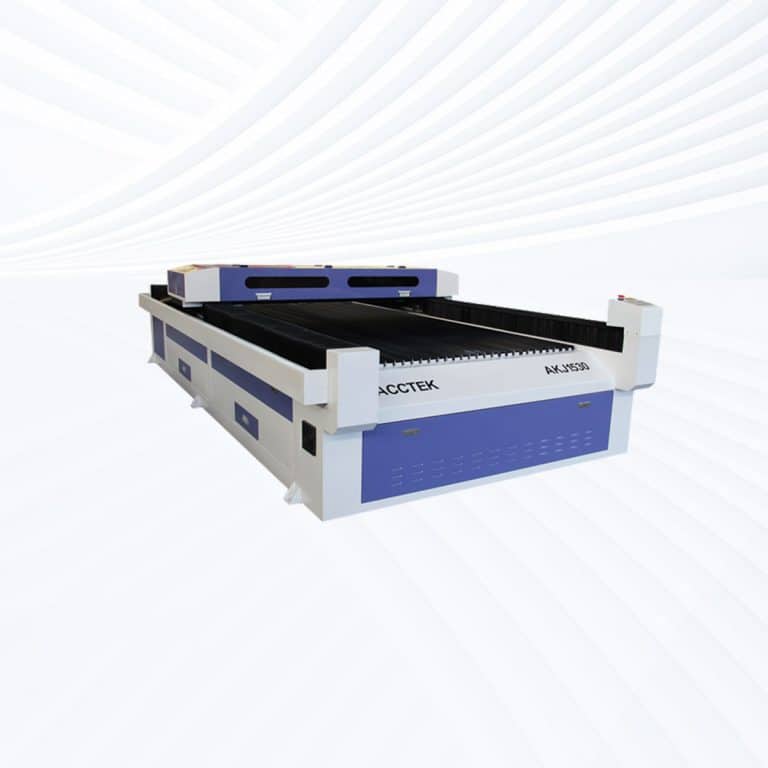

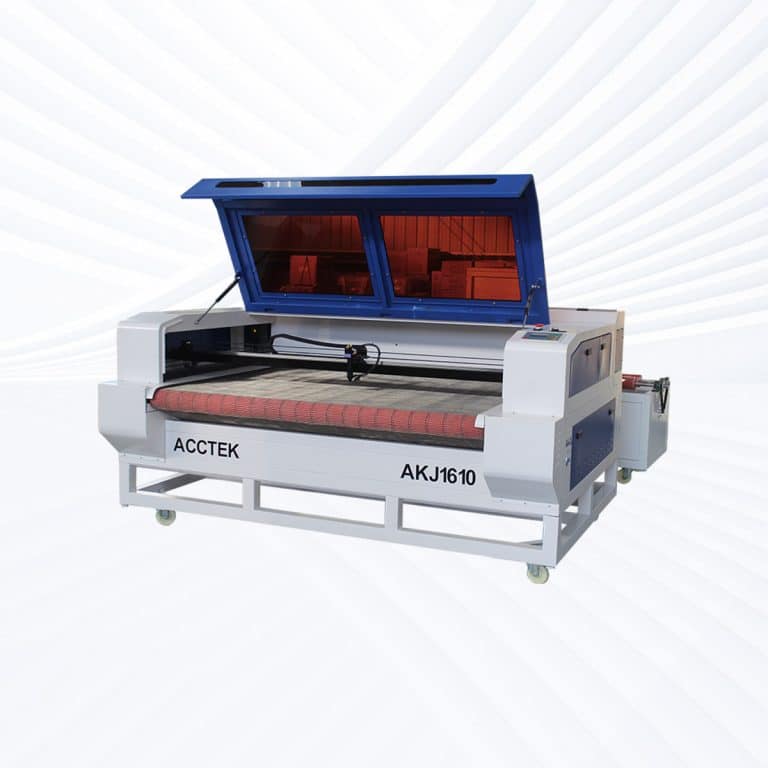

Product Introduction

Benefits of Laser Cutting Composite

Precise, Fray-Free Edges

CO2 lasers deliver smooth, sealed edges on composite materials without causing fraying, chipping, or delamination. This eliminates the need for post-processing and ensures high-quality, production-ready parts with tight tolerances and a clean finish.

