwhelms the assist gas. Incorrect focus—especially focusing too high above the material—reduces cutting efficiency at the bottom, increasing slag buildup.

- Material Properties: Different materials behave differently under laser heat. Metals, some plastics, and rubber tend to melt rather than vaporize cleanly. Materials with high viscosity when molten do not flow easily, making them harder for the assisting gas to remove. Coated, layered, or composite materials can also produce uneven melting, increasing slag formation.

- Assist Gas Selection and Pressure: The type and pressure of assist gas play a critical role. Low gas pressure lacks the force needed to eject molten material, while incorrect gas selection may worsen slag. For example, oxygen increases cutting efficiency but can also promote excessive oxidation and sticky residues. Inadequate nozzle condition or misalignment further reduces gas effectiveness.

- Thermal Conductivity and Cooling Effects: Materials with high thermal conductivity cool rapidly, causing molten material to solidify before it can be expelled. This rapid solidification at the bottom edge is a common cause of slag adhesion.

- Optical and Mechanical Issues: Dirty lenses, damaged nozzles, or misaligned optics reduce effective laser power at the cut zone. Reduced energy leads to uneven melting and poor slag removal.

Why Is The Cut Quality Poor At Laser-Cut Corners?

- Reduced Cutting Speed at Corners: When the laser head approaches a corner, the motion system decelerates to maintain accuracy and avoid mechanical overshoot. Although the laser power often remains constant, the reduced speed increases the energy delivered per unit area. This localized energy buildup causes excessive melting, burning, or charring, depending on the material. As a result, corners may appear wider, darker, or rougher than straight sections.

- Excessive Heat Accumulation: Corners concentrate heat because the laser repeatedly interacts with nearly the same point while changing direction. This leads to a larger heat-affected zone (HAZ), causing deformation, discoloration, or edge rounding. In materials like plastics, rubber, foam, leather, and wood, excessive heat can result in melting, carbonization, or shrinkage, specifically at corners.

- Beam Overlap and Dwell Time Effects: At sharp corners, the laser path often overlaps slightly, increasing dwell time. Even a brief pause can cause over-processing. This overlap intensifies thermal damage, leading to slag buildup, edge thickening, or material recession at the corner compared to straight cuts.

- Assist Gas Inefficiency: Assist gas flow is optimized for linear cutting. At corners, turbulent airflow and slower motion reduce the gas’s ability to remove molten material effectively. Poor melt ejection allows molten or semi-molten material to solidify on the edge, creating roughness or slag accumulation precisely at corner points.

- Focus and Kerf Geometry Changes: The laser beam naturally has a tapered profile. When changing direction, slight deviations in focus position or kerf geometry become more noticeable. This can produce uneven kerf widths, corner rounding, or incomplete penetration, especially in thicker or low-thermal-conductivity materials.

- Material-Specific Behavior: Different materials react uniquely at corners. Paper and cardboard scorch easily, plastics melt and reflow, leather carbonizes, and rubber degrades thermally. These effects are amplified at corners due to higher localized temperatures and longer exposure times.

- Control System Limitations: Basic laser controllers may lack advanced corner compensation features. Without dynamic power modulation or corner smoothing algorithms, the system cannot automatically reduce laser power during deceleration, resulting in overcutting.