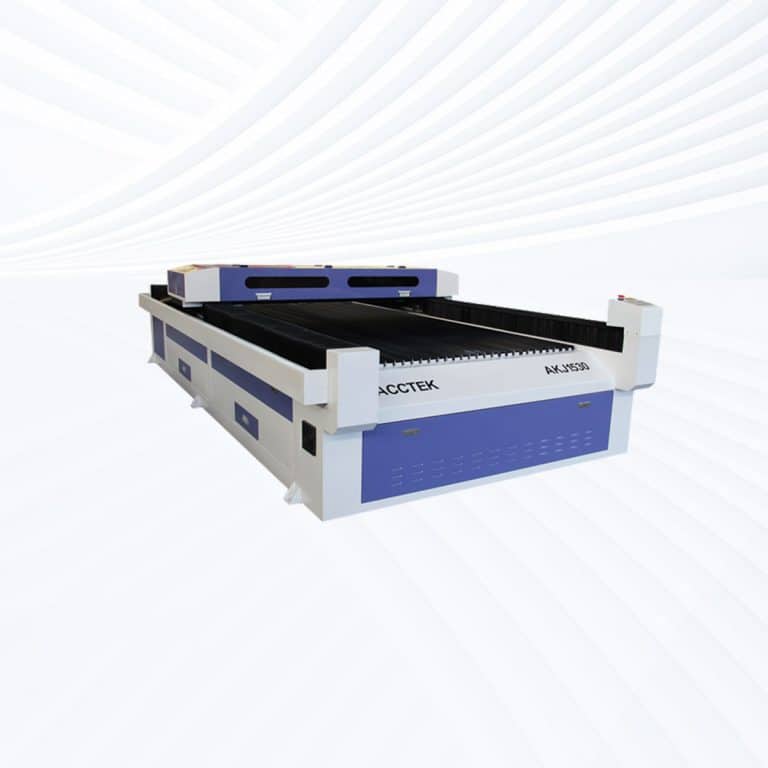

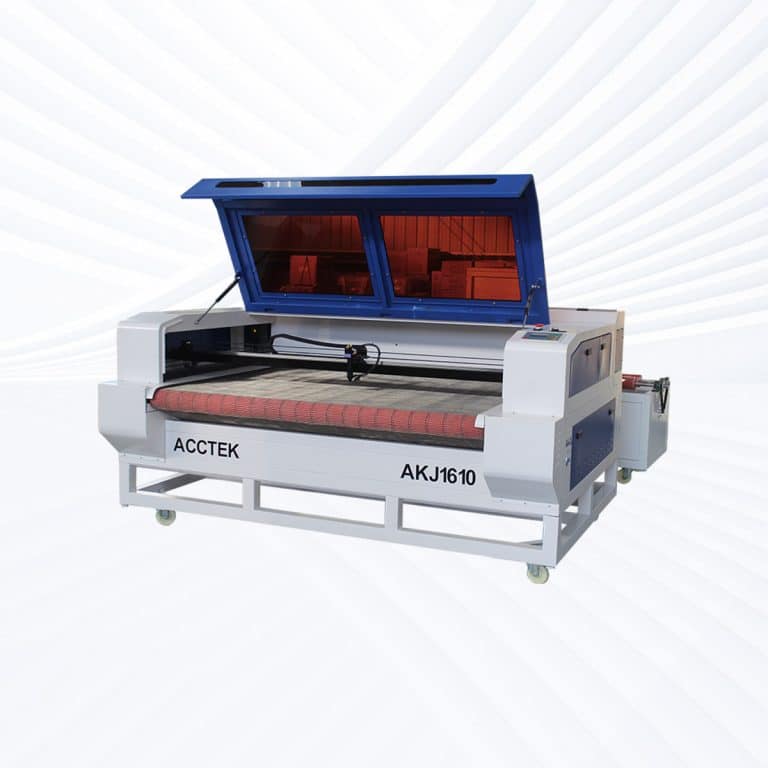

Product Introduction

Benefits of Laser Cutting Leather

Clean, Sealed Edges

CO2 lasers cut leather with precision and heat-seal the edges as they go, preventing fraying or curling. This results in smooth, clean cuts with no need for additional finishing, making production faster and more efficient.