Non-Contact, Stress-Free Cutting

Laser cutting applies no physical force, avoiding distortion, cracking, or material deformation. This is especially important for layered or brittle composites where traditional cutting can compromise structural integrity or introduce surface damage.

High Design Flexibility

CO2 lasers can process intricate patterns, tight contours, and complex geometries directly from digital files—perfect for prototyping, customization, or nested part layouts with no need for dies, molds, or mechanical adjustments.

No Tool Wear or Blade Changes

Because the laser beam doesn’t make physical contact, there’s no tool wear or sharpening required. This reduces downtime, eliminates tool-related inconsistencies, and maintains consistent cut quality over long production runs.

Cleaner Work Environment

With proper fume extraction, CO2 laser cutting systems produce minimal debris or dust compared to mechanical methods. This helps keep work areas cleaner and reduces airborne particles that can affect sensitive components or equipment.

Compatible with Diverse Composites

CO2 lasers can cut non-metallic composites such as FRP, GFRP, carbon-reinforced polymers, epoxy resins, phenolics, and polymer laminates. This makes them suitable for a wide range of industrial and engineering applications.

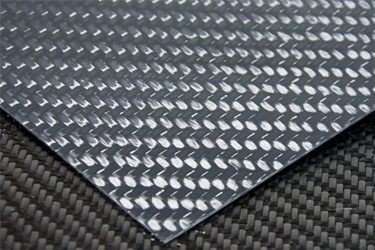

Compatible Composite Materials

- Fiberglass Reinforced Plastic

- Glass Fiber Reinforced Polymer

- Carbon Fiber Reinforced Polymer

- Epoxy Resin Composites

- Phenolic Resin Sheets

- Paper Phenolic Laminates

- Cotton Phenolic Laminates

- Fabric-Based Laminates

- Thermoplastic Composites

- Thermoset Composites

- Foam Core Composites

- Polymer Foam Composites

- Honeycomb Polymer Panels

- Polypropylene Composites

- Polyethylene Composites

- ABS/Polycarbonate Blends

- Wood-Plastic Composites

- Vinyl Ester Composites

- Resin-Impregnated Fabrics

- Composite Gasket Materials

- Silicone/Fiberglass Laminates Sheets

- Kevlar-Fabric Composites

- Nylon-Reinforced Composites

- Acrylic Composites Sheets

- PET-G Based Composites

- Teflon-Filled Composites

- PVC-Free Composites Panels

- Recycled Composites Board

- Reconstituted Composite Sheets

- Laminate Floor Composites

- Compressed Fiberboard

- Cardboard Composites

- Cork-Rubber Composites

- Textile-Laminated Composites

- Nonwoven Composite Sheets

- Insulation Board Composites

- Composite Foam board

- Industrial Paper Laminates

- FR-grade Composite Panels

- Phenolic Resin Boards

Application of Composite Laser Cutting Machines

Customer Testimonials

Comparison VS Other Cutting Technologies

| Comparison Item | Laser Cutting | CNC Routing | Knife Cutting | Waterjet Cutting |

|---|---|---|---|---|

| Suitability for Composite Materials | Highly suitable for many composites | Suitable but tool-dependent | Limited to soft composites | Excellent |

| Cutting Precision | Very high precision | High | Medium | High |

| Edge Quality | Clean, consistent edges | Good, may require finishing | Acceptable, may fray fibers | Very clean |

| Heat-Affected Zone (HAZ) | Small and controllable | None | None | None |

| Mechanical Stress on Material | None (non-contact) | Moderate | Low | None |

| Risk of Delamination | Low with proper settings | Medium | Medium to high | Very low |

| Kerf Width | Very narrow | Medium | Narrow | Wide |

| Tool Wear | No tool wear | High tool wear | Blade wear | Nozzle wear |

| Cutting Speed | High for thin–medium materials | Moderate | High for soft materials | Moderate |

| Thickness Capability | Thin to medium composites | Medium to thick | Thin, flexible materials | Thin to very thick |

| Material Waste | Low | Medium | Medium | Higher due to kerf |

| Setup and Changeover Time | Very fast | Moderate | Fast | Longer |

| Automation and Repeatability | Excellent | Excellent | Good | Good |

| Operating Cost | Moderate | Moderate | Low | High |

| Overall Efficiency for Composite Production | Excellent | Good | Fair | Very good |

Why Choose Us

Advanced Technology

Our laser cutting machines feature high-speed, precision cutting with the latest laser technology, ensuring smooth edges, minimal waste, and superior efficiency across various materials and thicknesses.

