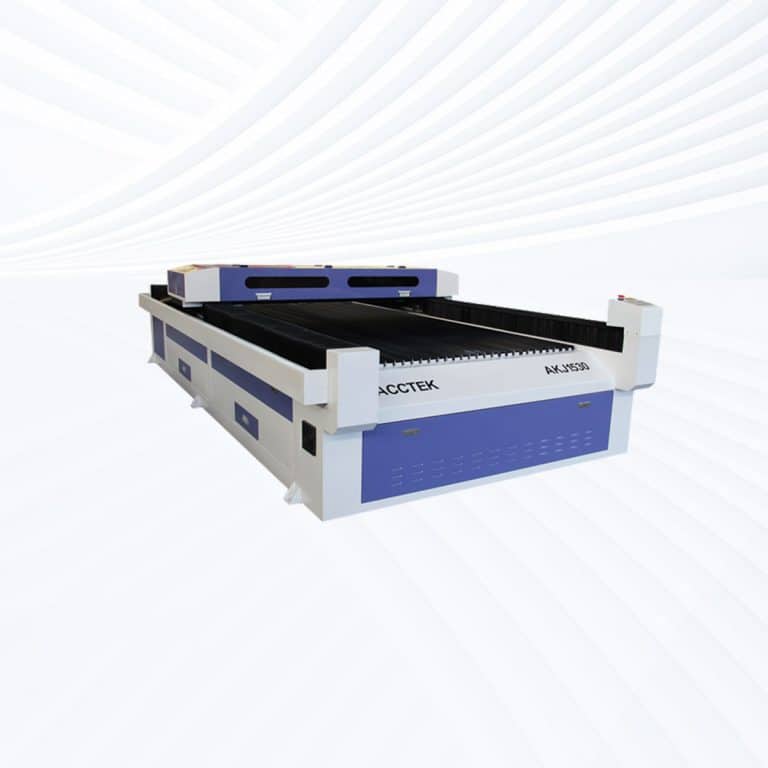

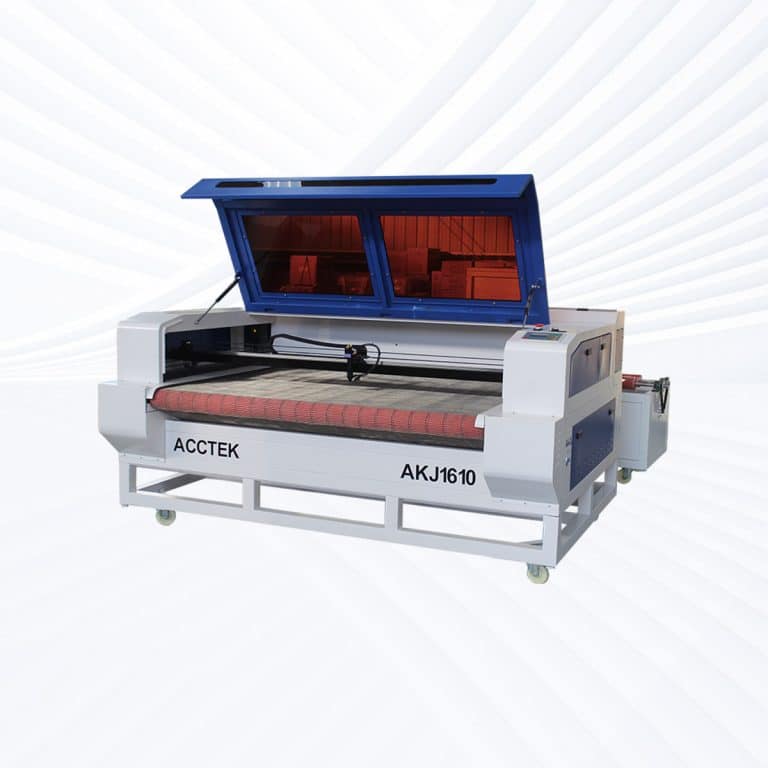

Product Introduction

Benefits of Laser Cutting Foam

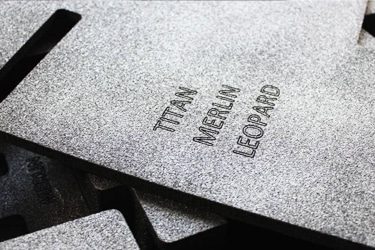

Clean, Sealed Edges

CO2 lasers cut foam with smooth, sealed edges that prevent fraying, crumbling, or dusting. This eliminates the need for post-processing and ensures a polished, professional finish on inserts, gaskets, and packaging components.