Non-Contact Cutting

Laser cutting is a non-contact process, so the leather isn’t stretched, dragged, or physically pressured during cutting. This preserves the material’s natural texture and thickness, ensuring high-quality results even on delicate or textured surfaces.

High Design Flexibility

CO2 lasers handle detailed patterns, logos, and fine engravings with ease. From intricate perforations to custom branding, these machines enable creative freedom and precise replication, perfect for personalized leather goods and decorative products.

No Tool Wear or Replacement

Unlike blades, laser heads don’t dull or need replacement. This reduces downtime, maintenance costs, and quality inconsistencies, especially during high-volume or long-duration production runs with repeatable accuracy.

Supports a Wide Range of Leather

CO2 laser cutting machines can cut and engrave various leather types, including genuine leather, suede, synthetic (PU), and bonded leather, making them versatile for footwear, fashion, upholstery, and accessories manufacturing.

Reduced Material Waste

Laser software allows tight nesting and accurate cuts, maximizing material usage. Combined with the precision of the laser, this reduces offcuts and production waste, helping lower costs and improve sustainability.

Compatible Leather Materials

- Full Grain Leather

- Top Grain Leather

- Genuine Leather

- Suede

- Nubuck

- Split Leather

- Corrected Grain Leather

- Embossed Leather

- Aniline Leather

- Semi-Aniline Leather

- Pigmented Leather

- Oil-Tanned Leather

- Vegetable-Tanned Leather

- Chrome-Tanned Leather

- Combination-Tanned Leather

- Rawhide

- Patent Leather

- Bonded Leather

- Reconstituted Leather

- Synthetic Leather

- Microfiber Leather

- Eco-Leather

- Faux Leather

- Vegan Leather

- PVC Leather

- Perforated Leather

- Laser-Ready Leather Sheets

- Dyed Leather

- Metallic-Finish Leather

- Soft Glove Leather

- Upholstery Leather

- Automotive Leather

- Garment Leather

- Tooling Leather

- Saddle Leather

- Bag Leather

- Belt Leather

- Watch Strap Leather

- Footwear Leather

- Decorative Embossed Leather

Application of Leather Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Leather | Highly suitable | Limited | Very suitable | Poor |

| Cutting Precision | Very high | Medium | Medium | High |

| Edge Quality | Clean, sealed edges | Rough edges | Clean but unsealed | Clean but wet |

| Material Deformation | None (non-contact) | High risk | Medium | None |

| Heat-Affected Zone (HAZ) | Small and controlled | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High | Moderate | High | Slow |

| Thickness Capability | Thin to medium leather | Medium | Thin to medium | Thin to thick |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent | Good | Limited | Good |

| Automation and Repeatability | Excellent | Good | Good | Good |

| Operating Cost | Moderate | Moderate | Low | High |

| Overall Efficiency for Leather Processing | Excellent | Good | Good | Poor |

Why Choose Us

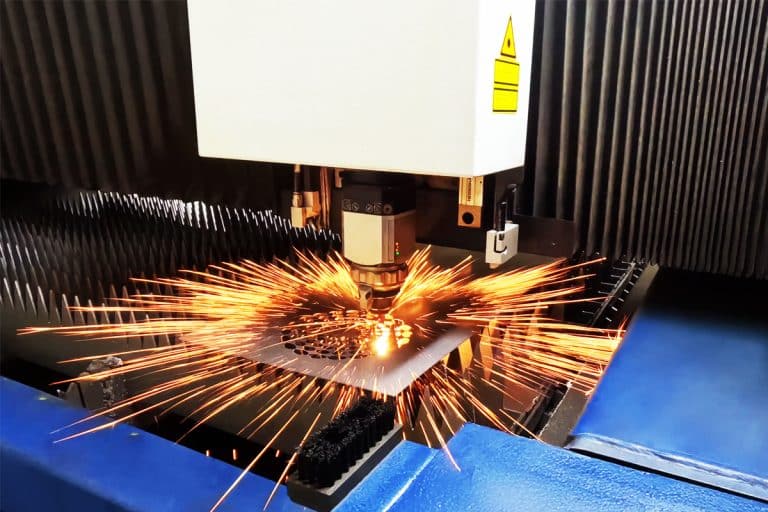

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

Frequently Asked Questions

What Is The Difference Between Laser Cutting And Blade Cutting For Leather?

