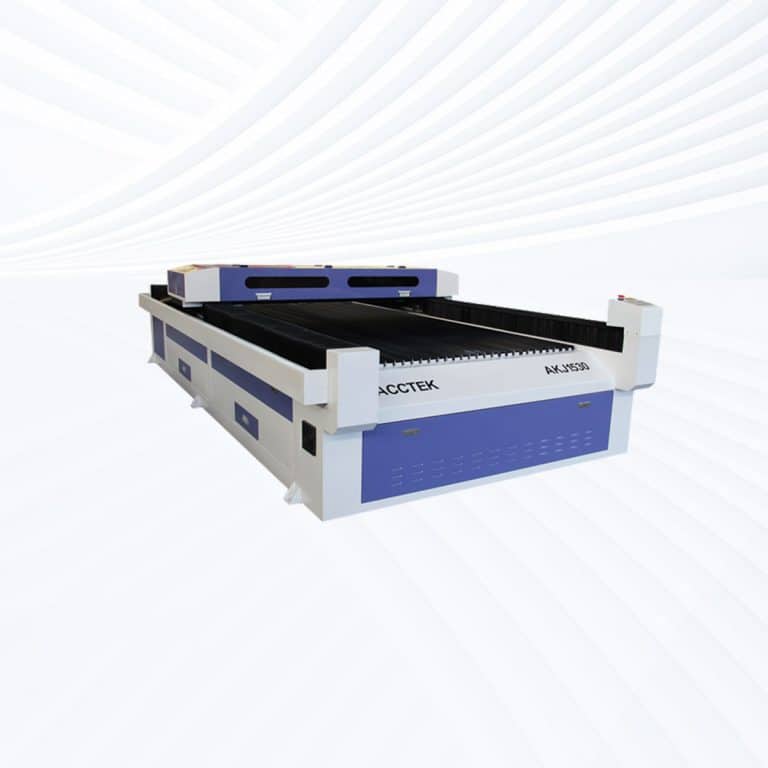

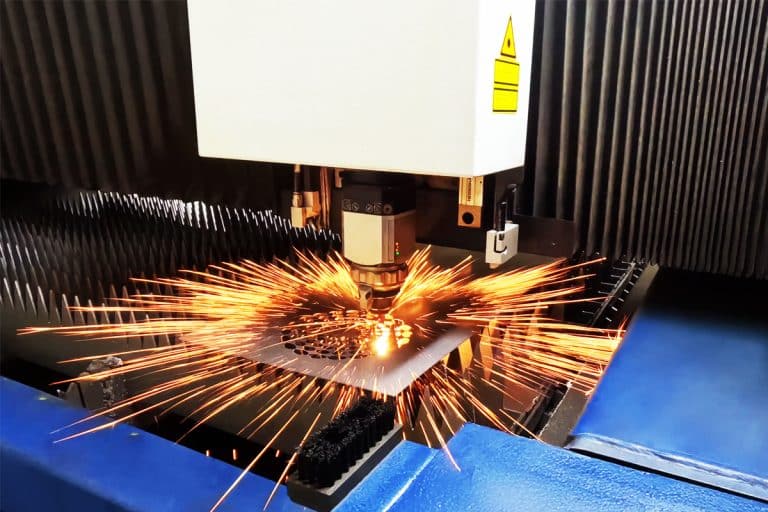

Product Introduction

Benefits of Laser Cutting Textile

Sealed, Fray-Free Edges

CO2 lasers heat-seal the edges of synthetic fabrics during cutting, preventing fraying and eliminating the need for hemming. This ensures a clean, durable edge—ideal for fashion, sportswear, and technical textile applications.

Non-Contact, No Pressure Cutting

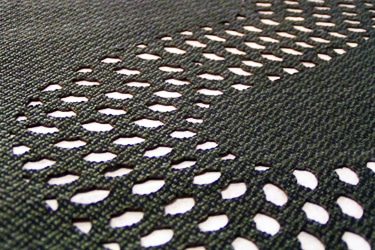

Laser cutting is a non-contact process, so there’s no dragging, tearing, or stretching of delicate or elastic textiles. This preserves material integrity and is especially beneficial for cutting intricate or soft materials like lace, mesh, or knits.