Reliable Quality

Each machine undergoes rigorous quality control and durability testing to ensure long-term stability, low maintenance, and consistent high performance, even under demanding industrial conditions.

Comprehensive Support

We provide full technical support, including installation guidance, operator training, and after-sales service, ensuring smooth machine operation and minimal downtime for your business.

Cost-Effective Solutions

Our machines offer high performance at competitive prices, with customizable options to fit different production needs, helping businesses maximize their investment without compromising on quality.

Related Resources

Addressing the Challenges of Fiber Laser Cutting: Common Problems and Solutions

This article explores common challenges in fiber laser cutting, including material-related issues, machine performance, and operator-related problems, offering practical solutions to optimize cutting quality and efficiency.

Precautions for Operating Laser Cutting Machines

This article provides a detailed overview of basic precautions for operating laser cutting machines, covering safety risks, proper setup, operating guidelines, maintenance procedures, and emergency preparedness.

Is Laser Cutting Fume Toxic

This article explains what laser cutting fumes are, how they form, their health and environmental risks, and the safety measures needed for proper fume control and extraction.

Laser Cutting Machine Nozzle Guide

This article is a comprehensive guide explaining laser cutting machine nozzles – their types, functions, materials, maintenance, and best practices for achieving precise, efficient cutting results.

Frequently Asked Questions

Does Laser Cutting Alter The Mechanical Properties Of The Composite?

- Reduced Strength at the Edge: Resin burn-off or fiber breakage can reduce tensile or shear strength locally.

- Delamination: Excess heat can cause layers to separate, especially in laminated composites.

- Brittleness Increase: Some thermoset resin systems may become more brittle when overheated.

- Resin Recast: In thermoplastic composites, melted resin may resolidify unevenly, creating stiff spots or stress risers.

Does Laser Cutting Cause Heat Damage To Composites?

- How Heat Damage Occurs: Laser cutting relies on concentrated energy that rapidly vaporizes material at the cut line. In composites, the resin often absorbs heat faster than the fibers, causing:

- Resin Charring or Burning: Especially in thermoset resins, which can degrade rather than melt.

- Fiber Degradation: High heat can embrittle glass fibers or weaken carbon fibers at the edges.

- Delamination: Heat can cause the resin to soften and separate from the fiber layers.

- Surface Discoloration: Visible charring or whitening depending on resin and fiber type.

- Composite Type Sensitivity

- CFRP (Carbon Fiber Reinforced Polymer): Cuts cleanly but is prone to resin burn-off and slight fiber edge fraying.

- GFRP (Glass Fiber Reinforced Polymer): Susceptible to microcracking and fiber embrittlement from heat exposure.

- Thermoplastic Composites: Can be more heat-tolerant but may suffer from localized melting or shrinkage.

- Honeycomb and Sandwich Panels: Core materials like foam or aluminum can be damaged if heat spreads too deeply.

- Factors Affecting Heat Damage

- Laser Power: Excessive power increases HAZ size and risk of burning.

- Cutting Speed: Slow speeds allow heat to build up, deepening thermal effects.

- Material Thickness: Thicker composites require more energy, raising heat damage potential.

- Focus Position: Incorrect focus can cause wider heat spread and rougher edges.

- Reducing Heat Damage

- Use the lowest power that still produces a full cut.

- Increase cutting speed to limit heat dwell time.

- Use air assist or inert gas to cool the cutting zone.

- Consider multiple low-power passes instead of a single high-power cut.

How Does Laser Power Affect Composite Cutting Quality?

- Low Laser Power

- The laser may not fully penetrate the material, leaving uncut fibers or resin.

- Edges may appear rough and fibrous, requiring additional finishing.

- Multiple passes may be necessary, which increases the heat-affected zone (HAZ) and can still degrade cut quality.

- Cutting speed must be slowed significantly, reducing productivity.

- Optimal Laser Power

- Smooth, consistent edges with minimal fraying or delamination.

- Controlled heat application, limiting resin charring and fiber damage.

- Minimal kerf taper, maintaining dimensional accuracy.

- Higher cutting speeds without sacrificing precision.

- Excessive Laser Power

- The resin may overheat, char, or vaporize unevenly, leaving brittle or discolored edges.