- Laser Cutting for Leather

- Precision and Detail: CO2 lasers can produce highly intricate cuts, engravings, and perforations with minimal physical contact.

- Edge Sealing: The laser slightly melts or cauterizes the edge, preventing fraying and giving a finished look, especially useful for synthetic or coated leathers.

- Speed: Laser cutting can be faster for complex patterns, especially in small-scale or repeat jobs.

- Design Versatility: Supports detailed artwork, custom logos, and variable-depth engraving.

- Potential Drawbacks: The beam generates heat, which can cause discoloration or burning on natural leather. Ventilation and protective masking help minimize this.

- Blade Cutting for Leather

- Clean, Cold Cut: A sharp blade slices through leather fibers without heat, avoiding scorch marks or discoloration.

- Material Integrity: Preserves the natural texture and color of the edge, especially important for high-end hides.

- Thickness Handling: Effective for thick or very soft leathers where lasers may struggle or require multiple passes.

- Lower Risk of Odor and Fumes: Mechanical cutting does not release the same volume of vapors as laser cutting, although dust may still be generated.

- Potential Drawbacks: Complex, small, or intricate patterns can be harder to achieve, and blades require frequent sharpening to maintain precision.

Will Laser Cutting Burn The Edges Of Leather?

- How and Why Burning Occurs

- Heat Concentration: The laser beam focuses intense energy on a narrow path, vaporizing the leather fibers and generating localized heat.

- Material Composition: Natural hides char and turn darker where cut; synthetic leathers may melt or release fumes from their polymer coatings.

- Beam Dwell Time: Slow speeds or excessive power increase exposure time, leading to deeper burns and wider darkened edges.

- Surface Finishes: Oils, waxes, and dyes on the leather can scorch differently, sometimes making the burn marks more pronounced.

- Controlling and Minimizing Burn Marks

- Optimize Laser Settings: Use the lowest power that achieves a clean cut and combine with higher cutting speeds to reduce heat buildup.

- Multiple Passes for Thick Leather: Fast, low-power passes limit edge darkening compared to a single high-power cut.

- Air Assist: Blowing clean air or nitrogen at the cut line helps dissipate heat and remove smoke particles before they deposit on the surface.

- Masking: Applying low-tack masking tape or paper film to the leather surface can protect it from smoke staining.

- Test Cuts: Different leathers vary greatly; run small trials before committing to a final piece.

- Edge Appearance by Leather Type

- Vegetable-Tanned Leather: Darkens significantly at the edges, which can be desirable for a rustic, finished look.

- Chrome-Tanned Leather: May darken less, but can emit stronger odors during cutting.

- Synthetic Leather: Edges may melt, harden, or become glossy; ventilation is critical due to fumes.

How Can I Prevent Burn Marks On Leather?

What Is The Available Laser Power Range For Leather Laser Cutting Machines?

How Much Do Leather Laser Cutting Machines Cost?

- Entry-Level Leather Laser Cutting Machines ($3,000–$5,000)

- Power Range: Typically 60W to 150W CO2 lasers.

- Work Area: Small to medium beds, often 400 × 600 mm to 900 × 600 mm.

- Best For: Small craft businesses, custom leather goods, prototyping.

- Features: Manual focusing, basic air assist, and minimal automation.

- Trade-Offs: Slower on thick hides, lower cutting speeds, less robust components.

- Mid-Range Leather Laser Cutting Machines ($5,000–$10,000)

- Power Range: 150W to 300W CO2 lasers.

- Work Area: Medium to large beds, often up to 1300 × 900 mm.

- Best For: Small-to-medium production runs, faster throughput.

- Features: Motorized focus, better cooling systems, and more robust motion parts.

- Advantages: Higher cutting speeds, improved edge quality, better reliability.

- High-End Leather Laser Cutting Machines ($10,000–$15,000)

- Power Range: 300W to 600W CO2 lasers (sometimes higher).