Non-Contact Cutting

Laser cutting applies no physical pressure to the foam, avoiding distortion, compression, or tearing. This is especially important for soft or delicate foam materials where traditional blades can deform the shape during processing.

High Precision and Detail

CO2 lasers can produce complex shapes, tight curves, and intricate internal cutouts with exceptional accuracy. This allows for detailed layouts in tool trays, foam inserts, or protective packaging without manual trimming or die tooling.

Minimal Material Waste

Advanced nesting software and the laser’s fine kerf width help maximize sheet yield and reduce offcuts. This leads to more efficient use of materials and lower production costs—ideal for custom and high-volume orders.

No Tool Wear or Replacement

Because lasers don’t rely on physical blades, there’s no wear or sharpening needed. This results in consistent cut quality over time and reduced maintenance costs compared to mechanical or die-cutting systems.

Versatile Foam Compatibility

CO2 laser cutting machines can cut various foam types, including EVA, PE, PU, sponge, neoprene, and PVC-free foam. This versatility makes them suitable across the packaging, automotive, aerospace, and custom manufacturing industries.

Compatible Foam Materials

- EVA Foam

- PE Foam

- PU Foam

- EPE Foam

- EPDM Foam

- Neoprene Foam

- PVC-Free Foam Sheets

- Sponge Rubber

- Cross-Linked PE Foam

- Open-Cell Polyurethane Foam

- Closed-Cell Polyethylene Foam

- Acoustic Foam

- Foam Rubber

- Memory Foam

- Latex Foam

- Anti-Static Foam

- Conductive Foam

- Tool Control Foam

- Fire-Retardant Foam

- High-Density EVA Foam

- Low-Density PU Foam

- Medical-Grade Foam

- Packaging Foam Inserts

- Charcoal Foam

- Convoluted Foam

- Laminated Foam Sheets

- Colored EVA Foam

- Craft Foam Sheets

- Silicone Foam

- Flame-Laminated Foam

- Rebonded Foam

- Microcellular Foam

- Insulating Foam

- Industrial Foam Pads

- Custom Foam Composites

- Thermoformable Foam Sheets

- Gasket Foam

- Helmet Liner Foam

- Foam Core board

- Aerospace-Grade Foam

Application of Foam Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Foam Materials | Highly suitable for most foams | Suitable but limited for soft foams | Very suitable for soft foams | Suitable but often excessive |

| Cutting Precision | Very high precision | High | Medium | High |

| Edge Quality | Clean, sealed edges | Rougher, may need finishing | Clean but can compress | Very clean |

| Material Compression | None (non-contact) | High risk | Medium | None |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Cutting Speed | High | Moderate | High | Slow |

| Thickness Capability | Thin to medium foam | Medium to thick foam | Thin foam sheets | Thin to very thick foam |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Material Waste | Very low | Medium | Medium | High |

| Setup and Changeover Time | Very fast | Moderate | Fast | Long |

| Design Flexibility | Excellent for complex shapes | Good | Limited | Good |

| Automation and Repeatability | Excellent | Excellent | Good | Good |

| Operating Cost | Moderate | Moderate | Low | High |

| Overall Efficiency for Foam Processing | Excellent | Good | Fair | Good |

Why Choose Us

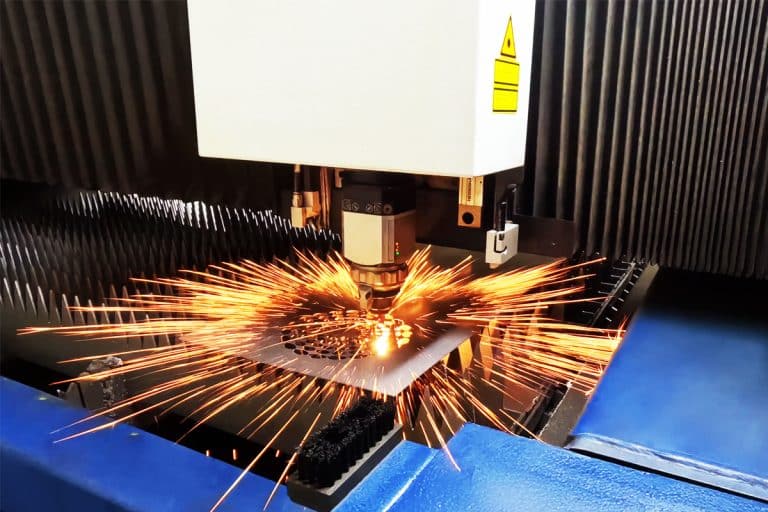

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

Frequently Asked Questions

Does Laser Cutting Seal Foam Edges?

