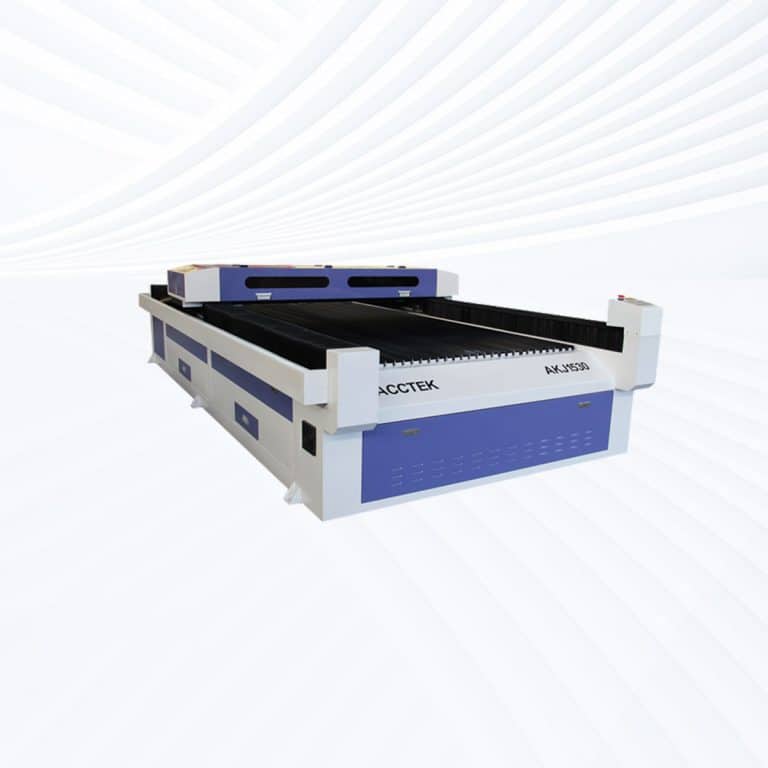

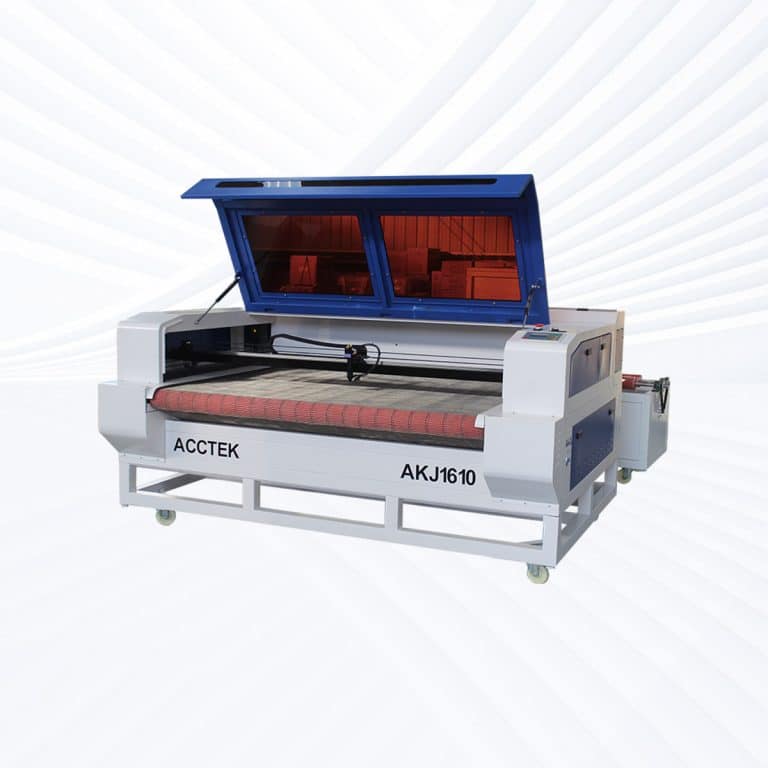

Product Introduction

Benefits of Laser Cutting Wood

Precision and Accuracy

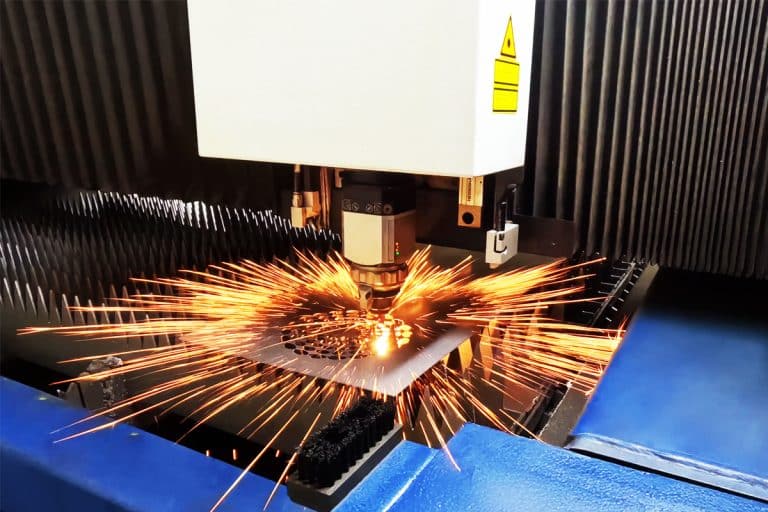

CO2 laser cutting machines deliver pinpoint accuracy, allowing for complex patterns and tight tolerances without manual finishing. This precision ensures clean lines, sharp corners, and consistent quality across multiple pieces, making it ideal for detailed woodworking and professional-grade output.

Clean, Burn-Free Edges

Advanced CO2 laser cutting systems minimize charring and reduce edge burn, producing smooth, sealed cuts with minimal discoloration. This eliminates the need for post-processing like sanding or edge cleaning, saving time and preserving the natural beauty of the wood.

Non-Contact Cutting

The laser beam cuts without touching the material, preventing mechanical stress, splintering, or warping. This makes it ideal for delicate woods, veneers, and thin sheets, ensuring surfaces remain unblemished and structural integrity is fully maintained.

Design Flexibility

CO2 laser cutting machines handle everything from sharp angles to intricate curves and engravings. Whether you're producing artwork, signage, or functional parts, the machine adapts to any design input, opening creative possibilities without the limitations of traditional tools.