- Work Area: Large-format beds up to 1600 × 1000 mm or larger.

- Best For: Industrial-scale leather cutting, multi-layer processing.

- Features: Auto-feeding conveyors, camera alignment for pattern matching, high-speed servo motors.

- Advantages: Maximum speed, precision, and durability for high-volume production.

How Does Laser Power Affect The Quality Of Leather Cutting?

- Edge Darkness: Higher power increases the likelihood of darker or charred edges, especially on vegetable-tanned leather.

- Cut Smoothness: Proper power levels produce clean, sealed edges; too low or too high can cause roughness.

- Kerf Width: More power can slightly widen the cut line, affecting fine detail accuracy.

- Material Deformation: Excessive heat from high power can warp thin leather.

Does Cutting Leather Produce Harmful Fumes?

- Natural Leather (Vegetable-Tanned)

- Fume Composition: Mainly organic carbon-based smoke, vaporized collagen, and trace dyes.

- Risks: Eye, nose, and throat irritation; unpleasant burnt odor.

- Precautions: Local exhaust ventilation with particulate and carbon filters.

- Chrome-Tanned Leather

- Fume Composition: Organic compounds plus chromium oxide and other metal oxides from tanning agents.

- Risks: Inhalation of chromium compounds can be toxic and may pose long-term health risks.

- Precautions: Strong extraction with multi-stage filtration, including HEPA and activated carbon; avoid cutting in poorly ventilated spaces.

- Synthetic Leather (PU or PVC-Coated)

- Fume Composition: PU-coated leather emits isocyanates and nitrogen-based compounds; PVC-coated leather releases hydrogen chloride gas and dioxins.

- Risks: Highly toxic; PVC should never be cut with a laser due to corrosive and carcinogenic byproducts.

- Precautions: Only cut synthetic leathers that are verified laser-safe; always use robust fume extraction and air filtration.

How Should I Maintain Leather Laser Cutting Machines?

- Daily Maintenance

- Clean the Optics: Use lens-safe wipes and cleaning fluid to remove smoke and residue from mirrors and lenses after each use. Dirty optics reduce beam power and can cause burning.

- Check the Air Assist Nozzle: Ensure it’s clear of debris to maintain proper airflow and prevent smoke from settling on the workpiece.

- Wipe Down the Work Area: Remove dust, char, and leather scraps from the cutting bed to prevent buildup and fire hazards.

- Inspect the Exhaust System: Verify that fans are operating and airflow is unobstructed.

- Weekly Maintenance

- Lubricate Moving Parts: Apply appropriate lubricants to linear rails, belts, and bearings to prevent wear from abrasive leather dust.

- Check Belt Tension and Alignment: Loose or misaligned belts can cause uneven cuts and reduced accuracy.

- Empty and Clean Filtration Units: Remove trapped particulates from pre-filters and inspect HEPA/activated carbon filters for replacement needs.

- Inspect Water Cooling System (for CO2 tubes): Ensure coolant levels are sufficient and that water is clean to prevent overheating.

- Monthly Maintenance

- Check Laser Tube Output: Measure beam strength to detect early signs of power loss.

- Inspect Optics Alignment: Misaligned mirrors can lead to uneven cuts and higher power requirements.

- Deep Clean the Exhaust Ducts: Remove tar-like residue from leather cutting to maintain optimal airflow.

- Software & Firmware Updates: Keep the machine’s control software up to date for improved performance and compatibility.

- Annual Maintenance

- Professional Service: Schedule a technician to inspect and recalibrate the laser system, check electronics, and replace worn components.

- Replace Worn Parts: Install new belts, bearings, and optics as needed to maintain peak performance.

- Coolant System Flush: Replace coolant entirely to prevent algae growth or sediment buildup.

- Special Considerations for Leather Cutting

- Residue Build-Up: Leather smoke contains oils and resins that stick to optics and ventilation surfaces faster than many other materials.

- Fume Management: Chrome-tanned and synthetic leathers can release harmful chemicals—ensure proper multi-stage filtration.

- Masking: Using protective film on leather can reduce residue spread inside the machine.