- How Edge Sealing Works: When the laser beam passes through foam, its concentrated energy vaporizes the cut path while simultaneously melting the surrounding material. As the molten edge cools, it forms a smooth, closed surface rather than an open-cell texture. This prevents fraying, reduces particle shedding, and can improve durability in certain uses.

- Laser Setting Influence: Lower power with higher cutting speed can produce a cleaner, lighter seal, while slower speeds or excessive power deepen the melted zone and create heavier discoloration. Air assist can help reduce heat buildup and improve sealing uniformity.

Does Foam Cutting Produce Burnt Smells?

- Nature of the Smell: When foam is cut with CO2 lasers, the beam melts and vaporizes the material along the cut path. This process releases heated vapors from the polymer structure, often giving off a burnt, chemical-like smell. The odor can range from mildly unpleasant to strong and irritating, depending on the type of foam and whether it contains additives or fire retardants.

- Material-Specific Factors

- EVA Foam: Typically produces a sweet, burnt-plastic odor that can linger in the workspace.

- Polyethylene Foam: Gives off a sharp, chemical smell, which may be more irritating to the nose and throat.

- Polyurethane Foam: Can produce a strong, acrid smell and may release more harmful fumes, requiring extra caution.

- Some specialty foams may include dyes, adhesives, or flame retardants that intensify odor and fume toxicity during cutting.

- Impact of Laser Settings: Excessive power or slow cutting speeds increase heat buildup, which deepens the burn marks and strengthens the odor. Optimizing settings to cut efficiently with minimal overheating helps reduce the smell intensity.

- Ventilation and Fume Extraction: Even if the smell is not harmful at low levels, proper ventilation is essential to keep the air clear and comfortable. An exhaust system with activated carbon filtration can capture and neutralize much of the odor before it spreads. Without ventilation, foam-cutting smells can linger in the workspace for hours.

- Safety Considerations: While most laser-safe foams do not release highly toxic fumes in small amounts, inhaling their vapors regularly can irritate the respiratory tract. Operators should confirm the foam safety data sheets (SDS) and use appropriate fume extraction, especially when cutting in enclosed areas.

What Is The Price Of Foam Laser Cutting Machines?

- Entry-Level Machines ($3,000–$6,000): Compact tabletop or small-format CO2 lasers fall into this category. They usually have power ratings between 40W and 150W, suitable for thin foam sheets and light production work. While they can deliver clean cuts on foam, their smaller work areas limit part size, and they may require slower cutting speeds for thicker materials.

- Mid-Range Machines ($6,000–$10,000): These models offer larger bed sizes, often 150W–300W of laser power, and more robust construction. They handle thicker foam and higher production volumes more efficiently. Mid-range machines often include better cooling systems, improved air assist, and higher-speed motion controls, resulting in faster throughput and cleaner edges.

- High-End Machines ($10,000–$15,000): Designed for industrial production, high-end CO2 foam-cutting systems can include laser powers up to 600W, large-format beds, precision motion systems, and integrated fume extraction. They can cut thick or dense foam in fewer passes and at higher speeds, making them ideal for large-scale manufacturing and custom fabrication.

- Additional Costs to Consider: While the machine price is the largest expense, operators should budget for accessories such as an air compressor for air assist, water chillers for cooling, and a fume extraction system, especially important when cutting foam. Software upgrades, replacement laser tubes, and maintenance supplies also add to long-term costs.

Does It Require Special Ventilation When Laser Cutting Foam?

- Why Ventilation Is Important for Foam Cutting: When a laser beam cuts through foam, it melts and vaporizes the material along the cut path. This process releases smoke and gaseous byproducts, which can include volatile organic compounds (VOCs), particulates, and in some cases, potentially harmful chemicals. Even laser-safe foams can produce strong odors and airborne particles that should not be inhaled.

- Material-Specific Considerations

- EVA Foam: Produces a sweet, plastic-like odor and light smoke; manageable with standard exhaust systems but still requires filtration.