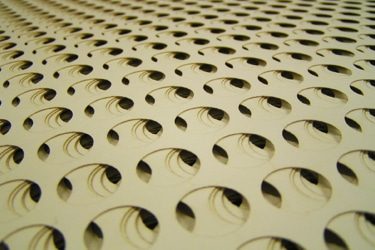

High Precision for Complex Designs

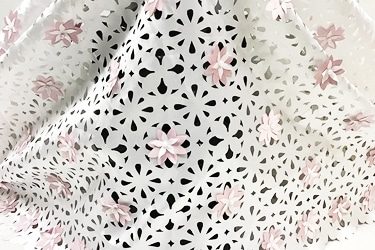

CO2 lasers can follow fine curves, small holes, and intricate patterns with pinpoint accuracy. Designers gain the freedom to create complex motifs, detailed cutouts, and layered textures that are difficult or impossible with traditional cutting tools.

Reduced Material Waste

Laser systems use tight nesting and minimal kerf width to maximize fabric yield. Combined with precise cuts and no need for dies, this reduces material waste and lowers overall production costs, especially in high-volume or custom runs.

Fast, Automated Cutting

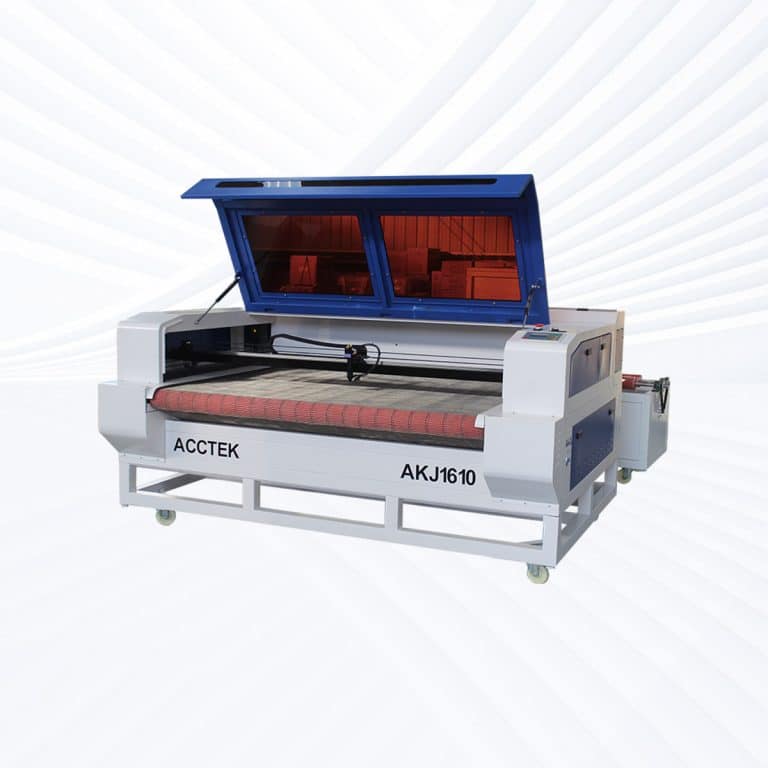

With high cutting speeds and the ability to integrate conveyor systems, textile laser cutting machines support continuous, high-throughput workflows—ideal for mass production or fast turnarounds in fashion and industrial sectors.

Versatile Fabric Compatibility

These machines can process a wide range of materials, including cotton, polyester, leather, felt, silk, and technical textiles. This flexibility makes them ideal for use across apparel, automotive, upholstery, and soft signage industries.

Compatible Textile Materials

- Cotton

- Polyester

- Silk

- Wool

- Nylon

- Spandex

- Acrylic Fabric

- Denim

- Canvas

- Felt

- Fleece

- Lycra

- Microfiber

- Velvet

- Satin

- Tulle

- Lace

- Chiffon

- Organza

- Rayon

- Modal

- Hemp Fabric

- Bamboo Fabric

- Jersey Knit

- Suede

- Leather

- Faux Leather

- Neoprene

- PVC-Coated Fabric

- Mesh Fabric

- Upholstery Fabric

- Upholstery Vinyl

- Technical Textiles

- Softshell Fabric

- Nonwoven Fabric

- Aramid

- Carbon Fiber Fabric

- Filter Fabric

- Embroidered Textiles

- Reflective Textile Film

Application of Textile Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Textiles | Highly suitable | Poor | Very suitable | Limited |

| Cutting Precision | Very high | Medium | Medium | High |

| Edge Quality | Clean, sealed (synthetics) | Rough edges | Clean but unsealed | Clean but wet |

| Material Deformation | None (non-contact) | High risk | Medium | None |

| Fraying Control | Excellent on synthetics | Poor | Medium | Poor |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High | Moderate | High | Slow |

| Thickness Capability | Thin to medium textiles | Limited | Thin textiles | Thin to thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent for complex patterns | Limited | Limited | Good |

| Automation and Repeatability | Excellent | Good | Good | Good |

| Overall Efficiency for Textile Processing | Excellent | Poor | Good | Fair |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

Frequently Asked Questions

Can Laser Cutting Elastic Textiles Be Cut Without Deformation?