High-Speed Production

CO2 laser cutting machines operate at fast speeds with minimal setup time. Ideal for both short runs and large-scale jobs, they streamline production and boost output, especially valuable for workshops or businesses managing tight turnaround times.

Low Operating Costs

With minimal maintenance, long-lasting laser tubes, and no need for blades or physical tools, CO2 laser cutting systems offer an efficient, cost-effective solution. They reduce waste, require fewer consumables, and provide consistent performance for high ROI over time.

Compatible Wood Materials

- Plywood

- Birch Plywood

- Maple Plywood

- Poplar Plywood

- MDF

- HDF

- Balsa Wood

- Basswood

- Birch

- Cherry

- Maple

- Oak

- Walnut

- Ash

- Beech

- Pine

- Cedar

- Redwood

- Fir

- Spruce

- Bamboo

- Teak

- Mahogany

- Alder

- Hickory

- Sycamore

- Rosewood

- Ebony

- Veneer Sheets

- Exotic Wood Veneers

- Cork

- Engineered Wood

- Reclaimed Wood

- Particle Board

- Luan Plywood

- Melamine-Coated MDF

- Painted Wood

- Stained Wood

- Composite Plywood Panels

- Live Edge Slabs

Application of Wood Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Wood Materials | Highly suitable | Very suitable | Limited | Suitable |