- Fibers may be damaged, embrittled, or burned away at the cut line.

- The HAZ increases, which can weaken edge strength.

- Delamination risk rises due to sudden thermal expansion between layers.

What Is The Available Laser Power Range For Composite Laser Cutting Machines?

What Is The Price Range For Composite Laser Cutting Machines?

What Fumes Are Generated When Laser Cutting Composites?

How Can I Prevent Burn Marks On Composite Edges When Laser Cutting?

- Laser Parameter Optimization

- Power and Speed Balance: Set the lowest power that still cuts cleanly, and combine it with higher cutting speeds. Reducing beam dwell time minimizes heat buildup.

- Multiple Pass Technique: For thicker composites, perform multiple faster, low-power passes rather than one slow, high-power pass.

- Beam Focus Adjustment: Slightly defocus the laser (0.5–1 mm) to spread heat over a wider area, reducing the likelihood of resin scorching.

- Test Cuts: Every composite behaves differently; run small trials to find the sweet spot before full-scale cutting.

- Air Assist and Gas Choice

- High-Pressure Air Assist: Direct a strong airflow into the cut line to remove vaporized resin and dust before they settle and burn onto the edges.

- Nitrogen Assist: Using nitrogen instead of air can further reduce oxidation and scorching, producing cleaner edges.

- Nozzle Alignment: Ensure the assist gas stream is perfectly aligned with the cut path for consistent debris removal.

- Surface and Edge Protection

- Masking Film or Transfer Tape: Apply low-tack tape to both sides of the composite to capture smoke particles before they contact the surface.

- Sacrificial Backing Board: Place a clean acrylic, MDF, or cardboard sheet beneath the workpiece to absorb excess heat and prevent underside marking.

- Material Considerations

- Resin Type: Polyester or phenolic resins generally resist burning better than epoxy-based composites.

- Pigment and Color: Lighter-colored composites reflect more laser energy and are less prone to charring than dark-pigmented materials.

- Post-Cut Cleanup

- Isopropyl Alcohol Wipe: Removes light residue and restores a clean finish.

- Fine-Grit Sanding: For tougher marks, light sanding smooths edges without damaging the composite structure.

How To Extend The Lifespan Of Composite Laser Cutting Machines?

- Maintain Optics and Beam Delivery

- Lens and Mirror Cleaning: Clean daily (or more often for heavy composite work) using approved lens wipes and solvents. Resin vapors can quickly cloud optics and reduce cutting power.

- Check for Scratches or Burns: Damaged optics degrade beam quality and should be replaced immediately.

- Correct Focus: Regularly calibrate and verify the beam focus to prevent overworking the laser source.

- Manage Dust and Fume Extraction

- High-Efficiency Filtration: Use HEPA or activated carbon filters to trap fine composite dust and resin fumes.

- Routine Filter Changes: Don’t wait for airflow to drop—replace filters on schedule to prevent backflow of particles.

- Dedicated Extraction for Composites: If possible, separate composite cutting from other materials to avoid cross-contamination and filter overload.

- Protect Motion Systems

- Linear Rail and Bearing Lubrication: Composites shed abrasive particles that can grind into rails; clean and lubricate them regularly.

- Seal and Shield Moving Parts: Install dust guards or bellows around sensitive areas to keep particulate matter out.

- Check Belt and Gear Tension: Excess wear or looseness can cause cutting inaccuracies.

- Control the Cutting Environment

- Stable Temperature and Humidity: Prevent condensation on optics and electronics by keeping conditions stable.

- Clean Workspace: Sweep and vacuum around the machine daily to reduce airborne dust that can settle inside.

- Avoid Overheating: Ensure proper cooling of the laser tube or source, checking coolant levels and quality.

- Operate Within Design Limits

- Avoid Overpowering: Consistently running at maximum power accelerates tube wear.

- Match Settings to Material: Using optimized cutting parameters for composites reduces strain on optics, motion parts, and filters.

- Warm-Up and Cool-Down Cycles: Let the machine stabilize before high-load cutting and allow cooldown before shutdown.

- Perform Regular Preventive Maintenance

- Scheduled Inspections: Check alignment, belts, lubrication, and filters at set intervals.

- Software and Firmware Updates: Keep systems up to date for improved performance and safety features.

- Professional Servicing: Annual or semi-annual tune-ups by qualified technicians catch small issues before they become major problems.