- Natural and Synthetic Elastic Blends: Elastic materials that combine spandex with cotton, polyester, or nylon respond well to laser cutting. The beam cleanly vaporizes the fibers, preventing the fabric from stretching under mechanical stress. However, synthetics may emit fumes during cutting, so proper ventilation is essential.

- Lycra and Elastane: These high-stretch fabrics can be cut without edge curling or physical deformation. The heat from the laser can seal the edges slightly, giving a smooth finish that prevents unraveling.

- Neoprene and Stretch Knits: Neoprene cuts cleanly with a sealed edge, though its foam-like core can produce mild discoloration or odor. Stretch knit fabrics maintain their elasticity and contour after cutting, as the process applies no mechanical tension.

- Deformation Risks and Controls: While laser cutting avoids tension-based distortion, heat can cause shrinkage in some elastic textiles if settings are too high or cutting speeds are too slow. Using optimized power levels, high cutting speeds, and sharp beam focus minimizes thermal impact. Air assist and cooling also help preserve fabric elasticity.

What Is The Available Laser Power Range For Textile Laser Cutting Machines?

- Light-Duty Power Levels (60W–100W): These machines are ideal for cutting and engraving lightweight fabrics such as cotton, silk, polyester, felt, and thin elastic textiles. Lower power minimizes the risk of burning delicate fibers and ensures fine edge quality.

- Medium-Duty Power Levels (130W–180W): A common choice for most garment production, upholstery fabrics, and medium-weight materials like denim or canvas. This range balances cutting speed with clean, sealed edges, allowing for both single-layer and stacked cutting in industrial environments.

- High-Duty Power Levels (220W–300W): Suited for cutting multiple layers at once, thicker textiles, technical fabrics, or composite materials (like fabric bonded to foam or rubber). These higher wattages increase production speed but require careful parameter tuning to avoid excessive heat.

- Industrial Heavy-Duty Power Levels (500W–600W): These are typically found in high-volume manufacturing, particularly for cutting dense or reinforced textiles used in automotive, aerospace, or protective gear. At these power levels, the focus is on throughput and penetrating layered or specialized fabrics efficiently.

What Is The Price Range For Textile Laser Cutting Machines?

- Entry-Level Machines ($3,000–$6,000): These systems usually range from 60W to 100W, with smaller working areas suited for hobbyists, small workshops, and light production tasks. They handle delicate fabrics well, such as silk, polyester, and cotton, but may have slower cutting speeds for thicker materials or multiple layers.

- Mid-Range Machines ($6,000–$10,000): Offering 100W to 180W of power and larger bed sizes, these machines suit small to medium-sized textile businesses. They provide faster processing speeds, better cooling systems, and often include features like automatic focusing or conveyor systems for continuous feeding—ideal for batch production of apparel, upholstery, or promotional items.

- High-End Machines ($10,000–$15,000): These are heavy-duty, industrial-grade textile cutting machines with power ratings from 180W up to 300W (and sometimes higher). They feature high-speed motion systems, advanced controllers, and large or custom bed sizes for processing large-format textiles or multiple layers at once. Many include automated feeding, material unwinding, and integration with CAD/CAM design systems for high-volume manufacturing in sectors like fashion, automotive, or protective gear.

What Is The Maximum Cutting Thickness For Laser Cutting Textiles?

- Single-Layer Cutting: For most fabrics—cotton, polyester, silk, felt, denim, or technical textiles—CO₂ lasers can easily cut through thicknesses from 0.1 mm to about 5 mm in a single pass. Fabrics above 3 mm thick are usually specialty materials such as heavy felts or composite cloths used in industrial applications.

- Multi-Layer Cutting: Industrial machines equipped with higher power levels (150W–300W) and conveyor systems can cut multiple layers stacked together, reaching an effective combined thickness of up to 20–25 mm, depending on fabric density and weave tightness. This is common in upholstery production, automotive interior manufacturing, and large-scale garment cutting.