| Cutting Precision | Very high | High | Medium | High |

| Edge Quality | Clean, fine edges | Good, may need sanding | Rough edges | Clean but wet |

| Material Deformation | None (non-contact) | Low to medium | Medium | None |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Detail and Intricate Cutting | Excellent | Good | Poor | Good |

| Cutting Speed | High for thin wood | Moderate | High for thin sheets | Slow |

| Thickness Capability | Thin to medium wood | Medium to thick wood | Thin sheets only | Thin to very thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent | Good | Limited | Good |

| Automation and Repeatability | Excellent | Excellent | Good | Good |

| Overall Efficiency for Wood Processing | Excellent | Very good | Fair | Good |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

Frequently Asked Questions

How Accurately Can I Laser Cut Wood?

- Cutting Tolerance: Well-calibrated CO2 lasers can routinely achieve tolerances in the range of ±0.1 mm to ±0.2 mm on wood, with some high-end systems achieving even finer precision. Dimensional accuracy depends on the laser’s focus point, mechanical stability, and the software’s ability to compensate for kerf (the width of the material removed by the cut).

- Kerf Width: Kerf for wood typically ranges from 0.1 mm to 0.4 mm, depending on the lens focal length, laser power, and cut speed. Thinner kerfs allow for finer details, but also require careful parameter tuning to avoid excessive charring.

- Material Factors: Different woods respond differently to laser cutting. Hardwoods (e.g., maple, walnut) tend to cut more cleanly and predictably, while softwoods and resin-rich species can char more easily. Plywood may contain glue layers that resist cutting and slightly widen the kerf. Moisture content can also subtly shift dimensions after cutting due to warping or shrinkage.

- Edge Quality: At optimal settings, CO2 lasers produce smooth, clean edges on most woods with minimal sanding required. However, edges may show a darkened “burn” effect from heat exposure, which can be desirable for decorative work or undesirable for precise joinery, depending on the application.

- Repeatability: Modern laser cutting machines with quality motion systems can produce identical parts across multiple runs with negligible variation, provided the wood stock is consistent. This makes them ideal for small-batch production, inlays, and intricate patterns.

- Fine Detail Capability: Intricate designs with narrow bridges (as thin as 0.5 mm) are possible, though smaller elements risk breaking during handling if the wood is brittle. Thin veneers can handle even finer cuts but require gentler handling.

What Are The Disadvantages Of Laser Cutting Wood?

- Material Stability and Warping: The intense heat from a CO2 laser can cause thin or low-moisture-content woods to warp slightly, especially when cutting large, intricate patterns. This can impact dimensional accuracy and may require flattening or pressing afterward.

- Fire Risk: Because wood is combustible, there is a constant risk of ignition, particularly with dry or resin-rich species. Adequate air assist, strong ventilation, and active supervision are essential to prevent flare-ups.

- Kerf and Dimensional Tolerance: The laser’s kerf (the width of material removed) must be considered in design, as it can slightly reduce part dimensions. For precision joinery or interlocking components, this dimensional loss can be critical if not compensated for.

- Fume and Smoke Generation: Laser cutting wood produces smoke, soot, and particulates that must be removed via an exhaust or filtration system. Cutting treated or resin-rich wood can produce irritating or harmful fumes.

- Production Speed Limitations: While lasers excel at fine detail work, cutting thick hardwoods can be slower than alternative methods such as CNC routing. Large projects or high-volume production may require significant time.

- Maintenance Requirements: Wood cutting produces soot and debris that can build up on lenses, mirrors, and internal parts, reducing accuracy and potentially damaging components. Regular cleaning and upkeep are necessary to maintain performance.

What Power Levels Are Available For Wood Laser Cutting Machines?

- 60W – 80W: Best suited for light to medium wood cutting and engraving. These machines can handle thin hardwoods, plywood, and MDF up to about 5–8 mm thick in a single pass. They excel at fine detail work, intricate patterns, and small-scale projects, but are slower for thicker stock.