- Polyethylene Foam: Creates a sharper smell and more noticeable smoke; benefits from activated carbon filtration.

- Polyurethane Foam: Can emit stronger fumes that may be more irritating or harmful over time, requiring higher-grade ventilation.

- Foams with flame retardants, adhesives, or dyes may release more complex chemical vapors that need specialized filtration to capture safely.

- Special Ventilation Requirements: For frequent foam cutting or cutting thicker sheets, an exhaust system that includes:

- Fume Extraction: A high-CFM blower to pull fumes directly from the cutting area.

- Particulate Filtration: HEPA filters to trap fine particles.

- Gas and Odor Filtration: Activated carbon or charcoal filters to absorb VOCs and smells.

- In industrial settings, some operators connect their laser exhaust directly to a dedicated duct system venting outdoors, bypassing indoor air recirculation entirely.

- Benefits of Proper Ventilation

- Protects the operator from inhaling potentially harmful vapors.

- Reduces lingering odors in the workspace.

- Keeps laser optics and mechanical components cleaner by preventing residue buildup.

- Maintains compliance with workplace safety regulations.

What Is The Maximum Foam Thickness It Can Cut?

- 40–60W Lasers: Generally cut foam up to 8–10 mm thick effectively. Beyond this, multiple passes or slower speeds are needed, which may cause edge melting.

- 80–100W Lasers: Capable of cleanly cutting 10–20 mm foam in a single pass, depending on density and color (darker foams absorb heat better).

- 150W and Above: Industrial CO2 lasers can cut closed-cell foam up to 30 mm in one pass and thicker with multiple passes, although precision decreases at extreme thicknesses.

What Is The Laser Cutting Foam Accuracy Or Tolerance?

- High-Quality Industrial CO2 Lasers: ±0.1–0.2 mm on thin to medium-thickness foam.

- Mid-Range Machines: ±0.2–0.5 mm, suitable for most packaging, insert, and craft applications.

- Hobby-Grade Lasers: ±0.5–1.0 mm, due to less precise motion systems and variations in foam compression.

Does Foam Cutting Produce Harmful Fumes?

- Fume Composition and Risks: When foam is laser cut, the intense heat breaks down the polymer chains, releasing vapors that can include:

- Volatile Organic Compounds (VOCs): Organic chemical vapors that may irritate the respiratory system and cause headaches or nausea with prolonged exposure.

- Particulates: Fine particles that can be inhaled deep into the lungs, potentially causing irritation or long-term respiratory issues.

- Specific Chemical Gases

- EVA Foam: Usually produces acetaldehyde and acetic acid vapors; irritating but generally low in acute toxicity when ventilation is adequate.

- Polyethylene Foam: Releases hydrocarbons with a burnt-plastic smell; prolonged inhalation should be avoided.

- Polyurethane Foam: Can emit isocyanates, which are more hazardous and can cause serious respiratory reactions.

- Additive-Related Vapors: Foams with flame retardants, adhesives, or pigments may emit more toxic fumes when heated.

How Should I Maintain Foam Laser Cutting Machines?

- Daily Maintenance

- Clean the Work Area: Remove foam scraps, dust, and melted residue from the cutting bed after each session to prevent buildup and airflow blockages.

- Inspect Optics: Check the laser lens and mirrors for residue or clouding caused by foam fumes. Clean with lens-safe wipes and solution as needed to maintain beam quality.

- Empty Waste Trays: Foam debris can accumulate quickly, posing a fire risk if not cleared.

- Check Air Assist: Ensure air assist nozzles are free of blockages so cooling and debris removal remain effective.

- Weekly Maintenance

- Clean Exhaust System: Foam cutting produces light but sticky particles that can coat ducts and fans. Wipe down accessible exhaust areas and inspect filters for clogging.

- Check and Clean Machine Rails: Use lint-free cloths to remove dust and residue from linear rails, applying light lubrication if recommended by the manufacturer.

- Inspect Cooling System: Verify water chiller or cooling pump performance to prevent overheating of the laser tube.

- Monthly Maintenance

- Deep Clean Fume Extraction Filters: HEPA and activated carbon filters should be cleaned or replaced depending on cutting frequency. Foam vapors can saturate carbon faster than some other materials.

- Check Belt Tension and Alignment: Ensure drive belts are not loose or fraying, which can affect cutting accuracy.

- Examine Electrical Connections: Look for dust buildup around control boards and safely clean with compressed air if necessary.