Are Exhaust Systems Required To Remove Fumes When Laser Cutting Textiles?

- Why Exhaust Systems Are Needed

- Fume Removal: Cutting natural fabrics like cotton, silk, or wool releases organic smoke and particulates, while synthetics such as polyester, nylon, and spandex can emit harmful gases (including VOCs) when vaporized.

- Fire Prevention: Continuous airflow reduces the buildup of flammable vapors and helps keep the cutting area cooler.

- Optics Protection: Fumes and particulates can settle on the laser’s mirrors and lens, degrading beam quality and shortening the life of optical components.

- Workplace Safety Compliance: Many industrial safety regulations require localized exhaust ventilation for processes generating airborne contaminants.

- Exhaust & Filtration Options

- Direct Duct Venting: Fumes are vented outside through ducting and an inline fan. Effective for high-volume cutting environments.

- Fume Extractors with Filters: Self-contained systems use pre-filters, HEPA filters, and activated carbon to trap particles and adsorb harmful gases—ideal when outdoor venting is impractical.

- Combination Systems: Use both filtration and external exhaust for maximum safety.

- Material Considerations

- Natural Textiles: Produce mainly organic smoke, less toxic but still irritating, without ventilation.

- Synthetic Textiles: Can emit hazardous gases (e.g., formaldehyde from treated cotton, or antimony compounds from polyester), making filtration and ventilation critical.

- Mixed-Fiber Fabrics: Require the same precautions as synthetics since even partial synthetic content can produce toxic emissions.

What PPE Does The Operator Need When Laser Cutting Textiles?

- Laser safety glasses rated for CO2 wavelengths (10.6 μm) are required if using an open-beam system.

- Respiratory protection (N95, P100, or activated carbon filters) to protect against fabric dust and fumes from melted synthetic fibers.

- Heat-resistant gloves for handling freshly cut materials that may retain heat.

- Flame-resistant clothing made from natural fibers reduces burn risk.

- Closed-toe shoes to protect from falling debris and off-cuts.

What Is The Service Life Of Textile Laser Cutting Machines?

- Laser Tube Lifespan: Typically 4,000–10,000 hours for glass CO2 tubes; longer for RF metal tubes. Tubes can be replaced without replacing the entire machine.

- Optics: Mirrors and lenses need cleaning and eventual replacement due to wear from dust, fibers, and heat exposure.

- Motion System: Linear rails, belts, and bearings last for years with regular lubrication and cleaning.

- Cooling System: Proper chiller maintenance prevents overheating, extending both machine and tube life.

Is Laser Cutting Textiles Safe?

- Textile Categories and Safety Considerations

- Natural Fabrics (Cotton, Wool, Silk, Linen): These cut cleanly with CO2 lasers, producing smooth edges and minimal fraying. They can scorch or ignite if settings are too high or the beam lingers, so proper power and speed calibration are essential. Ventilation is needed to remove smoke and burnt-fiber odors.

- Synthetic Fabrics (Polyester, Nylon, Acrylic Blends): Most synthetics cut well, sealing the edge with a melted finish that prevents unraveling. The downside: they release chemical fumes—sometimes hazardous—when vaporized. Adequate exhaust systems and, ideally, air filtration are a must to protect the operator.

- Felt and Nonwoven Textiles: Both natural and synthetic felt cut well, producing crisp shapes. Synthetic felt produces more fumes, so treat it like polyester for safety.

- Leather and Faux Leather: Natural leather cuts cleanly and engraves well. Faux leather often contains PVC, which should never be laser cut due to the release of toxic chlorine gas. Always verify material composition before cutting.

- Specialty Textiles (Coated, Laminated, or Fire-Resistant Fabrics): Coatings may include chemicals that release harmful vapors when burned. Even fire-retardant fabrics can emit dangerous byproducts. Always consult material safety data sheets (MSDS) and test in small quantities first.

- Operational Safety Tips

- Ventilation: Use a strong exhaust and, ideally, a fume filtration system to remove gases and particulates from the workspace.

- Supervision: Never leave the laser cutting machine unattended when cutting flammable materials like textiles.

- Material Verification: Always confirm fabric composition, especially with blends or unknown materials.

- Fire Prevention: Keep a fire extinguisher nearby and monitor closely for flare-ups.