- 90W – 100W: A versatile range for both hobbyists and light industrial use. Capable of cutting up to 8–12 mm hardwood and thicker softwoods at moderate speeds. Provides a good balance between detail and productivity. Common in small production workshops.

- 130W – 150W: Designed for higher throughput and thicker materials. Suitable for regular cutting of 12–15 mm hardwood or up to 20 mm softwood in one pass. Faster cutting speeds make them well-suited to small-batch manufacturing and signage work where efficiency is important.

- 180W – 220W: High-power systems for industrial applications. Can handle up to 20–25 mm wood thickness with ease and maintain higher speeds on dense hardwoods. Useful for large-format cutting, furniture production, and high-volume output.

- 260W – 300W: Heavy-duty industrial lasers for cutting thick stock quickly. Often used in large-scale manufacturing where multiple passes are not desirable. They can cut over 30 mm of hardwood in one pass, though fine engraving detail is less precise at these high power levels due to a larger beam spot size.

- 500W – 600W: Extremely high-powered CO2 laser cutting systems, generally beyond the needs of most woodworking applications. Ideal for specialty production environments that require rapid cutting of very thick materials or high-volume throughput. These machines are costly, require significant cooling infrastructure, and may be overkill for standard wood projects.

What Is The Price Of Wood Laser Cutting Machines?

- Entry-Level Machines ($3,000 – $6,000): Typically equipped with 60W–150W laser tubes and small to medium cutting beds. Suitable for cutting thin to medium-thickness wood (up to 12–15 mm) and detailed engraving. Best for small businesses, craft shops, and custom design work. These models may have slower cutting speeds, lighter-duty frames, and basic ventilation systems.

- Mid-Range Machines ($6,000 – $10,000): Often feature 150W–300W tubes, larger cutting areas, and faster motors for improved productivity. Capable of cutting thicker wood (up to 20–25 mm in some cases) and handling moderate production volumes. These machines usually include better cooling systems, more robust frames, and upgraded optics for consistent performance.

- High-End Machines ($10,000 – $15,000): Industrial-grade systems with 300W–600W power options, large-format cutting beds, and heavy-duty construction. Built for high-volume production, thicker materials, and continuous operation. These machines often come with advanced motion systems, precision autofocus, integrated air assist, and professional-grade exhaust and filtration systems.

What Gases Are Used For Laser Cutting Wood?

- Compressed Air: The most common and cost-effective option for wood laser cutting. Compressed air helps remove char and debris from the kerf while providing cooling to reduce scorching and flare-ups. It is widely used for both cutting and engraving, offering a balance of clean edges and affordability.

- Nitrogen (N2): An inert gas that prevents oxidation and significantly reduces edge charring. Nitrogen produces lighter, cleaner edges compared to compressed air but comes at a higher cost due to the need for gas cylinders or generators. Often used in applications where a natural wood finish without burn marks is required.

- Oxygen (O2): Rarely used for wood cutting because it actively promotes combustion and can cause excessive burning. In most woodworking cases, oxygen is avoided unless a specific burnt-edge effect is desired for decorative purposes.

- Gas Mixtures: Some industrial systems use custom gas blends (often nitrogen-rich) to fine-tune cutting performance and further minimize discoloration. This is typically reserved for high-precision or specialty wood products where consistent edge quality is critical.

What Are The Risks Of Laser Cutting Wood?

- Fire Hazards: Wood is flammable, and the high heat of the laser beam can ignite thin, dry, or resin-rich pieces. Small flare-ups can occur during cutting, and in severe cases, unattended ignition can cause machine or workshop fires. Active supervision, air assist, and having fire suppression equipment on hand are critical precautions.

- Fume and Particulate Emissions: Cutting wood produces smoke, soot, and fine dust particles. These emissions can irritate the respiratory system and, in the case of composite or treated woods (like MDF or plywood), may contain hazardous chemicals from glues or finishes. Effective ventilation or an air filtration system is necessary to maintain safe air quality.

- Material Discoloration and Damage: Heat from the laser can cause excessive charring, burn marks, or resin bubbling, especially on light-colored woods or thin veneers. While sometimes desirable for aesthetic effect, it can also ruin the intended finish and require additional post-processing.

- Kerf Variability and Dimensional Accuracy: The width of the cut (kerf) can vary with wood density, moisture content, and laser settings. Inaccurate kerf compensation can result in parts that do not fit as designed, especially in precision joinery.

- Warping and Structural Weakening: Intense localized heat can cause thin wood sheets to warp, and in extreme cases, weaken the structure of the workpiece. This is particularly common in large, intricate designs with narrow connecting sections.

- Equipment Contamination and Wear: Wood cutting produces soot and sticky residues that can build up on the laser lens, mirrors, and internal components. Without regular cleaning, this can reduce cutting efficiency, distort the beam, or even damage optics.

What Problems Can Be Encountered When Laser Cutting Wood?

- Charring and Burn Marks: The intense heat of the laser can leave dark edges and surface discoloration, especially on light-colored woods or thin veneers. This may require sanding or finishing work to restore a clean appearance.

- Excessive Smoke and Resin Build-Up: Certain woods, particularly resinous softwoods, release heavy smoke and sticky residue during cutting. This can reduce cut quality, slow production, and cause build-up on the machine’s optics, requiring frequent cleaning.

- Material Warping: Thin wood sheets or low-moisture-content pieces can warp from localized heating during cutting. This can cause misalignment in intricate designs or lead to gaps in joinery.

- Incomplete Cuts: If laser power or cutting speed is not set correctly, the beam may fail to cut through completely, leaving uncut fibers that require manual trimming. This is more common in dense hardwoods or multi-layer plywood.

- Kerf Variations: The kerf (cut width) can vary depending on wood type, thickness, and laser settings. Inaccurate kerf compensation can lead to poor-fitting parts in precision woodworking.

- Fire Risk: Wood is combustible, and cutting dry or thin materials can result in flare-ups. Without proper air assist and supervision, these can escalate into dangerous fires.

- Machine Contamination: Soot, dust, and resin can settle inside the machine, on lenses, and mirrors, reducing cutting efficiency and risking damage to optical components over time.

How Should I Maintain Wood Laser Cutting Machines?

- Cleaning the Optics (Lenses and Mirrors): Soot and smoke residue can settle on the laser lens and mirrors, reducing beam quality and cutting efficiency. Cleaning optics regularly with approved lens wipes or solvents helps maintain precision and prevents heat damage to these components.

- Bed and Work Area Cleaning: Wood cutting produces ash and debris that can block airflow and interfere with material alignment. Clearing the cutting bed and surrounding area after each job improves ventilation and reduces fire hazards.

- Ventilation and Filtration System Maintenance: Filters and ducting in exhaust systems can become clogged with fine dust, resin, and smoke particles. Regularly checking and cleaning, or replacing filters, ensures safe air quality and prevents reduced airflow that can lead to overheating or poor smoke extraction.

- Lubricating Moving Parts: Rails, bearings, and belts should be inspected and lubricated as needed to maintain smooth and accurate motion. This reduces wear and ensures precise movement for detailed cutting and engraving.

- Cooling System Checks: CO2 laser tubes require effective cooling to prevent overheating. Checking coolant levels, inspecting for leaks, and cleaning water chiller systems help maintain optimal operating temperature and extend tube life.

- Alignment and Calibration: Over time, vibration or handling can cause mirrors and the laser head to become misaligned. Regular calibration ensures the beam is properly focused and aligned, maintaining cut quality and reducing wasted material.

- Software and Firmware Updates: Keeping control software and firmware updated can improve cutting efficiency, add features, and fix known performance issues.